Slag line control method of continuous casting crystallizer

A continuous casting crystallizer and control method technology, applied in the field of continuous casting, can solve the problems of individual parts such as erosion and easy fracture, and achieve the effects of reducing labor intensity, prolonging service life, and uniform erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

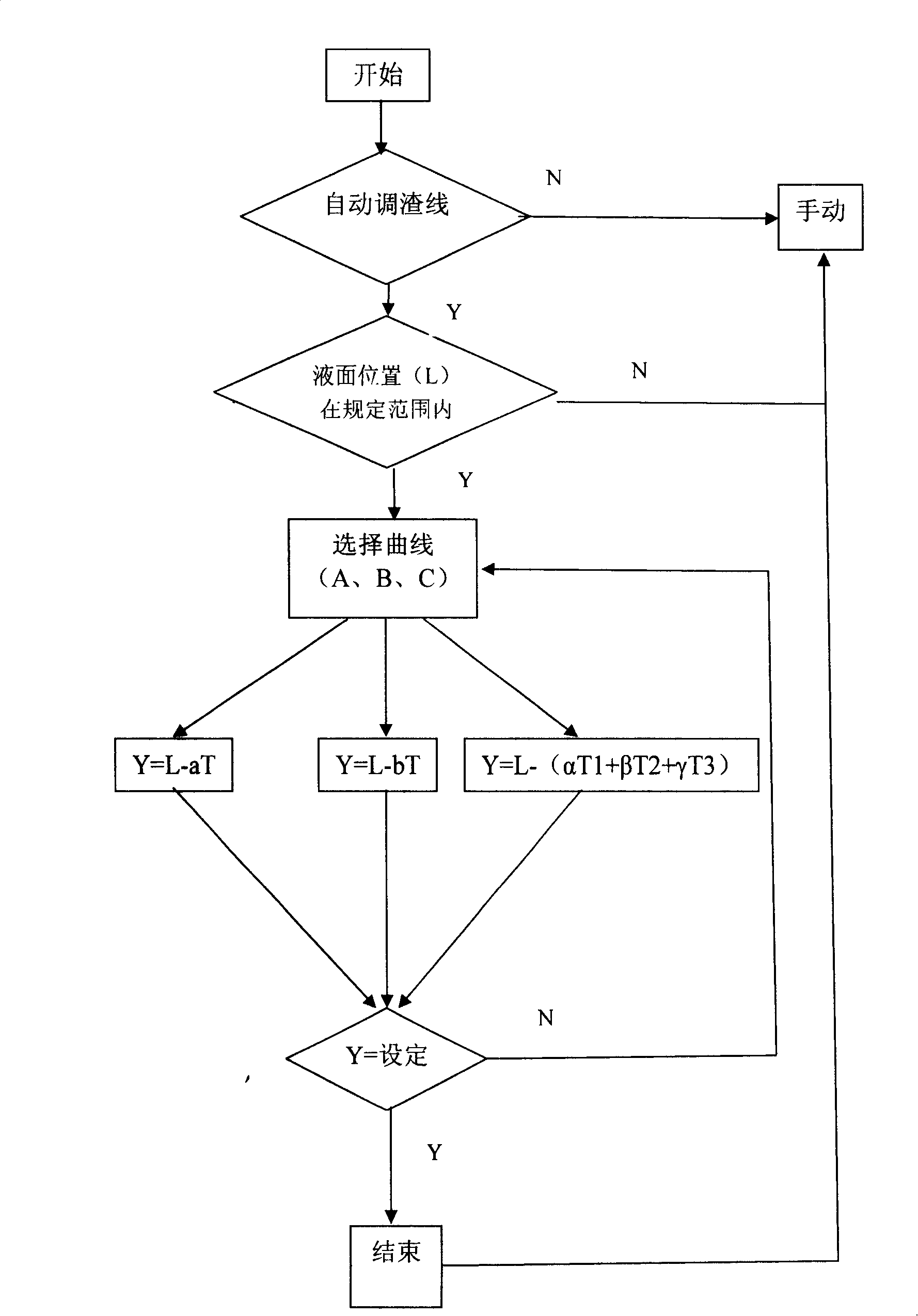

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] A continuous casting mold slag line control method of the present invention is based on the existing continuous casting mold liquid level automatic control system, and adjusts its slag layer by continuously and automatically changing the setting value of the system in small amounts as time changes Location. Among them, the adjustment rate (slope) of the system setting value varies with the position of the water outlet and the superimposed part of the liquid level fluctuation.

