High-strength hot-rolled steel sheet and manufacturing method therefor

A hot-rolled steel plate and manufacturing method technology, applied in the direction of manufacturing tools, metal rolling, heat treatment furnaces, etc., can solve the problems of promoting strength deviation, difficulty in obtaining accurate formability, and decreasing strength stability, and achieve stable dimensional accuracy, Excellent stretch flangeability and small change in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

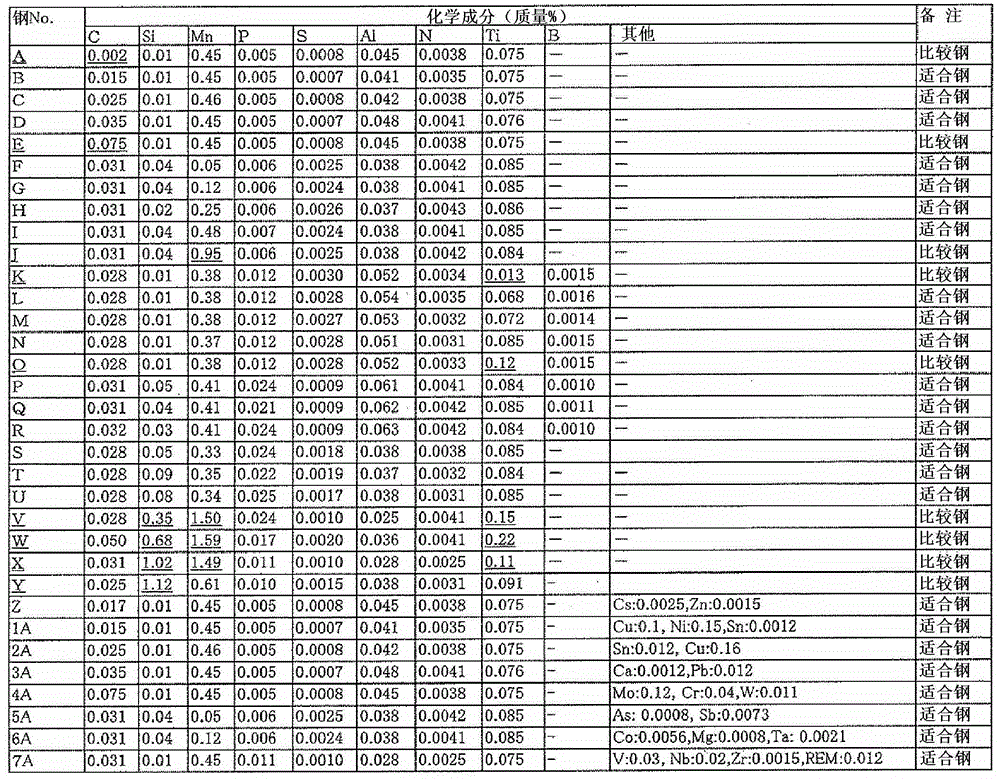

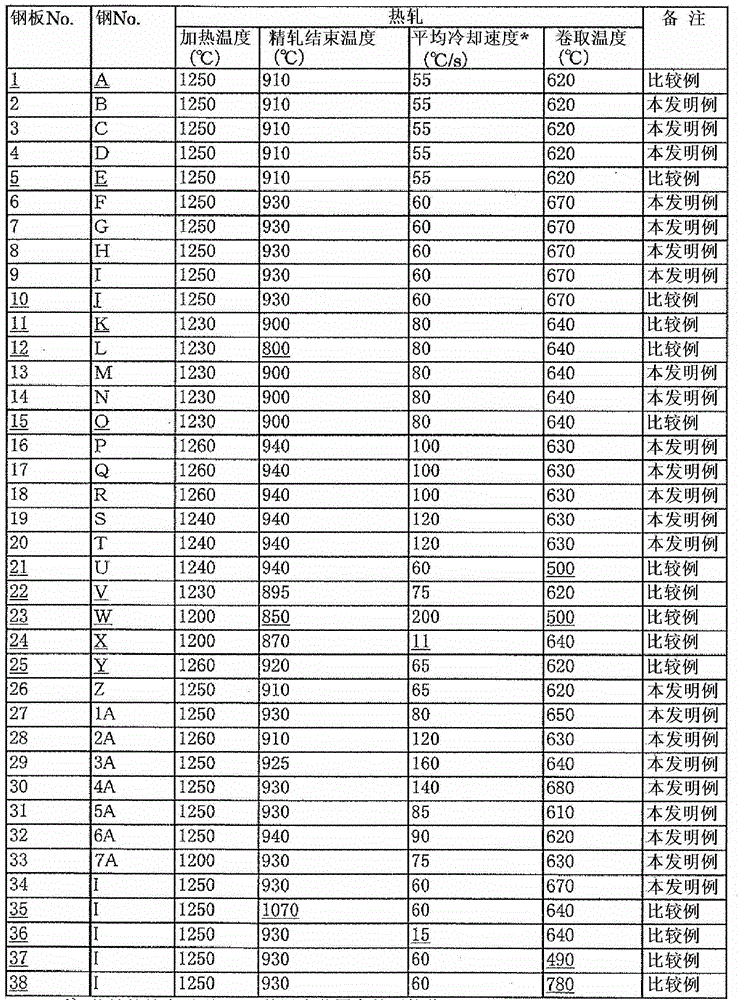

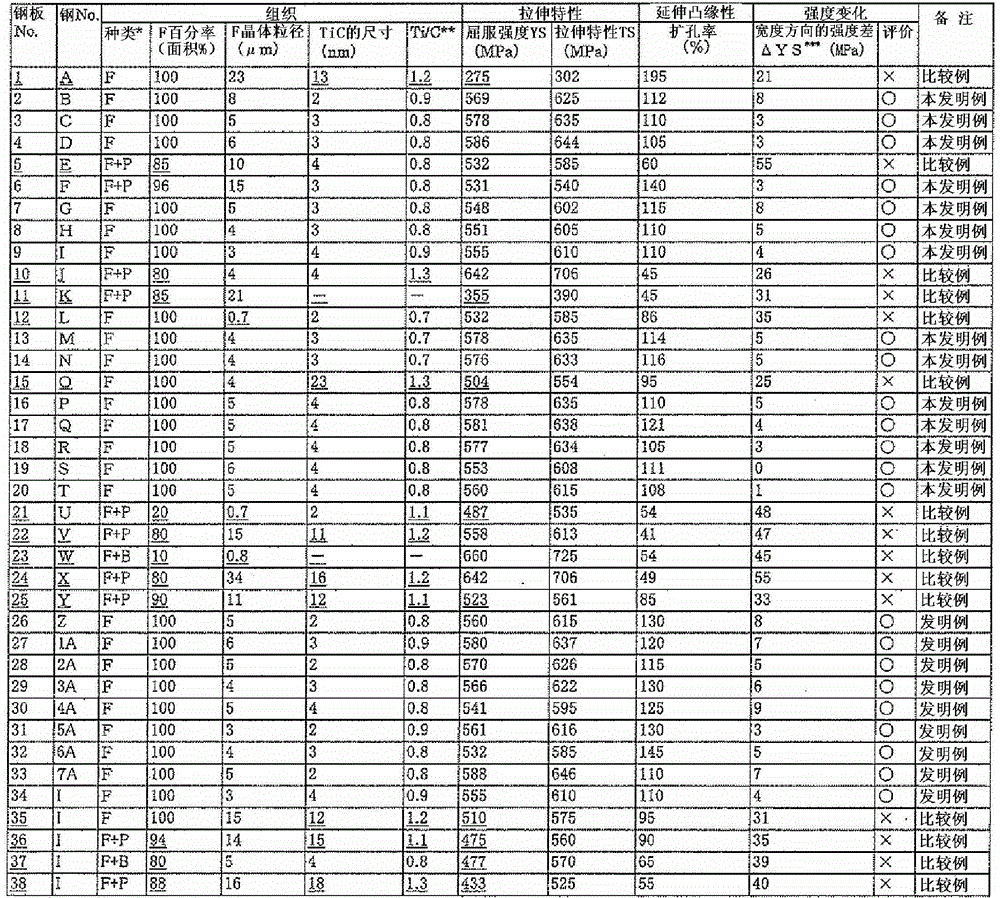

[0094]Molten steel having the composition shown in Table 1 was smelted by a common smelting method (converter furnace), and cast into a billet (steel raw material) (wall thickness: 270 mm) by continuous casting. These slabs were heated to the heating temperature shown in Table 2, rough rolled, and then finished rolling was carried out under the conditions shown in Table 2. After the finish rolling was completed, in the temperature range up to 750°C, the temperature shown in Table 2 was Cooling was accelerated at an average cooling rate, coiled into a coil at the coiling temperature shown in Table 2, and a hot-rolled steel sheet having a thickness of 2.3 mm was produced. In addition, some hot-rolled steel sheets (steel sheets No. 6 to 10) were pickled to remove surface scale, and then hot-dip galvanized to form a plated layer on the surface of the steel sheet. On a part of the steel plate, the alloying treatment of the coating is carried out to form an alloyed hot-dip galvanize...

Embodiment 2

[0117] Molten steel having the composition of steel No.H and No.M shown in Table 1 was melted in a converter, and a slab (thickness: 270 mm) was produced by continuous casting in the same manner as in Example 1. Under the same conditions as steel plates No.8 and No.12 shown in Table 2, these billets were heated, rough rolled and finish rolled, then accelerated cooling, coiled into coils, and made into 2.6 mm thick steel billets. Hot rolled steel plate. For the obtained coil, JIS No. 5 tensile test pieces and hole expansion test pieces were cut out from the central part in the plate width direction at each position in the longitudinal direction shown in Table 4, and stretched under the same conditions as in Example 1. Test, hole expansion test. The obtained results are shown in Table 4. In addition, the yield strength difference ΔYS at each position in the longitudinal direction is also shown based on the 40 m position in the longitudinal direction.

[0118] [Table 4]

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com