Polishing agent, method and system for polishing inner runner of nickel base alloy workpiece

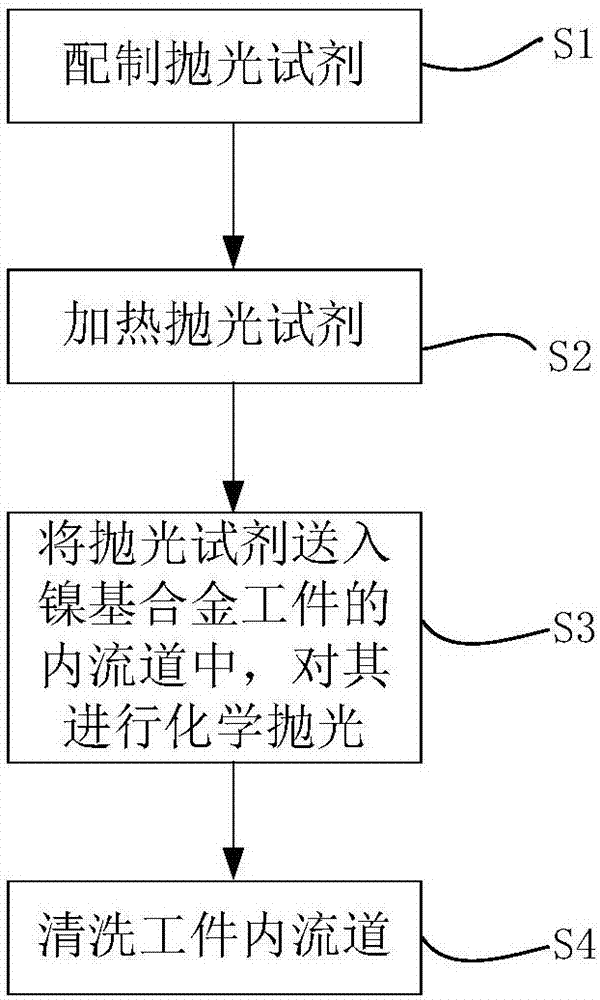

A nickel-based alloy, inner flow channel technology, applied in the field of chemical polishing, can solve problems such as difficult to control polishing effect, poor polishing effect, inability to polish inner flow channel, etc., achieve good chemical polishing effect, improve surface finish, save polishing reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

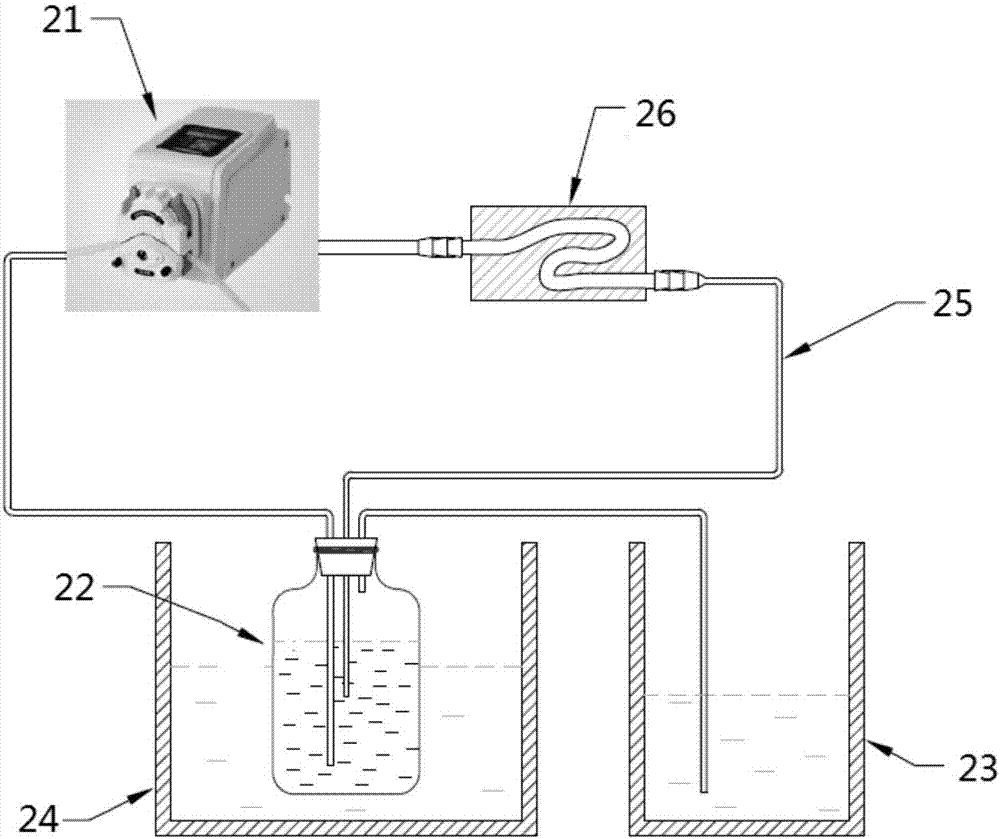

Embodiment 1

[0060] The 3D printed HastlloyX nickel-based alloy workpiece used in this embodiment has a linear inner flow channel, and the original surface roughness of the inner flow channel after forming is Ra12.5-25.

