Lining brick structure for cooling section of coke dry quenching furnace and building method

A technology for CDQ coke oven and cooling section, which is applied in coke cooling, coke oven, petroleum industry, etc. It can solve the problems of unevenness, fast erosion of lining bricks, and short service life, so as to achieve balanced erosion, reduced wear, and The effect of life cycle improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

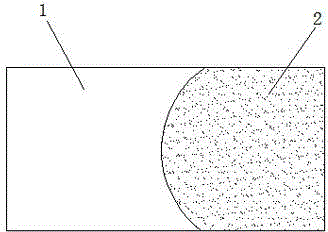

[0025] A lining brick structure for the cooling section of a CDQ coke oven: it is composed of a working layer 1 and an insulating layer 2; the interface between the working layer 1 and the insulating layer 2 is arc-shaped; wherein: the composite lining brick I of the upper cooling section The thickness of the type II composite lining brick working layer 1 is 230mm, and the thickness of the insulation layer 2 is 25mm; the thickness of the II type composite lining brick working layer 1 is 220mm, and the thickness of the insulation layer 2 is 35mm; the thickness of the composite lining brick in the lower cooling section According to the design of 1.01 times the thickness of the composite lining brick in the upper cooling section, the thickness of the Type III composite lining brick working layer 1 in the lower cooling section is 232.1mm, and the thickness of the insulation layer 2 is 25.3mm; the Type IV composite lining brick working layer The thickness of 1 is 222.1mm, and the th...

Embodiment 2

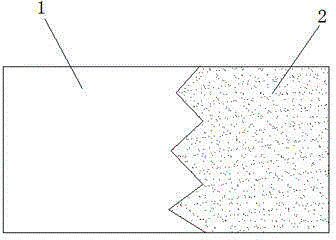

[0030] A lining brick structure for the cooling section of a CDQ coke oven: it is composed of a working layer 1 and an insulating layer 2; the interface between the working layer 1 and the insulating layer 2 is zigzag; wherein: the composite lining brick I of the upper cooling section The thickness of the working layer 1 of type II composite lining brick is 280mm, and the thickness of insulation layer 2 is 32mm; the thickness of working layer 1 of type II composite lining brick is 260mm, and the thickness of insulation layer 2 is 52mm; According to the design of 1.1 times the thickness of the composite lining brick in the upper cooling section, the thickness of the Type III composite lining brick working layer 1 in the lower cooling section is 308mm, and the thickness of the insulation layer 2 is 35.2mm; the Type IV composite lining brick working layer 1 The thickness of the insulation layer 2 is 288mm, and the thickness of the insulation layer 2 is 55.2mm; the thickness of the...

Embodiment 3

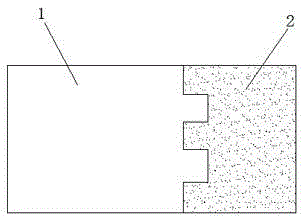

[0035] A lining brick structure for the cooling section of a CDQ coke oven: it is composed of a working layer 1 and an insulating layer 2; the interface between the working layer 1 and the insulating layer 2 is concave-convex; wherein: the composite lining brick I of the upper cooling section The thickness of the type II composite lining brick working layer 1 is 365mm, and the thickness of the insulation layer 2 is 39mm; the thickness of the II type composite lining brick working layer 1 is 335mm, and the thickness of the insulation layer 2 is 69mm; the thickness of the composite lining brick in the lower cooling section According to the design of 1.15 times the thickness of the composite lining brick in the upper cooling section, the thickness of the III-type composite lining brick working layer 1 in the lower cooling section is 420mm, and the thickness of the insulation layer 2 is 45mm; the IV-type composite lining brick working layer 1 The thickness is 390mm, and the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com