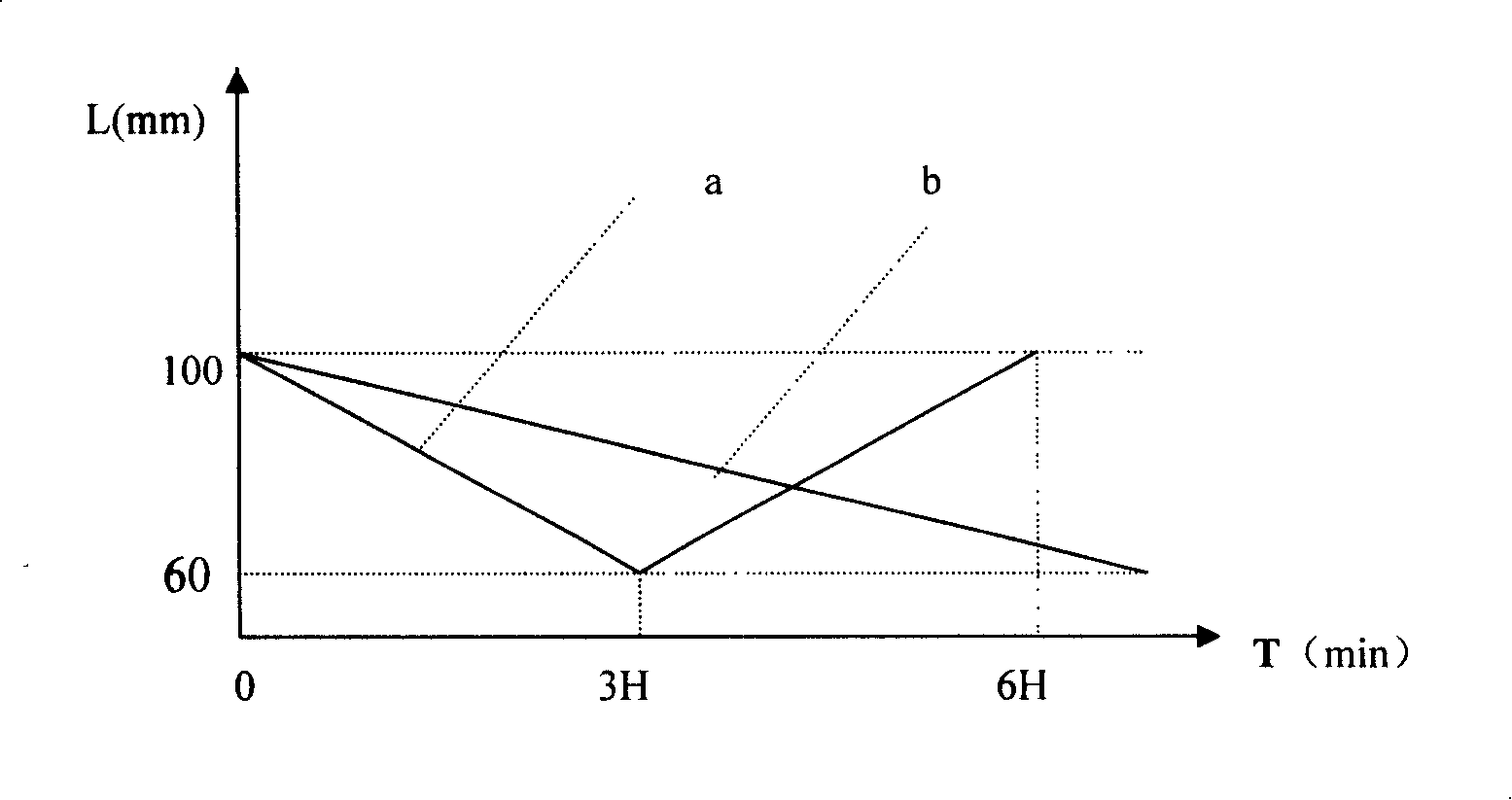

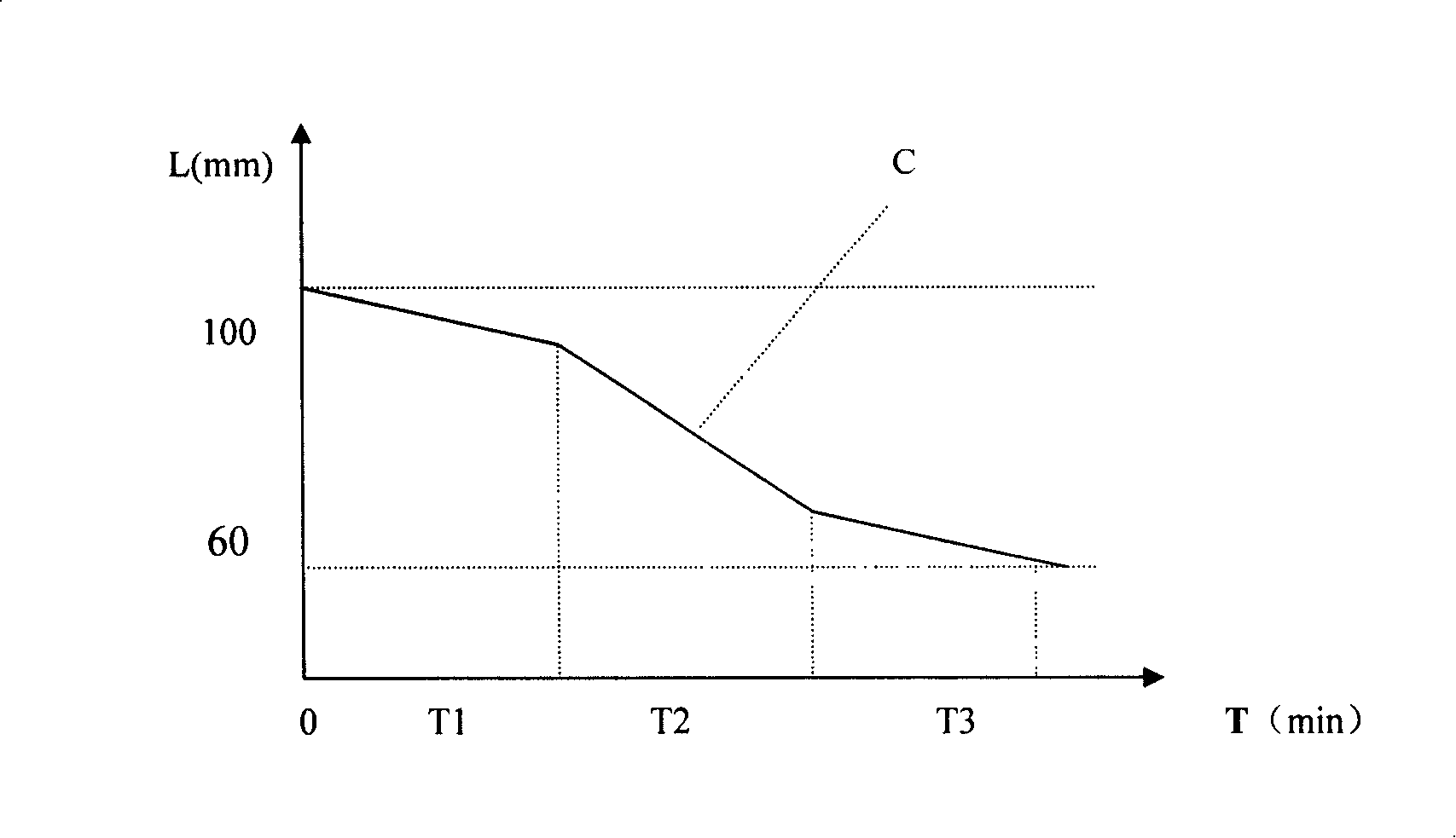

[0013] The automatic setting of the crystallizer liquid level position of the present invention is through the computer operation screen (MMI) that is connected with the PLC controller of the continuous casting machine, and the automatic adjustment slag line program (such as figure 1 shown) to achieve. Draw several different given function curves on the computer operation scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com