Patents

Literature

58results about How to "High resistance precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atmospheric corrosion test procedure and its apparatus

InactiveUS20130164852A1Improve test accuracyReduce varianceWeather/light/corrosion resistanceBiological testingSaline waterSalt content

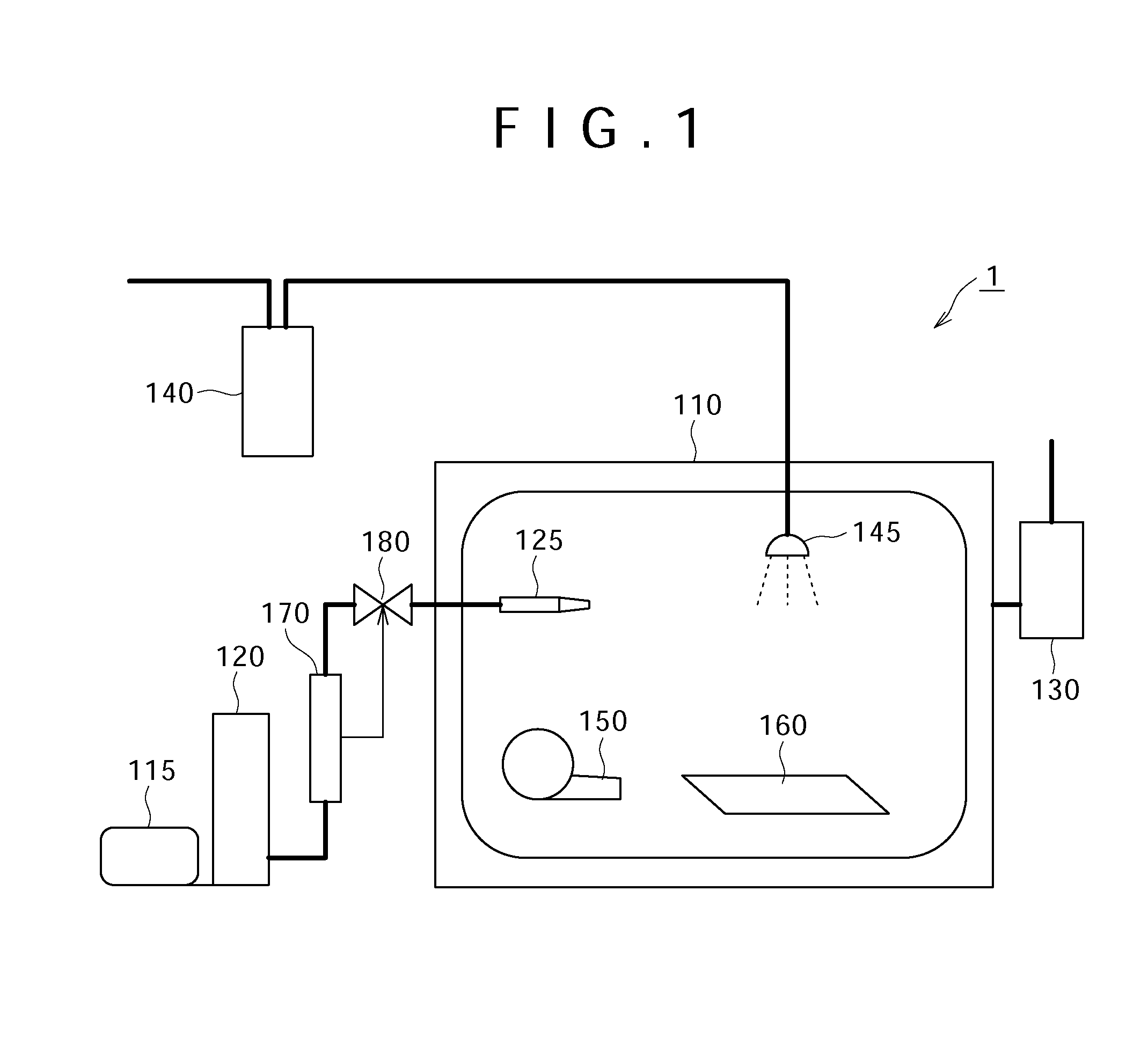

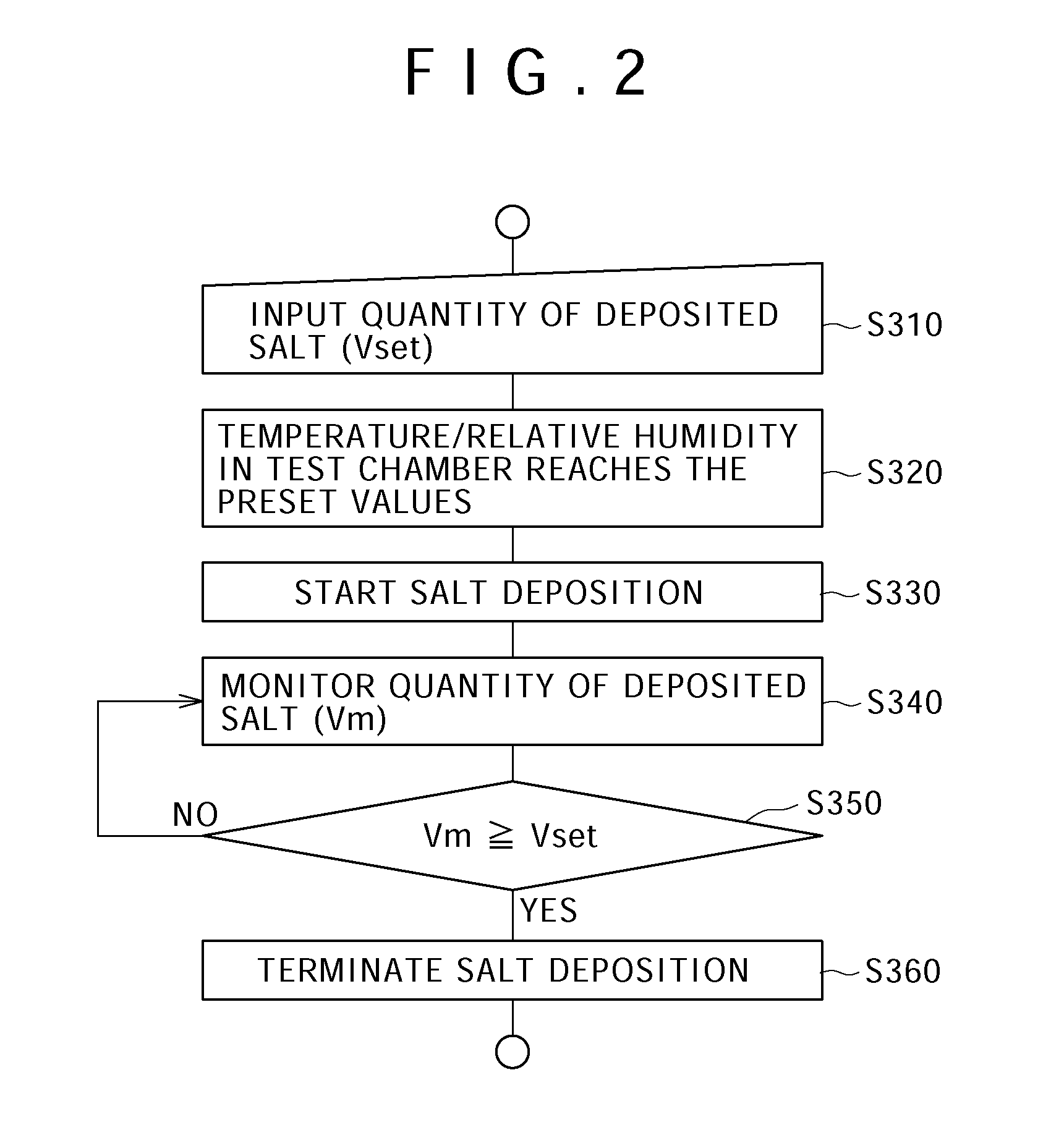

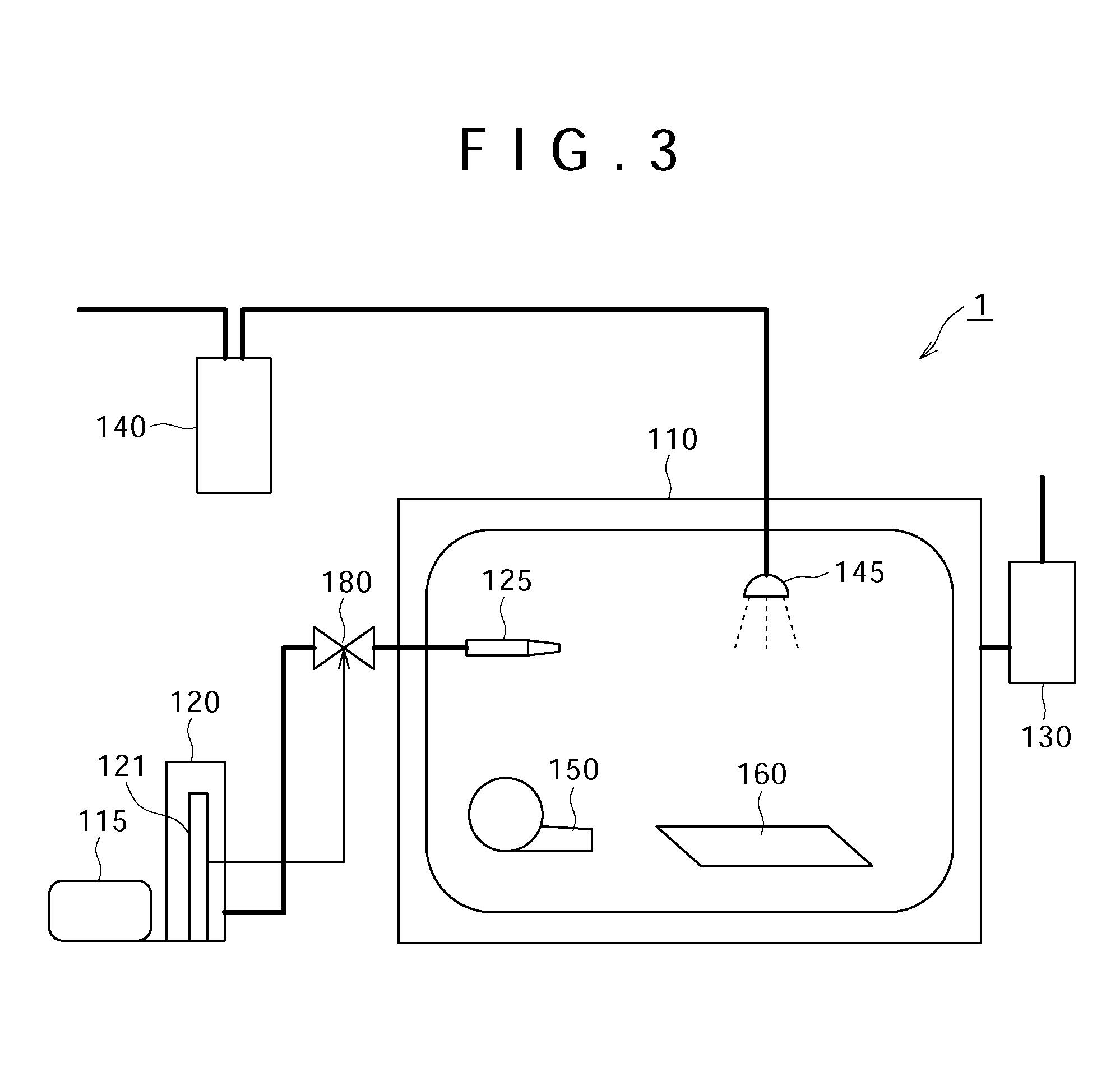

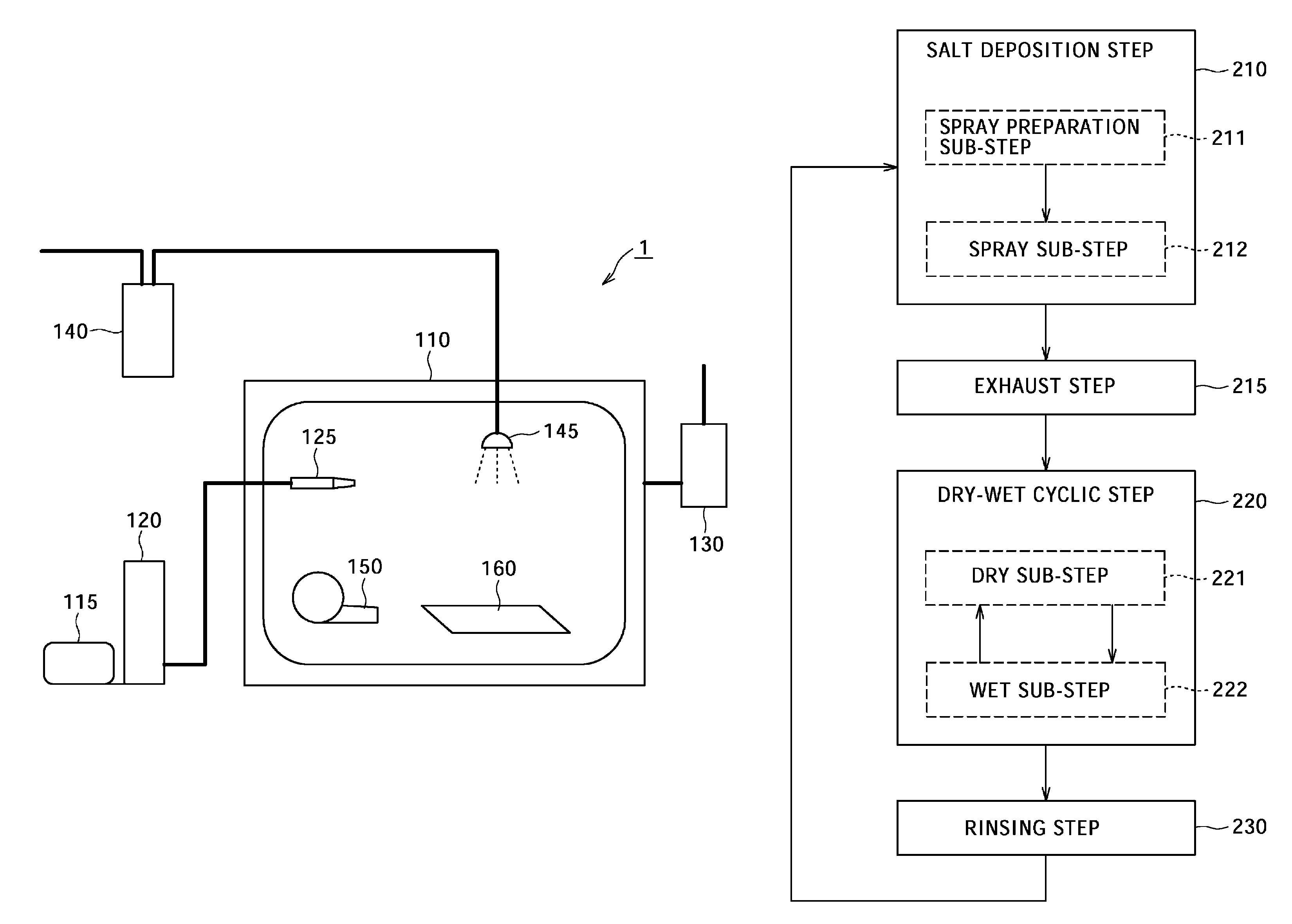

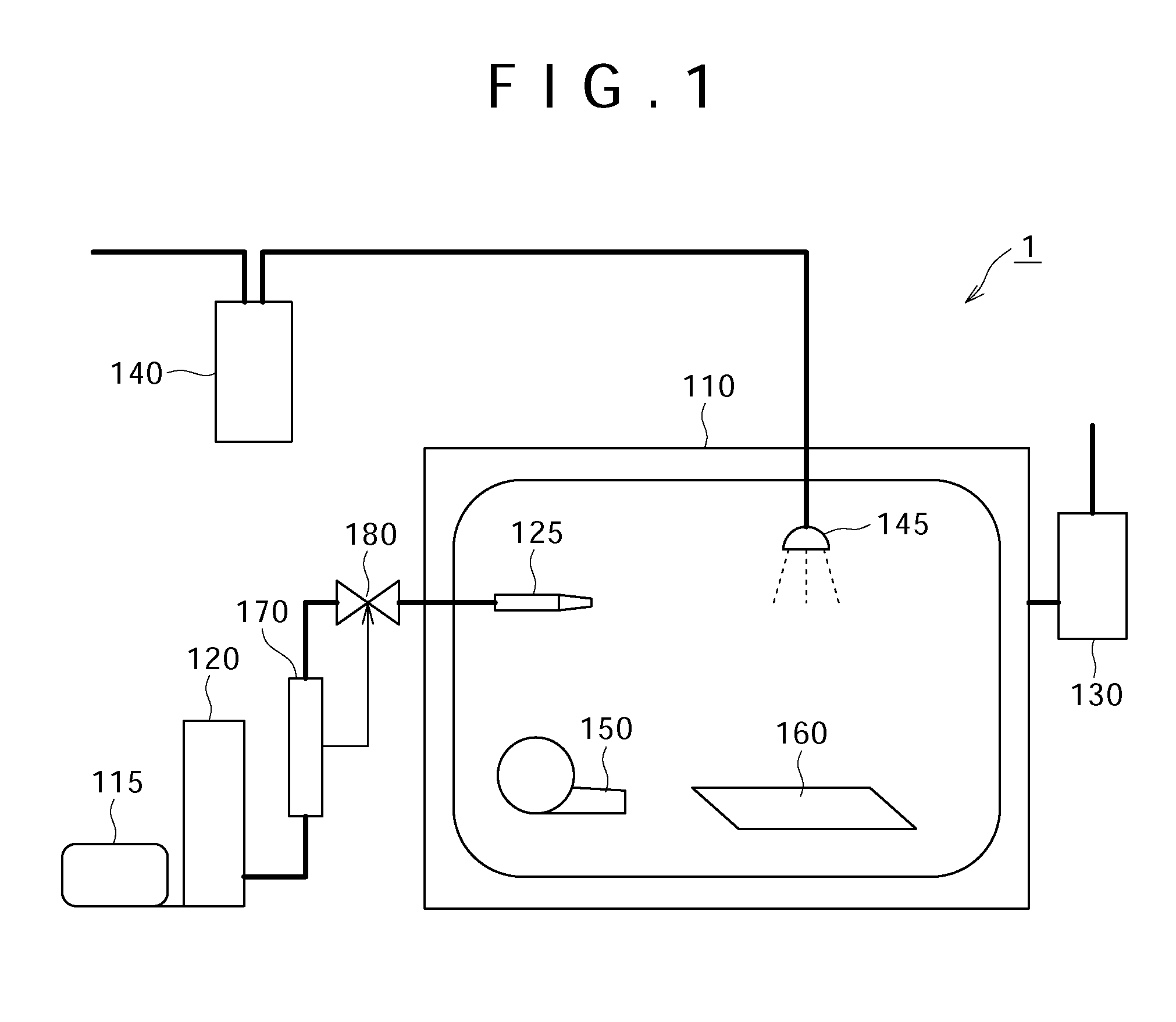

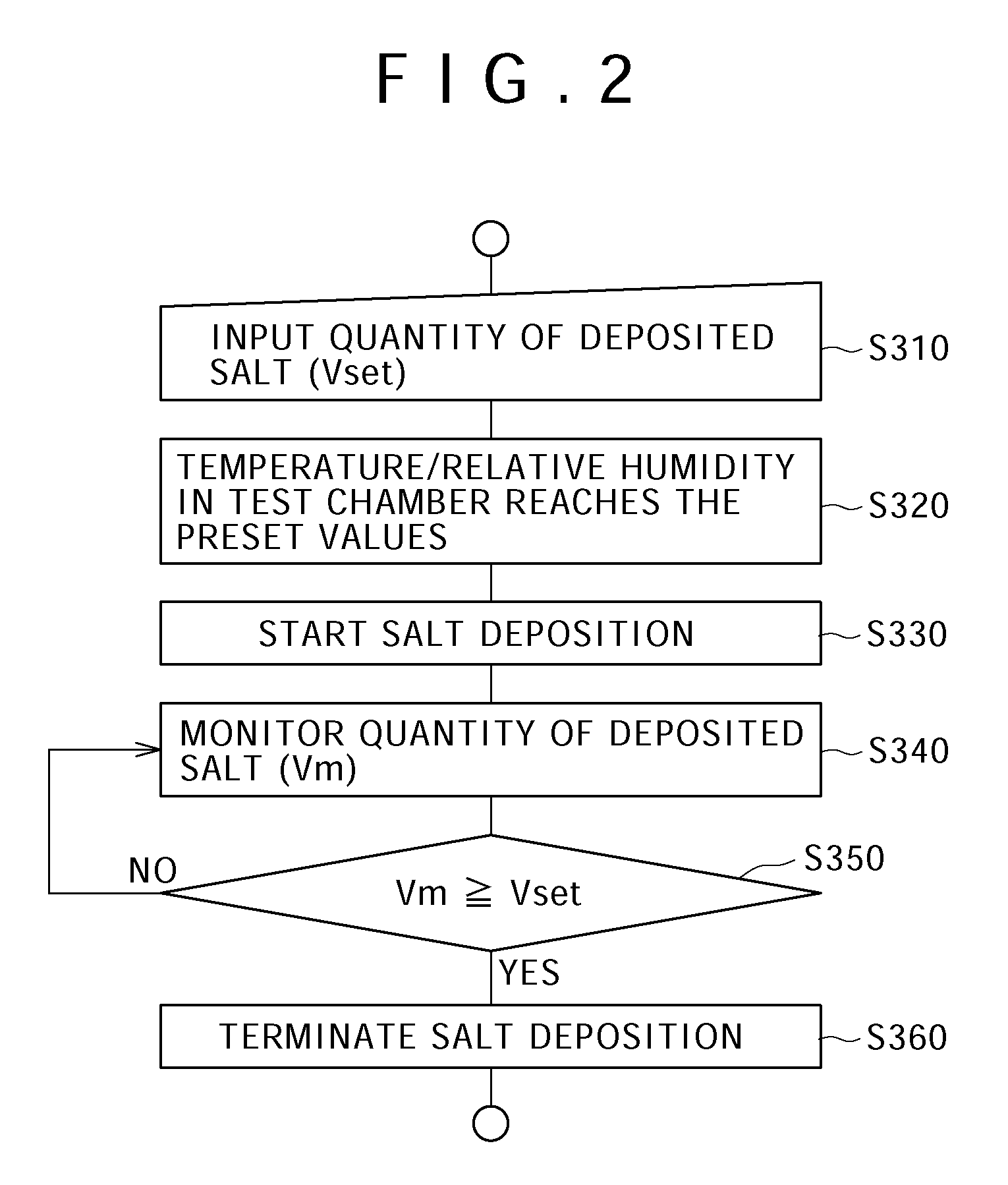

Provided are an atmospheric corrosion test procedure and an apparatus used for the test. The procedure involves a salt spray step for supplying salt content containing chloride ions on the surfaces of test pieces placed in a thermo-humidistat chamber and a subsequent dry-wet cyclic step including a dry sub-step for drying the surface of the test pieces in the thermo-humidistat chamber at a low relative humidity and a subsequent wet sub-step at a higher relative humidity than that in the dry sub-step, which are cycled. The salt content is supplied by spraying the salt water in the salt spray step. An exhaust step for removing the salt mist sprayed inside thermo-humidistat chamber is further inserted between the salt deposition step and the dry sub-step. The quantity of the salt content deposited on the surfaces of the test pieces is controlled by adjusting the quantity of the sprayed salt water.

