A halogen-free flame retardant reinforced pa/pok alloy material resistant to humidity and heat aging

A technology of alloy materials and heat and humidity resistance, which is applied in the field of polymer composite materials, can solve the problems of poor flame retardant effect, lower polymer surface temperature, and unsatisfactory flame retardant effect, and achieve small changes in mechanical properties, excellent wear coefficient, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

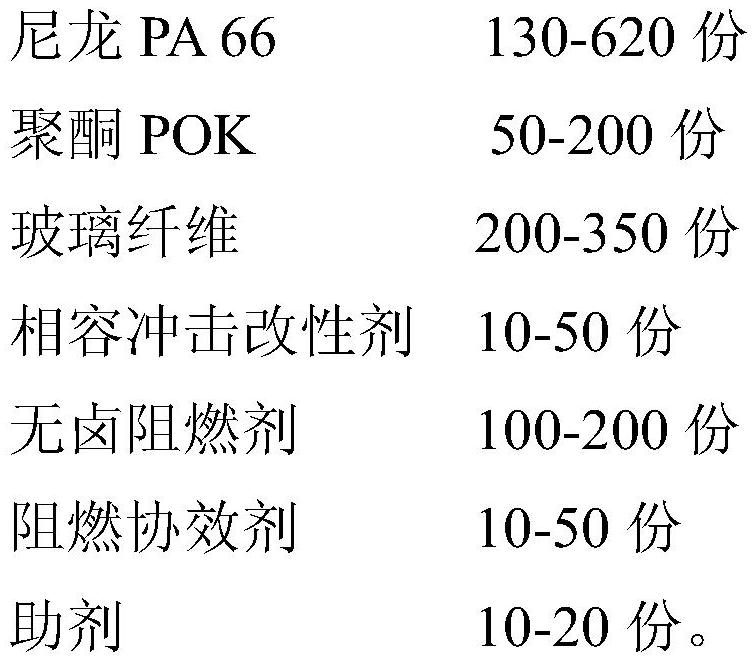

Method used

Image

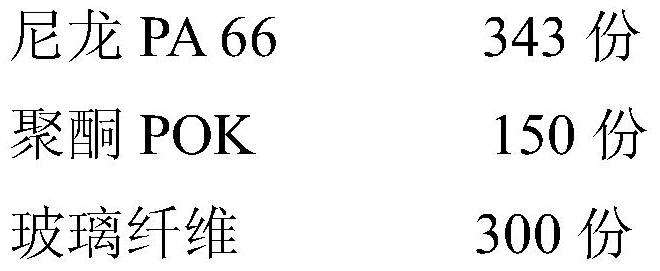

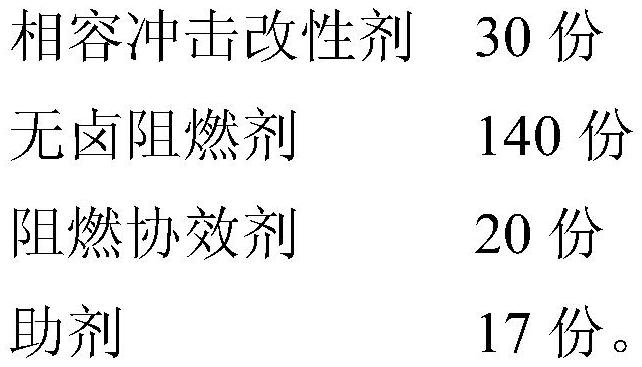

Examples

Embodiment 1-6 and comparative example 1-4

[0068] Components and proportioning of table 1 embodiment 1-6 and comparative examples 1-4

[0069]

[0070] Preparation:

[0071] (1) Weigh the raw materials according to the weight ratio, and dry PA66 and POK at 100°C for 4 hours respectively;

[0072] (2) Add the dried PA66, POK, compatible impact modifier, halogen-free flame retardant, flame retardant synergist, and additives into a high-speed mixer and mix for 6-8 minutes;

[0073] (3) Then the mixed material and glass fiber are extruded, cooled, and granulated through a twin-screw extruder. Note that the glass fiber is fed from the side of the 5th zone of the extruder; the temperature of the 11 zones of the twin-screw extruder is set Set at 250°C, 260°C, 270°C, 270°C, 260°C, 260°C, 250°C, 250°C, 250°C, 250°C, 250°C; the obtained pellets were dried at 120°C for 4 hours and then dried at 260-280°C Under injection molding into standard splines, that is.

Embodiment 7

[0074] Embodiment 7: Evaluation of implementation effect

[0075] With comparative example 1-4, the sample that embodiment 1-6 obtains, according to American Society for Testing and Materials (ASTM) standard test mechanical property, according to UL94 standard test flame retardancy, according to the abrasion coefficient of GB 3960-83 standard test material, Damp heat aging is carried out according to GB / T 2423.3-2016, and the aging time is 300h. The test results are shown in Table 2 below:

[0076] The test result of table 2 embodiment 1-6 and comparative example 1-4

[0077]

[0078]

[0079] The test performance results in Table 2 show that:

[0080] (1) From the analysis of Comparative Example 1, Examples 2, 5, and 6, it is obtained that during the damp heat aging process, the water plasticization caused by water absorption, hydrolytic degradation, and thermal oxygen aging under high humidity act together, resulting in the stretching of PA66+GF And the bending perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com