High-recovery battery negative electrode slurry, preparation method thereof and lithium battery

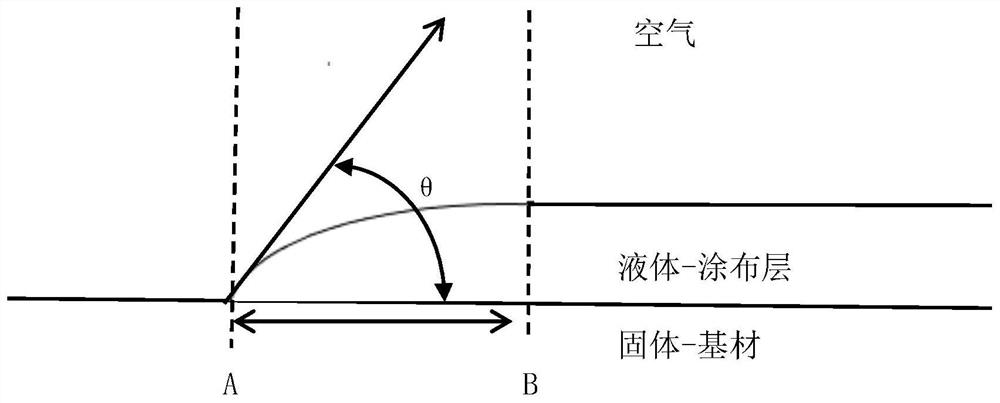

A battery negative electrode and recovery technology, which is applied to the high recovery battery negative electrode slurry and its preparation method and the field of lithium batteries, can solve the problems of complicated and tedious operation and limited adjustment range, and achieves good sag, large wetting angle, and battery The effect of increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

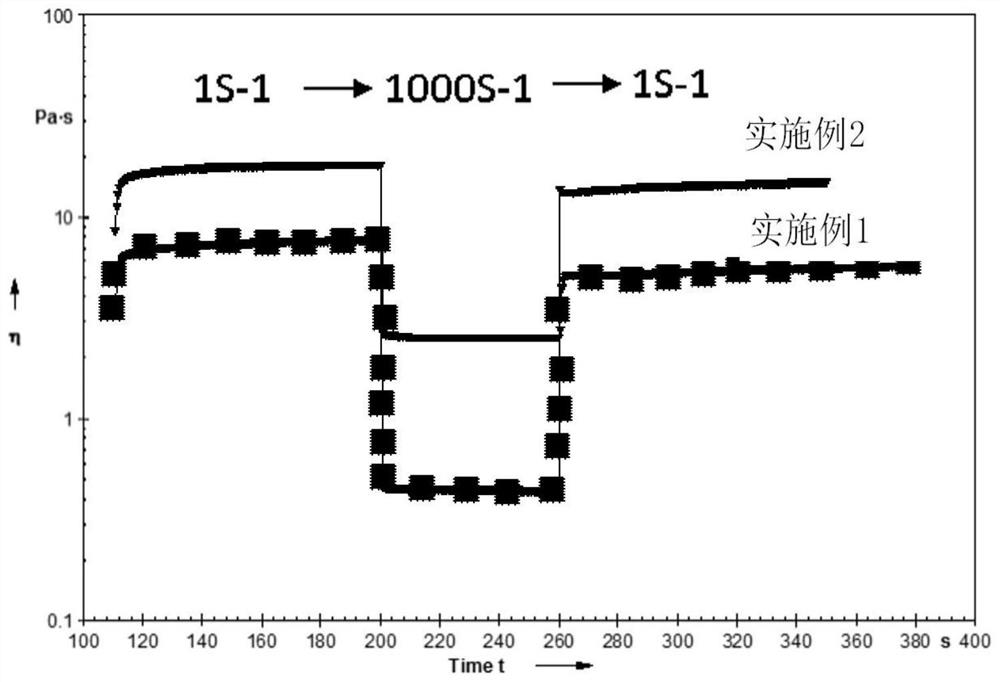

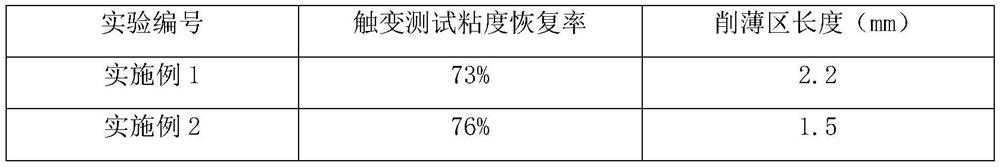

[0031] The negative electrode slurry has a viscosity recovery rate of more than 73% in a thixotropic test, and the length of the thinned area of the negative electrode sheet prepared by it is 2.2mm. The production process is as follows: ① dry mix 100% negative electrode graphite and 100% conductive agent, turn on revolution, disperse at a linear speed of 6m / s, stir and disperse for 30min; ② add the first CMC solution, and the amount of CMC is 60% of the total amount added , open revolution, disperse linear speed 10m / s, stir and disperse for 30min ③ add the remaining CMC solution and appropriate amount of deionized water, the solid content is 55%, open revolution, disperse linear speed 10m / s, stir and disperse for 30min ④ finally add SBR solution, open Revolution, dispersing line speed 6m / s, stirring and dispersing for 20min to obtain sample 1.

Embodiment 2

[0033] A negative electrode slurry, the viscosity recovery rate of which is above 76% in the thixotropic test, and the length of the thinned area of the negative electrode sheet prepared by it is 1.5mm. The production process is as follows: ① dry mix 100% negative electrode graphite and 100% conductive agent, turn on revolution, disperse at a linear speed of 6m / s, stir and disperse for 30min; ②add the first CMC solution, and the amount of CMC is 50% of the total amount added , open revolution, disperse linear speed 10m / s, stir and disperse for 30min ③ add the remaining CMC solution and appropriate amount of deionized water, the solid content is 55%, open revolution, disperse linear speed 10m / s, stir and disperse for 30min ④ finally add SBR solution, open Revolution, dispersing line speed 6m / s, stirring and dispersing for 20min to obtain sample 2.

Embodiment 3

[0035] A negative electrode slurry whose viscosity recovery rate in a thixotropy test is above 80%, and the length of the thinned area of the negative electrode sheet prepared by it is 1.0mm. The production process is as follows: ① Dry mix 100% negative electrode graphite and 100% conductive agent, open revolution, disperse at a linear speed of 6m / s, stir and disperse for 30min ②Add the first CMC solution, the amount of CMC is 40% of the total amount added , open revolution, disperse linear speed 10m / s, stir and disperse for 30min ③ add the remaining CMC solution and appropriate amount of deionized water, the solid content is 55%, open revolution, disperse linear speed 10m / s, stir and disperse for 30min ④ finally add SBR solution, open Revolution, dispersing line speed 6m / s, stirring and dispersing for 20min to obtain sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com