Concrete making formula

A technology of concrete and concrete synergist, which is applied in the field of concrete manufacturing formula, can solve the problems of leakage, reduce the use function and durability, and achieve the effects of reducing bleeding, improving impermeability, and low pumping friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

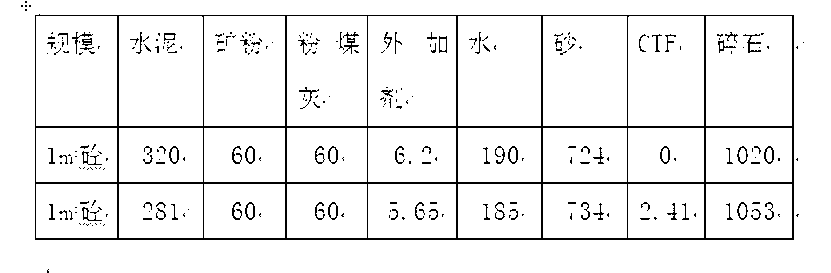

[0009] Table 1 is the concrete preparation formula in the prior art and the concrete preparation formula of the present invention.

[0010] Below in conjunction with the preparation formulas of Table 1 and Table 2, do a detailed description. In the existing technology, the proportioning of each component when preparing concrete is: cement 320kg, mineral powder 60kg, fly ash 60kg, admixture 6.2kg, water 190kg, sand 724kg, gravel 1020kg. When using the preparation formula of this method to manufacture concrete of the same quality, the proportioning of each component is: cement 281kg, mineral powder 60kg, fly ash 60kg, admixture 5.65kg, water 185kg, sand 734kg, crushed stone 1053kg, CTF Concrete synergist is 2.41kg. It can be clearly seen from the two different proportions of ingredients that after adding CTF concrete synergist, the amount of cement required is significantly reduced, which solves the cost.

[0011] When using the concrete preparation formula of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com