Slag line brick for steel ladle and preparation method

A technology of slag line bricks and ladle, applied in the field of refractory materials, can solve the problems of reduced thermal shock resistance, frequent offline, high thermal stress, etc., and achieve the effects of improving thermal shock stability, increasing economic benefits, and buffering thermal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the slag line brick for ladle specifically comprises the following steps:

[0027] 1) Ingredients: Dry mix additives and fused magnesia with a particle size of less than 1 mm in a vibrating mill to make co-milled powder for later use;

[0028] 2) Mixing: Mix and stir the preheated fused magnesia with 3mm≤particle size<5mm, 1mm≤particle size<3mm and the binder at 40-50℃, so that the binder is evenly wrapped on the surface of the fused magnesia particles, and then 3 Add magnesia-carbon waste brick fine powder and flake graphite to mix and stir, and finally add co-milled powder and mix at a speed of 1000-1500 rpm for 8-12 minutes, then mix at a speed of 500-800 rpm for 10-15 minutes For discharge, ensure that the discharge temperature is 40-50°C, and in order to avoid dry material production, control the waiting time of the mud material, and control the time between the mud material being rolled out and the start of molding within 30 minutes to en...

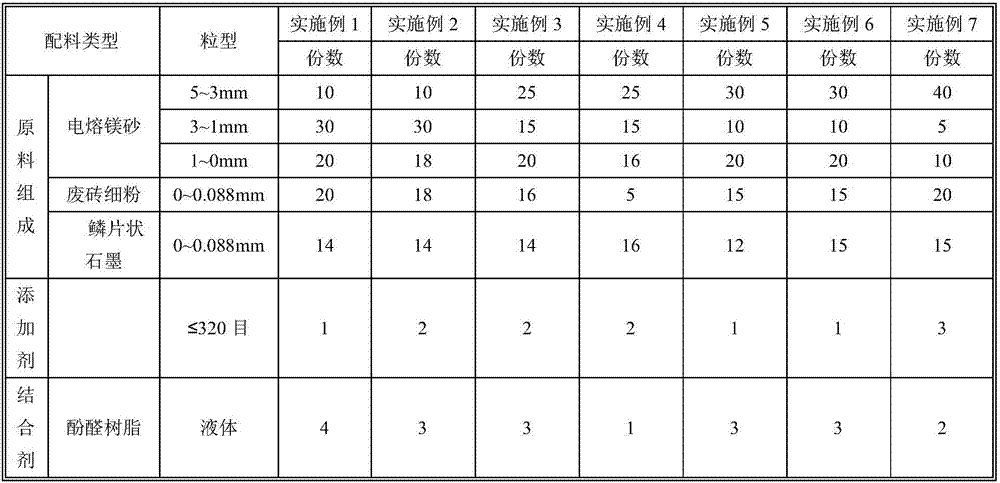

Embodiment 1-7

[0036] The preparation method of embodiment 1-7 ladle with slag line brick:

[0037] 1) Ingredients: Dry mix additives and fused magnesia fine powder in a vibrating mill evenly to make co-milled powder for later use, and weigh magnesia with various particle sizes, binder and additives according to the ratio for later use;

[0038] 2) Mixing: Mixing: Mix preheated fused magnesia with 3mm≤particle size<5mm, 1mm≤particle size<3mm and phenolic resin at 40-50°C, preferably at 45°C, and stir for 3-5min to make the binder Evenly wrap on the surface of fused magnesia particles, then add fine powder and flake graphite, mix and stir for 1-2 minutes, and finally add co-milled powder and mix at high speed for 8-12 minutes at a speed of 1000-1500 rpm, then mix at a low speed for 10-15 minutes The output speed is 500-800 rpm, and the output temperature is guaranteed to be 40-50°C. In order to avoid dry material production, the waiting time for the mud material is strictly controlled. To en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com