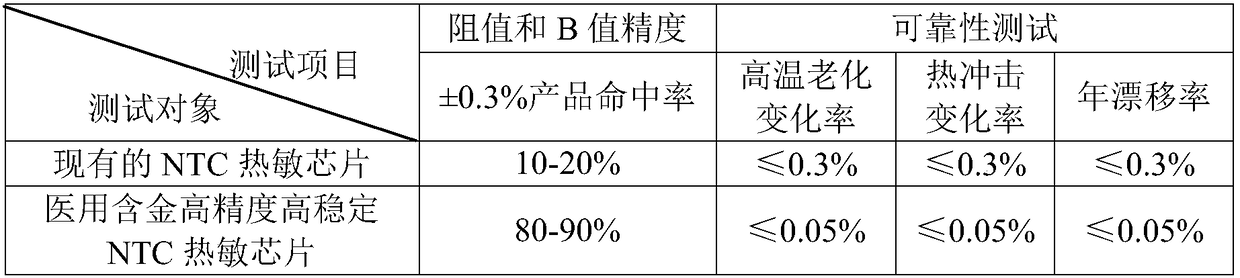

Medical gold-containing NTC (Negative Temperature Coefficient) thermosensitive chip with high accuracy and high stability, and manufacture method thereof

A production method and a high-stability technology, applied to thermometers, thermometers, and heat measurement of directly heat-sensitive electric/magnetic components, can solve problems such as short service life, poor stability, and low temperature measurement accuracy, and achieve improved Accuracy and stability, improved resistance accuracy, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

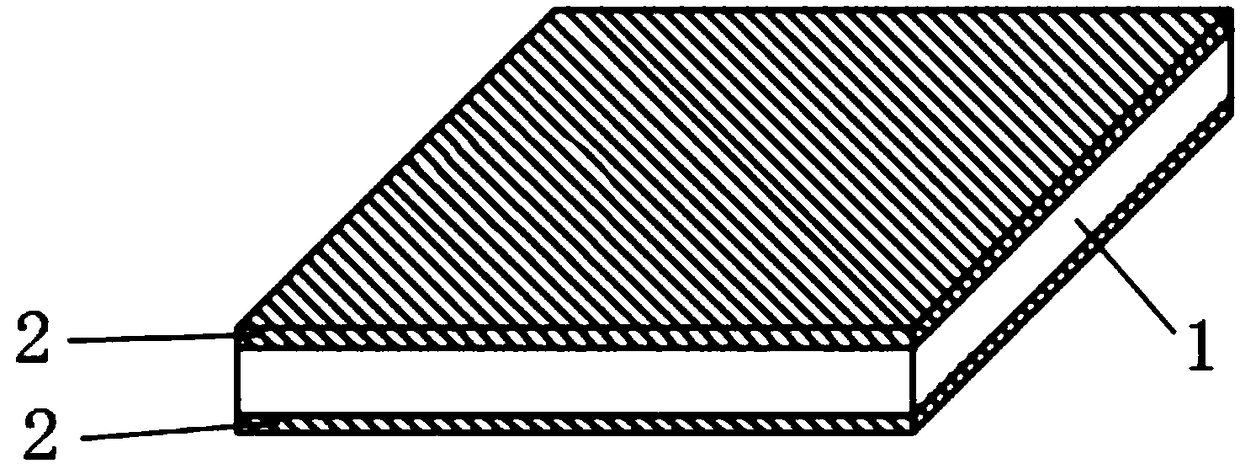

Image

Examples

Embodiment 1

[0034] In this embodiment, the steps of making a medical gold-containing high-precision and high-stability NTC thermal chip are as follows:

[0035] (1) Preparation of NTC thermosensitive ceramic powder:

[0036] ①Initial mixing: Weigh 40% manganese dioxide, 46% cobalt tetroxide, 9% ferric oxide, 3% nickel dioxide and 2% gold trioxide nano-scale powder according to the mass percentage, and then pour it into the dry Primary mixing in mixer.

[0037] ②Primary ball milling: Put the mixed powder obtained from the initial mixing into the ball mill tank, then add zirconium balls and purified water as the medium, the mass ratio of zirconium balls, mixed powder and purified water is 3:1:2, and then turn it at 90 rpm The frequency of ball milling per minute is 20-30 hours.

[0038] ③Primary drying: Send the slurry obtained from primary ball milling into an oven at 90°C for drying to remove moisture.

[0039] ④Primary sieving: sieve the powder obtained from primary drying.

[0040] ...

Embodiment 2

[0052] In this embodiment, the steps of making a medical gold-containing high-precision and high-stability NTC thermal chip are as follows:

[0053] (1) Preparation of NTC thermosensitive ceramic powder:

[0054] ①Initial mixing: Weigh 30% manganese dioxide, 52% cobalt tetroxide, 12% ferric oxide, 5% nickel dioxide and 1% gold trioxide nanoscale powder according to the mass percentage, and then pour it into the dry Primary mixing in mixer.

[0055] ②Primary ball milling: Add the mixed powder obtained from the initial mixing into the ball mill tank, then add zirconium balls and purified water as the medium, the mass ratio of zirconium balls, mixed powder and purified water is 3:1:2, and then turn it at 90 rpm The frequency of ball milling per minute is 20-30 hours.

[0056] ③Primary drying: Send the slurry obtained from primary ball milling into an oven at 90°C for drying to remove moisture.

[0057] ④Primary sieving: sieve the powder obtained from primary drying.

[0058] ...

Embodiment 3

[0070] In this embodiment, the steps of making a medical gold-containing high-precision and high-stability NTC thermal chip are as follows:

[0071] (1) Preparation of NTC thermosensitive ceramic powder:

[0072] ①Initial mixing: Weigh 50% manganese dioxide, 40% cobalt tetroxide, 5% ferric oxide, 3% nickel dioxide and 2% gold trioxide nano-scale powder according to the mass percentage, and then pour it into the dry Primary mixing in mixer.

[0073] ②Primary ball milling: Add the mixed powder obtained from the initial mixing into the ball mill tank, then add zirconium balls and purified water as the medium, the mass ratio of zirconium balls, mixed powder and purified water is 3:1:2, and then turn it at 90 rpm The frequency of ball milling per minute is 20-30 hours.

[0074] ③Primary drying: Send the slurry obtained from primary ball milling into an oven at 90°C for drying to remove moisture.

[0075] ④Primary sieving: sieve the powder obtained from primary drying.

[0076] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com