A kind of high-efficiency laser marking material and preparation method thereof

A laser marking and high-efficiency technology, applied in the field of materials, can solve the problems of low marking speed, blurred marking, and inability to meet the needs of industrial production, and achieve the effect of improving the printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

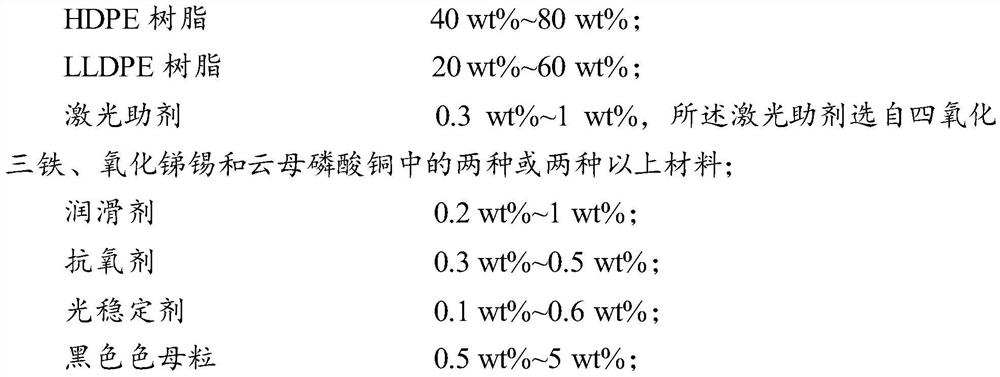

[0038] The present invention also provides a method for preparing the above-mentioned high-efficiency laser marking material, comprising the following steps:

[0039] A) After mixing HDPE resin and LLDPE resin, add laser auxiliary agent, lubricant, antioxidant, light stabilizer and black masterbatch and mix to obtain a mixture;

[0040] B) extruding and granulating the mixed material to obtain a high-efficiency laser marking material.

[0041] In the present invention, the HDPE resin and the LLDPE resin are first mixed, and the present invention has no special limitation on the mixing method, and the mixing method known to those skilled in the art will suffice. In the present invention, preferably mix according to the following method:

[0042] Put the HDPE resin and LLDPE resin into the batch mixing equipment to reciprocate and mix up and down to obtain the batch mixed resin;

[0043] The batch-mixed resin is placed in a discharge bin, and then automatically weighed, and th...

Embodiment 1~4

[0058] 1. See Table 1 and Table 2 for formula type and dosage respectively

[0059] Table 1 type of formula

[0060]

[0061]

[0062] Note: HDPE resins in Table 1 include low-melt HDPE resins whose melt flow rate is not more than 1.0g / 10min, one or more blended materials selected from 7000F, FB1350, HDPE3363, HDPE00952 and HDPE041; high-melt index The melt flow rate of HDPE resin is not more than 10.0g / 10min, and it is selected from one or more blending materials of HDPE (FMA026), HDPE8008, HDPE (FMA025). The melt flow rate of LLDPE resin is not more than 1.0g / 10min, and it is selected from one or more blended materials of LLDPE7042, LLDPE (FB2230), LLDPE (FK1820). The laser engraving auxiliary agent in the laser auxiliary agent is Heqirun HZ-889A.

[0063] Table 2 formula dosage (unit: kg)

[0064] Example 1 Example 2 Example 3 Example 4 HDPE 60 40 80 75 LLDPE 40 60 20 25 Laser Auxiliary 0.1 0.4 0.5 0.8 lubricant 0....

Embodiment 5

[0088] Based on the formula and preparation method of Example 4, change the amount of raw materials or laser additives, and keep other conditions unchanged, prepare high-efficiency laser marking materials. The specific dosage of the formula is shown in Table 7

[0089] Table 7 formula dosage

[0090]

[0091] Note: In the example 4, 4-1, 4-2, 4-3 in Table 7, the laser auxiliary agent is selected from the mixture of Iriotec8835 and Iriotec8815 with a mass ratio of 4:1; Example 4-4 does not add laser auxiliary agent ; Embodiment 4-5 selects the laser auxiliary agent as Heqi Run radium carving auxiliary agent HZ-889A;

[0092] The performance of the above-mentioned high-efficiency laser marking materials was tested, and the results are shown in Table 8

[0093] Table 8 Cabling performance of high-efficiency laser marking materials

[0094]

[0095] It can be seen from Table 8 that the mechanical properties of the product basically do not change much with the change of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com