[0061] Phosphoric acid, nitric acid, hydrochloric acid, hydrofluoric acid and distilled water are uniformly mixed according to the molar ratio of 16:12:16:51:239 to obtain a mixed solution.

[0062] Add ferric chloride hexahydrate and sulfosalicylic acid into the mixed solution, completely dissolve and stir evenly to obtain a polishing reagent. The molar ratio of ferric chloride hexahydrate to phosphoric acid is 3.7:16, and the molar ratio of sulfosalicylic acid to phosphoric acid is 0.4:16.

[0063] The polishing reagent is heated to 40°C, and then sent into the inner flow channel to polish the inner flow channel. The polishing reagent is in a flowing state in the inner channel, the flow rate is 700ml / min, and the polishing time is 1min.

[0064] The polishing agent is...

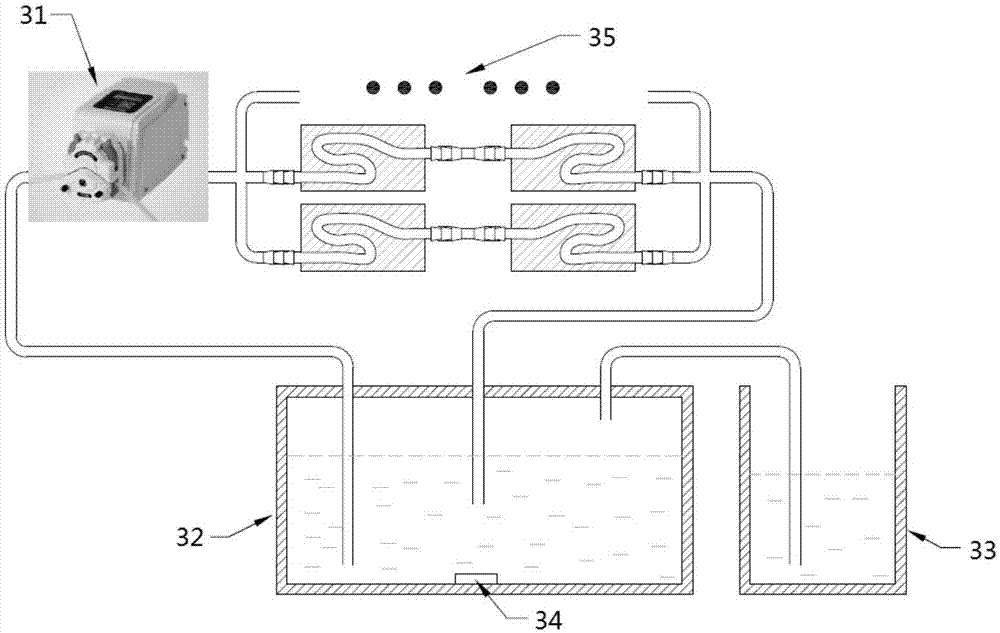

Embodiment 2

[0070] The 3D printed IN718 nickel-based alloy workpiece used in this embodiment has an L-shaped inner flow channel, and its surface roughness is Ra12.5-25.

[0071] Phosphoric acid, nitric acid, hydrochloric acid, hydrofluoric acid and distilled water are uniformly mixed in a molar ratio of 17:8:17:47:250 to obtain a mixed solution.

[0072] Add ferric chloride hexahydrate and sulfosalicylic acid into the mixed solution, completely dissolve and stir evenly to obtain a polishing reagent. The molar ratio of ferric chloride hexahydrate to phosphoric acid is 4:17, and the molar ratio of sulfosalicylic acid to phosphoric acid is 0.8:17.

[0073] The polishing reagent is heated to 60°C, and then sent into the inner flow channel to polish the inner flow channel. The polishing reagent is in a flowing state in the inner flow channel, the flow rate is 400ml / min, and the polishing time is 3min.

[0074] The polishing agent is discharged and the workpiece is cleaned.

[0075] The surf...

Embodiment 3

[0080] The 3D printed IN625 nickel-based alloy workpiece used in this embodiment has an S-like inner flow channel, and its surface roughness is Ra12.5-25.

[0081] Phosphoric acid, nitric acid, hydrochloric acid, hydrofluoric acid and distilled water are uniformly mixed according to the molar ratio of 22:12:19:42.5:194 to obtain a mixed solution.

[0082] Add ferric chloride hexahydrate and sulfosalicylic acid into the mixed solution, completely dissolve and stir evenly to obtain a polishing reagent. The molar ratio of ferric chloride hexahydrate to phosphoric acid is 4.4:22, and the molar ratio of sulfosalicylic acid to phosphoric acid is 0.8:22.

[0083] The polishing reagent is heated to 50°C, and then sent into the inner flow channel to polish the inner flow channel. The polishing reagent keeps flowing in the inner channel, the flow rate is 600ml / min, and the polishing time is 2min.

[0084] The polishing agent is discharged and the workpiece is cleaned.

[0085] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com