Air blowing and slag removing spray gun for foundry ladle and preparation method thereof

A technology of ladle and spray gun, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of long cleaning time and incomplete cleaning of iron slag, and achieve the effect of preventing spalling and damage, improving thermal shock stability and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

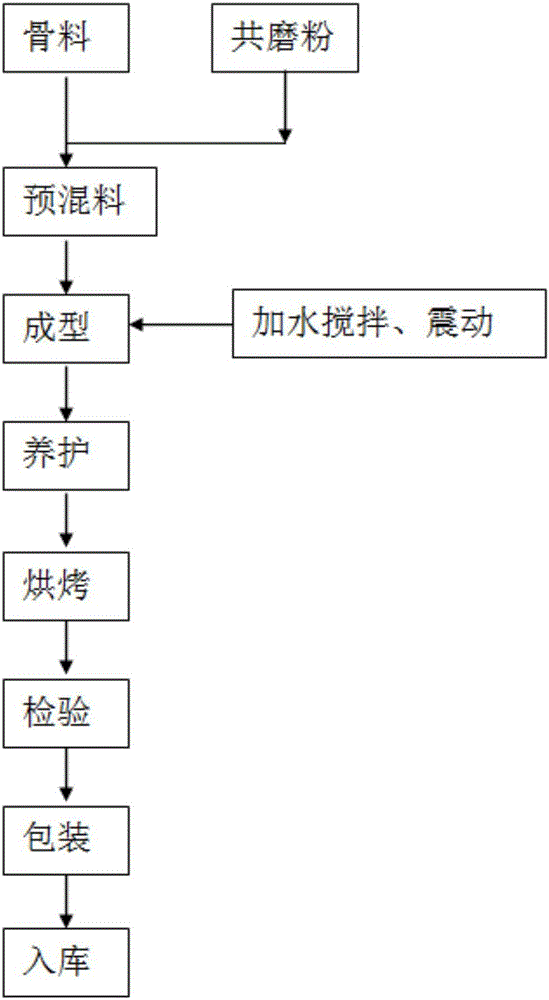

Method used

Image

Examples

Embodiment 1

[0071] A kind of air blowing slag removing spray gun for ladle, its raw material comprises the following components by weight:

[0072] Al with a particle size of 5-3mm 2 o 3 20 parts of super-grade alumina particles with a content greater than 88%;

[0073] 40 parts of andalusite particles, including 25 parts of particle size 3-1mm and 15 parts of particle size 1-0mm;

[0074] 10 parts of fused white corundum fine powder with a particle size of 320 mesh;

[0075] 10 parts of 60 sintered mullite with a particle size of 200 mesh;

[0076] α-Al with a particle size of 3-5 microns 2 o 3 6 parts of micro powder;

[0077] Particle size 180 mesh 97SiC5 parts;

[0078] The particle size is ≤5μm silica powder (in which α-Al 2 o 3 Micropowder size distribution curve is bimodal structure) 3 parts;

[0079] 0.1 part of explosion-proof fiber with a length of 4mm (water-soluble, melting temperature is 70°C);

[0080] Water reducing agent (ADS 3 )0.5 copies;

[0081] Calcium al...

Embodiment 2

[0092] A kind of air blowing slag removing spray gun for ladle, its raw material comprises the following components by weight:

[0093] 25 parts of special-grade alumina particles with a particle size of 5-3mm and a content of 88%-90%;

[0094] 40 parts of andalusite particles, including 25 parts of particle size 3-1mm and 15 parts of particle size 1-0mm;

[0095] 10 parts of fused white corundum fine powder with a particle size of 320 mesh;

[0096] 5 parts of 60 sintered mullite with a particle size of 200 mesh;

[0097] α-Al with a particle size of 3-1 microns 2 o 3 6 parts of micro powder;

[0098] Particle size 180 mesh 97SiC3 parts;

[0099] Particle size ≤ 5μm silica powder (of which α-Al 2 o 3 Micropowder size distribution curve is bimodal structure) 3 parts;

[0100] 0.1 part of explosion-proof fiber with a length of 4mm (water-soluble, melting temperature is 70°C);

[0101] Water reducing agent (ADS 3 )0.5 copies;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com