Owner:HITACHI LTD

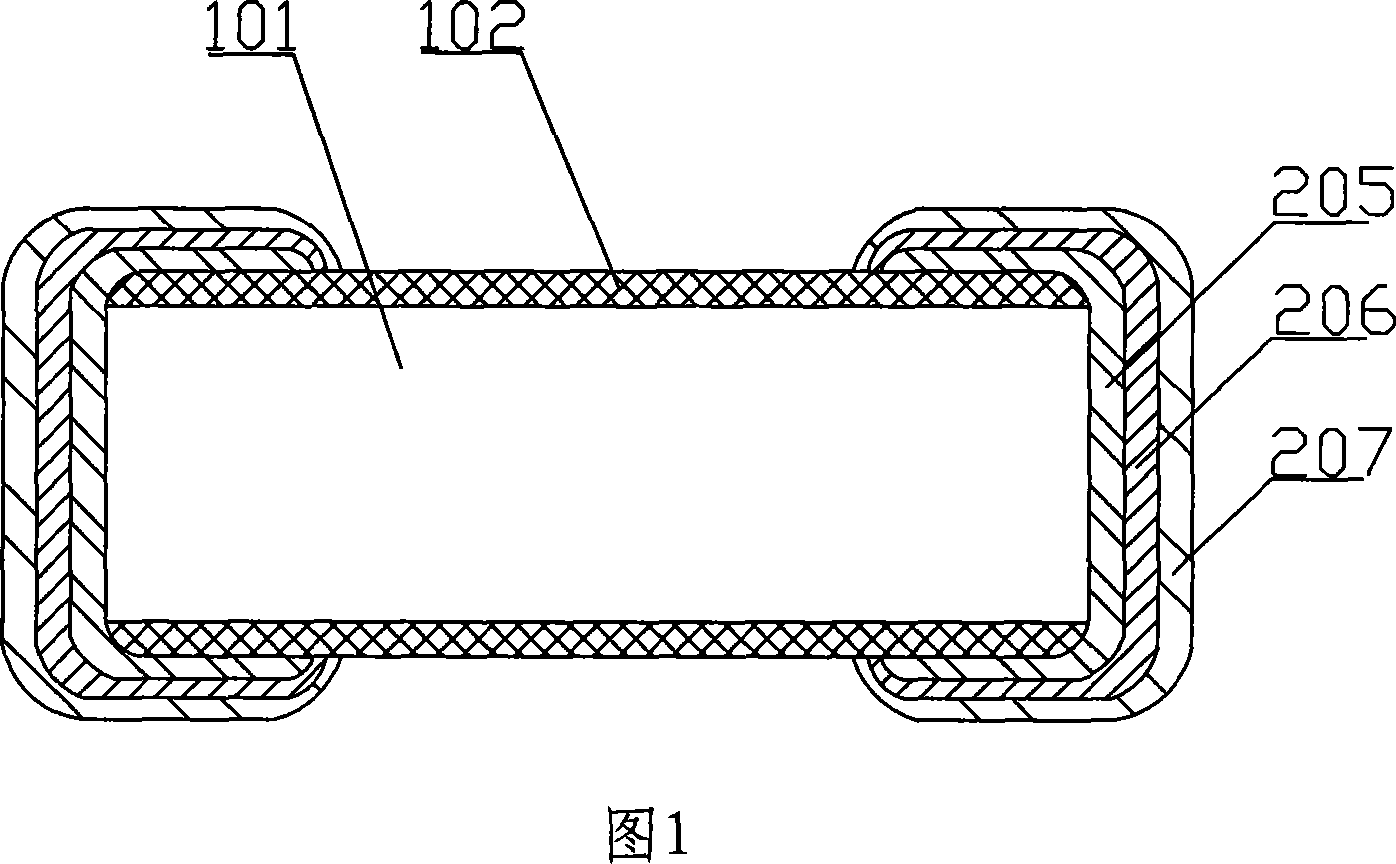

Resin size used for chip resistor

InactiveCN1512522AHigh resistance precisionReduce manufacturing costOther chemical processesResistor housing/enclosing/embeddingEpoxyOrganic solvent

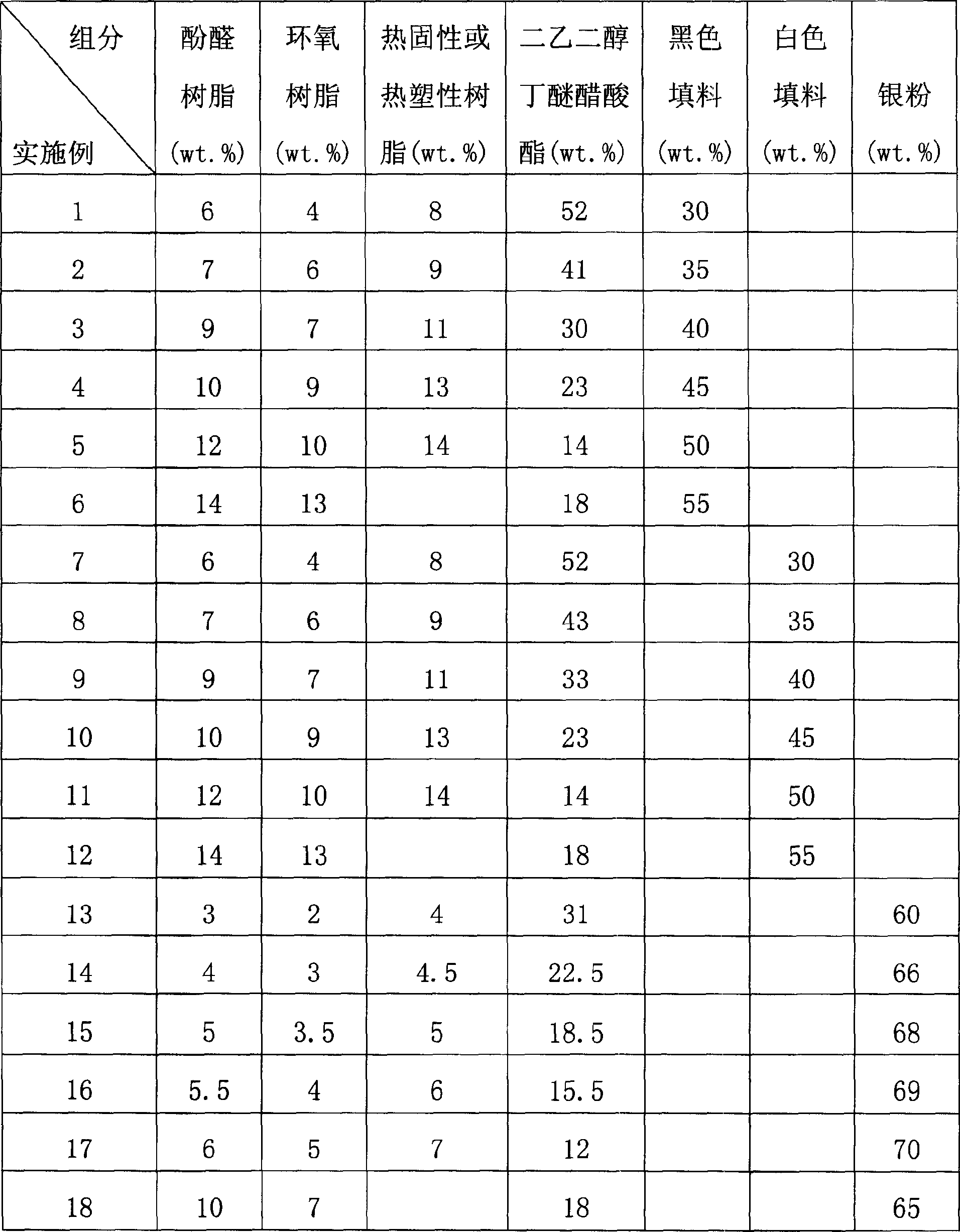

This invention relates to resin sizing material used in sheet resistors including an adhesive and a filler, among which, the adhesive is a mixture of bakelite and epoxy resin formed in an organic solution, the filler is one of white, black fillers or a noble metal powder. The said sizing material is used in a secondary enveloper, markers and end electrodes of the resistor and completely solidified under 160-250deg.C not influencing the sheet resistors.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Method for producing sheet type thermosensitive resistor

InactiveCN101067981ASimplify the manufacturing processEasy to operateNegative temperature coefficient thermistorsResistor manufactureThermal resistorProtection layer

This invention discloses a manufacturing method for slice thermal resistors, which prints a back electrode on the back of a marked slot side of an insulated ceramic chip, prints a face electrode on the slot side, then prints a thermal resisting layer and a protection layer with a thick film silk screen, which can reduce the processing time of slice thermal resistors effectively.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

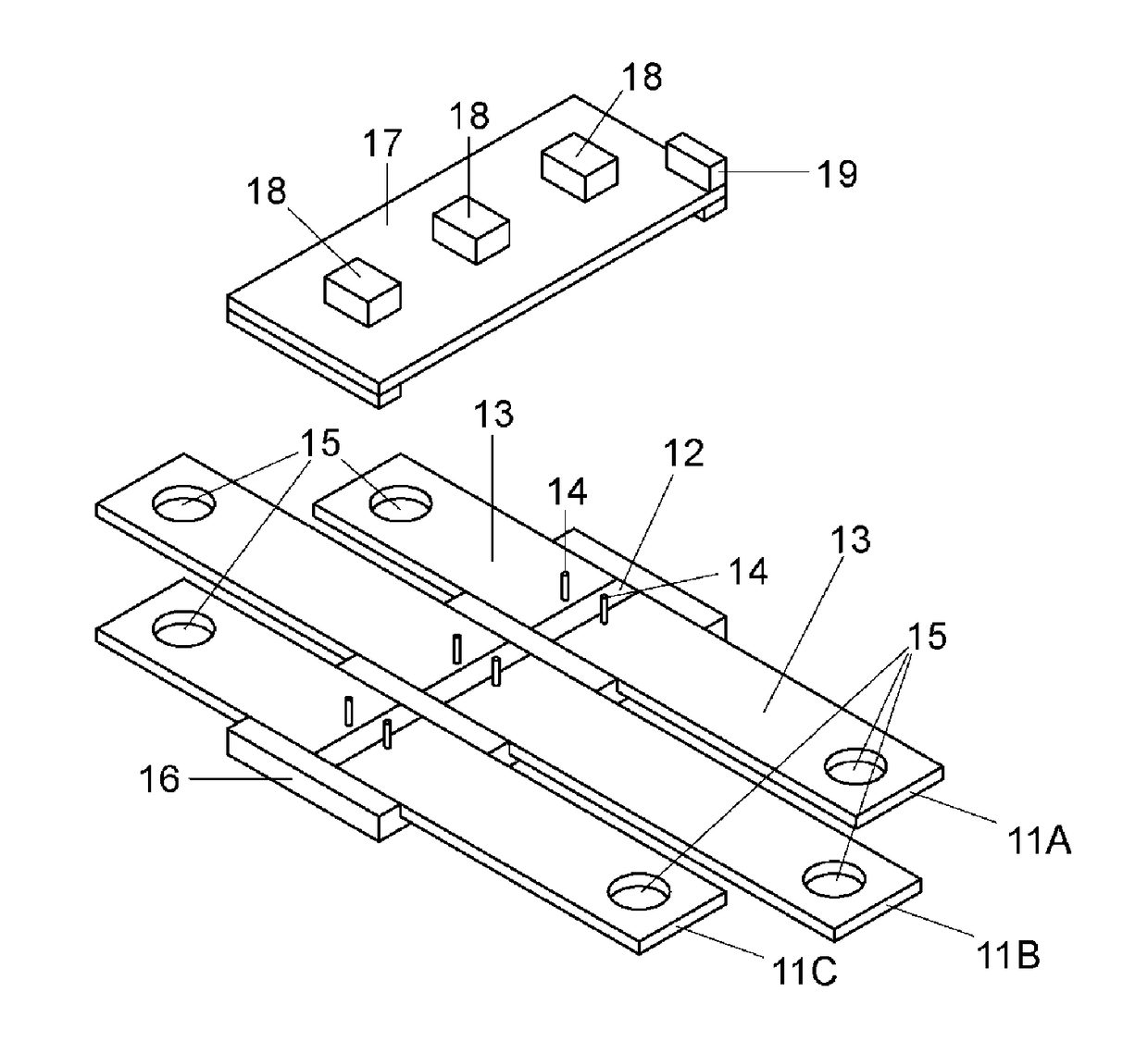

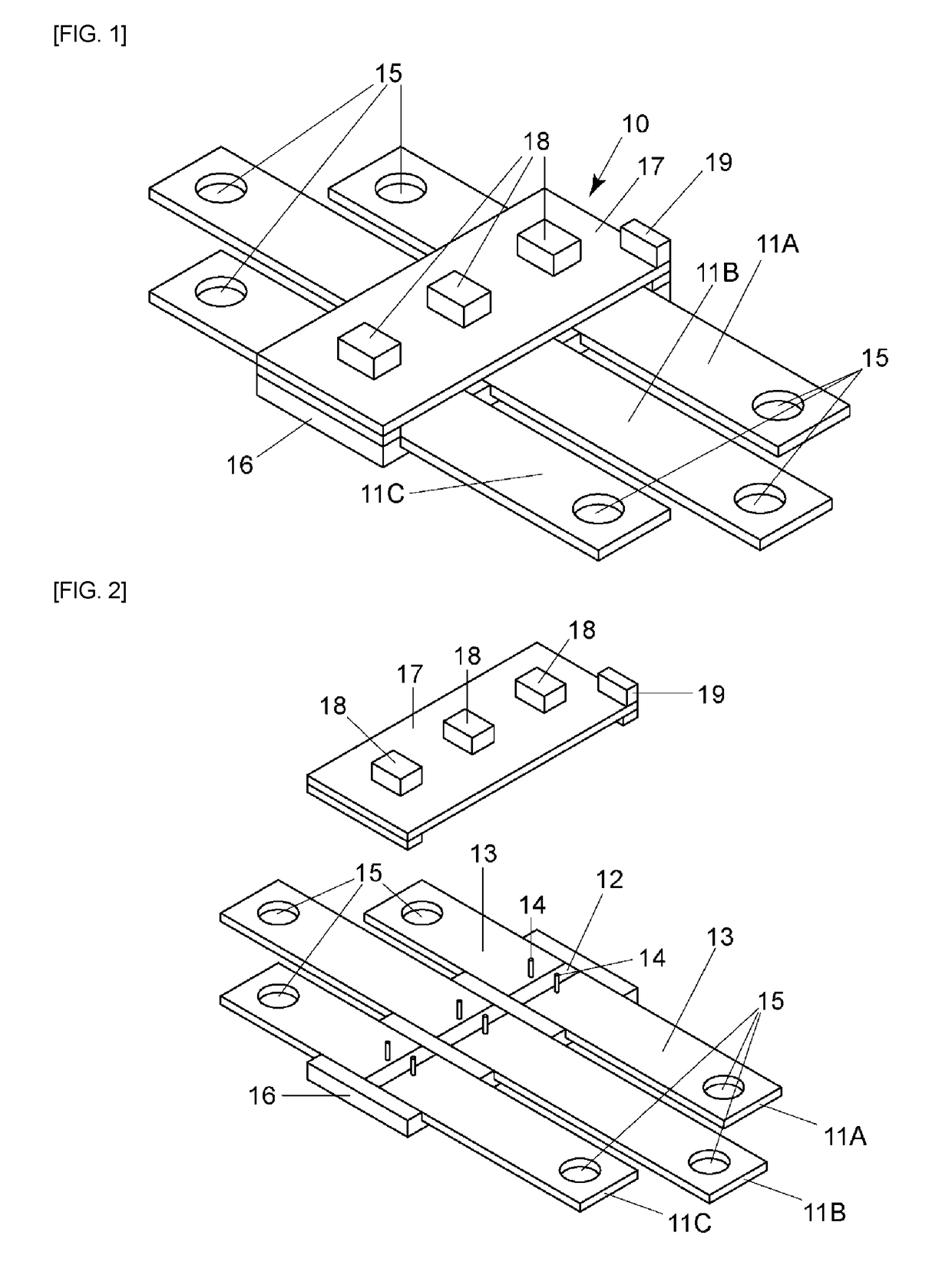

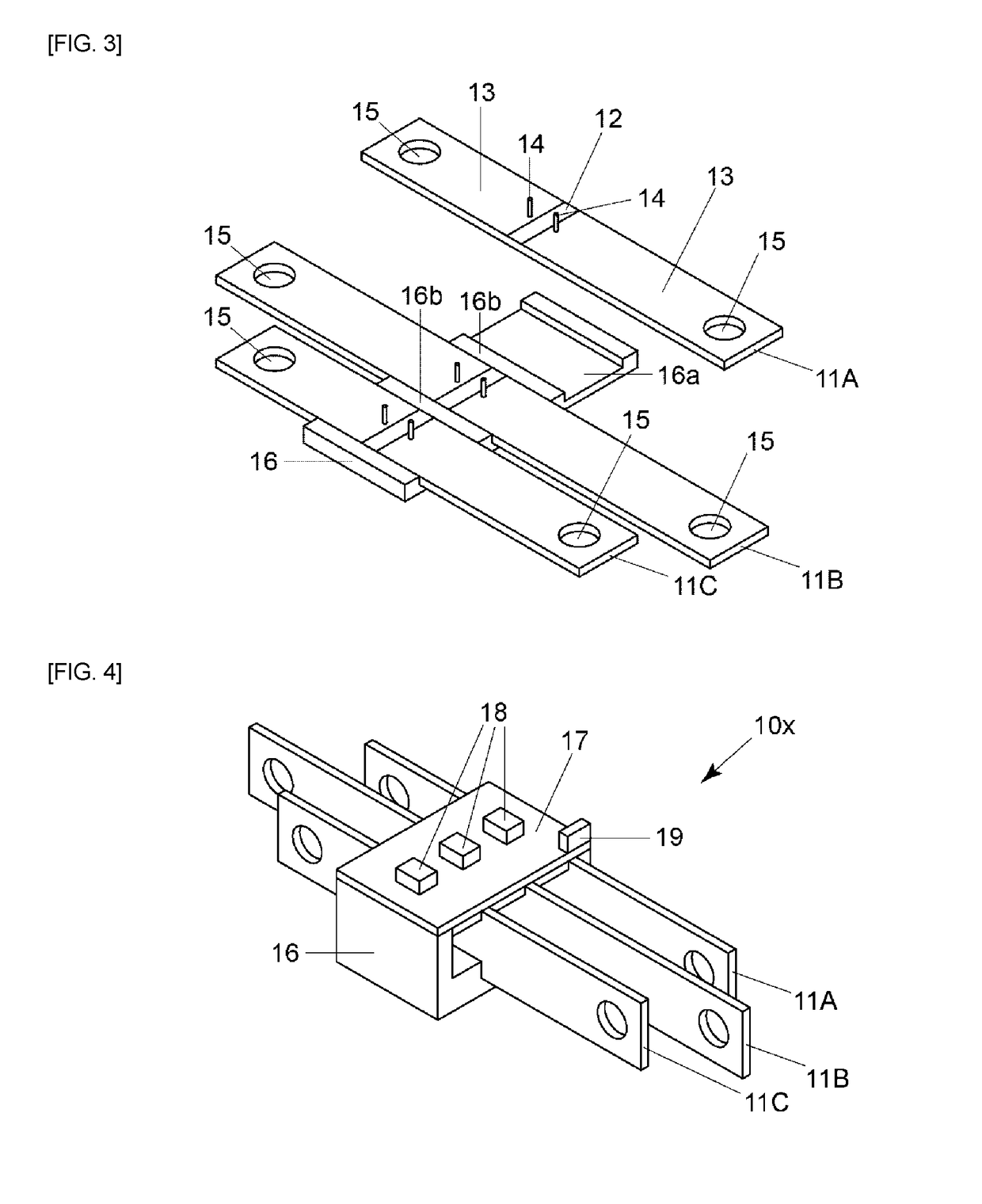

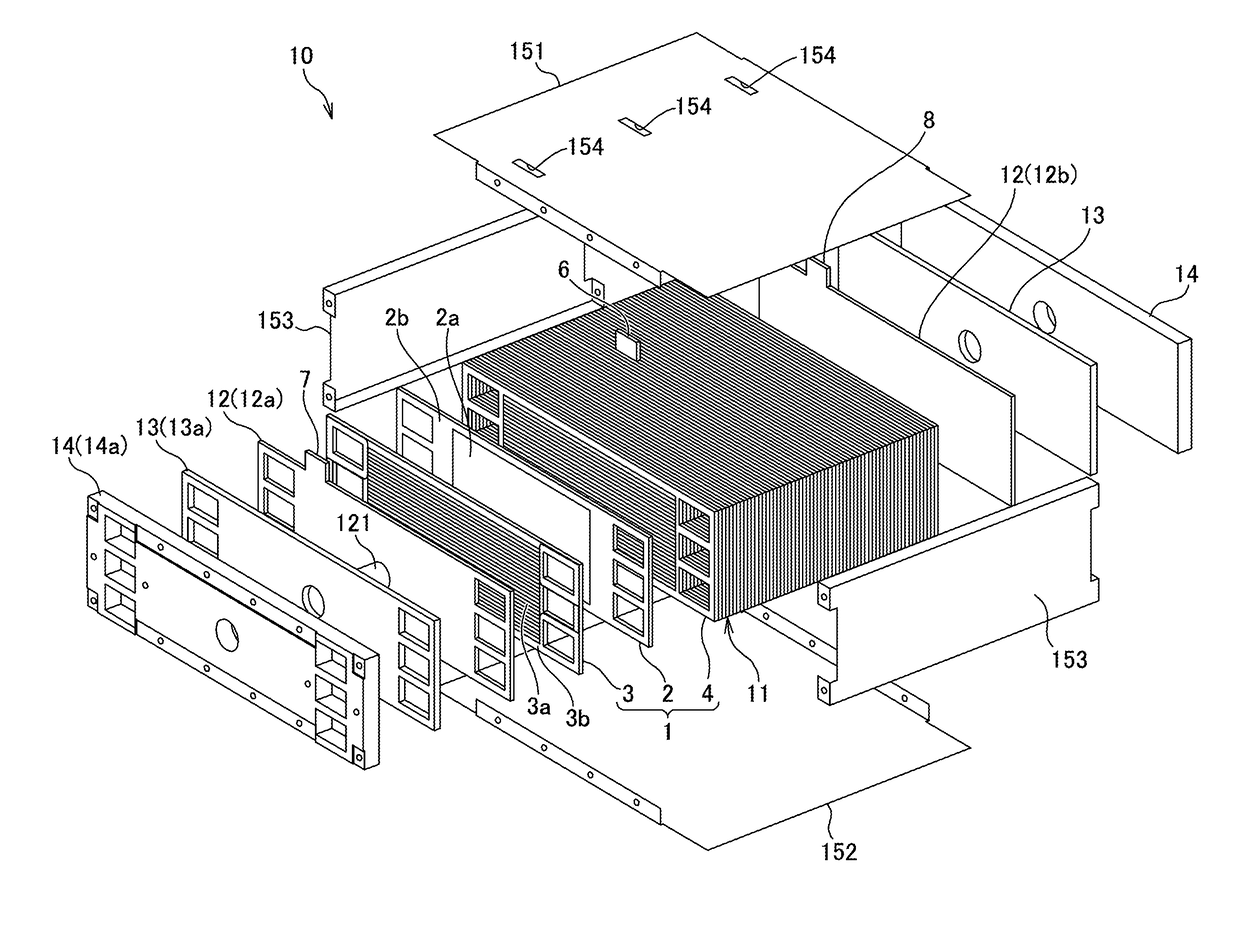

Current detection device

InactiveUS20180156847A1Easily obtainEasily connectElectrical measurement instrument detailsCurrent measurements onlyResistorElectrical current

Provided is a compact and easily mountable current detection device in which a resistor body can be easily inserted in a current path, and a voltage value produced by the current can be easily obtained. The current detection device comprises a unit metal member (11A, 11B, 11C) that pass a current to be detected, a pair of voltage terminals (14, 14), which obtain a voltage signal from the unit metal member, and a holding member (16) that holds a plural of the unit metal members in parallel. A plural of the unit metal members (11A, 11B, 11C) is interposed between the holding member (16) and the board (17) on which a plural of wiring patterns is formed, and each pair of the voltage terminals (14, 14) of the unit metal member is connected to each wiring pattern formed on the board.

