Seepage-scouring-resistant concrete and preparation method thereof

A concrete and seepage-resistant technology, applied in the field of building materials, can solve the problems of small shrinkage, poor durability of underground concrete structures, and short setting time, and achieve the effect of reducing porosity, hard texture and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

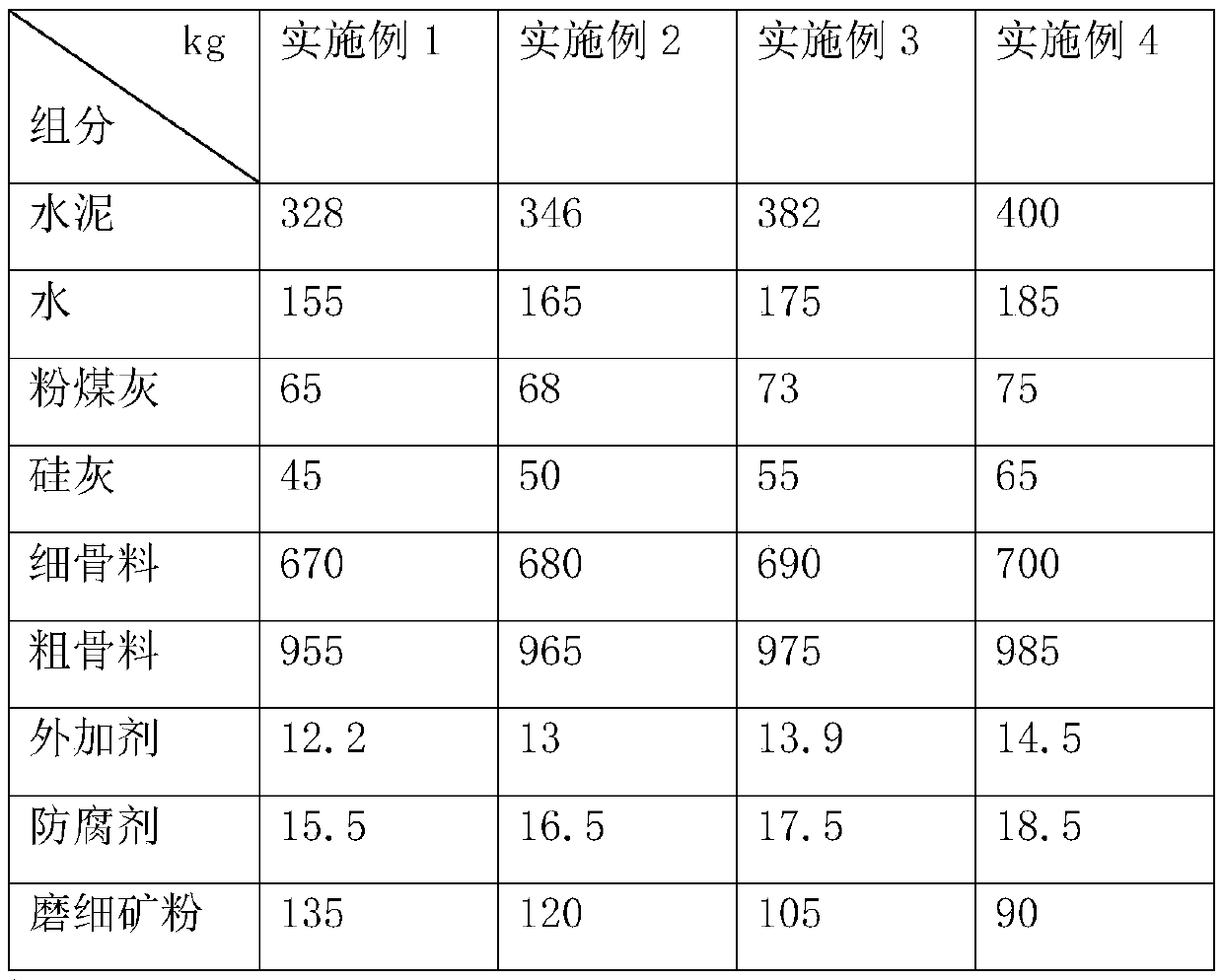

Examples

preparation example 1-3

[0041] In Preparation Example 1-3, the expansion agent is selected from the expansion agent sold by Shandong Lujie New Building Materials Co., Ltd. with the product number D548551, and the silane coupling agent is selected from the silane coupling agent of the model KH172 sold by Jinan Huanzheng Chemical Co., Ltd. The polycan fiber is selected from the chitosan fiber sold by Qingdao Jifa Group Co., Ltd. with the article number JF-100-F.

preparation example 1

[0042] Preparation Example 1: Calcinate 2kg of coal gangue powder at 1000°C for 50 minutes, take it out, mix and pulverize it with 1.2kg of expansion agent, 2.5kg of modified sepiolite powder and 1.1-1.5kg of calcium oxide to obtain a mixed powder with a particle size of 60um , then mix powder with 2.8kg PANI / PAN composite nanofiber, 1.6kg chitosan fiber, grind, make the expanded fiber anti-crack waterproofing agent that particle size is 10 μ m, wherein modified sepiolite has following method to make: Put sepiolite powder in a calcium chloride solution with a concentration of 2mol / L, stir at 40°C for 1d, filter with suction, wash with deionized water, dry, add silane coupling agent and absolute ethanol, and place in a water bath at 60°C 2h, after mixing evenly, dry, make modified sepiolite powder, the mass ratio of sepiolite powder and calcium chloride is 2:1, the mass ratio of sepiolite powder and silane coupling agent and dehydrated alcohol is 1: 5:6; PANI / PAN composite nano...

preparation example 2

[0043] Preparation Example 2: Calcinate 2.6kg of coal gangue powder at 1100°C for 40min, take it out, mix and pulverize it with 1.5kg of expansion agent, 3kg of modified sepiolite powder and 1.3kg of calcium oxide to obtain a mixed powder with a particle size of 80um, and then Mix and grind the mixed powder with 3.2kg PANI / PAN composite nanofibers and 2kg chitosan fibers to obtain an expanded fiber anti-crack waterproofing agent with a particle size of 25 μm, wherein the modified sepiolite is made by the following method: sepiolite powder Place in a calcium chloride solution with a concentration of 2mol / L, stir at 40°C for 2d, filter with suction, wash with deionized water, dry, add silane coupling agent and absolute ethanol, bathe in water at 60°C for 2.5h, mix After uniformity, dry to obtain modified sepiolite powder, the mass ratio of sepiolite powder to calcium chloride is 2:0.8, and the mass ratio of sepiolite powder to silane coupling agent and dehydrated alcohol is 1:6.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com