Weather-resistant flame-retardant polypropylene composite material and preparation method thereof

A flame retardant polypropylene and composite material technology, applied in the field of weather-resistant flame-retardant polypropylene composite material and its preparation, can solve the problems of weather-resistant and flame-retardant, large amount of flame retardant, failure, etc., and achieve the change of mechanical properties. Small size, excellent weather resistance, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

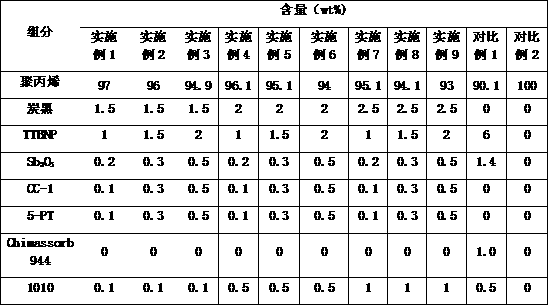

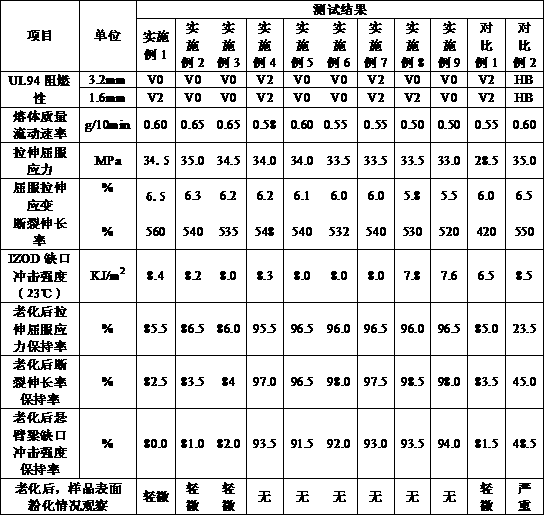

[0029] A weather-resistant flame-retardant polypropylene composite material, comprising 93-97 wt% of polypropylene, 1-2 wt% of a main flame retardant, 0.2-0.5 wt% of a synergistic flame retardant, 0.1-0.5 wt% of a chain breaker, and foaming 0.1-0.5 wt % of additives, 1.5-2.5 wt % of carbon black, and 0.1-1 wt % of other additives; the other additives are one or a combination of antioxidants, dispersants, and lubricants.

[0030] In the formulas of specific examples and comparative examples, the polypropylene used is the product of Yanshan Petrochemical Company, the model is PP T1701, the ethylene content is 2 o 3 ), is a product of Hunan Xikuangshan Flashing Star Antimony Industry Co., Ltd., with a purity of >98.5% and a particle size of 2000; Antioxidant 1010 is a product of Ciba, Switzerland.

[0031] The component contents of the formulations of Examples 1-9 of the weather-resistant flame-retardant polypropylene composite material and two comparative examples are shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com