Owner:KOA CORP

Manufacturing method of platinum film thermal resistor

InactiveCN105632670AReduce manufacturing costReduce contact timeResistive material coatingPlatinumHigh resistance

The invention discloses a manufacturing method of a platinum film thermal resistor, and belongs to the manufacturing method of a chip film resistor. The manufacturing method comprises a ceramic substrate polishing step, a platinum film layer sputtering step, a film layer heat treatment step, a plasma etching step, a digital laser trimming step, a resistor body encapsulating step, a sintering step, a manual splitting step, a lead welding step, a welding spot encapsulating step and an encapsulated layer solidifying step. The manufacturing method has the advantages of low production cost, high production efficiency, small product volume, high resistance value precision and the like, and is an ideal method for producing the platinum film thermal resistor on a large scale.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

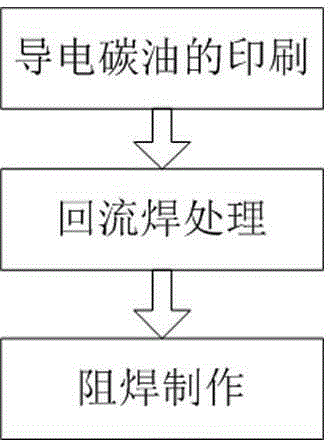

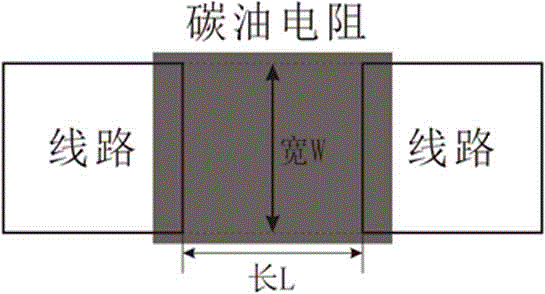

Manufacturing technology for improving resistance precision of conductive carbon oil printed circuit board

ActiveCN105307393AStable resistanceFree from acid and alkaliPrinted resistor incorporationPrinted circuit manufactureHigh resistanceResist

The invention discloses a manufacturing technology for improving resistance precision of a conductive carbon oil printed circuit board. The manufacturing technology comprises the working procedures of conductive carbon oil printing, reflow soldering processing and solder resist manufacturing and the like; the single surface or double surfaces of the conductive carbon oil are printed among the circuits of the circuit board to form the conductive carbon oil resistance; the good stability and higher precision of the conductive carbon oil are ensured by repeated rapid temperature rising processing; and the stability of the resistance is improved by performing the solder resist printing on the circuit board through a solder resist ink without adding a diluent. The manufacturing technology for improving resistance precision of the conductive carbon oil printed circuit board has the characteristics of high resistance precision, high product stability, high product yield, high production efficiency and low cost.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

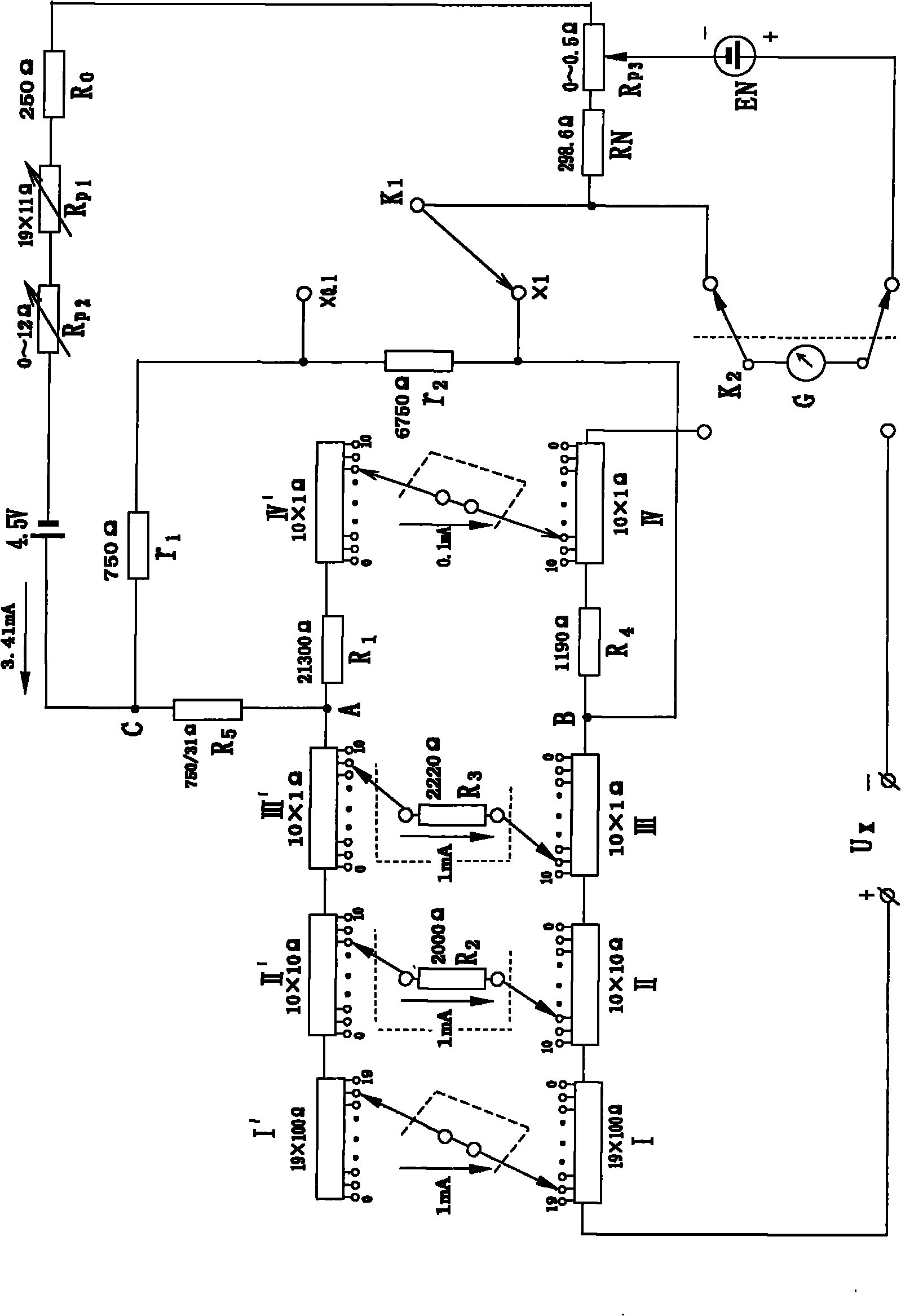

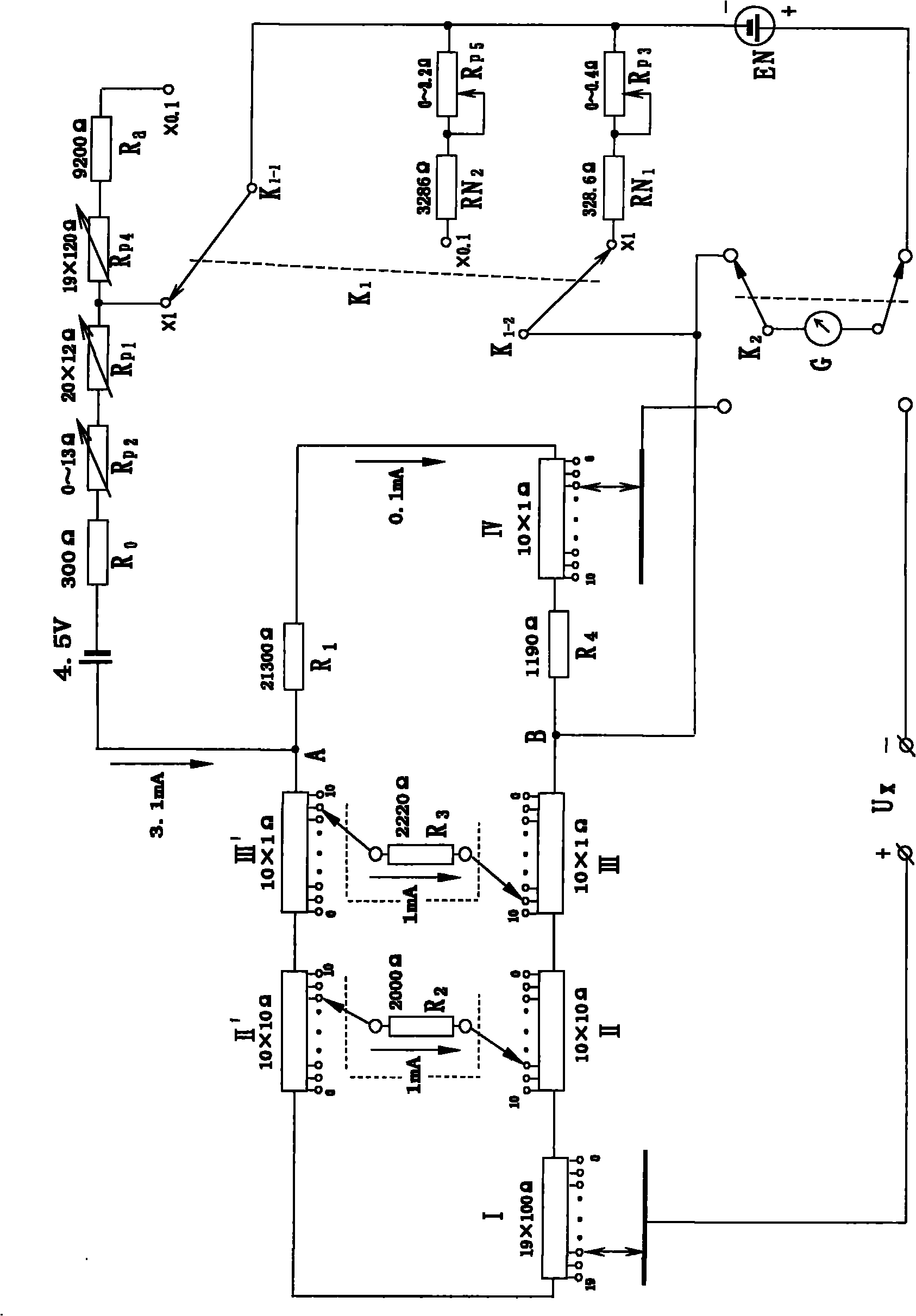

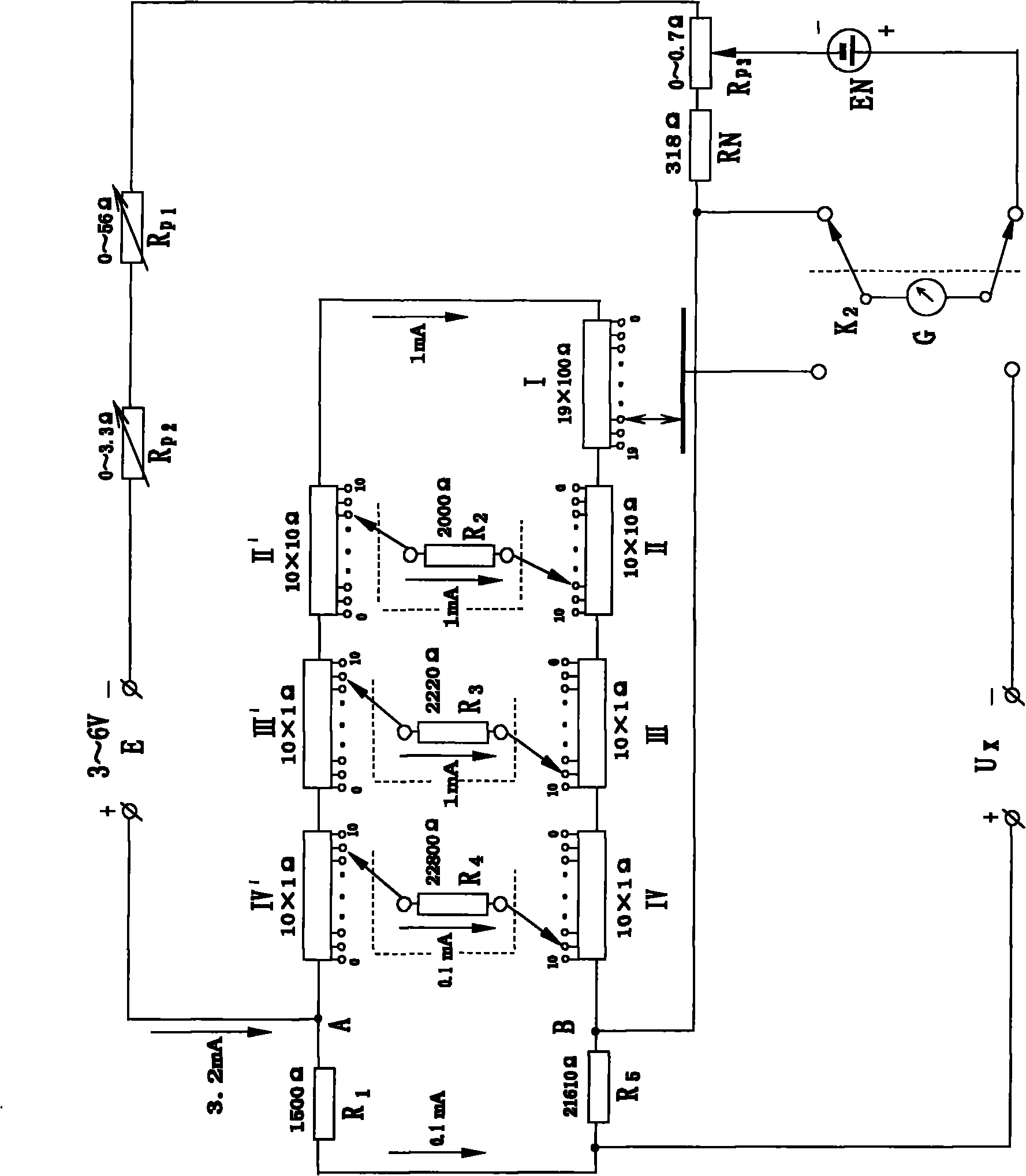

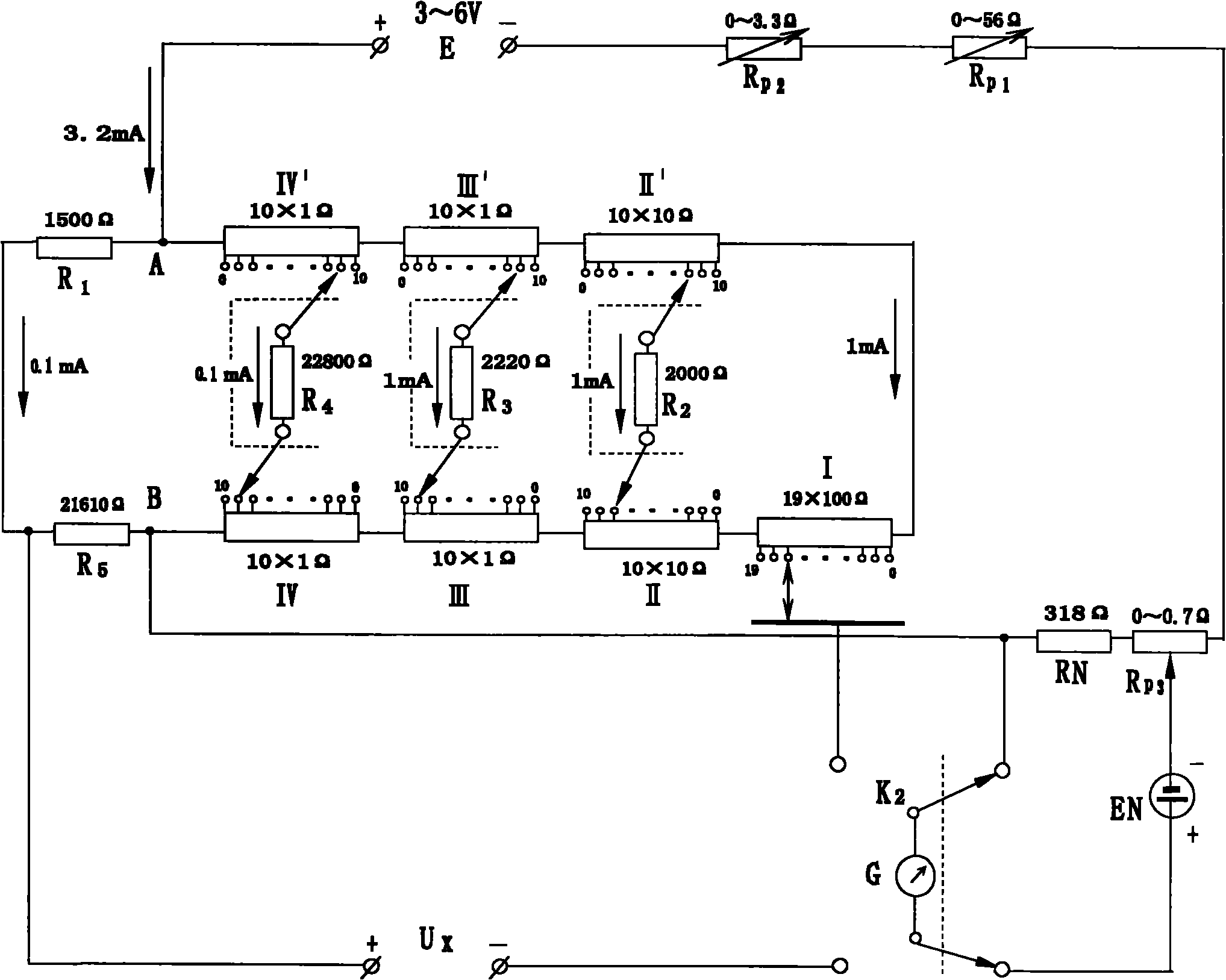

Voltage-measuring device with four measuring panels

InactiveCN101776704AImprove measurement accuracySimple structureAc/dc potentiometric measuring arrangementsElectrical resistance and conductanceImage resolution

The invention relates to a voltage-measuring device with four measuring panels, which is used to measure direct-current voltage. The resistance of each resistor on the measuring panel and the substitute panel of each stepping panel is the integer power of 10, consequently, the manufacturing precision of instrument parts is increased, and the measuring accuracy of the whole voltage-measuring device is increased as well; the four measuring panels are directly connected together by wires without needing switches, and thereby the impact caused by switch contact resistance variation does not exist when the voltage-measuring device carries out measurement.

Owner:FUYANG PRECISE INSTR CO

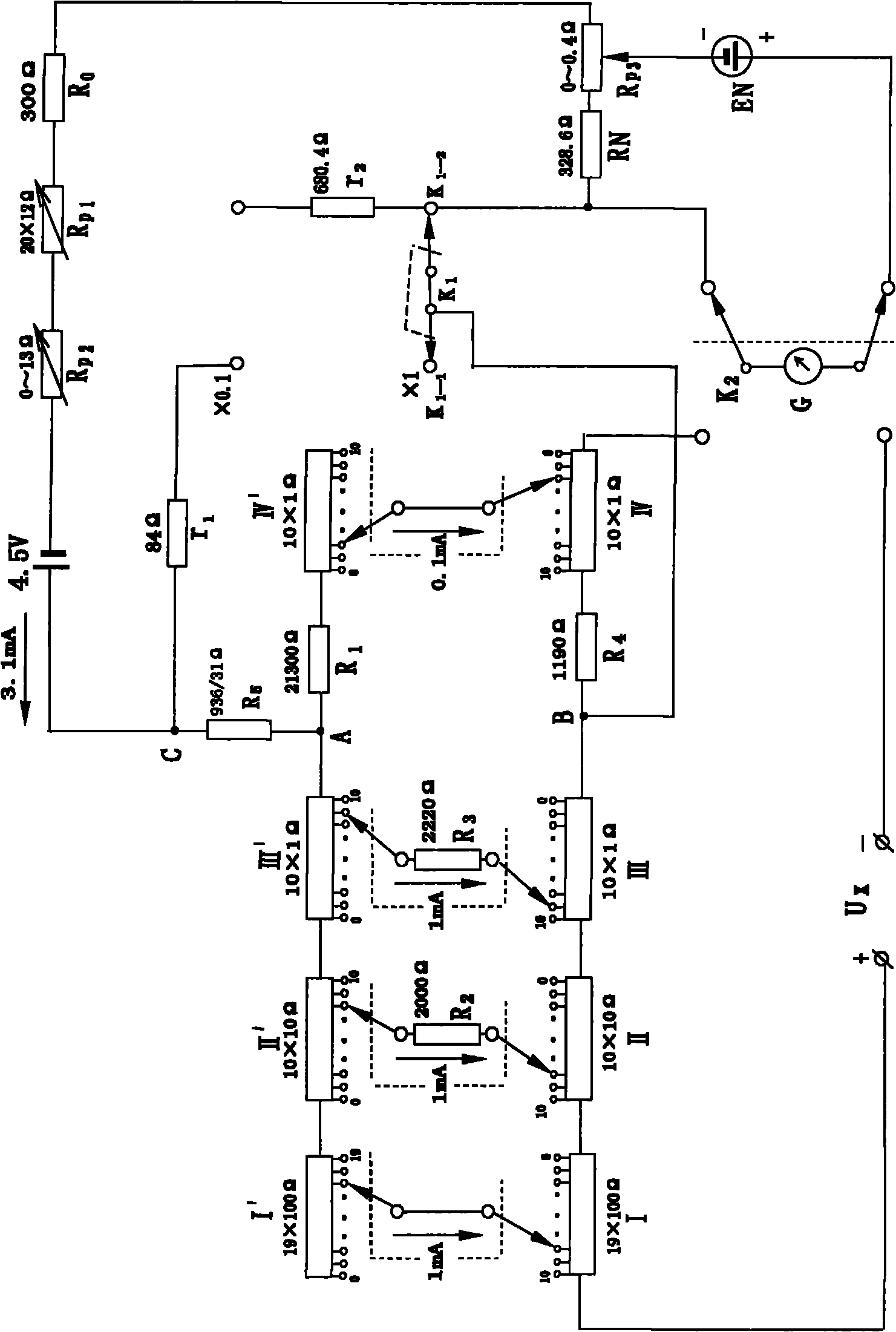

Potentiometer with four step plates

InactiveCN101776705ALower the altitudeHigh resistance precisionAc/dc potentiometric measuring arrangementsElectrical resistance and conductanceContact resistance

The invention relates to a potentiometer with four step plates for DV voltage measurement; resistors on the step plates are designed to have the resistance of the integral power of 10; standard resistors can be compared on a bridge, thereby facilitating instrument manufacturing, improving the manufacturing precision of the resistors on measuring plates and replacement plates, and improving the measurement accuracy of the complete potentiometer; the four measuring plates are directly connected by leads and are not switched by switches, so that no switch contact resistance difference impact exists when the potentiometer is used for measurement; because contacts and whole rings are made of the same material, heat thermo emf and variable heat thermo emf produced by the movement of a brush arethe same and in reverse directions; and therefore, the potentiometer can measure micro-voltage.

