Array substrate and manufacturing method thereof

An array substrate and array layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven display around the display panel, affecting display quality, etc., to achieve improved display quality, good display quality, and reduced leveling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

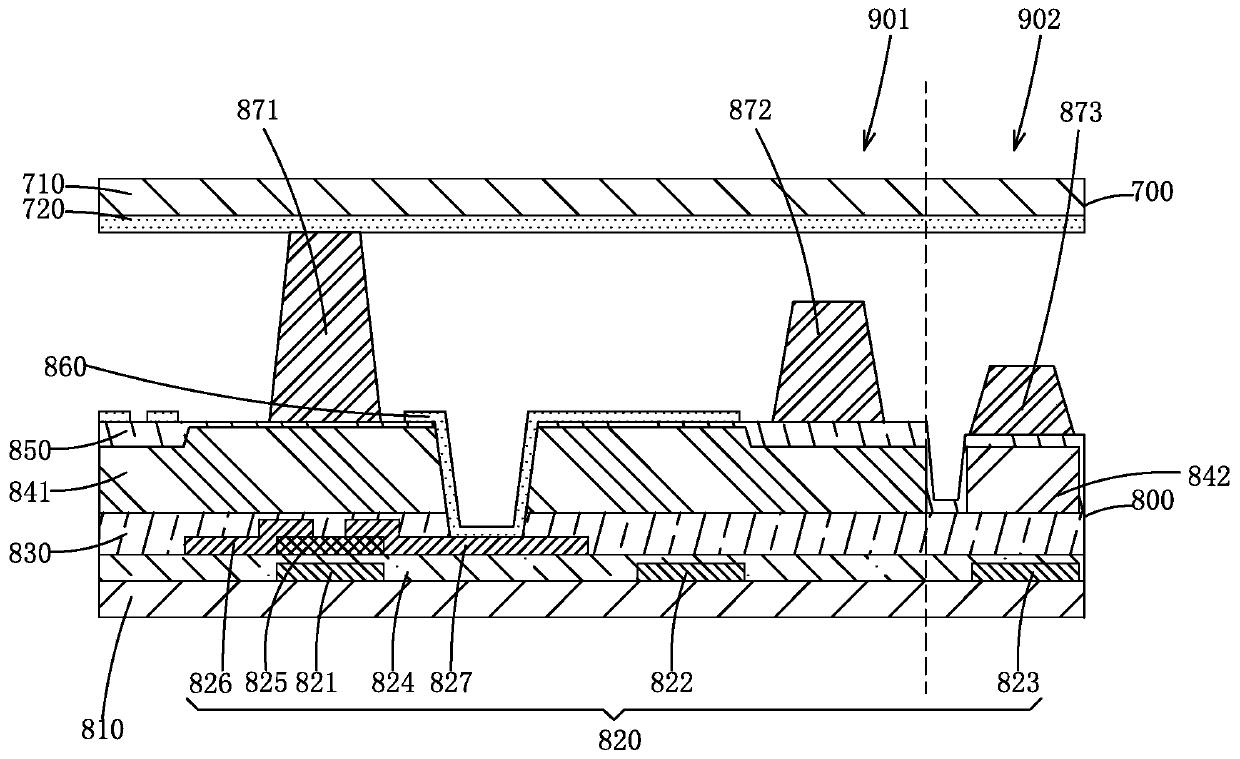

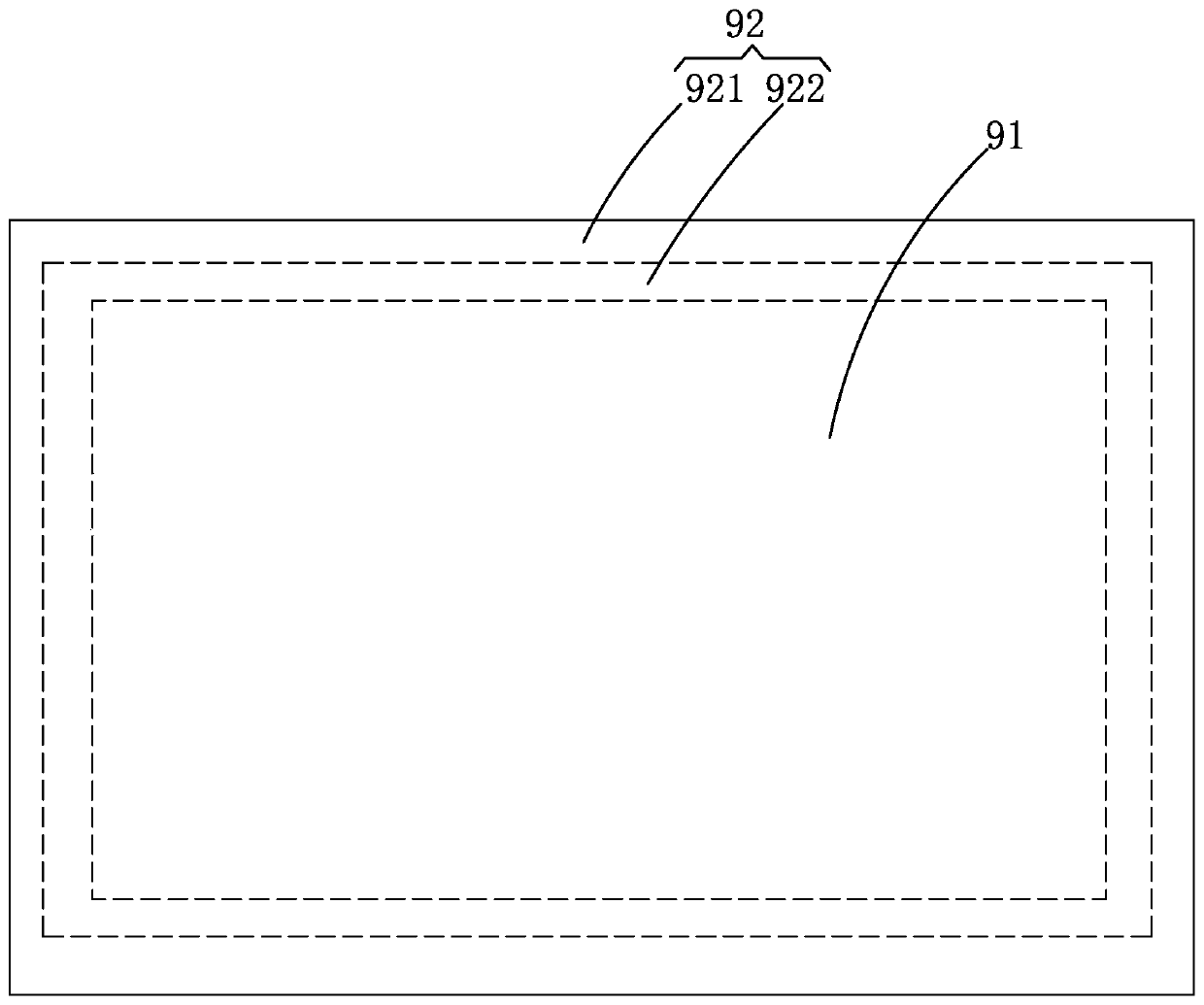

[0036] The present invention provides an array substrate using POA technology, please refer to image 3 , the array substrate has a display area 91 and a peripheral area 92 located outside the display area 91 . Please combine image 3 and Figure 4 The array substrate includes an edge color-resist pattern 32 disposed in the peripheral area 92 and an edge spacer 42 located above the edge color-resist pattern 32 . Please combine Figure 4 and Figure 5 The edge color-resist pattern 32 includes a block portion 321 and a retaining wall 322 located outside the block portion 321 .

[0037] Specifically, in Figure 4 In the illustrated embodiment, the array substrate further includes a base substrate 10, a thin film transistor array layer 20 dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com