Injector for gas fuel

A gaseous fuel and injector technology, which is applied in fuel injection devices, charging systems, combustion engines, etc., can solve the problems of flow drop and aperture narrowing, and achieve the effects of accurate fuel injection, accurate flow measurement, and excellent stripping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

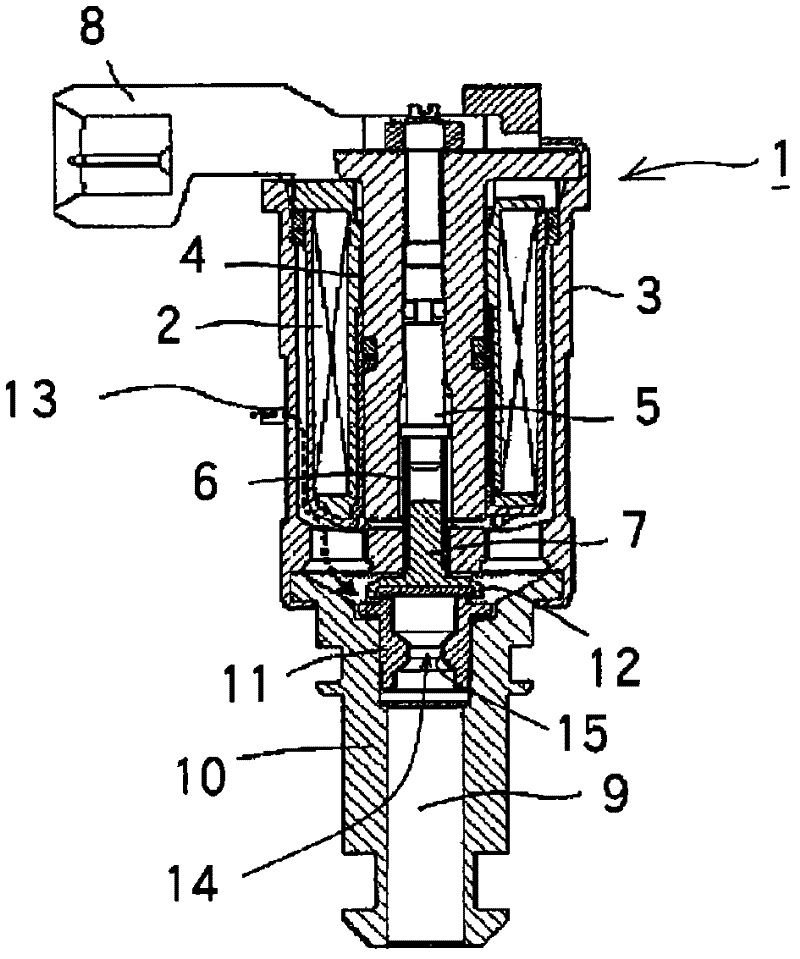

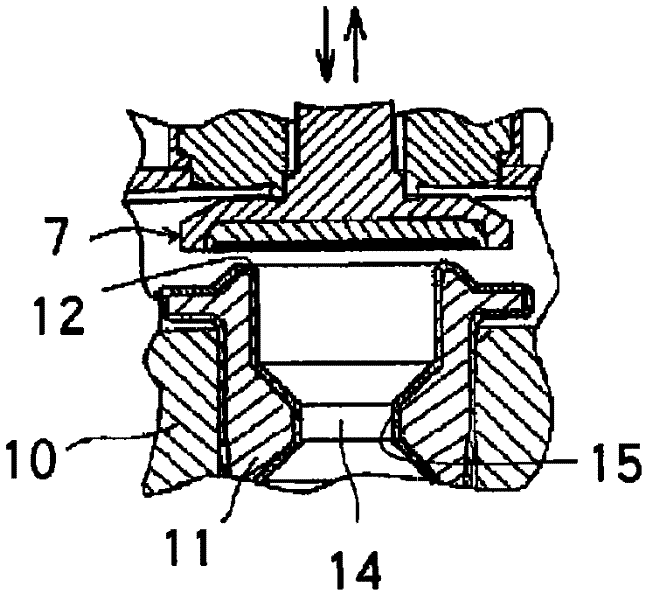

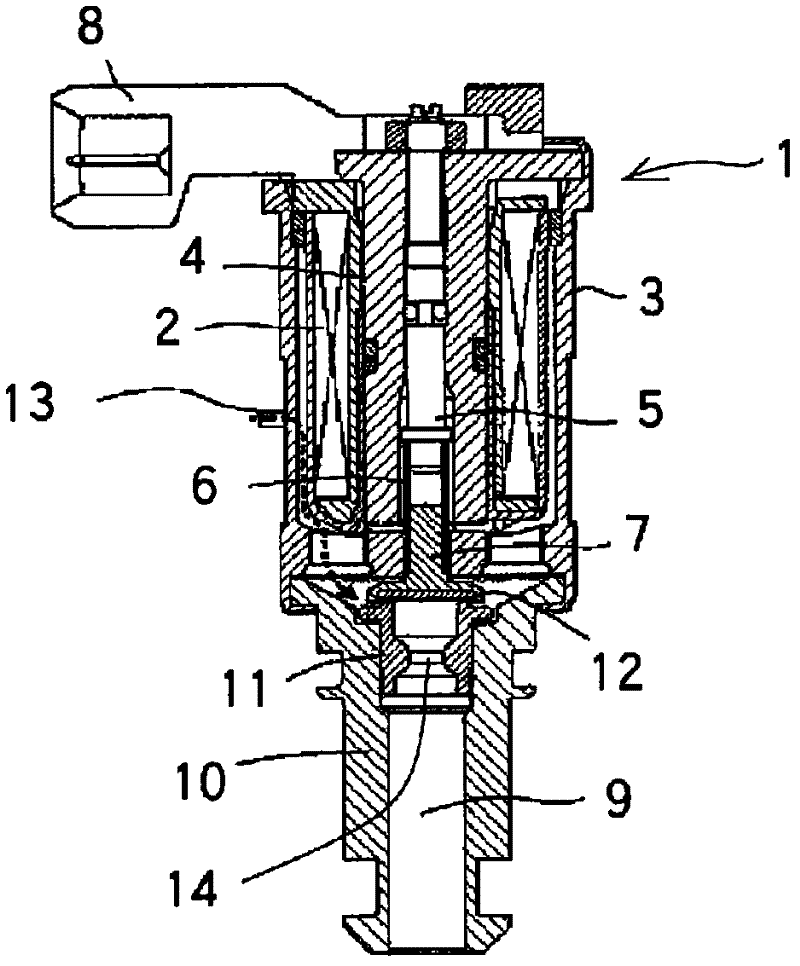

[0025] figure 1 is a schematic diagram of the injector of the present invention, figure 2 It is an enlarged view showing the main part of the injector. The overall structure of the injector is the same as that of the conventional injector. The flow rate regulator is arranged at the center of the coil holder 4 that holds the electromagnetic coil 2 and is embedded in the outer casing 3. Screw 5, at the lower end of the flow regulating screw 5, an injector spool 7 capable of reciprocating along the axial direction is disposed via a spring body 6, and in this injector, a wire connected to a connector 8 (not shown) ) receives instructions from the ECU (not shown), and makes the electromagnetic coil 2 turn on and off according to the instructions, so that the injector spool 7 lifts, and the injector spool 7 is in contact with the injection valve seat 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com