Owner:骆洪亮

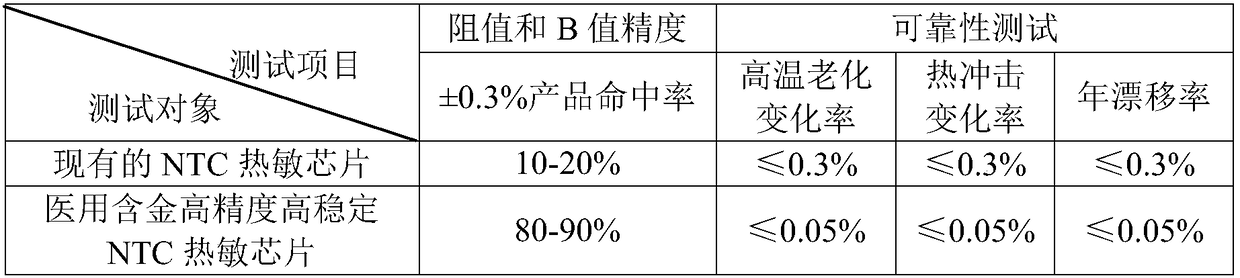

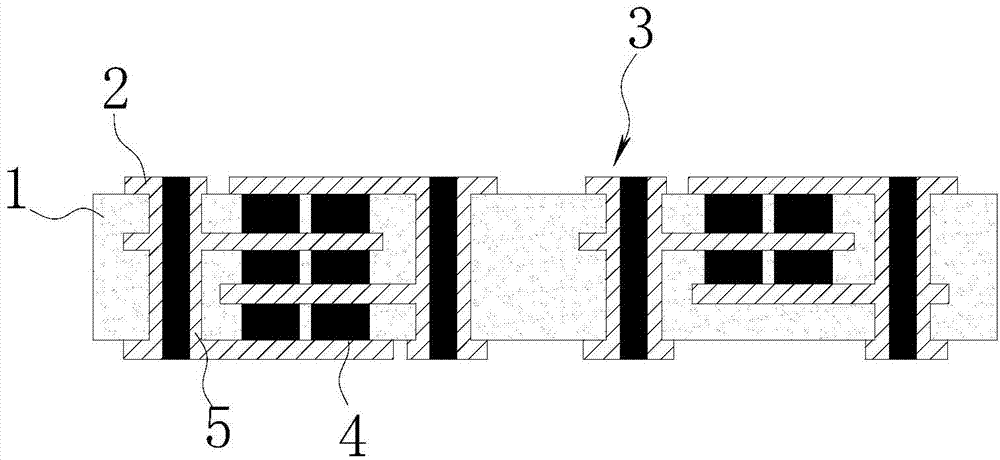

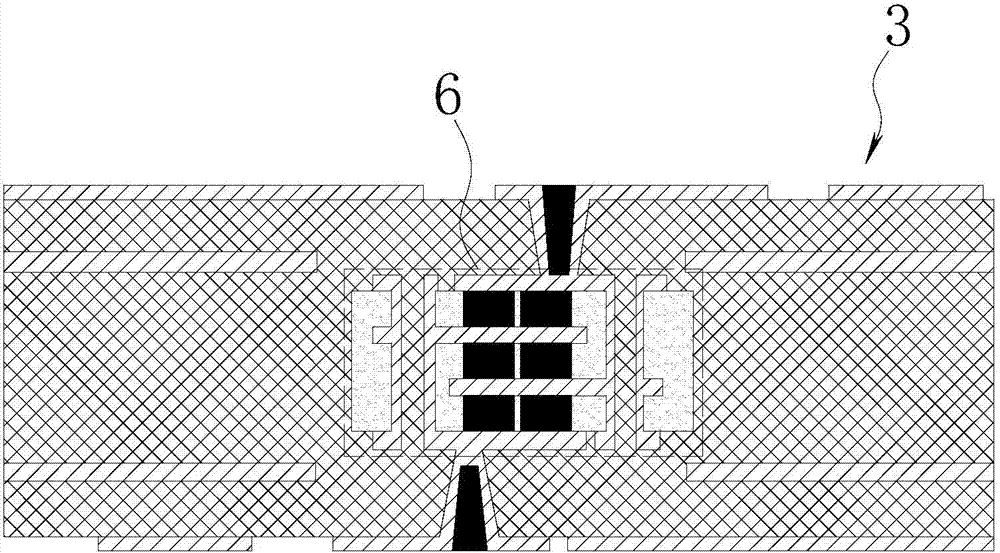

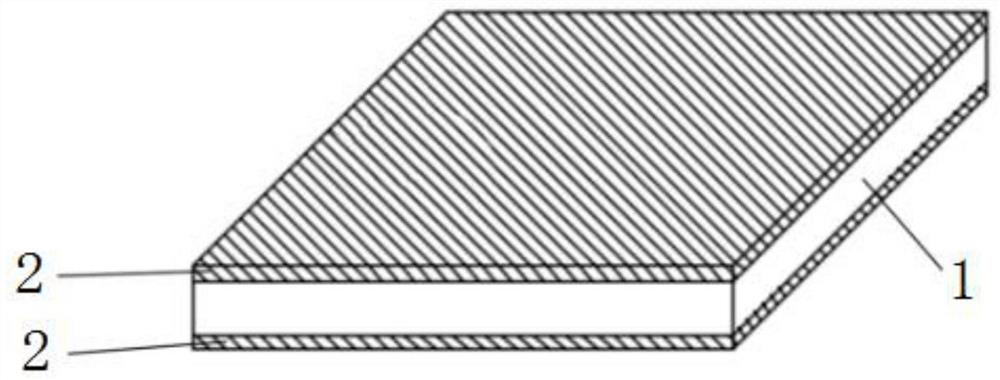

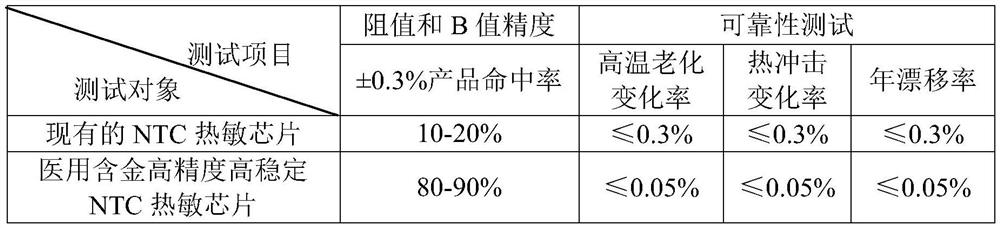

Medical gold-containing NTC (Negative Temperature Coefficient) thermosensitive chip with high accuracy and high stability, and manufacture method thereof

ActiveCN108147790AHigh precisionImprove stabilityThermometers using electric/magnetic elementsBody temperature measurementNegative temperatureCobalt(II,III) oxide

The invention relates to a medical gold-containing NTC (Negative Temperature Coefficient) thermosensitive chip with high accuracy and high stability. The medical gold-containing NTC thermosensitive chip with high accuracy and high stability comprises a thermosensitive ceramic chip and metal electrodes arranged on two surfaces of the thermosensitive ceramic chip, wherein the thermosensitive ceramicchip is formed by mixing and sintering the following nanoscale powder materials in percentage by mass: 30-50% of manganese dioxide, 40-52% of cobaltosic oxide, 5-12% of iron trioxide, 3-5% of nickeloxide and 1-2% of gold oxide. The invention also relates to a manufacture method of the medical gold-containing NTC thermosensitive chip with high accuracy and high stability. The medical gold-containing NTC thermosensitive chip with high accuracy and high stability has the advantages of high temperature measurement accuracy, high use stability and long service life.

Owner:ZHUHAI EXENSE MEDICAL TECH

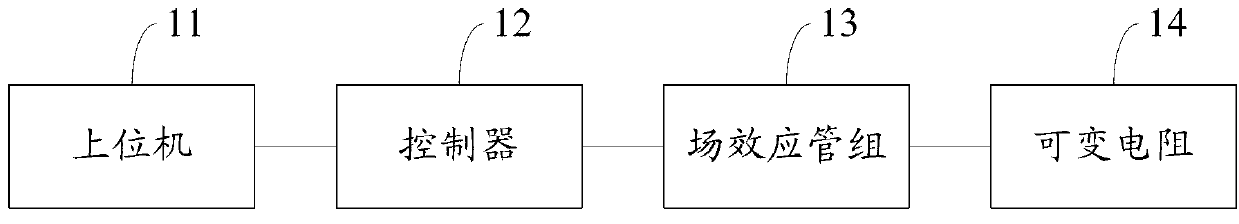

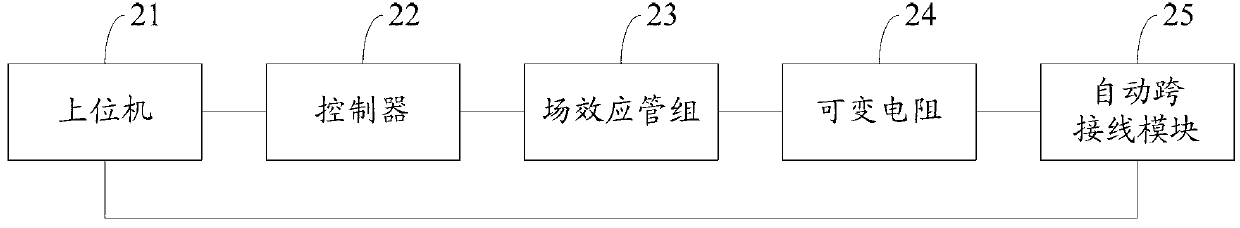

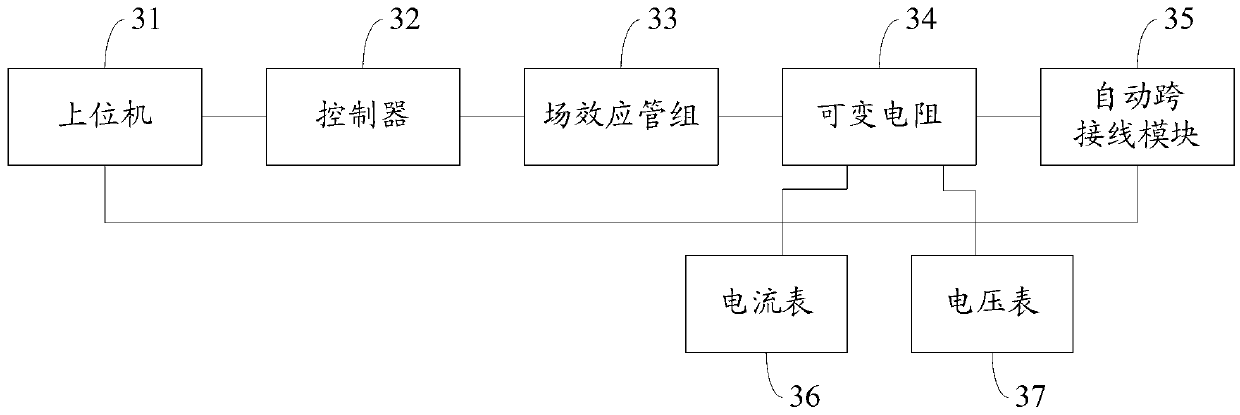

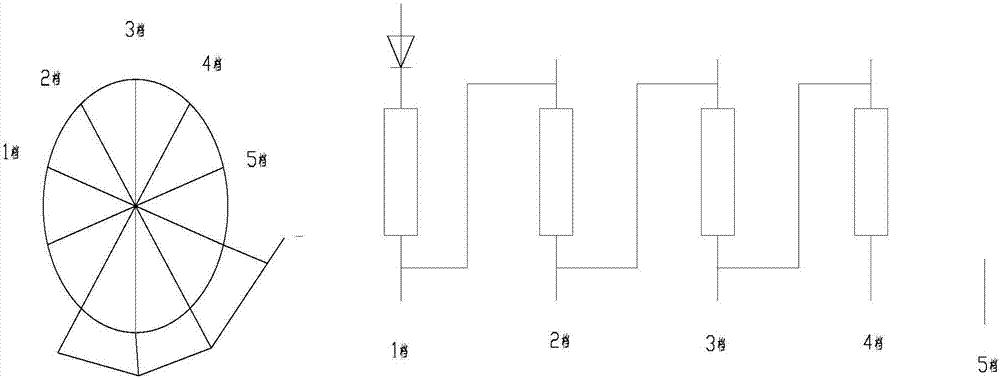

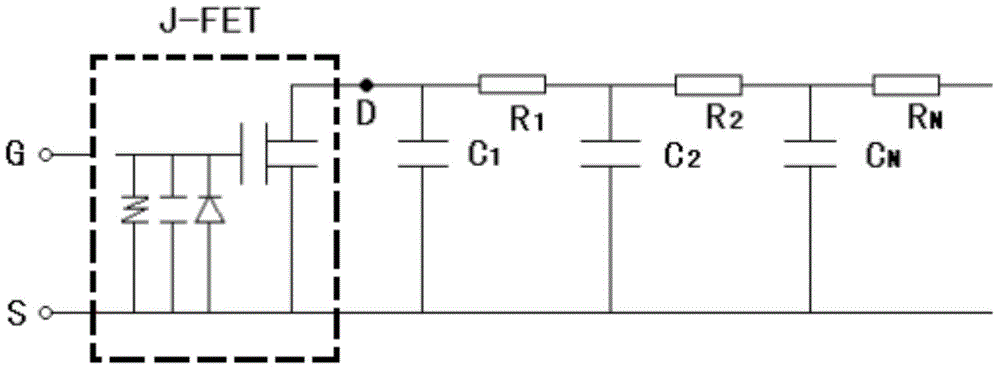

Program-control electronic load for relay protection

ActiveCN103344800ASmall adjustment stepHigh resistance precisionElectrical measurement instrument detailsElectrical testingAuto regulationElectronic load

The invention discloses a program-control electronic load for relay protection. The program-control electronic load comprises an upper computer, a controller, a field-effect tube set and a variable resistor. The upper computer sets variable resistance values, changes step parameter information and sends the parameter information. The controller is connected with the upper computer, receives the parameter information and generates control signals according to the parameter information. The field-effect tube set is connected with the controller and performs actions according to control signals. The variable resistor is connected with the field-effect tube set and adjusts the variable resistance of the resistance values according to the actions of the field-effect tube set. The program-control electronic load for relay protection can achieve automatic adjustment of the variable resistor and is small in step size adjustment and high in resistance value precision.

Owner:STATE GRID CORP OF CHINA +3

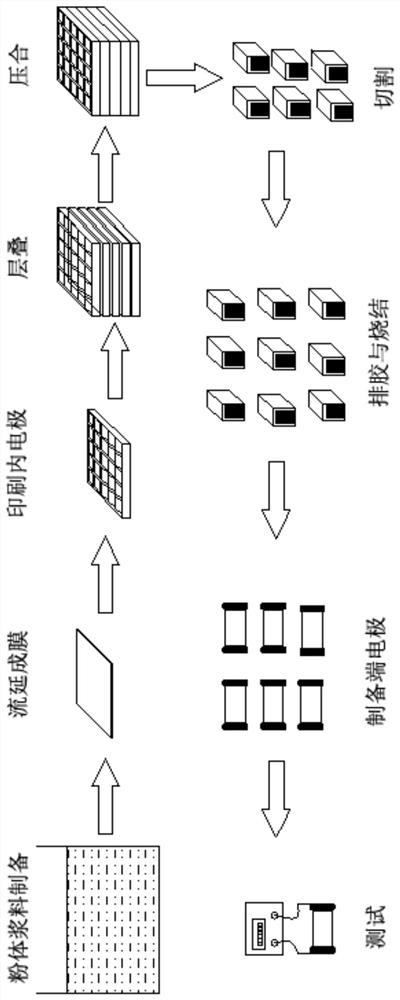

Thermistor chip and preparation method thereof

ActiveCN105575569AHigh resistance precisionImprove stabilityNegative temperature coefficient thermistorsSlurrySolvent

The invention provides a thermistor chip and a preparation method of the thermistor chip. The thermistor chip is prepared from the following raw materials in percentage by mass: 40 to 60 percent of manganese nitrate, 20 to 35 percent of cobalt nitrate, 10 to 20 percent of nickel nitrate and 5 to 10 parts of aluminum nitrate, wherein the raw materials are all chemical pure crystals. The preparation method comprises the following steps of dissolving the crystals into deionized water to prepare a mixed solution; carrying out thermal decomposition on the mixed solution to obtain mixed powder; mixing the mixed powder with a solvent, a binding agent, a dispersing agent and a plasticizing agent to prepare slurry; carrying out wet film casting on the slurry to obtain a block; carrying out the technologies of drying, cutting, adhesive discharging, sintering, polishing-grinding, silver coating and scribing on the block, thus obtaining the thermistor chip. The electrical resistivity of the thermistor chip provided by the invention is 20 Kohm.mm to 30 Kohm.mm, and a material B value is 4100 K to 4700 K; the preparation method of the thermistor chip is simple, a process of settling and standing or gelating is not needed, and the thermistor chip has the characteristics of high sensitivity, less energy consumption and short production period.

Owner:SHENZHEN GUDIAN ELECTRONICS

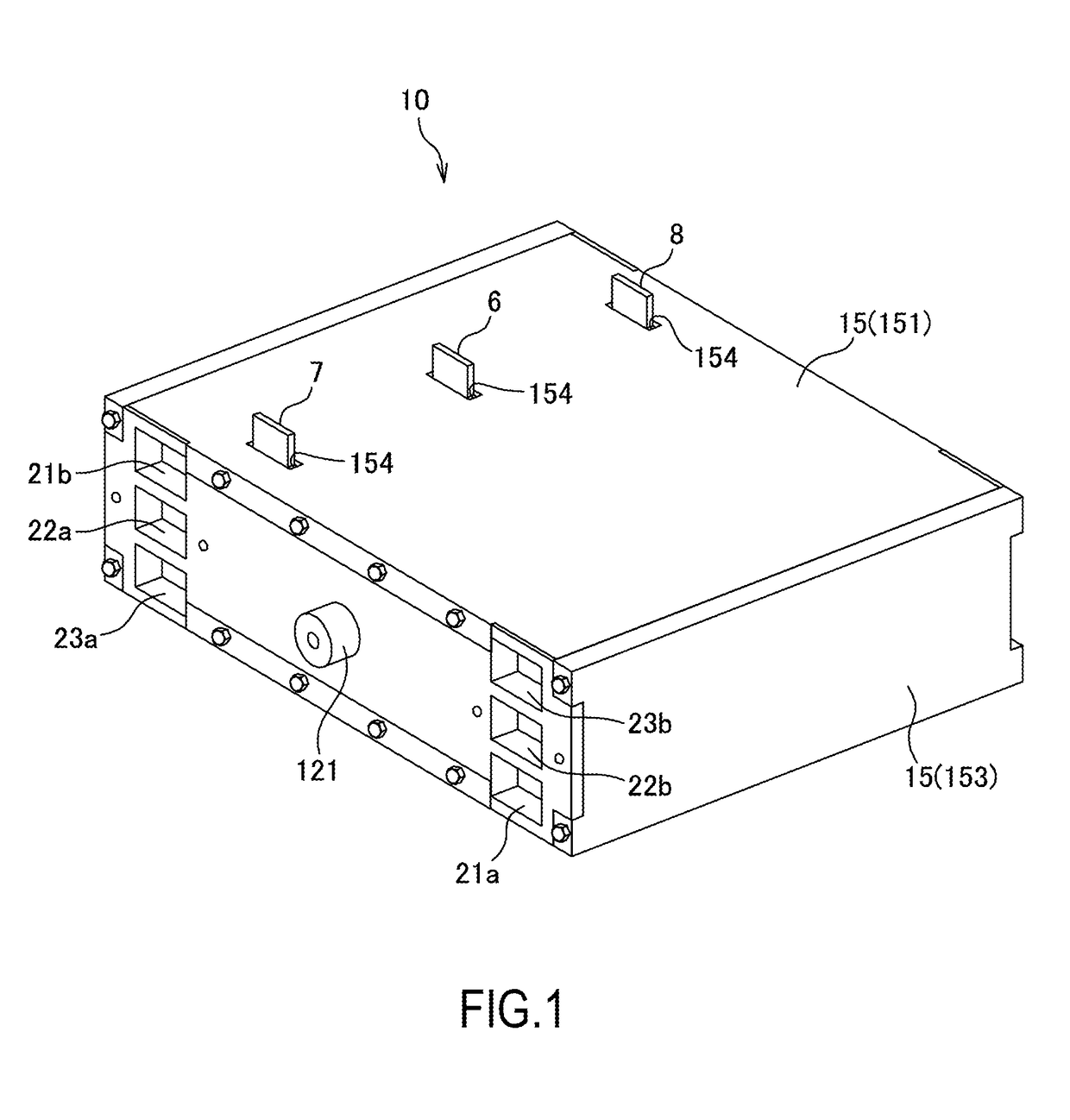

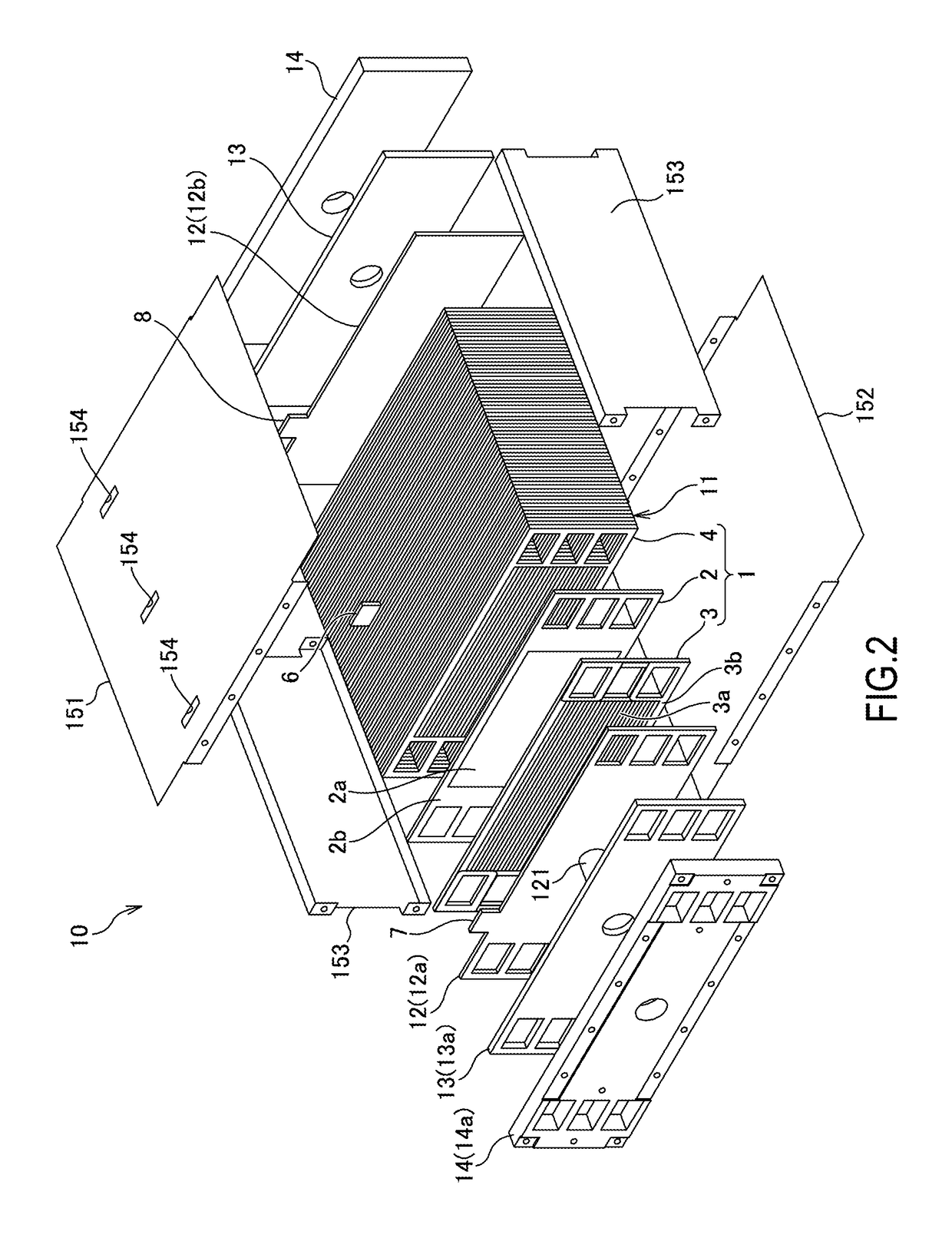

Atmospheric corrosion test procedure and its apparatus

InactiveUS8927289B2High resistance precisionReduce variationWeather/light/corrosion resistanceBiological testingSalt contentSalt water

Provided are an atmospheric corrosion test procedure and an apparatus used for the test. The procedure involves a salt spray step for supplying salt content containing chloride ions on the surfaces of test pieces placed in a thermo-humidistat chamber and a subsequent dry-wet cyclic step including a dry sub-step for drying the surface of the test pieces in the thermo-humidistat chamber at a low relative humidity and a subsequent wet sub-step at a higher relative humidity than that in the dry sub-step, which are cycled. The salt content is supplied by spraying the salt water in the salt spray step. An exhaust step for removing the salt mist sprayed inside thermo-humidistat chamber is further inserted between the salt deposition step and the dry sub-step. The quantity of the salt content deposited on the surfaces of the test pieces is controlled by adjusting the quantity of the sprayed salt water.

