Durable type three-expansion source cement expansive material

A technology of expansion agent and concrete, applied in the field of concrete expansion agent, can solve the problem of insufficient durability of concrete expansion agent, and achieve the improvement of sulfate corrosion resistance and carbonization resistance, safety and durability, and low alkali content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

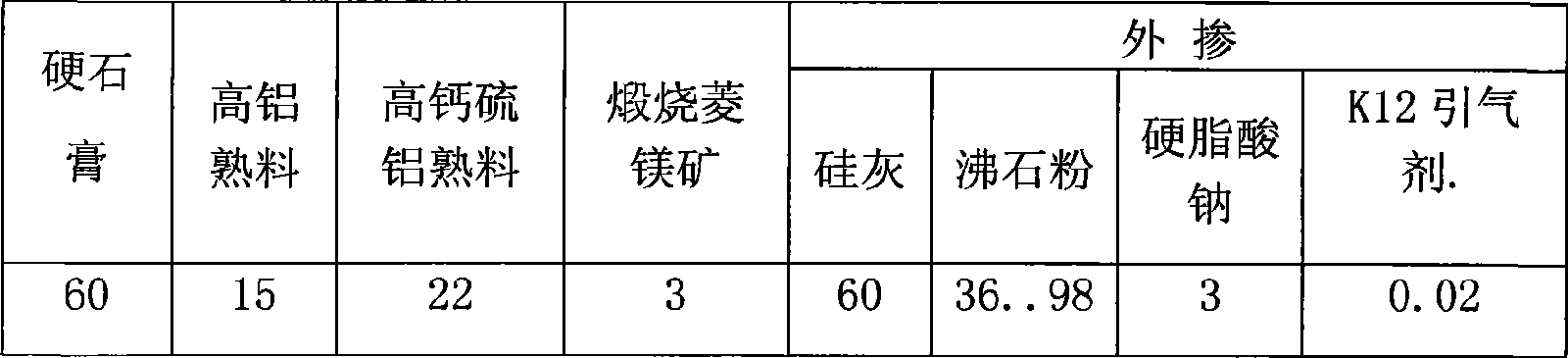

[0062] (1), the preparation process formula is shown in Table 1:

[0063] Table 1 (unit: kg)

[0064]

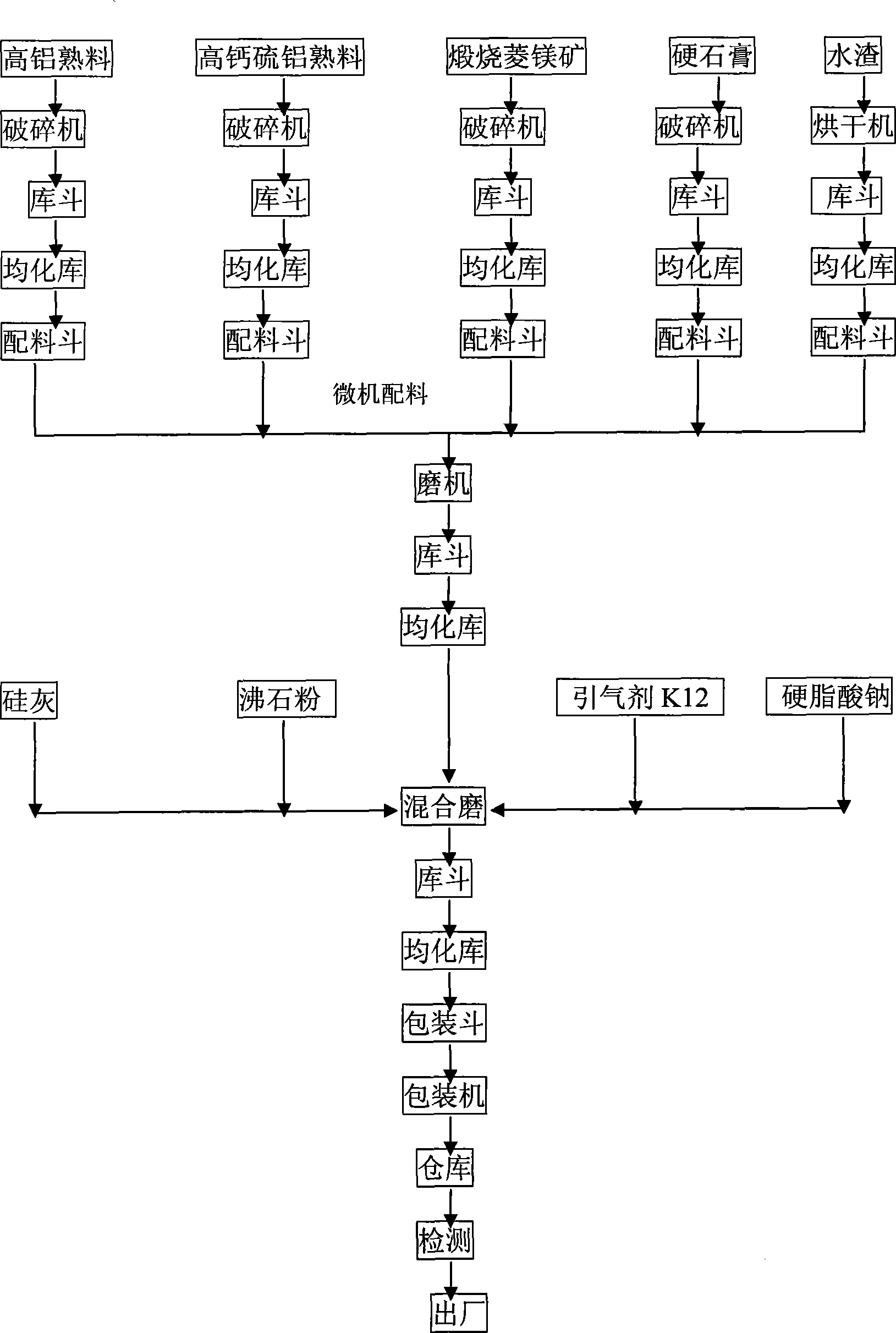

[0065] (2) Preparation process:

