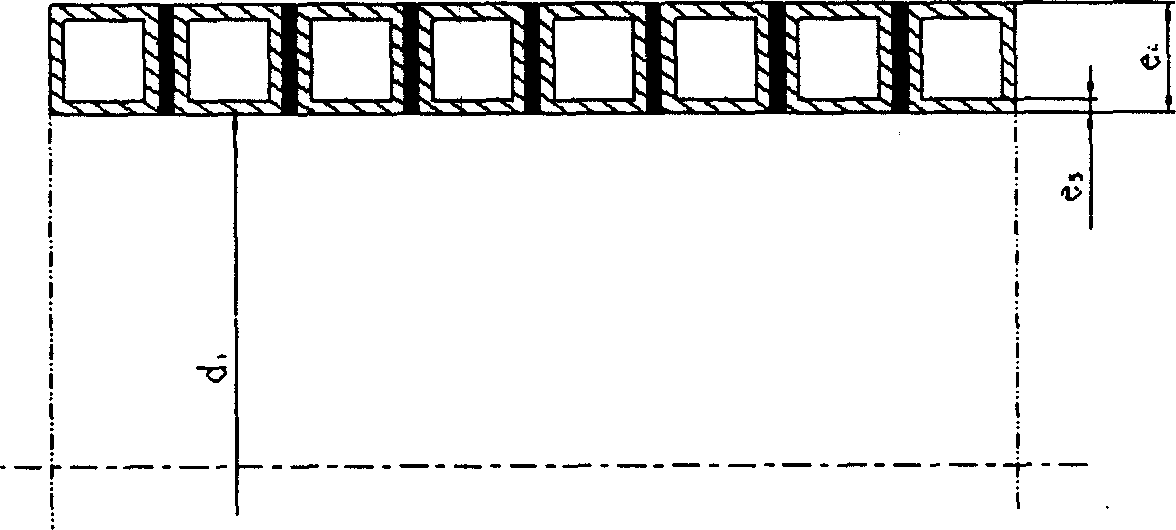

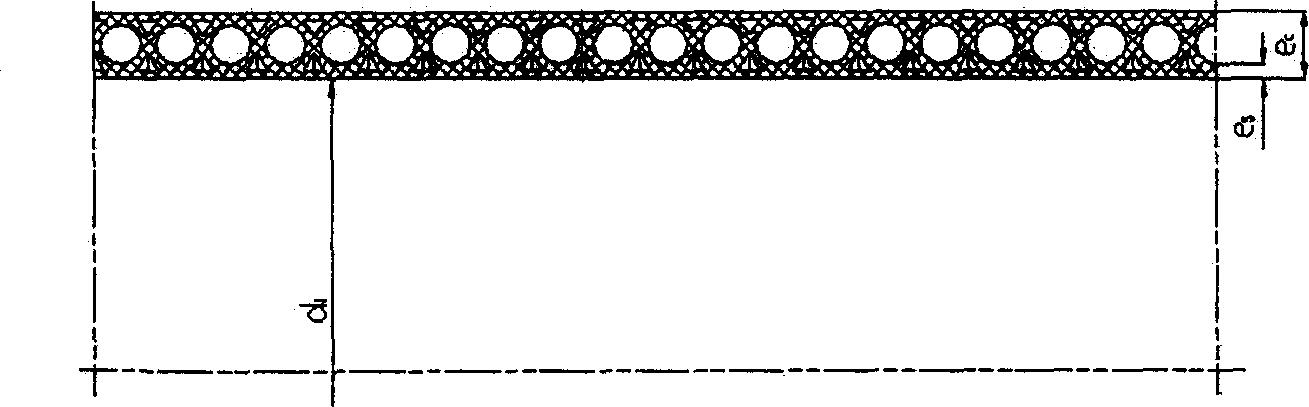

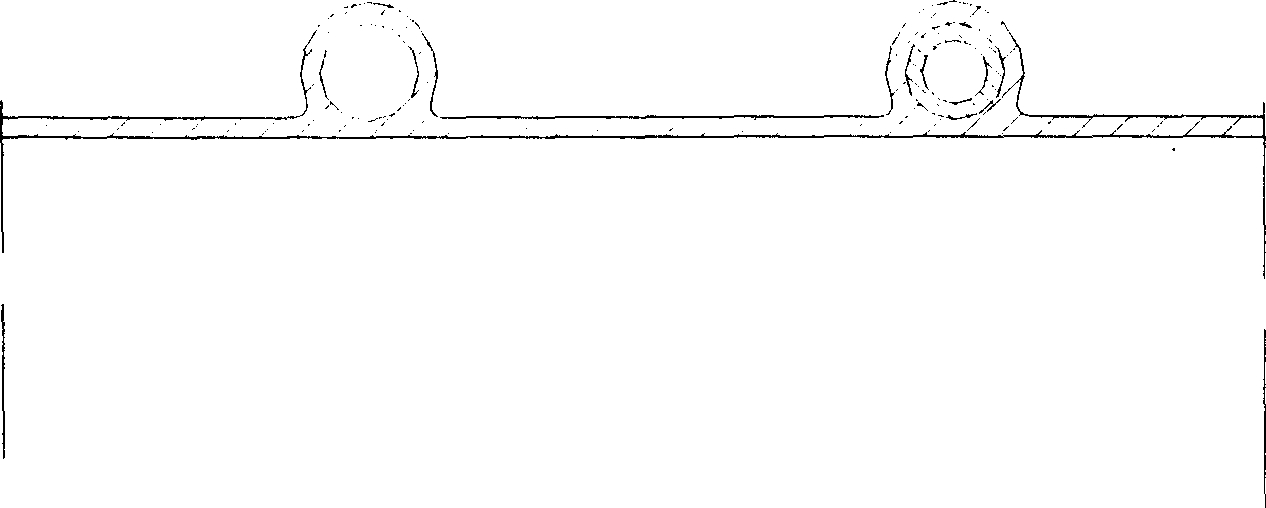

Structure wall pipe for coal mine

A technology for structural wall pipes and coal mines, applied in the direction of applications, pipes, rigid pipes, etc., can solve the problems of high price, ineffective effect, small diameter, etc., and achieve the effect of light weight, simple manufacturing process, and lower surface resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The material composition and the percentage by weight of each composition are:

[0021] High-density polyethylene 87% (TR490 produced by Phillips, USA)

[0022] Microencapsulated red phosphorus 9% (AMGARD CRP commercial product)

[0023] Conductive carbon black 4% (Mitsubishi carbon black Japan 3350)

[0024] Mix the above three raw materials in a high-speed mixer for 120 seconds, and then add them into a twin-screw extruder for melt blending and extrusion. The screw speed is 180 rpm, the processing temperature is 200°C, the middle is decompressed and exhausted, and the extrusion speed is 0.5 m / min. After cooling, coiling and packaging, it becomes a finished product.

[0025] Material

[0026] Material

[0027] Material

Embodiment 2

[0029] The material composition and the percentage by weight of each composition are:

[0030] High-density polyethylene 85% (TR490 produced by Phillips, USA)