Owner:HITACHI LTD

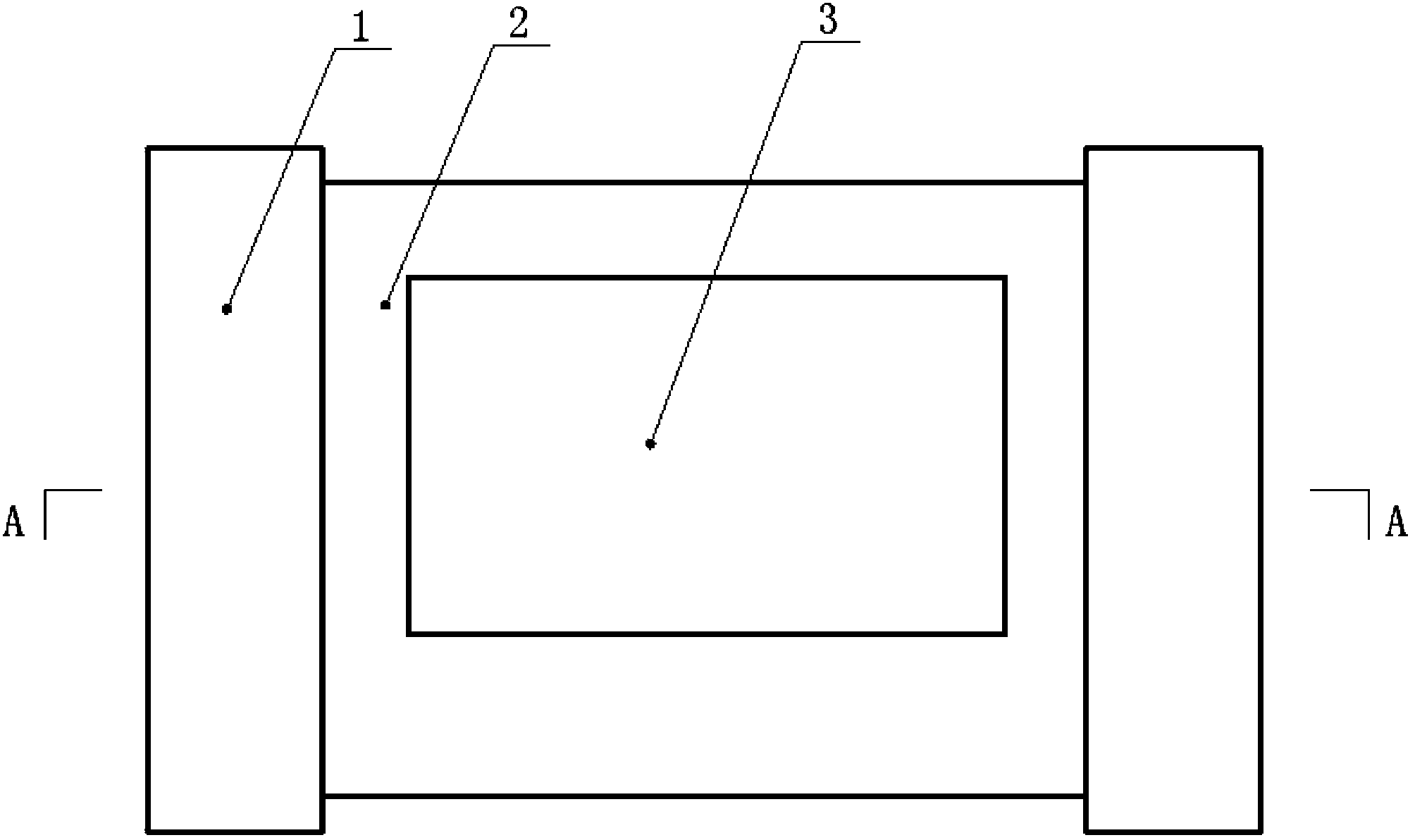

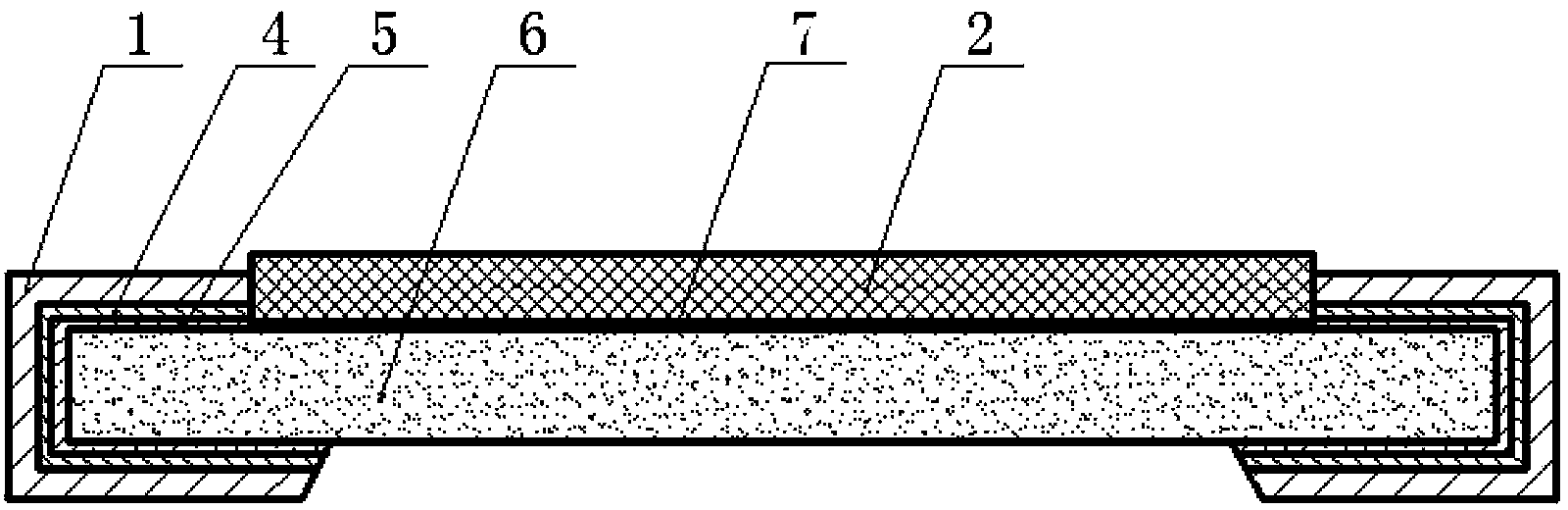

Laminated battery, separator and connection method of internal resistance measuring device

ActiveUS20170104230A1High resistance precisionElectrical testingCollectors/separatorsEngineeringFuel cells

A separator of a fuel cell to be laminated while sandwiching a membrane electrode assembly forming a power generation region includes a source connection point tab for inputting and outputting an alternating current for internal resistance measurement, a sense connection point tab for detecting a potential of the alternating current input and output to and from the source connection point tab and separation portion configured to separate the sense connection point tab from a current path of the alternating current for internal resistance measurement from the source connection point tab to the power generation region.

Owner:NISSAN MOTOR CO LTD

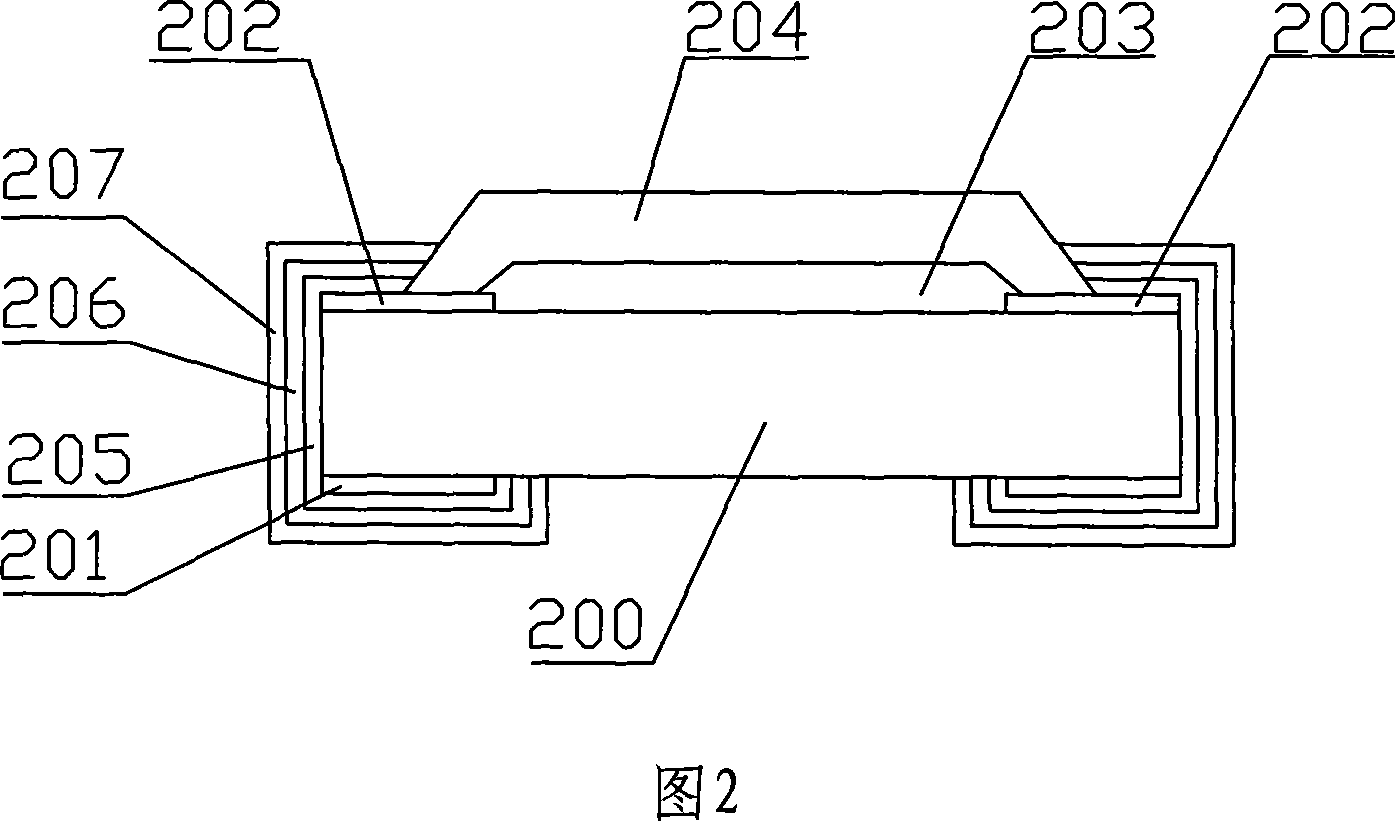

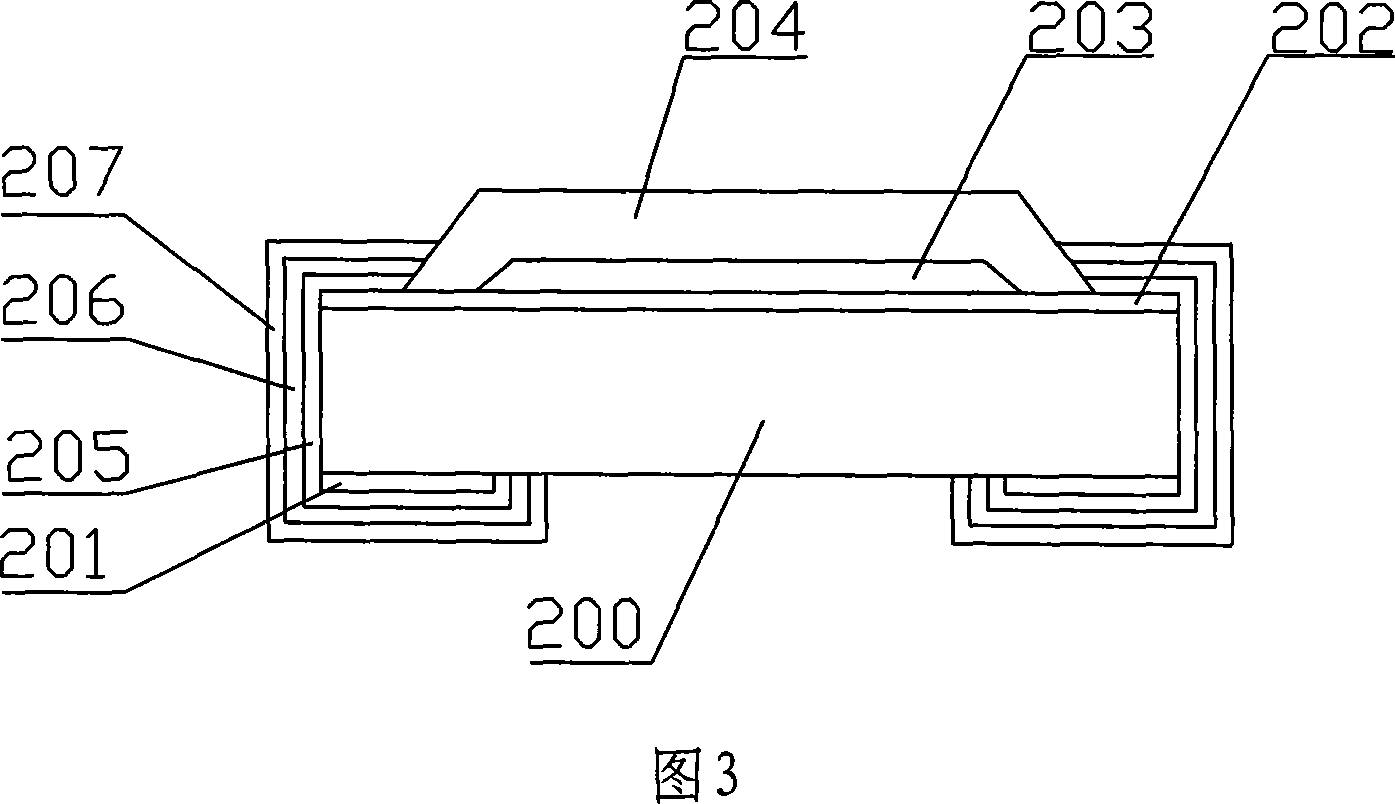

Chip film fixed resistor and its making method

InactiveCN104252932AHigh resistance precisionSmall temperature coefficientResistor housing/enclosing/embeddingResistor manufactureHigh resistanceMoisture resistance

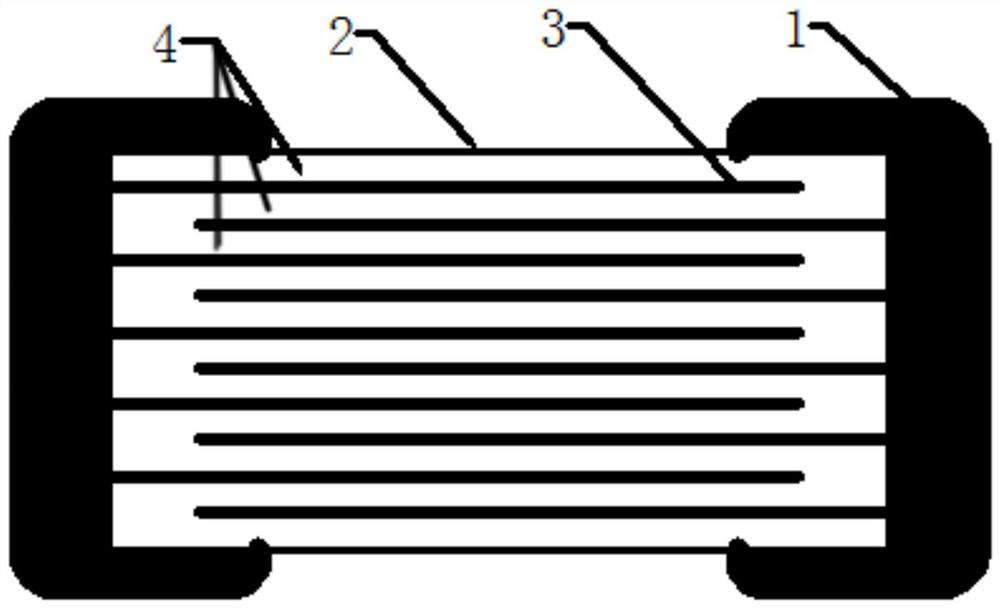

The invention relates to a chip film fixed resistor and its making method. The chip film fixed resistor includes a substrate, a metal resistance layer, inner electrode layers, outer electrode layers and a protection layer, the middle portion of the upper surface of the substrate is provided with the metal resistance layer, the substrate at two sides of the metal resistance layer is coated with the inner electrode layers in a mirror symmetry manner, the two inner electrode layers are connected with the metal resistance layer, the protection layer is covered between the connection portions of the two inner electrode layers and the metal resistance layer, and the inner electrode layers are coated with the outer electrode layers respectively. The resistor made by repeatedly measuring and calculating through a special technology has the advantages of high resistance precision, small temperature coefficient, good moisture resistance and good weldability, and is very suitable for being used in precise electronic circuits, the size of the resistor made through the making technology can be adjusted according to different requirements of power and resistance, the resistance can be 10-1Momega, the minimum value of the thickness of each of the outer electrode layers reaches 0.25mm, and the minimum value of the total length of the resistor reaches 0.8mm.

Owner:天津市三环电阻有限公司

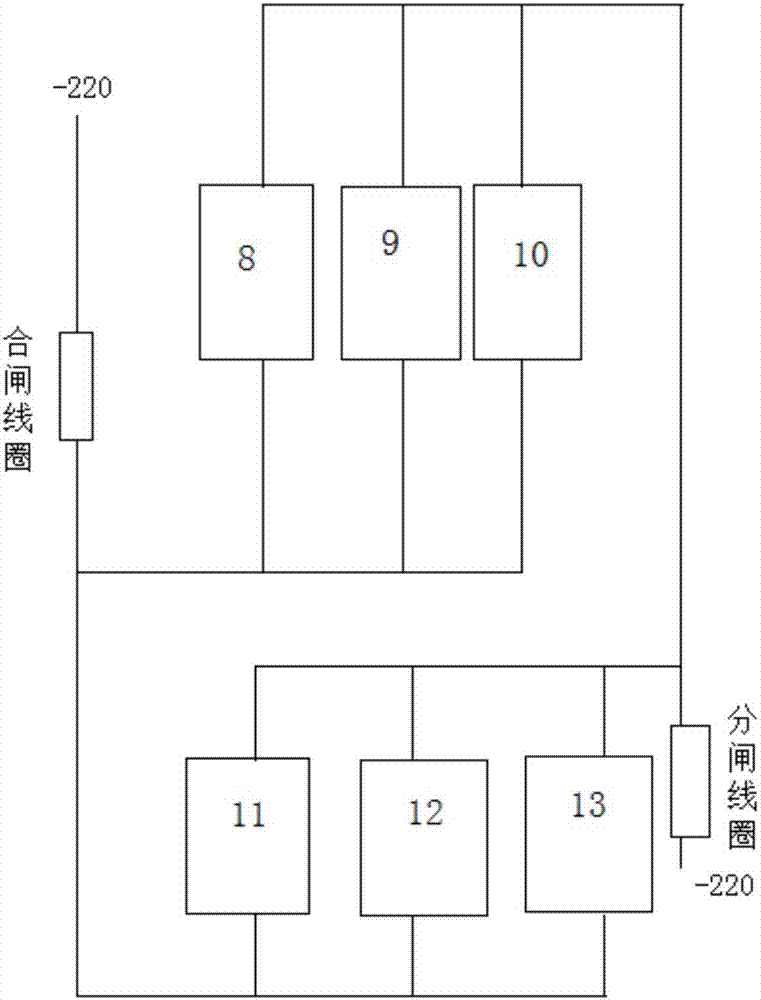

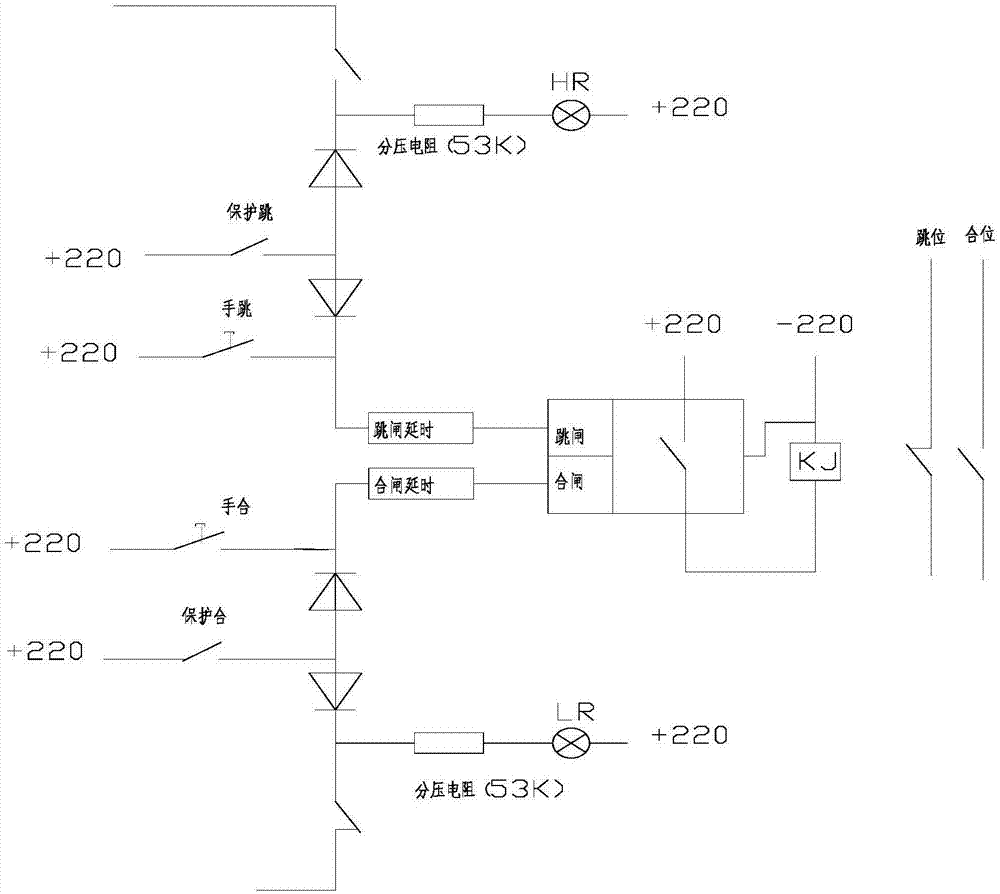

A circuit breaker simulation device used to replace real high-voltage circuit breakers in protection tests

InactiveCN104764998BHigh precisionThe simulation effect is real and effectiveCircuit interrupters testingEngineeringCircuit breaker

The invention discloses a breaker simulating device used for replacing a real high-voltage breaker in the protecting testing process. The breaker simulating device comprises a breaker circuit which comprises a plurality of breaker circuit bodies identical in circuit structure and a plurality of extension relay circuits identical in circuit structure. A breaker protecting switching-on switch is connected into a closing coil and a controller switching-on opening loop. The closing coil and the controller switching-on opening loop are connected in parallel. A breaker protecting trip switch is connected into a tripping coil and a controller tripping opening loop. The tripping coil and the controller tripping opening loop are connected in parallel. One relay is adopted in each extension relay circuit to serve as contact extension, and each extension relay circuit is used for simulating an auxiliary switch contact of the breaker to be opened at the switching-on and switching-off position. The switching-on and switching-off time of the sixth simulated breaker can be set according to needs, and the precision of the switching-on and switching-off time of the simulated breaker is high.