[0066] The bulk raw material gypsum, high alumina clinker, high calcium sulfur aluminum clinker and calcined magnesite are passed through the → the second silo → the second homogenization silo → get ordinary expansion agent → prepare external admixtures according to Table 1, externally mix air-entraining agent K12, silica fume, zeolite powder and water-repellent sodium stearate → mix in The third mill→the third storage hopper→the third homogenization storage→durable concrete expansion agent with three expansion sources→packing hopper→packing machine→warehouse→testing→delivery.

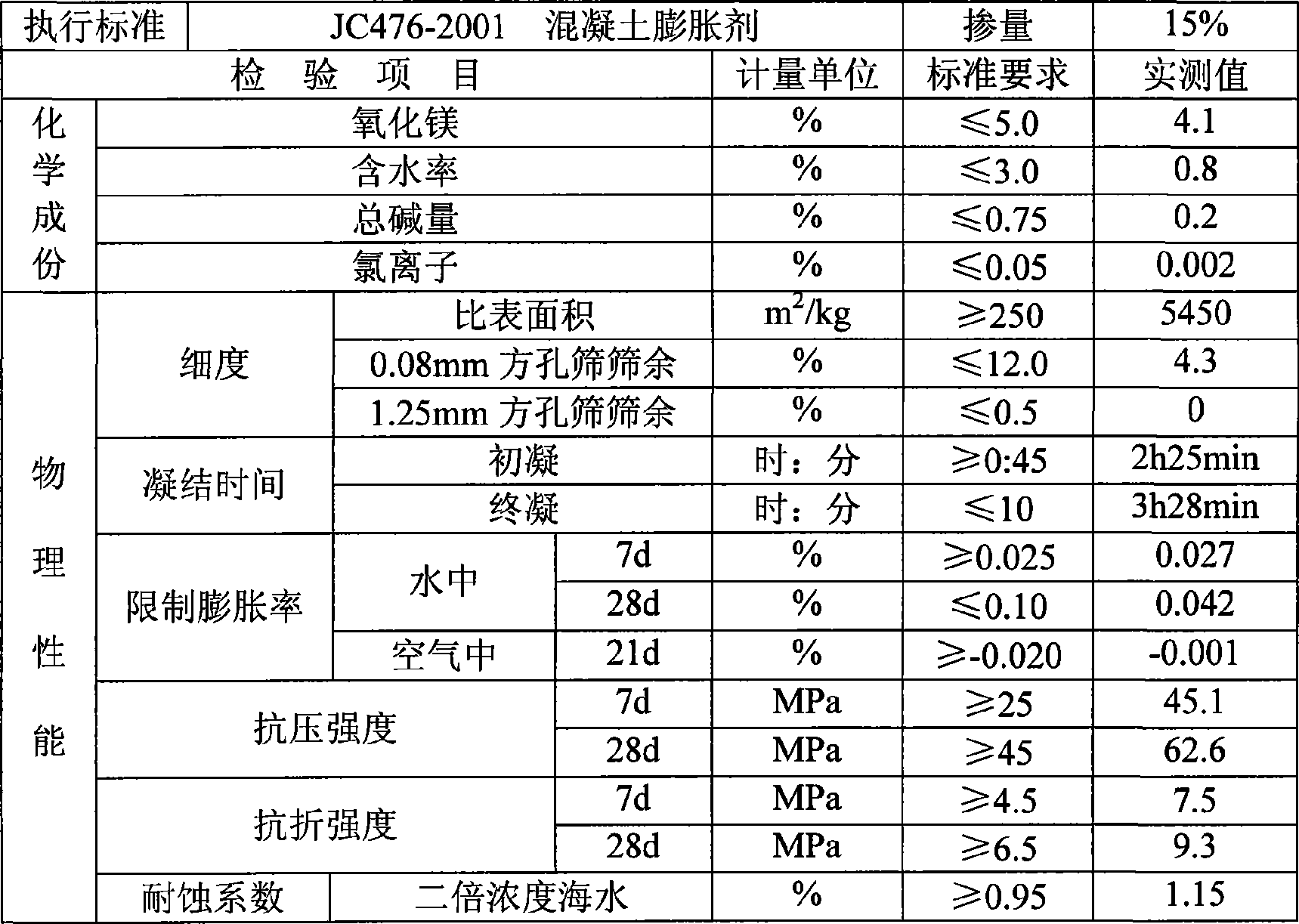

[0067] (3) The inspection data is shown in Table 2:

[0068] Table 2

[0069]

Embodiment 2

[0071] (1), the preparation process formula is shown in Table 3

[0072] Table 3 (unit: kg)

[0073]

[0074] (2), preparation process:

[0075] The bulk raw material gypsum, high alumina clinker, high calcium sulfur aluminum clinker and calcined magnesite are passed through the → the second silo → the second homogenization silo → get ordinary expansion agent → prepare external admixtures according to Table 1, externally mix air-entraining agent K12, silica fume, zeolite powder and water-repellent sodium stearate → mix in The third mill→the third storage hopper→the third homogenization storage→durable concrete expansion agent with three expansion sources→packing hopper→packing machine→warehouse→testing→delivery.

[0076] (3) The inspection data is shown in Table 4:

[0077] Table 4

[0078]

[0079] Only two examples have been cited above, and the products prepared within the range of raw material ratio in actual production can meet the quality requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com