Mask plate and manufacturing method thereof

A manufacturing method and mask plate technology, applied in the field of semiconductors, can solve problems such as photoresist patterns with inconsistent heights on the upper surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

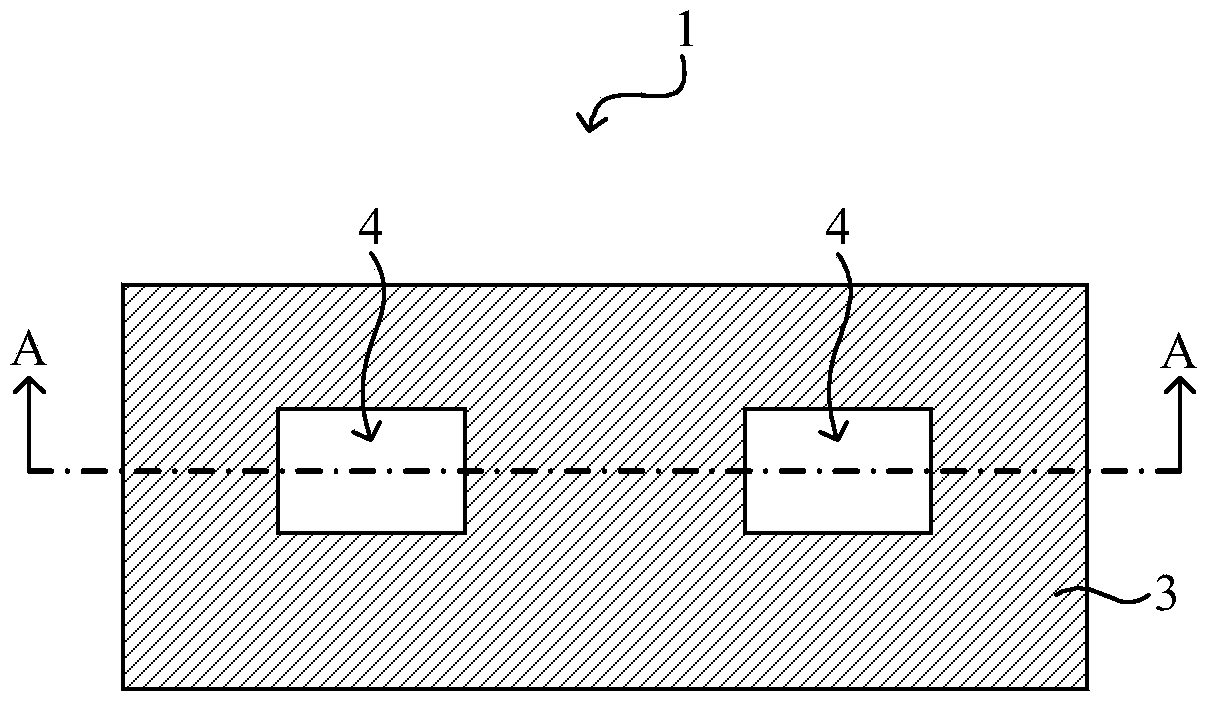

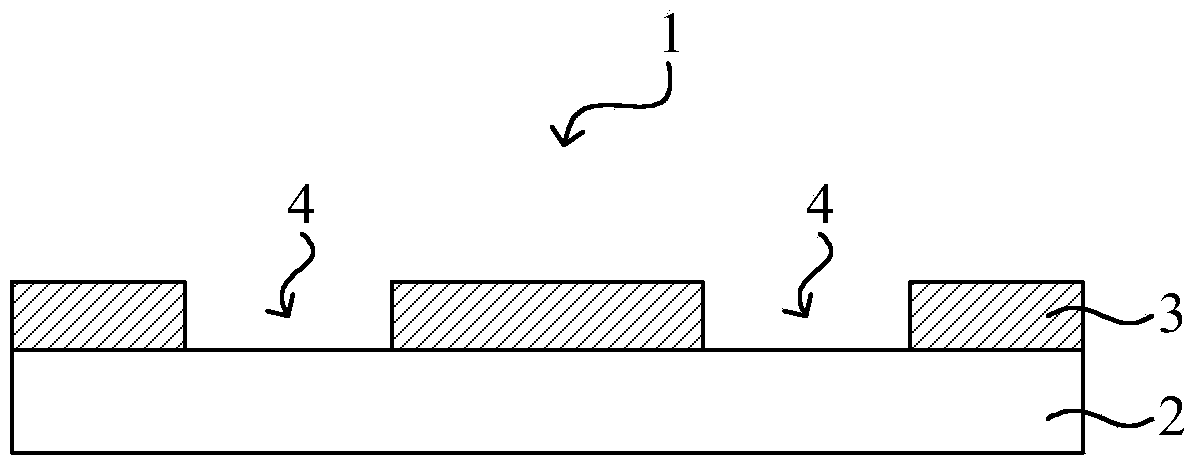

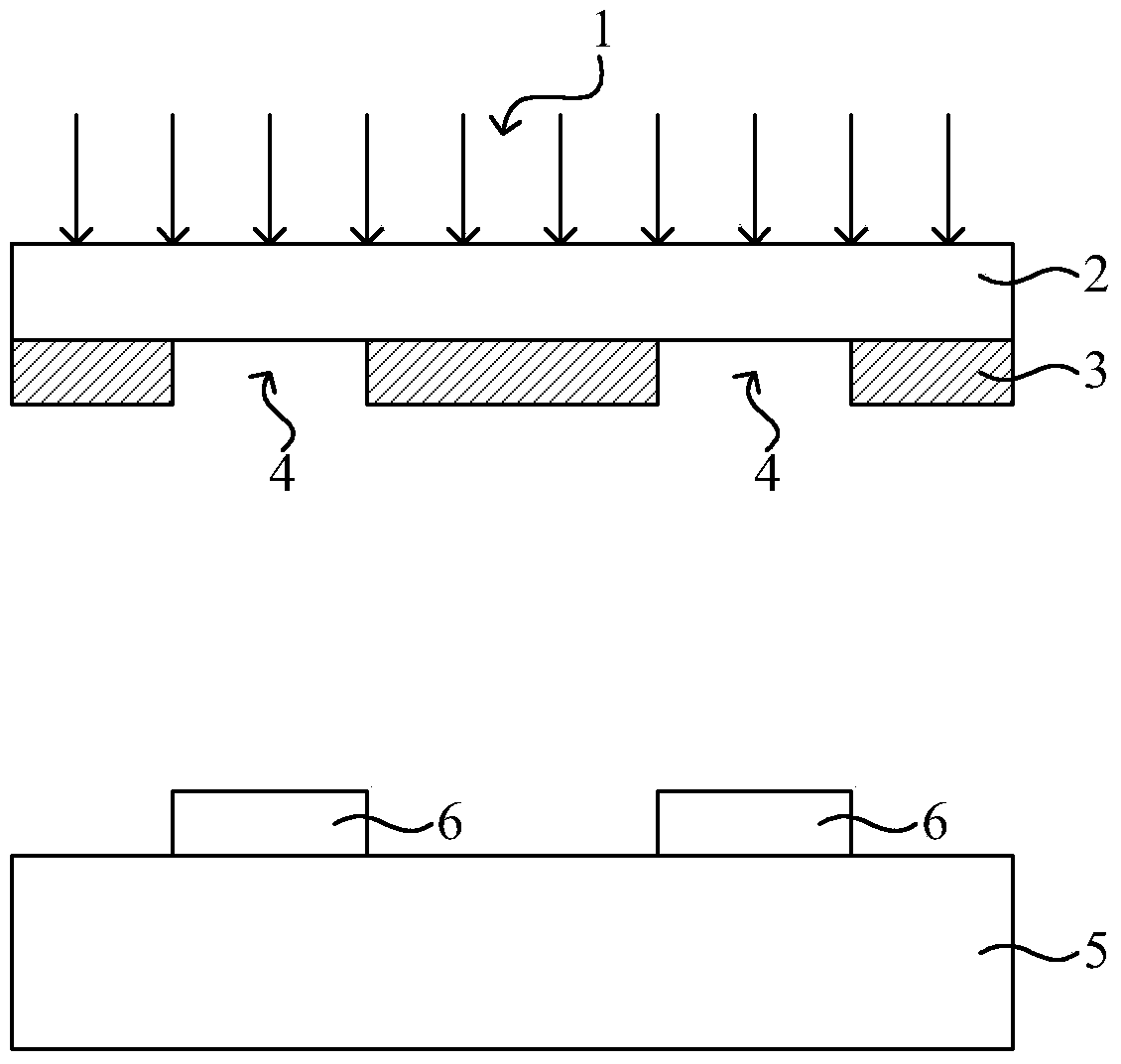

[0046] combine Figure 4 and Figure 5 As shown, the mask plate 100 includes: a transparent substrate 110 ; a patterned light-shielding layer 120 on the transparent substrate 110 , and the patterned light-shielding layer 120 has an opening 130 exposing the transparent substrate 110 . The regions corresponding to the openings 130 on the mask 100 are all light-transmitting regions.

[0047] The opening 130 is divided into a first opening unit 131 and a second opening unit 132 , the bottom of the first opening unit 131 exposes the transparent substrate 110 , and the bottom of the second opening unit 132 is covered with a transparent film 140 . Therefore, the light-transmitting area of the mask plate 100 is divided into a first light-transmitting area and a second light-transmitting area, wherein, the area corresponding to the first opening unit 131 on the mask plate 100 is the first light-transmitting area, and The area corresponding to the second opening unit 132 is the seco...

no. 2 example

[0071] The difference between the second embodiment and the first embodiment is that in the second embodiment, the combination Figure 10 and Figure 11 As shown, the transparent substrate 110 below the second opening unit 132 in the opening 130 is doped with a metal 180 . After the transparent substrate 110 is doped with metal 180, the light transmittance of the transparent substrate will decrease. Therefore, the light transmittance of the area corresponding to the first opening unit 131 on the mask plate (that is, the first light-transmitting area) is greater than that of the mask plate. The light transmittance of the area on the stencil corresponding to the second opening unit 132 (ie, the second light transmission area).

[0072] In this embodiment, the entire thickness of the transparent substrate 110 under the second opening unit 132 is doped with metal 180 .

[0073] In this embodiment, the metal 180 is chromium. In other embodiments, the metal 180 may also be other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com