Owner:STATE GRID CORP OF CHINA +1

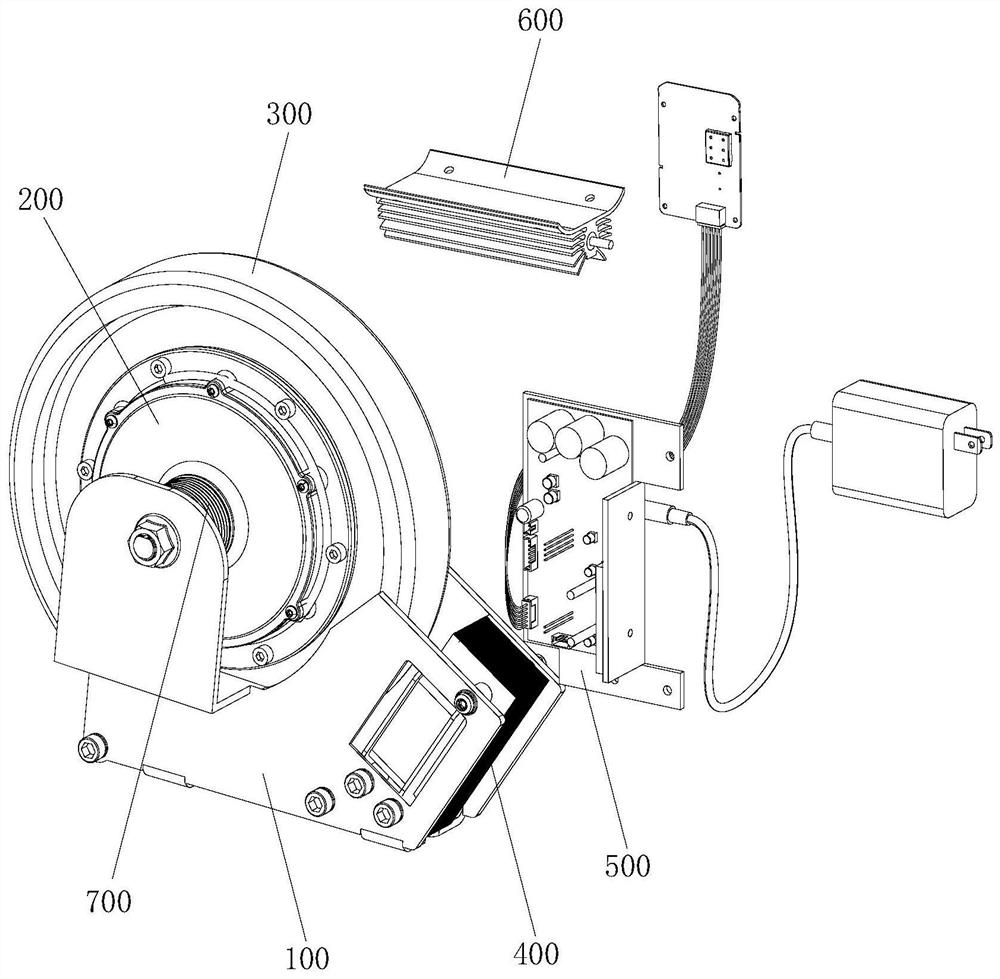

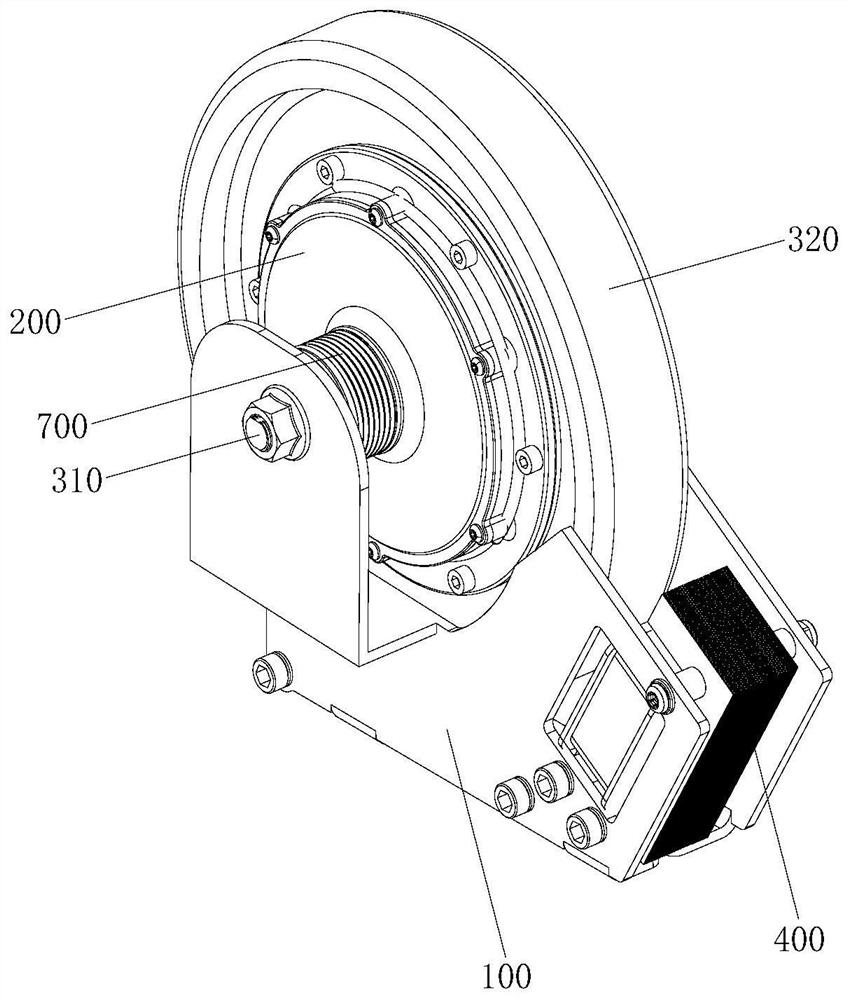

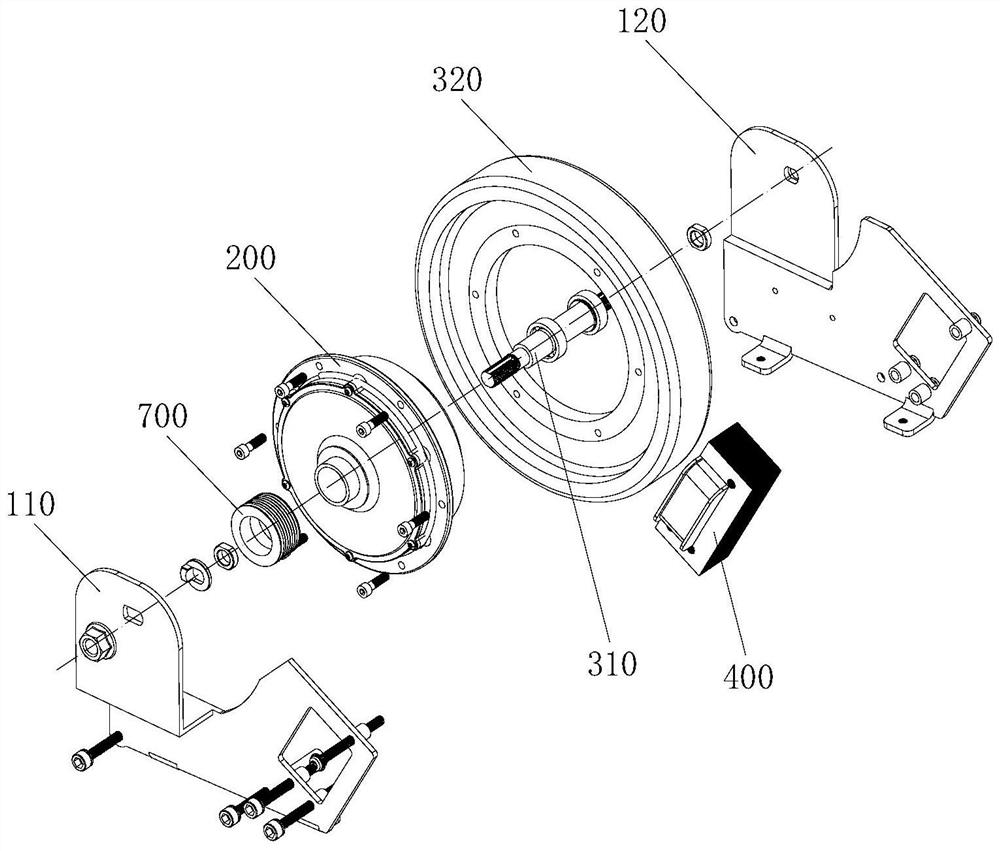

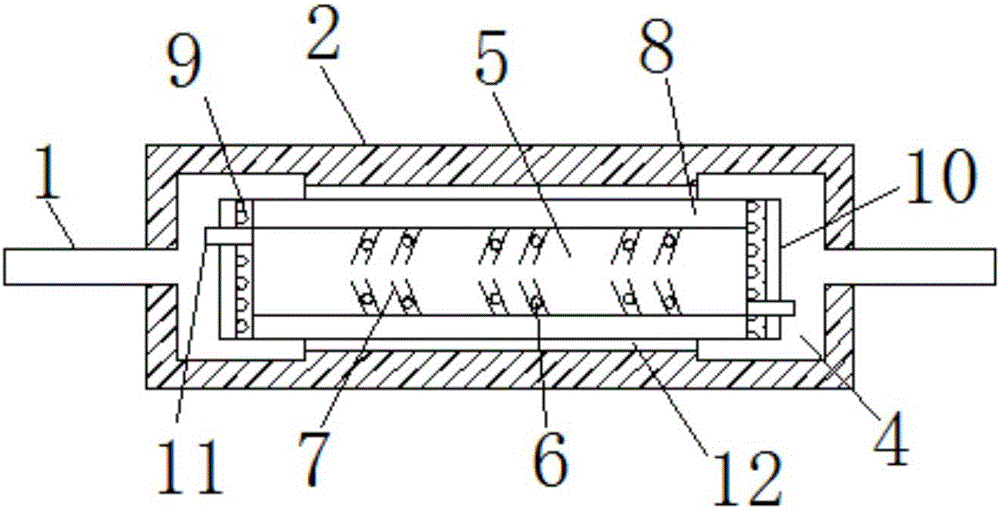

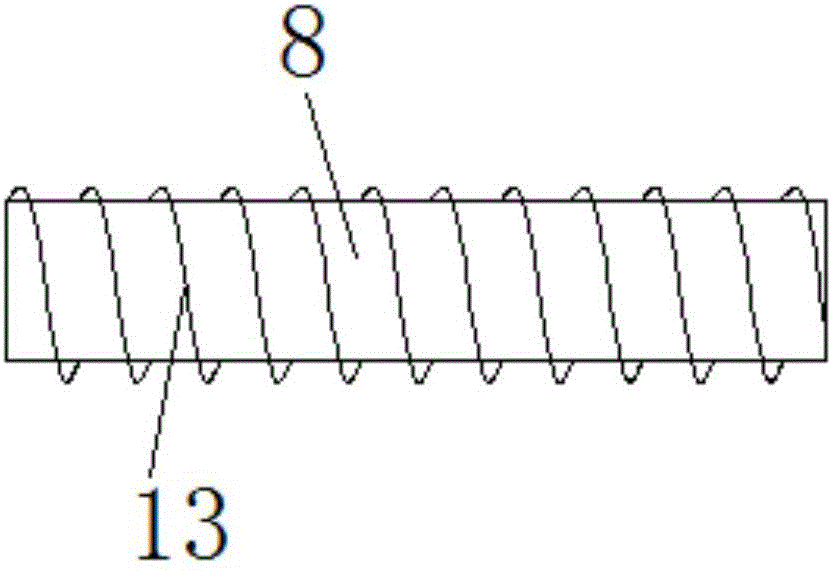

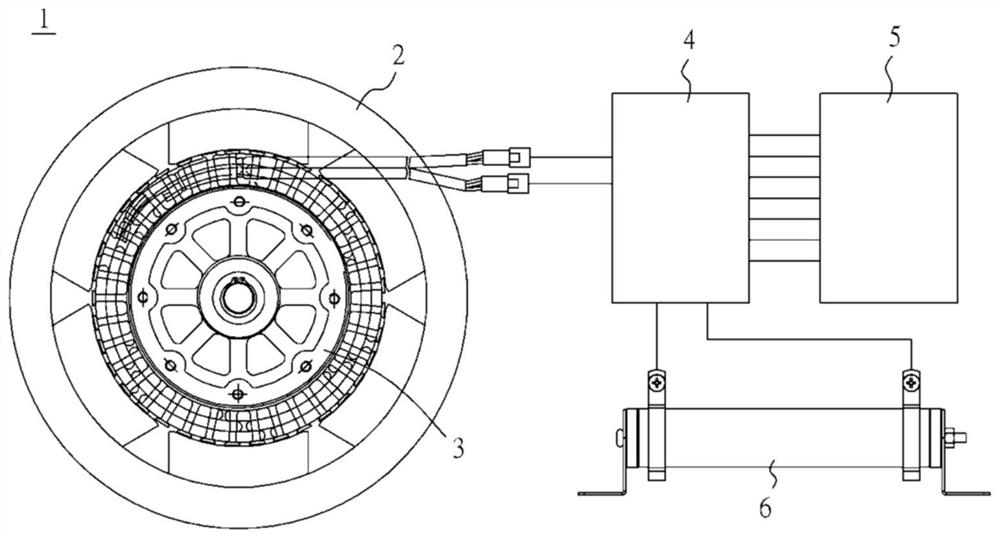

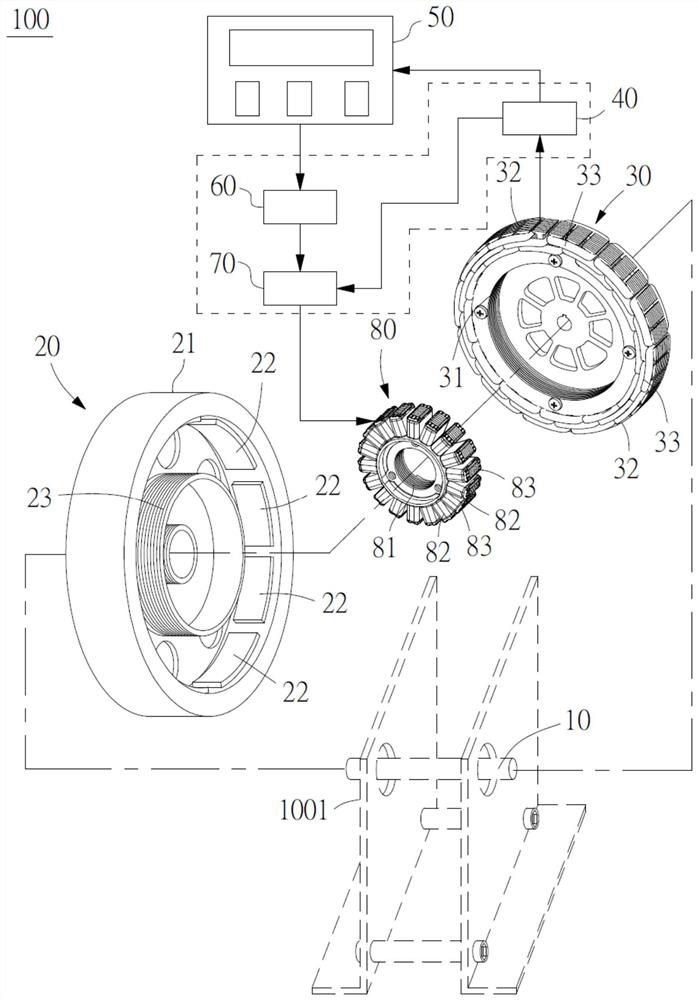

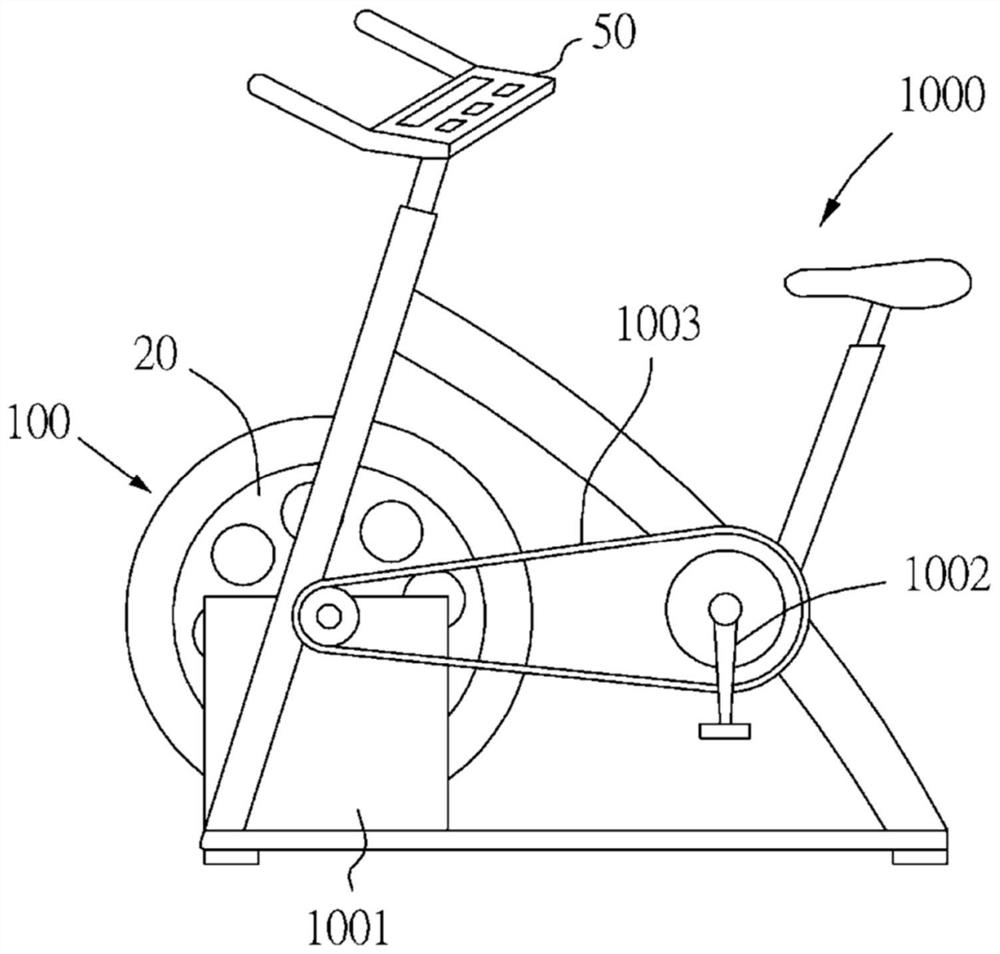

Cooperative damper for sports equipment and working method thereof

PendingCN113300531AHigh resistance precisionRotating vibration suppressionFlywheelsElectric machineSports equipment

The invention discloses a cooperative damper for sports equipment. The cooperative damper comprises a rack, a damping motor, a flywheel assembly, an electromagnet assembly and a controller. The flywheel assembly comprises a crankshaft and a metal piece; the electromagnet assembly is located on one side of the metal piece. The controller is used for controlling the magnitude of current passing through the damping motor and the electromagnet assembly. The invention further discloses a working method of the sports equipment collaborative damper. The working method comprises the following steps: S1, acquiring the pedaling frequency data of a user acting on the flywheel assembly and a torque value needed by the user; S2, comparing the obtained pedaling frequency data and the torque value required by the user with a pedaling frequency-torque threshold value, and controlling the generated resistance according to the comparison result; S3, continuously acquiring the pedaling frequency data in the next preset time and the torque value required by the user, and comparing the pedaling frequency data with the torque value required by the user to provide accurate resistance for the flywheel assembly. When the rotating speed is low, the defect that the damping motor generates resistance can be overcome through the electromagnet assembly, the resistance is mainly provided through the motor, and therefore, higher resistance precision is provided, and more electricity is saved.