[0031] Microencapsulated red phosphorus 5% (AMGARD CRP commercial product)

[0032] Conductive carbon black 10% (Mitsubishi carbon black Japan 3350)

[0033] Mix the above three raw materials in a high-speed mixer for 120 seconds, and then add them into a twin-screw extruder for melt blending and extrusion. The screw speed is 180 rpm, the processing temperature is 200°C, the middle is decompressed and exhausted, and the extrusion speed is 0.5 m / min. After cooling, coiling and packaging, it becomes a finished product.

[0034] Material

[0035] Material

[0036] Material

Embodiment 3

[0038] The material composition and the percentage by weight of each composition are:

[0039] High-density polyethylene 84% (Yanshan Petrochemical 6100M)

[0040] Microencapsulated red phosphorus 10% (Lianyungang CQFR-2002)

[0041] Conductive carbon black 6% (Carbot Elftex P100, USA)

[0042] The above three raw materials were mixed in a high-speed mixer for 150 seconds, and then fed into a twin-screw extruder for melt blending and extrusion. The screw speed is 200 rpm, the processing temperature is 220°C, the exhaust is exhausted in the middle, and the extrusion speed is 2 m / min. After cooling, coiling and packaging, it becomes a finished product.

[0043] Material

[0044] Material

[0045] Material

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com