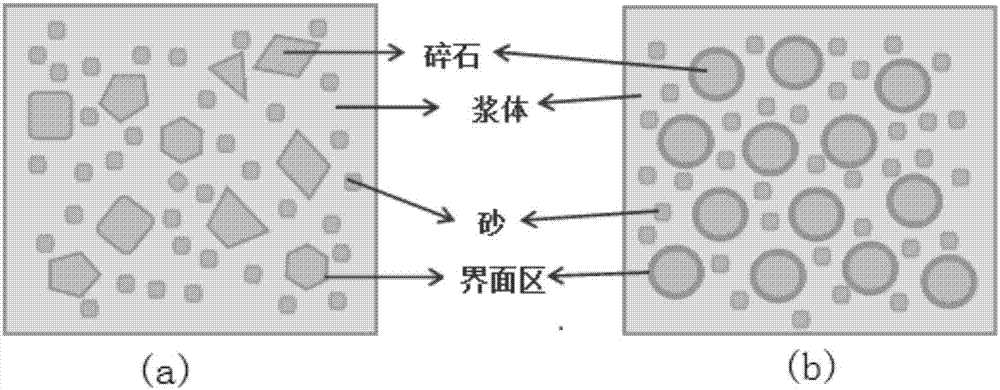

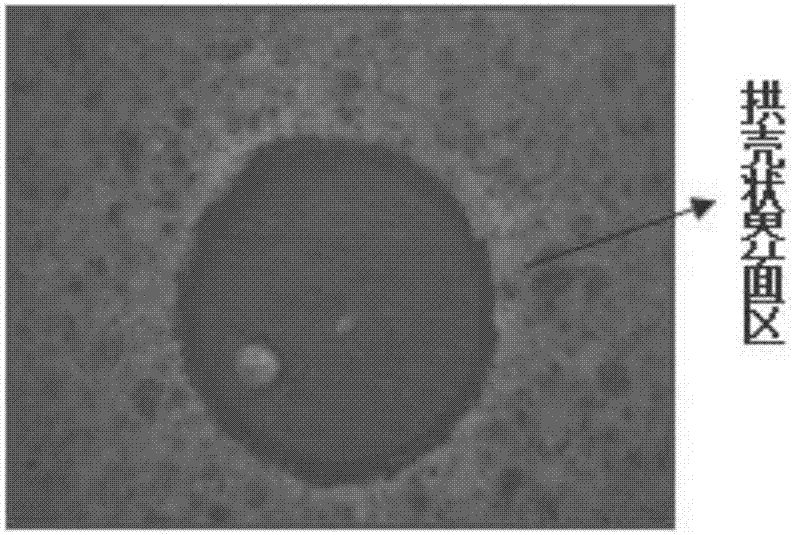

High-strength lightweight aggregate concrete based on arch shell-shaped interface region and preparation method thereof

A technology of light aggregate concrete and interface zone, which is applied in the field of building materials, can solve the problems of increasing the weight and cost of light aggregate concrete, and achieves improved resistance to chloride ion penetration, improved later strength and frost resistance, and workability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

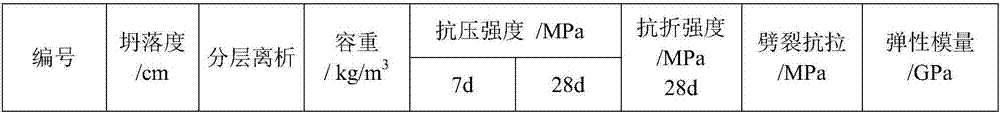

[0026] The raw materials were weighed according to the mix ratio in Table 1 to prepare CL50 concrete, which was used to prepare high-strength lightweight aggregate concrete based on the arch shell-shaped interface area. The performance test results are shown in Table 2, Table 3 and Table 4.

[0027] Table 1 CL50 high-strength lightweight aggregate concrete mix ratio Unit: kg / m 3

[0028] serial number

light aggregate

air entraining agent

water

Example 1

450

40

50

610

640

7.20

0.225

0.0216

155

Example 2

450

40

50

590

670

7.20

0.225

0.0216

155

Example 3

459

54

27

610

640

7.34

0.230

0.0220

155

Example 4

476

54

10

610

640

7.62

0.238

0.0229

155

Example 5

450

40

50

610

640

7.20

0.225

0.0216

170

[0029]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com