Owner:厦门景杉网络科技有限公司

Electrode magnetron sputtering process of NTC temperature sensor

InactiveCN102691044AUniform thicknessHigh purityThermometers using electric/magnetic elementsVacuum evaporation coatingTemperature controlSputtering

The present invention discloses an electrode magnetron sputtering process of an NTC temperature sensor, and the process comprises the following process steps of: (1) conducting cleaning treatment on the surface of a semiconductor sensitive ceramic substrate, then performing heating and drying for standby use, with the temperature controlled at 190-210DEG C; (2) carrying out magnetron sputtering: putting the semiconductor sensitive ceramic substrate in the vacuum chamber of a multi-target facing target magnetron sputtering device, employing different target materials respectively to implement target material deposition on the semiconductor sensitive ceramic substrate, thus making a transition layer and an electrode film layer attached to the surface of the semiconductor sensitive ceramic substrate in order. The NTC temperature sensor made by the process of the invention has high density and resistance precision, uniform thickness, and is exempt from environmental influence, and no electrode ion migration can occur, so that product reliability and stability are greatly improved.

Owner:XINGHUA XINXING ELECTRONICS

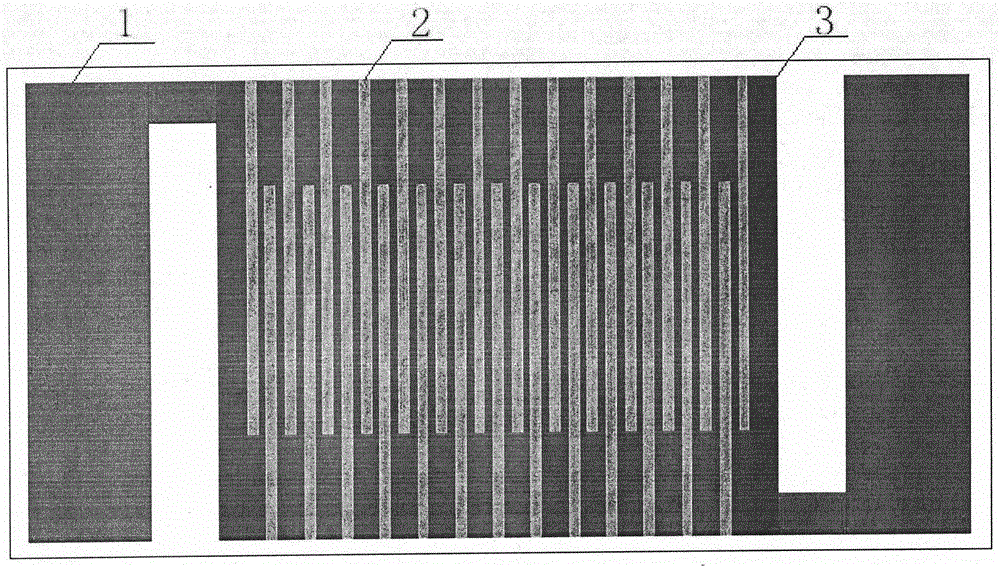

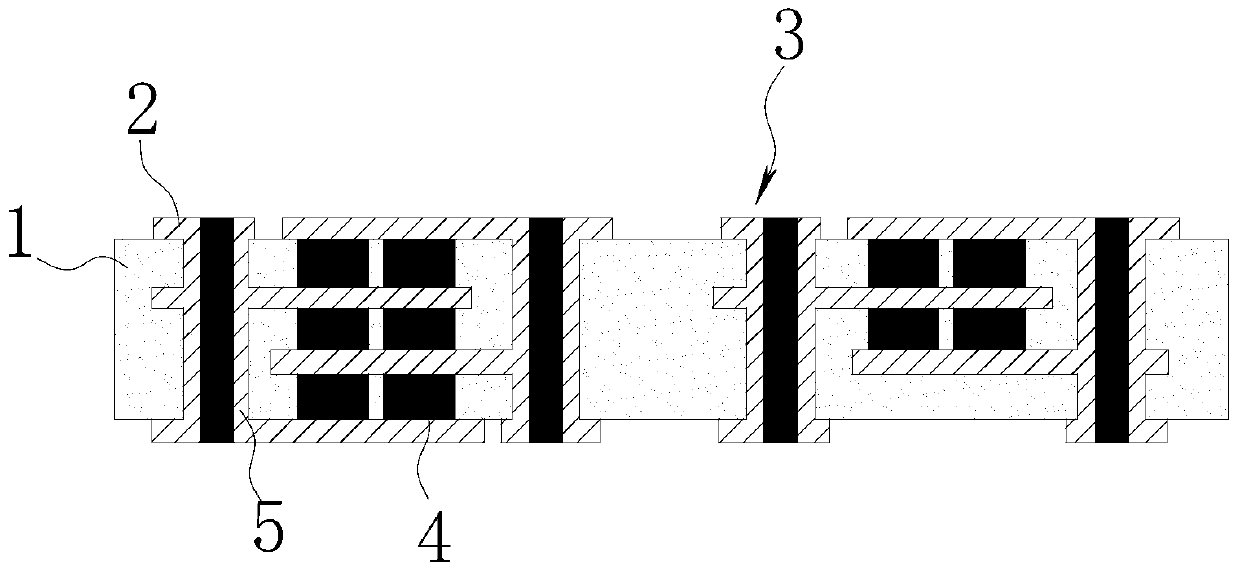

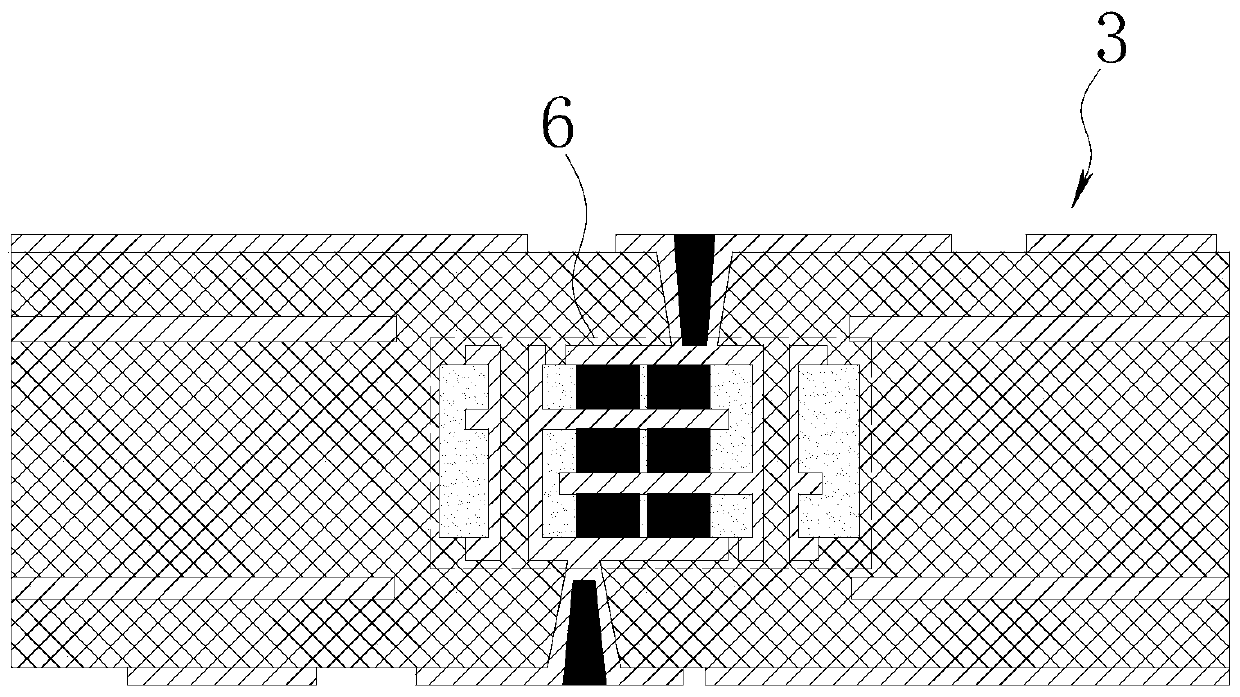

Method for embedding capacitors in printed-circuit board and printed-circuit board adopted by method

ActiveCN104780718AReduce the number of solder jointsSmall sizePrinted circuit assemblingMultilayer circuit manufactureCapacitanceEngineering

The invention discloses a method for embedding capacitors in a printed-circuit board and the printed-circuit board adopted by the method and belongs to the technical field of printed-circuit board manufacturing processes. According to the technical key point, the method comprises the following steps that (1) basic bodies are manufactured; (2) the basic body 1, the basic body 2, the basic body 3 and a metal layer are pressed by means of a multiple-layer board manufacturing process, one or more of the basic body 1, the basic body 2, the basic body 3 and the metal layer are combined and pressed to form a multiple-layer printed-circuit board, and the basic body 1 is arranged among the contact portions of the basic body 2, the basic body 3 and the metal layer; (3) drilling and metallization are performed; (4) outer-layer graph making is performed to form the multiple-layer printed-circuit board provided with multiple layers of embedded single capacitors and / or a multiple-layer single capacitor paralleled-connection structure. The method for embedding the capacitors in the printed-circuit board achieves accurate control of values of the embedded capacitors on the premise that additional cost is not needed to be increased, is simple in process and is used for manufacturing the printed-circuit board.

Owner:BOMIN ELECTRONICS CO LTD

Medical gold-containing high-precision and high-stability ntc thermal chip and its manufacturing method

ActiveCN108147790BHigh precisionImprove stabilityThermometers using electric/magnetic elementsBody temperature measurementEngineeringDiiron Trioxide

The invention relates to a medical gold-containing high-precision and high-stability NTC thermal chip. The medical gold-containing high-precision and high-stability NTC thermal chip comprises a thermal ceramic sheet and metal electrodes arranged on both surfaces of the thermal ceramic sheet. The heat-sensitive ceramic piece is made of 30-50% manganese dioxide, 40-52% cobalt tetroxide, 5-12% iron oxide, 3-5% nickel oxide and 1-2% gold oxide by mass percentage The nano-scale powder is mixed and sintered. The invention also relates to a manufacturing method of the medical gold-containing high-precision and high-stability NTC thermal chip. The medical gold-containing high-precision and high-stability NTC thermal chip of the invention has the advantages of high temperature measurement accuracy, high use stability and long service life.

Owner:ZHUHAI EXENSE MEDICAL TECH

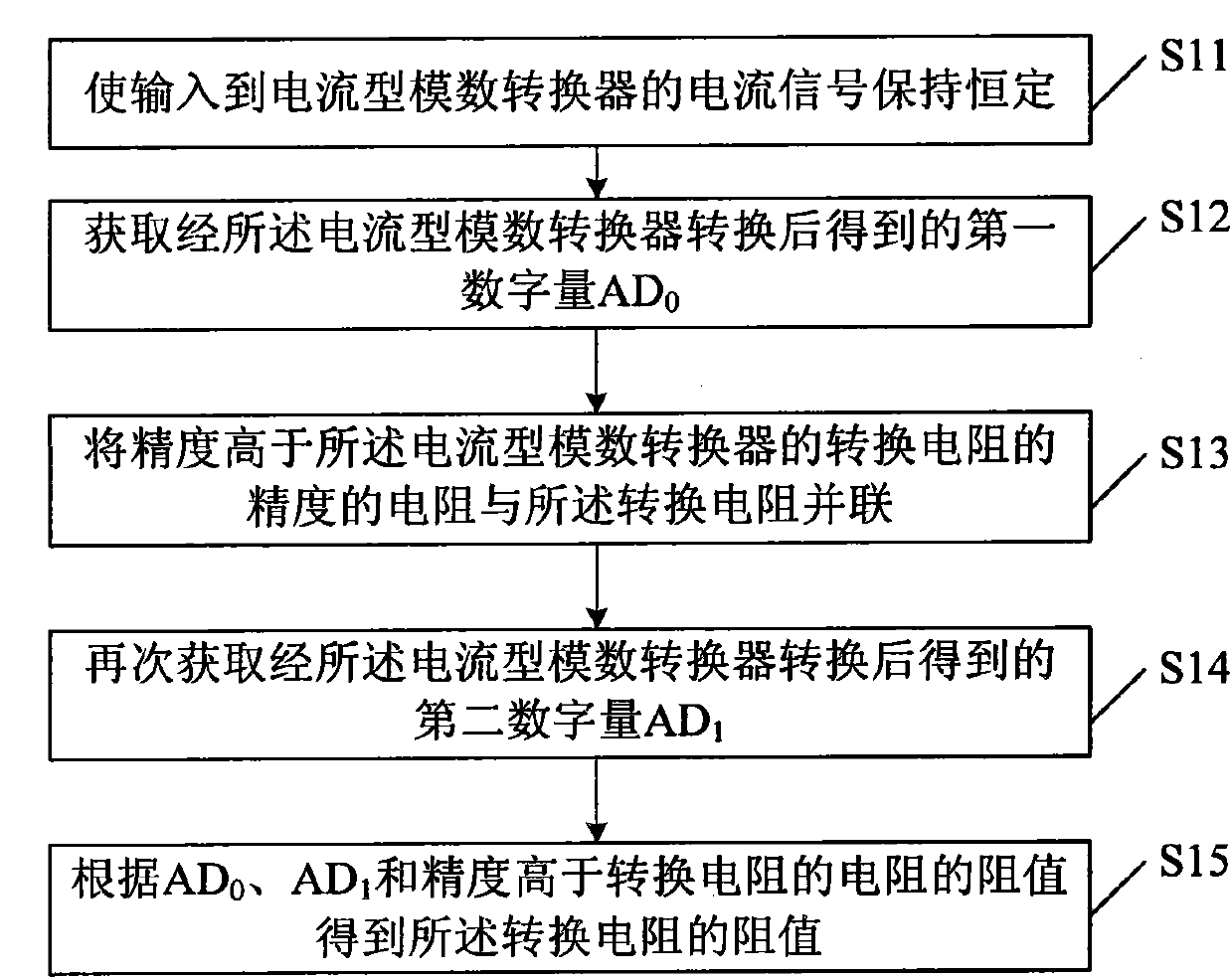

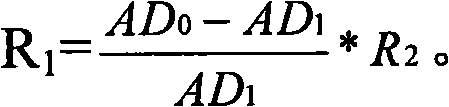

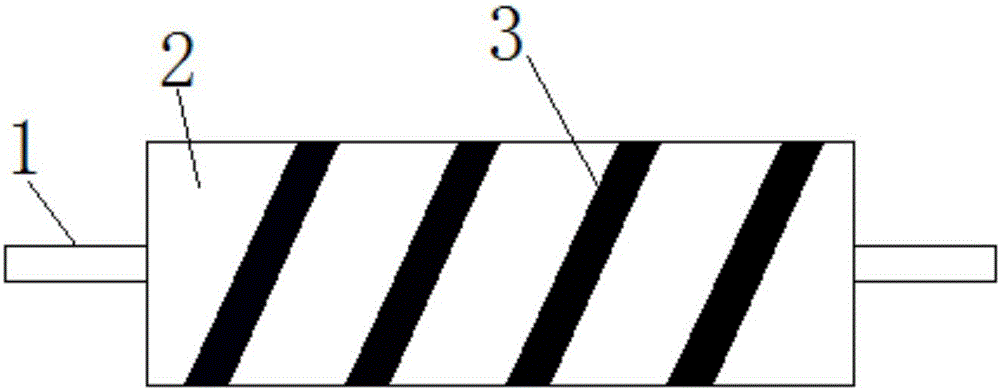

Method for measuring resistance value of conversion resistor of current-mode analog to digital converter

ActiveCN102043093AHigh resistance precisionEasy to controlResistance/reactance/impedenceAnalogue-digital convertersA d converterEngineering

The invention provides a method for measuring a resistance value of a conversion resistor of a current-mode analog to digital converter, which is used for improving the measurement and control precision of a measured physical object. The method comprises the following steps of: keeping a current signal input into the current-mode analog to digital converter constant; acquiring a first digital value AD0 which is obtained after the current signal is converted by the current-mode analog to digital converter; parallelly connecting a resistor Rj of which the precision is higher than that of the conversion resistor Rz of the current-mode analog to digital converter with the conversion resistor Rz; acquiring a second digital value AD1 which is obtained after the current signal is converted by the current-mode analog to digital converter again; and obtaining the resistance value of the conversion resistor Rz according to a formula shown in the specifications, wherein R1 is the obtained resistance value of the conversion resistor R2 and R2 is the resistance value of the resistor Rj of which the precision is higher than that of the conversion resistor Rz.

Owner:ZOOMLION HEAVY IND CO LTD

Fuse resistor

InactiveCN106298113AImprove electrical stabilityGood fusing effectResistor terminals/electrodesCoil/loop resistive elementsHigh resistanceEpoxy

The invention discloses a fuse resistor, comprising an outgoing line, a protective layer and a resistor color circle mark coating. The outgoing line is connected with caps. The caps are located at the inner side of the protective layer. The caps are symmetrically arranged at two ends of a metal conductive layer. A resistance band is winded on the outer wall of the metal conductive layer. Temperature isolation plates and side plates are arranged between the caps and the metal conductive layer. The side plates are close to the sides of the caps. A basic framework is packaged in the metal conductive layer. Wiring terminals at two ends of the basic framework are connected with the caps. Cutting slots are arranged on the inner wall of the basic framework. Epoxy resin blocks are filled in the cutting slots. The fuse resistor is good in electrical stability and fuse effect. The resistor is protected through a high temperature resistant layer, so the service life of the resistor is effectively prolonged. The resistor has a good temperature coefficient and relatively high resistance value precision. The performance is excellent. A new kind is increased in the electronic market. The sale of the electronic market is expanded.

Owner:重庆依凯科技有限公司

Method for Embedding Capacitor in Printed Circuit Board and Printed Circuit Board

ActiveCN104780718BReduce the number of solder jointsSmall sizePrinted circuit assemblingMultilayer circuit manufactureCapacitanceEngineering

The invention discloses a method for embedding capacitors in a printed circuit board and the printed circuit board thereof; it belongs to the technical field of circuit board manufacturing technology; its technical points include the following steps: (1) making a base body; (2) laminating , base 1, base 2, base 3 and metal layer, according to the multilayer board manufacturing process, base 1 and one or more combinations of base 2, base 3 and metal layer are pressed together to form a multilayer circuit board. The substrate 1 is provided between the contact parts of the substrate 2, the substrate 3 and the metal layer; (3) drilling and metallization; (4) making the outer layer pattern to form an embedded multilayer capacitor individual and / or multilayer A multi-layer printed circuit board with a parallel structure of individual capacitors; the present invention aims to provide a method for embedding capacitors in a printed circuit board with a simple process to achieve precise control of the resistance value of the embedded capacitor without additional cost And its printed circuit board; for circuit board production.

Owner:BOMIN ELECTRONICS CO LTD

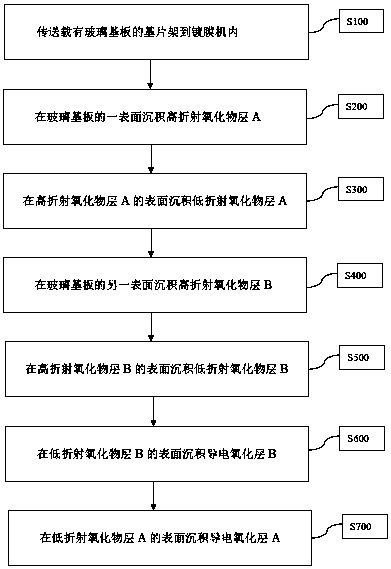

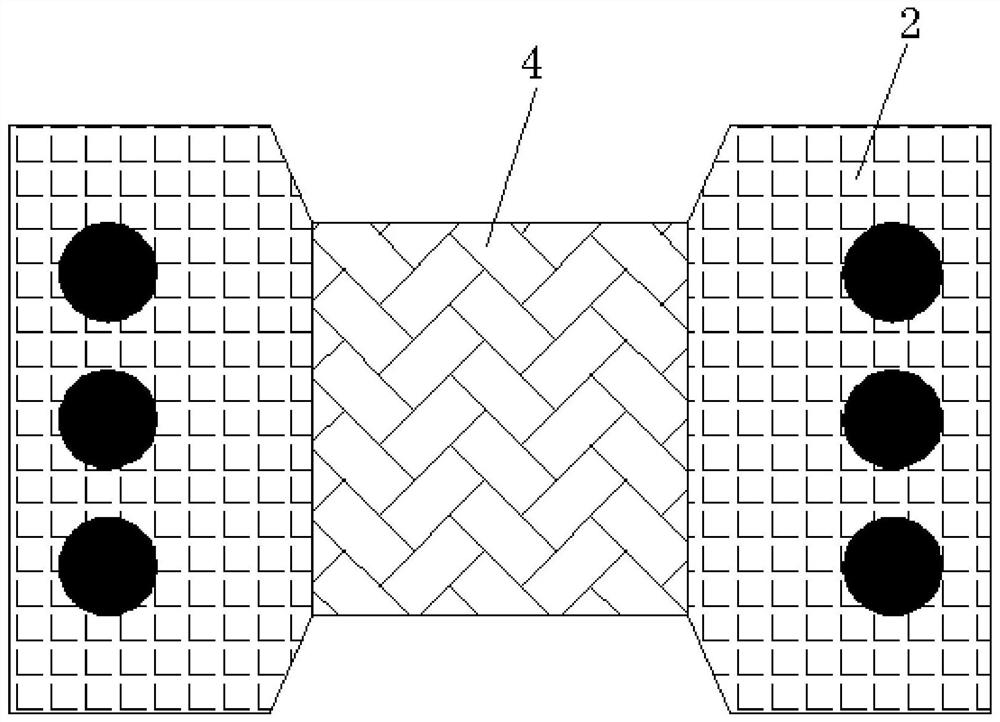

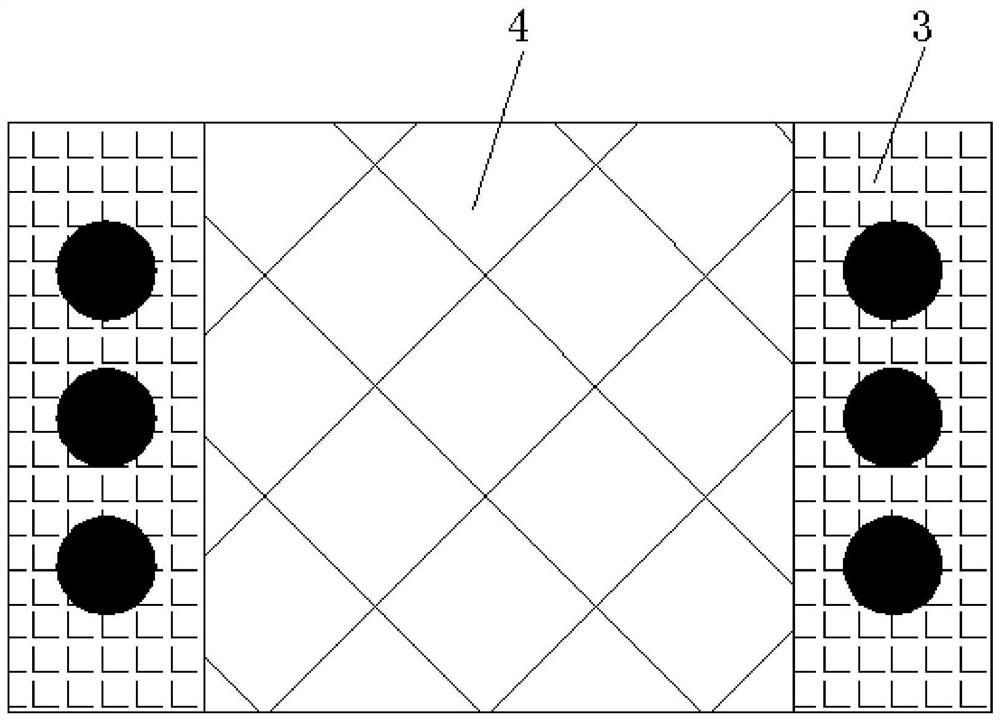

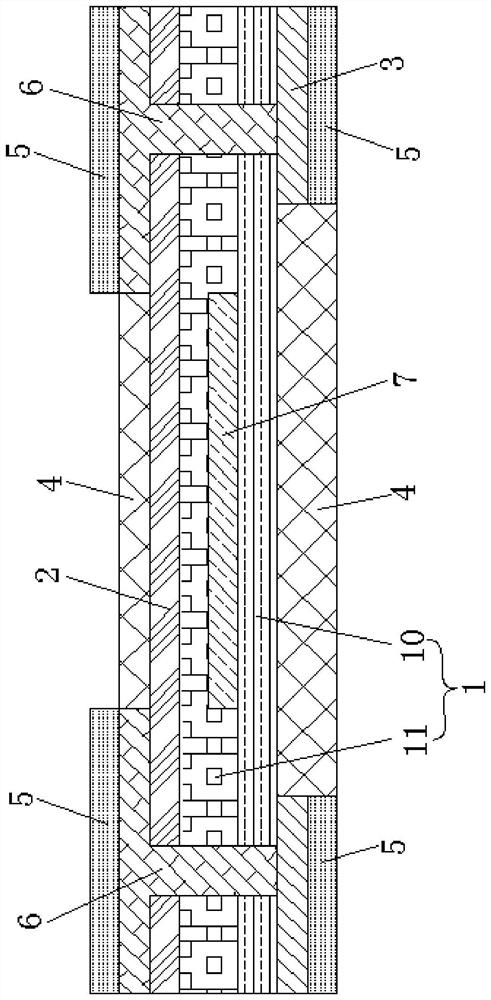

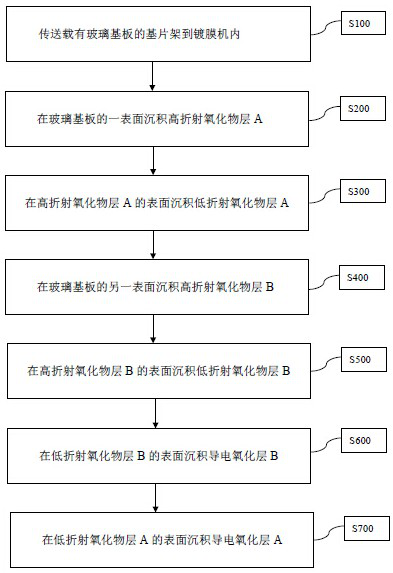

Anti-interference processing method for double-sided coated conductive glass

ActiveCN107777898AImprove technical levelImprove competitive advantageCoatingsIndium tin oxideOptoelectronics

