Weather-proof composite board

A composite sheet, weathering technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of poor weather resistance, deformation, easy corrosion, etc., to improve fire performance, improve weather resistance, Avoid the effects of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

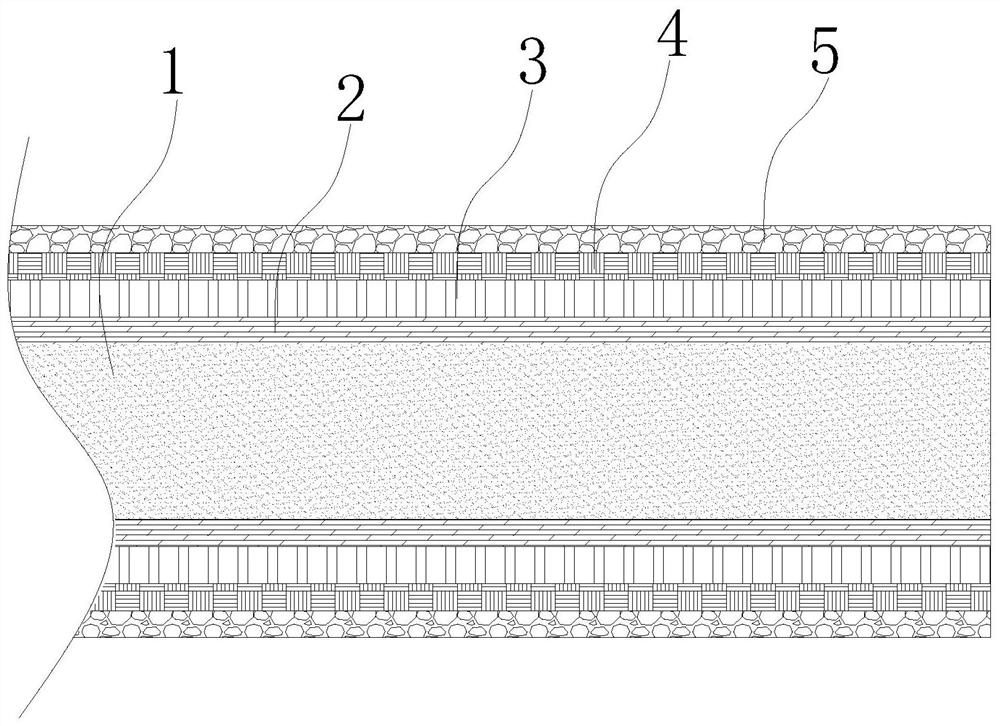

[0015] See figure 1 The present invention is a weather-resistant composite sheet comprising a wood plastic substrate 1, a sheet of wood-plastic material uses a wood cellulose or plant cellulose which is mixed with a hot-impeded polymer material processing aid, and then molded by extrusion The environmental protection material, such a sheet, the performance and characteristics of wood and plastic, with the wood plastic substrate 1 in the innermost layer as the base material, with a thickness of 6 mm to 10 mm, in the present embodiment, the wood plastic substrate 1 When the thickness is 6mm, in the production, the wood plastic substrate 1 is 62 parts of PVC powder, 25 copies of calcium carbonate, 8 yards of phosphate, 9 parts of polycarbonate, polyethylene terephthalate, 9 parts, carbonate 13 parts of sodium hydrogen, 13 parts of fumarate, 28 pieces of wood powder, 13 parts of linear low density polyethylene, 13 polypropylene, 6 icon shells, 5 grapes, 30 stone peel 30 1 part of dand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com