An anti-interference processing method for double-sided coated conductive glass

A conductive glass, double-sided coating technology, applied in the direction of coating, can solve the problems of low efficiency, complex process, low yield rate, etc., to achieve the effect of increasing resistance value accuracy, improving product performance, improving technical level and competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

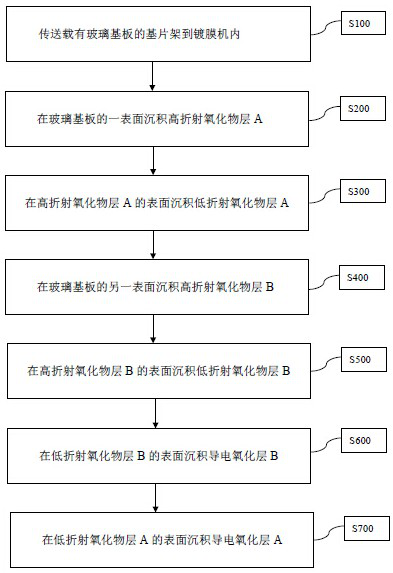

[0029] Such as figure 1 Shown, a kind of anti-interference processing method of double-sided coated conductive glass is characterized in that, comprises the steps:

[0030] 1) Transfer the substrate frame carrying the glass substrate into the vacuum chamber of the coating machine (step S100);

[0031] 2) Using plasma cations generated by a plasma gun to collide with a surface of the glass substrate, and depositing niobium pentoxide by sputtering to form a high-refractive oxide layer A (step S200 );

[0032] 3) Deposit SiO on the surface of the high refractive oxide layer A by sputtering deposition 2 And forming a low-refractive oxide layer A (step S300);

[0033] 4) Using plasma cations generated by a plasma gun to collide with the other surface of the glass substrate, and depositing niobium pentoxide by sputtering to form a high-refractive oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com