High-power sputtering source

A power and power supply technology, applied in sputtering coating, vacuum evaporation coating, coating and other directions, which can solve the problems of poor target utilization, distribution, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

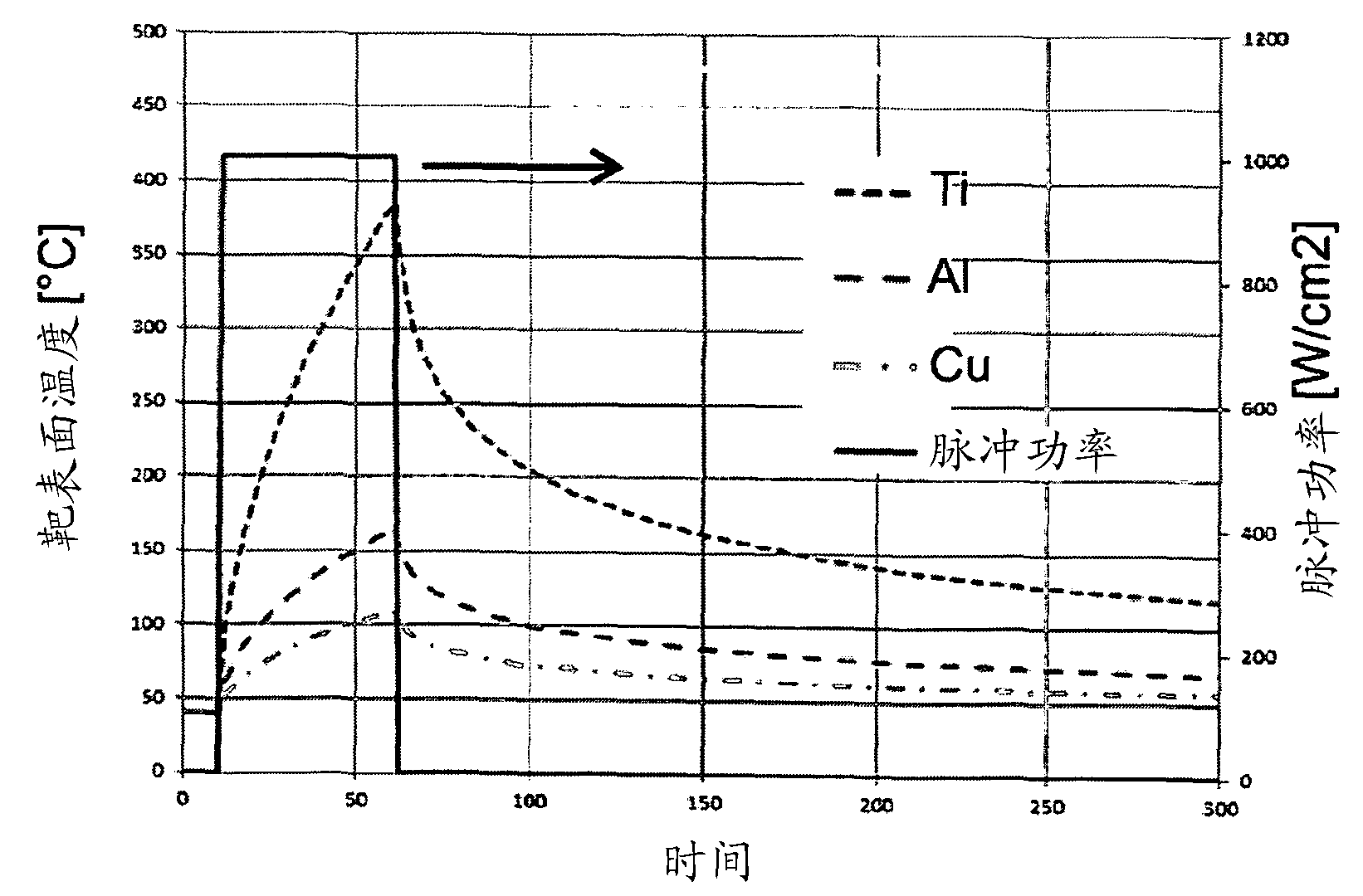

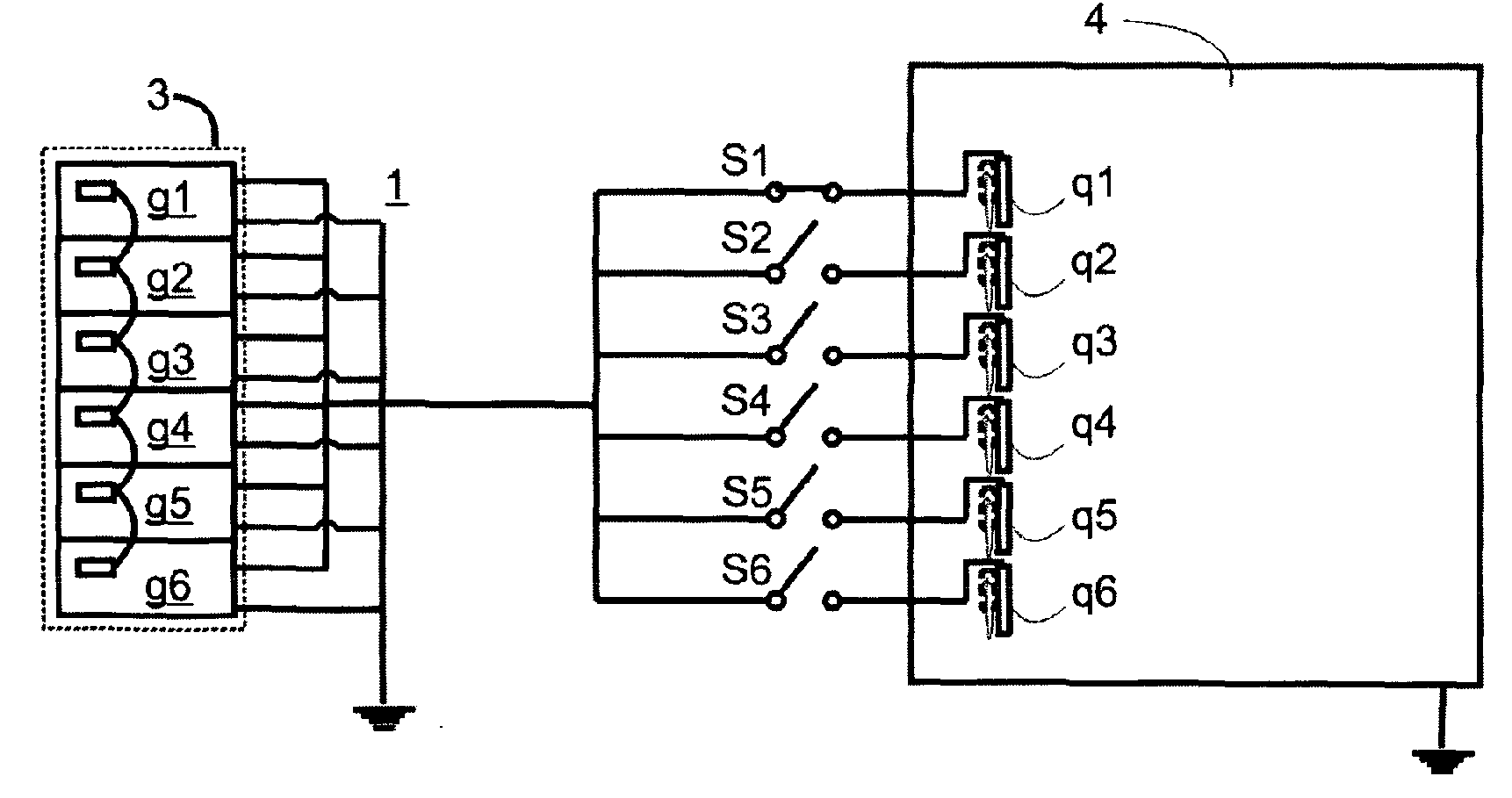

[0022] According to the first embodiment of the present invention, such as figure 2 As exemplarily shown in , the power supply unit 3 supplies voltage and current to the sputtering source q1 arranged in the vacuum chamber 4 via the switch S1 for operating the sputtering device in HIPIMS mode. The power supply unit 3 consists of a plurality of generators g1 to g6 connected in a master-slave configuration. They can be designed as DC generators, pulsed DC generators. The sputtering source q1 is designed as a magnetron sputtering source with a partial target, wherein according to a preferred variant of this embodiment, a movable, preferably rotatably mounted, magnet system is arranged behind the partial target of the sputtering source q1 msl. In application, the trajectory is moved over almost the entire surface of the target of the sputtering source q1 by movement, preferably rotation, of the magnetic system ms1.

[0023] Feed rare gas and / or reactive gas, such as N in the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com