Assembly type roadbed pile plate connecting structure

A connecting structure and assembled technology, which is applied in the direction of basic structure engineering, roads, sheet pile walls, etc., can solve the problems affecting the roads in the surrounding area, the inconvenience of surrounding residents' travel, and the difficulty in guaranteeing the construction quality, so as to reduce construction and maintenance costs, The effect of quick and easy installation, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

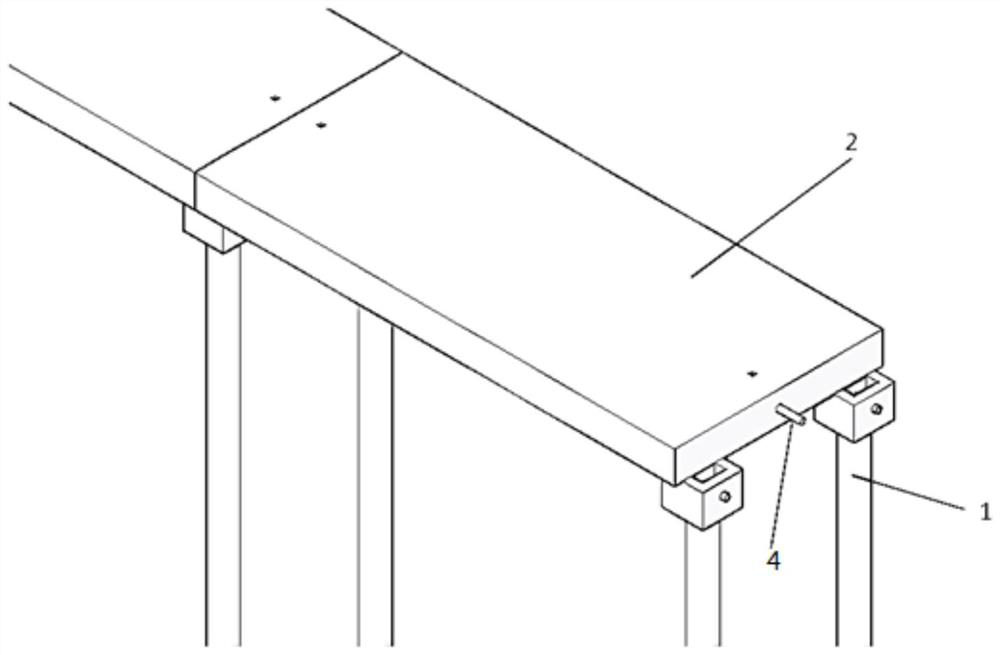

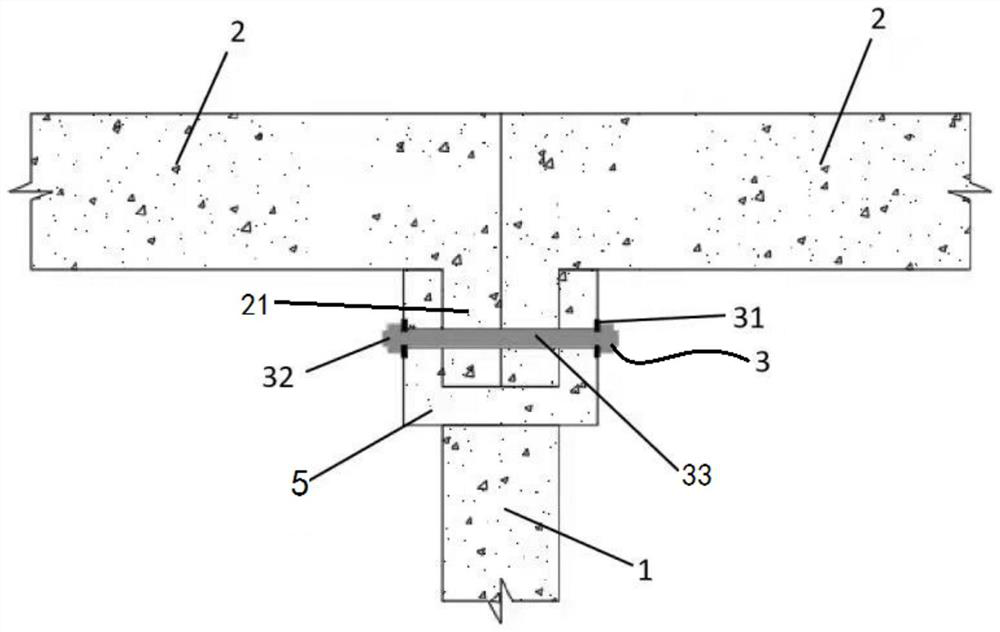

[0034] A prefabricated subgrade pile-slab connection structure, such as figure 1 , figure 2 , Figure 4 and Figure 5 , including a plurality of prefabricated bearing plates 2 spliced end to end in sequence, and two adjacent prefabricated bearing plates 2 are spliced by connecting components;

[0035] The two ends of the prefabricated bearing plate 2 along the splicing direction are symmetrically provided with inserts 21, the inserts 21 are located on the lower surface of the prefabricated bearing plate 2, the connecting components include the prefabricated pipe pile 1 and the first connecting component 3, the first connecting component 3 includes the first Connect the bolt 33 and the first nut 32. The prefabricated tubular pile 1 includes a pile body 11 and a concave cap 12 fixed at the end of the pile body 11. The concave cap 12 is square, and the insert 21 matches the concave cap 12. The platform 12 is provided with a third connection hole 13, and the insert block 2...

Embodiment 2

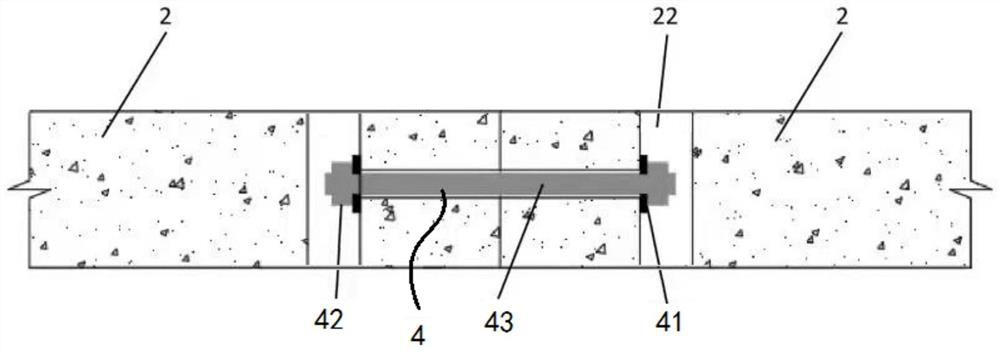

[0043] Such as figure 1 , image 3 and Figure 5 , in this embodiment, the upper surface of the prefabricated bearing plate 2 is symmetrically provided with two installation holes 22, and the two installation holes 22 are respectively close to the two ends of the prefabricated bearing plate 2 along the splicing direction, and the side of the prefabricated bearing plate 2 is provided with a second Two connection holes 24, the second connection hole 24 communicates with the inner wall of the installation hole 22, the connection assembly also includes a second connection assembly 4, the second connection assembly 4 includes a second connection bolt 43 and a second nut 42, the second connection bolt 43 The end passes through the second connection hole 24 and is fixed inside the installation hole 22 by the second nut 42. A second gasket 41 is provided between the second nut 42 and the side wall of the installation hole 22, and the structure is stable.

[0044] The reliability of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com