Multifunctional polypropylene material

A polypropylene material and polypropylene technology, applied in the field of multi-performance polypropylene materials, can solve the problems of expensive ultraviolet absorbers and hindered amine light stabilizers, can not meet the actual safe use, degradation and other side reactions, and reach a wide range of markets The effect of application prospect, easy processing and cheap materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A multi-performance polypropylene material, characterized in that the composition of the raw materials is as follows in terms of weight percentage: 75-90% of polypropylene with an ethylene content of less than 1% and a melt flow rate of 50-100g / 10min; : sepiolite powder 5-10%; main flame retardant: TTBNP 1-2%; synergistic flame retardant with particle size <10μm: antimony trioxide 0.2-0.5%; channel carbon with particle size 15-25nm Black: 1.5-2.5%; Talc powder: 5-6%; Chain breaker: 3,4-dimethyl-3,4-diphenylhexane 0.2-0.5%; Foaming agent: 5-phenyl tetra Azole 0.2-0.5%; Static Agent: Ethylene Oxide 2-3%; Antioxidant: Sodium Phosphite 0.2-0.3%; Heat Stabilizer DSTP0.2-0.3%; Penetrant: Sodium α-Alkenyl Sulfonate 0.2-0.3%; Dispersant: sodium lignosulfonate 0.2-0.3%.

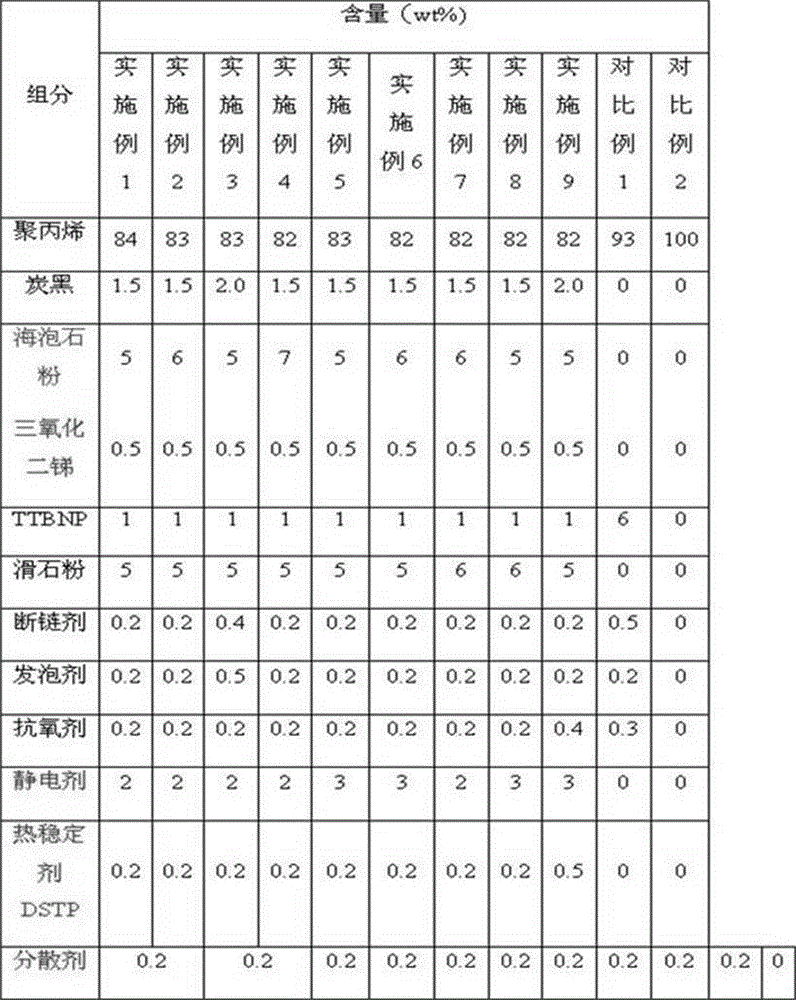

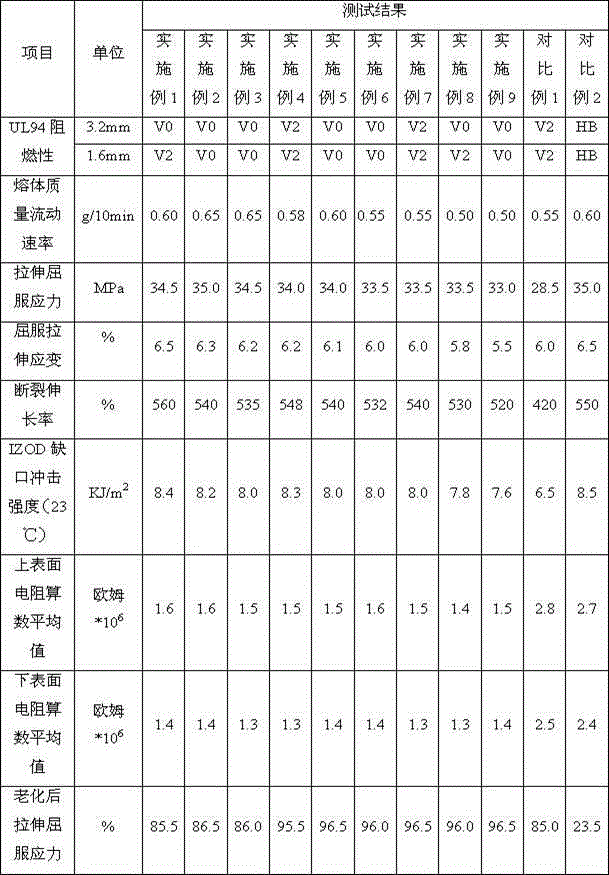

[0034] The component contents of the formulations of Examples 1-9 and two comparative examples of the polypropylene composite material are shown in Table 1.

[0035] The component content table of the formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| half-life | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com