The invention discloses an anti-interference processing method for double-sided coated conductive glass. The anti-interference processing method is characterized by comprising the following steps: 1)transferring a substrate support loaded with a glass substrate into a coating machine; 2) depositing a high-refraction oxide layer A on one surface of the glass substrate; 3) depositing a low-refraction oxide layer A on the surface of the high-refraction oxide layer A; 4) depositing a high-refraction oxide layer B on the other surface of the glass substrate; 5) depositing a low-refraction oxide layer B on the surface of the high-refraction oxide layer B; 6) depositing a conductive oxide layer B on the surface of the low-refraction oxide layer B; and 7) depositing a conductive oxide layer A onthe surface of the low-refraction oxide layer A. According to the processing method disclosed by the invention, the technical process is innovated, and the double-sided ITO (Indium Tin Oxide) resistance offset degree can be controlled in the production process to be within the needed + / -5%, so that the resistance accuracy is increased, the product performance is effectively improved, and the technological level and competitive advantages of coating enterprises are improved.

Owner:河源力友通讯科技有限公司

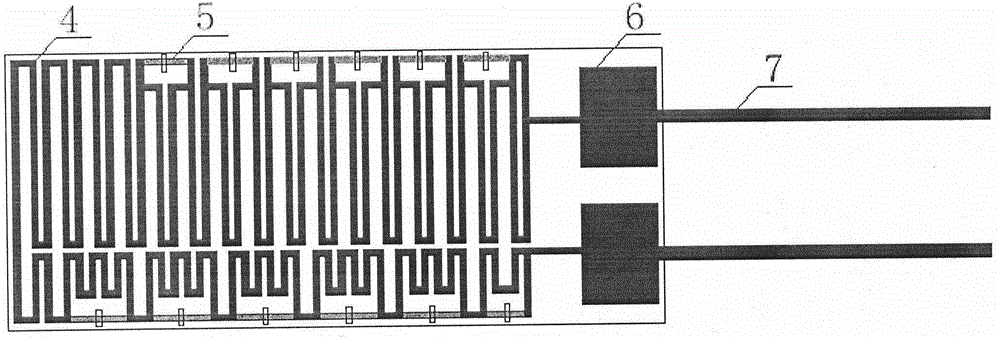

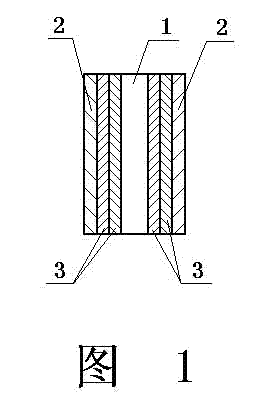

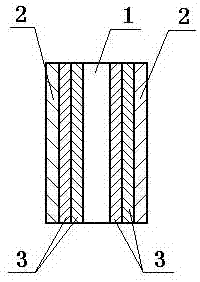

Sheet type heater and manufacturing process thereof

PendingCN111669844ANovel structureReasonable structureOhmic-resistance heating detailsHeating element materialsEpoxyGlass fiber

The invention discloses a sheet type heater and a manufacturing process thereof. The sheet type heater comprises a carrier layer, a heating layer and a copper foil welding layer, wherein the carrier layer is provided with a plurality of carrier base bodies which are sequentially arranged in a stacked mode, each carrier base body is composed of a high-temperature-resistant glass fiber cloth and a colloid layer located on the front face of the high-temperature-resistant glass fiber cloth, the heating layer is positioned on the front surface of the carrier layer, the copper foil welding layer ispositioned on the back surface of the carrier layer, the heating layer is further communicated with the copper foil welding layer, a heating layer pattern is etched on the front face of the heating layer, a welding layer pattern is etched on the back face of the copper foil welding layer, photosensitive epoxy resin packaging layers are packaged in the middle of the heating layer pattern and the middle of the welding layer pattern respectively, and tin plating layers are electroplated on the rest portions of the heating layer pattern and the rest portions of the welding layer pattern respectively. According to the invention, the sheet type heater is novel and reasonable in structure, low in product power consumption, high in resistance precision, high in power stability, not prone to damagedue to external force influence and long in product service life.

Owner:广德市镓锐电子有限公司

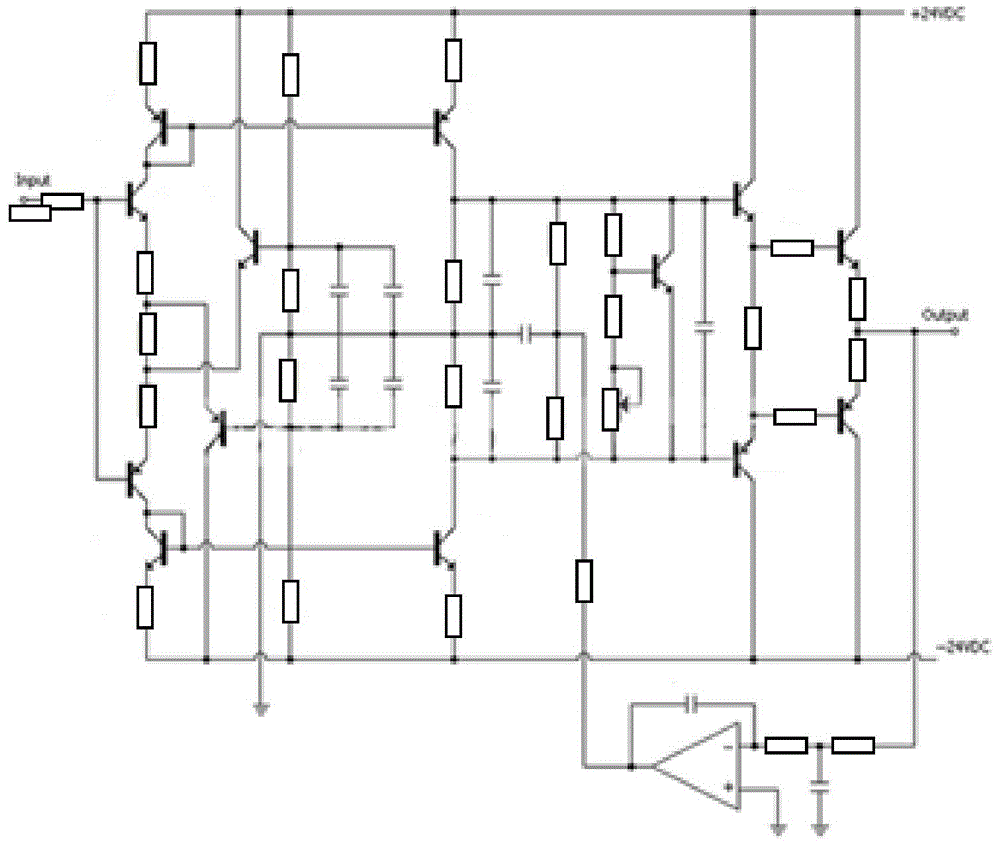

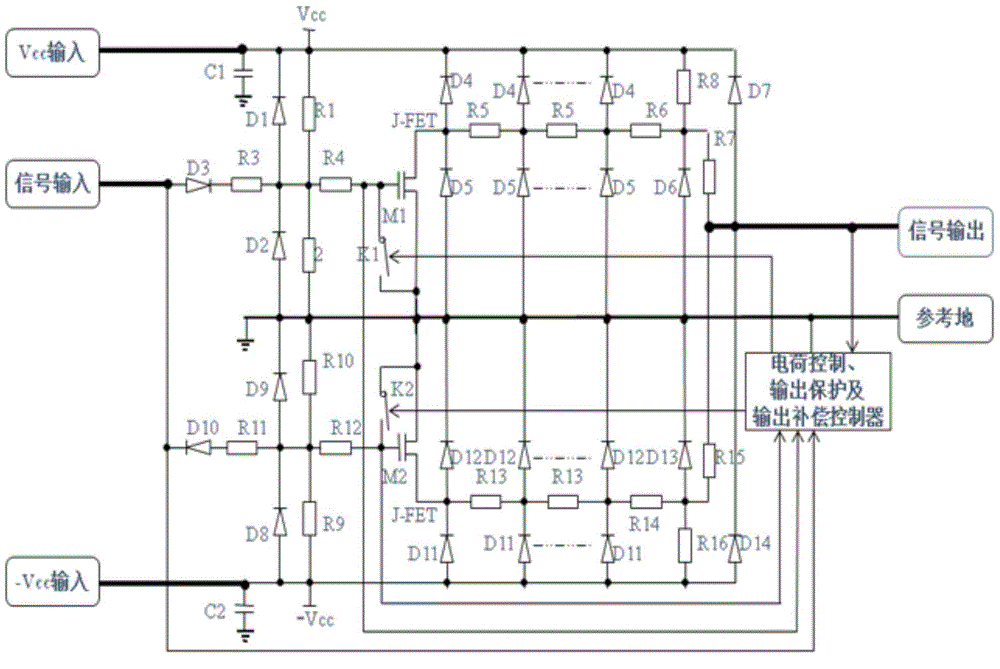

Precise voice control sensor integrated control device

ActiveCN104635675AImprove output qualityReduce Harmonic DistortionTotal factory controlProgramme total factory controlOxide semiconductorDistortion

The invention discloses a precise voice control sensor integrated control device. A charge control / output protection and output compensation controller is used for detecting voltage of a signal output end, detecting gate charge of an MOS (metal oxide semiconductor) transistor M1 and gate charge of an MOS transistor M2 and detecting voltage of a signal input end, signal output is compensated through an intelligent linear switch, and voltage of signal output is enabled to be within a set voltage range; or output is enabled to be zero or a switch K1 and / or a switch K2 is closed. The precise voice control sensor integrated control device has extremely high noise resistance, extremely wide voice rang, tiny distortion, extremely small size and extremely few ports; full-domain signal input is adopted, the variable-frequency intelligent linear switch is introduced in, the innovative charge algorithm control technique is adopted for charge control, output protection and output compensation control, further diodes, resistors and JFETs (junction field-effect transistors) adopted by the device are all special semiconductor processes, integration of a system is optimized fundamentally, and tiny size can be realized.

Owner:扬州江新电子有限公司

Preparation method of thermistor chip

ActiveCN105575569BHigh resistance precisionImprove stabilityNegative temperature coefficient thermistorsSlurryThermistor

Owner:SHENZHEN GUDIAN ELECTRONICS

A high-precision and high-reliability laminated thermistor chip and its manufacturing method

ActiveCN109727740BLight in massImprove performanceResistor terminals/electrodesNegative temperature coefficient thermistorsEngineeringMaterials science

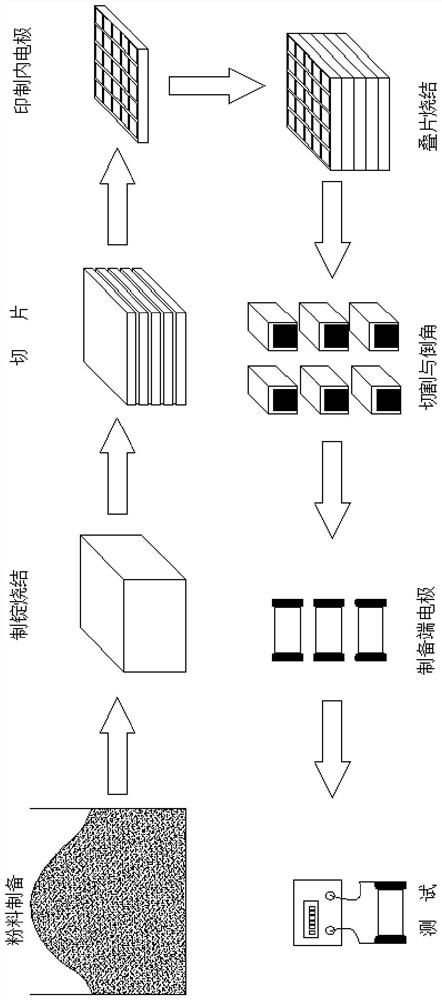

The invention relates to a method for manufacturing a high-precision and high-reliability laminated thermistor chip. The manufacturing method comprises the following steps: (1) preparing a thermistor ceramic powder; (2) preparing the thermistor ceramic powder (3) Slicing the ceramic body to obtain a cooked substrate; (4) Printing internal electrodes on the cooked substrate; (5) The cooked substrate with printed internal electrodes Sintering after stacking to obtain a thermistor; (6) cutting the thermistor into granules, and then chamfering; (7) preparing terminal electrodes on the semi-finished product obtained in step (6) to obtain a thermistor chip. The thermistor chip prepared by the manufacturing method of the invention is not easy to crack, has good compatibility among internal layers, is not easy to diffuse, has stable and reliable resistance performance, and achieves high precision.

Owner:DINGSENSE ELECTRONICS TECH CO LTD

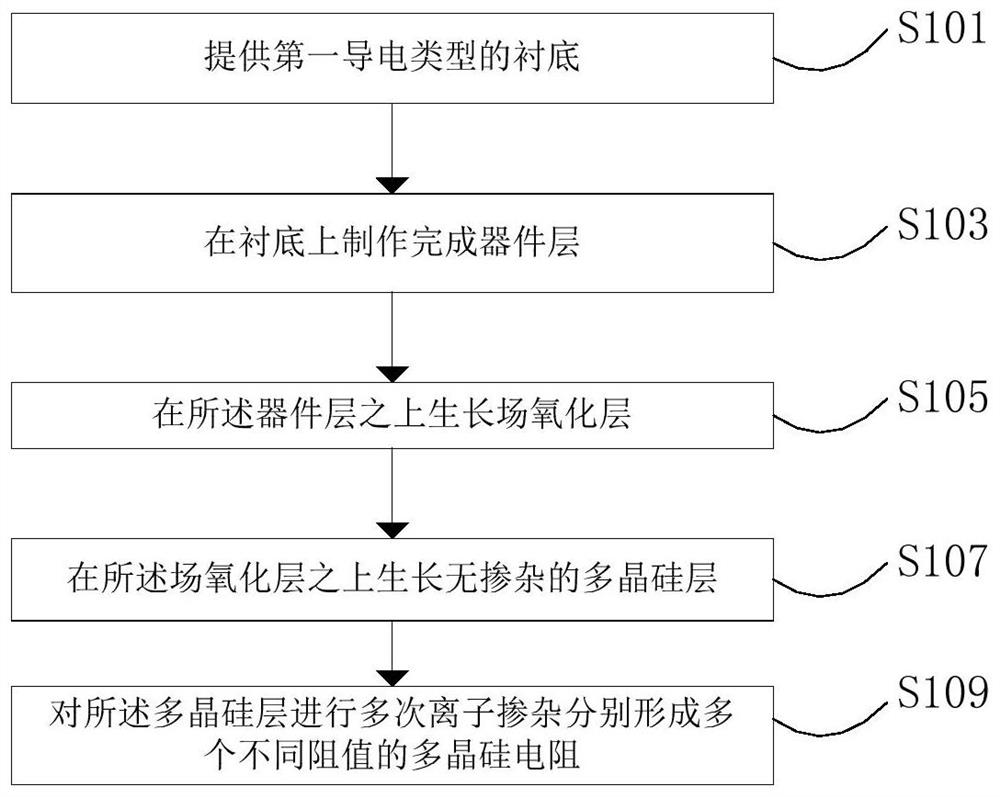

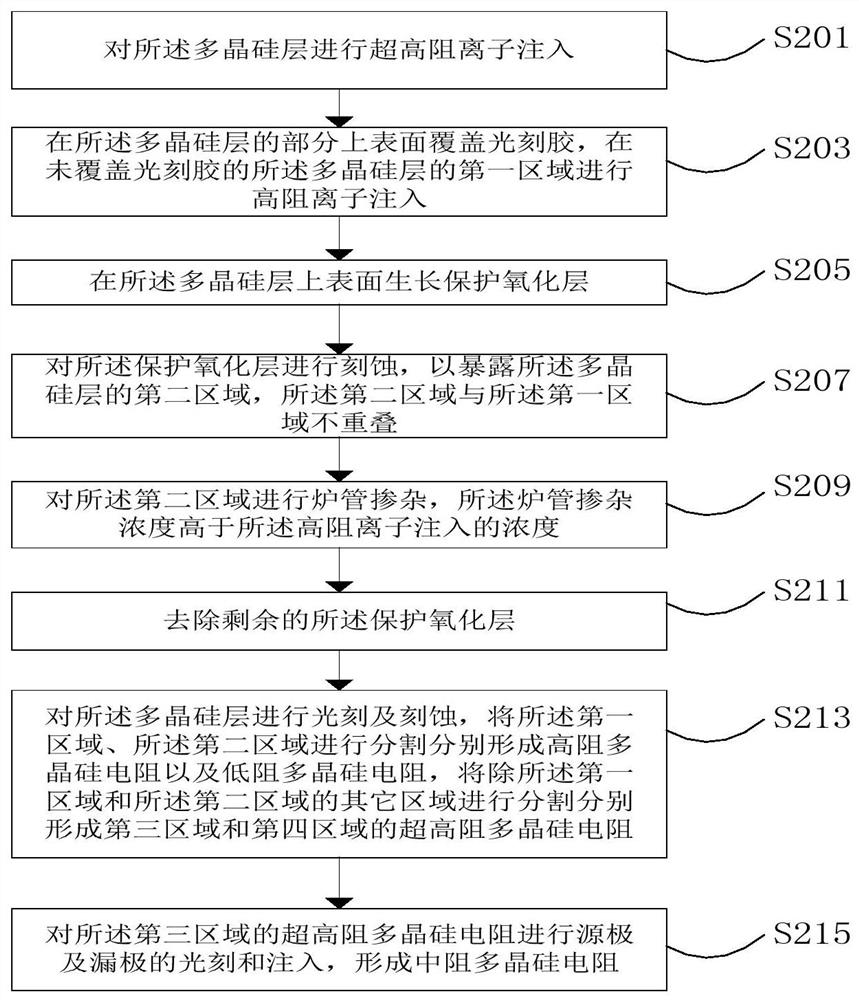

A method for integrating composite polysilicon resistors in integrated circuits

InactiveCN109326583BReduce manufacturing costHigh resistance precisionSemiconductor/solid-state device detailsSolid-state devicesEngineeringIon implantation

The invention relates to a method for integrating a composite polyresistor in an integrated circuit. The method includes that ultrahigh-resistance ion injection is performed on a polysilicon layer growing above a device field oxidation layer to obtain an ultrahigh-resistance polyresistor, high-resistance ion injection is performed on the ultrahigh-resistance polyresistor again to obtain a high-resistance polyresistor, doping ions are diffused into the ultrahigh-resistance polyresistor through a furnace tube to obtain a low-resistance polyresistor, a source electrode and a drain electrode are formed through ion injection while ions are injected into a part of the ultrahigh-resistance polyresistor to form a medium-resistance polyresistor, and four polyresistors different in resistance valueare obtained, so that great convenience is brought to circuit design engineers for design, resistance accuracy of a low-resistance-value resistor is improved substantially, chip occupation area of theultrahigh-resistance resistor is reduced, and chip making cost is lowered.

Owner:江苏清联光电技术研究院有限公司

Device for power generation and braking, assembly kit and braking unit thereof

ActiveCN112087101AImprove machining accuracyIncrease processing costMagnetic circuitMechanical energy handlingControl theoryMechanical engineering

The invention discloses a device for power generation and braking, an assembly kit and a braking unit thereof. A braking body in the braking unit is formed by assembling a plurality of braking blocks,so the braking unit has the characteristics that an electromagnetic air gap can be adjusted and the precision is high; therefore, on the premise that machining precision and machining cost of the brake unit are not required to be improved, the electromagnetic air gap between the brake unit and the wheel body can be set at a high-precision level, and the effect of improving the resistance precision is achieved.

Owner:曾源揆

An anti-interference processing method for double-sided coated conductive glass

ActiveCN107777898BImprove technical levelImprove competitive advantageCoatingsInterference resistanceIndium tin oxide

The invention discloses an anti-interference processing method for double-sided coated conductive glass. The anti-interference processing method is characterized by comprising the following steps: 1)transferring a substrate support loaded with a glass substrate into a coating machine; 2) depositing a high-refraction oxide layer A on one surface of the glass substrate; 3) depositing a low-refraction oxide layer A on the surface of the high-refraction oxide layer A; 4) depositing a high-refraction oxide layer B on the other surface of the glass substrate; 5) depositing a low-refraction oxide layer B on the surface of the high-refraction oxide layer B; 6) depositing a conductive oxide layer B on the surface of the low-refraction oxide layer B; and 7) depositing a conductive oxide layer A onthe surface of the low-refraction oxide layer A. According to the processing method disclosed by the invention, the technical process is innovated, and the double-sided ITO (Indium Tin Oxide) resistance offset degree can be controlled in the production process to be within the needed + / -5%, so that the resistance accuracy is increased, the product performance is effectively improved, and the technological level and competitive advantages of coating enterprises are improved.

Owner:河源力友通讯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com