Sheet type heater and manufacturing process thereof

A manufacturing process and technology for heaters, which are used in electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of low precision, high power consumption and damage of bridge wire heaters, and achieve high resistance precision and novel structure. , the effect of high power stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

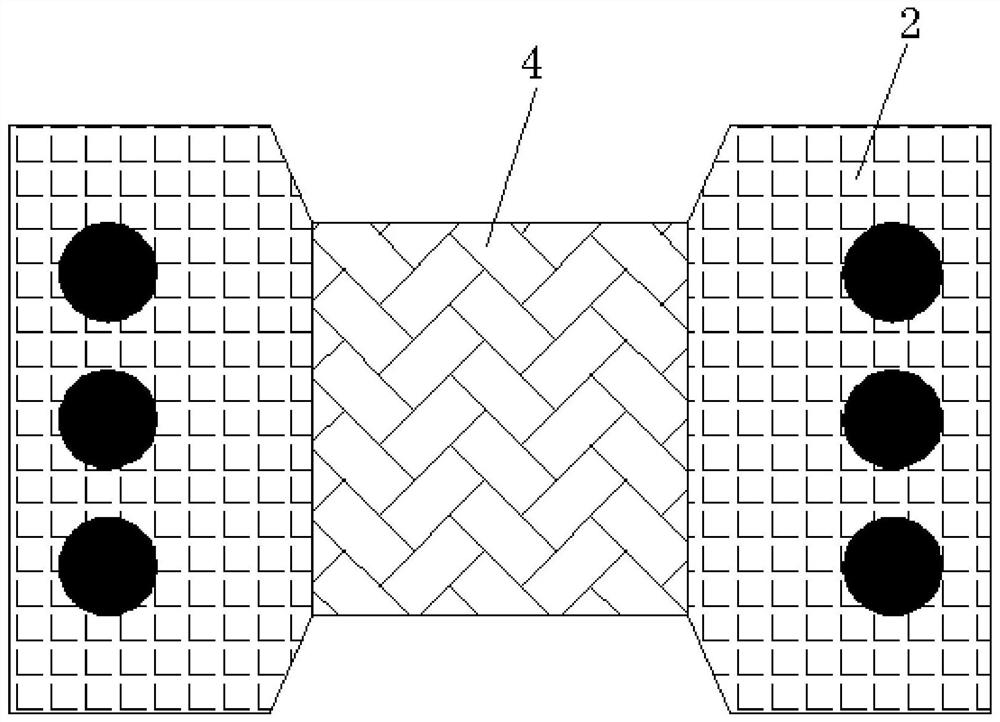

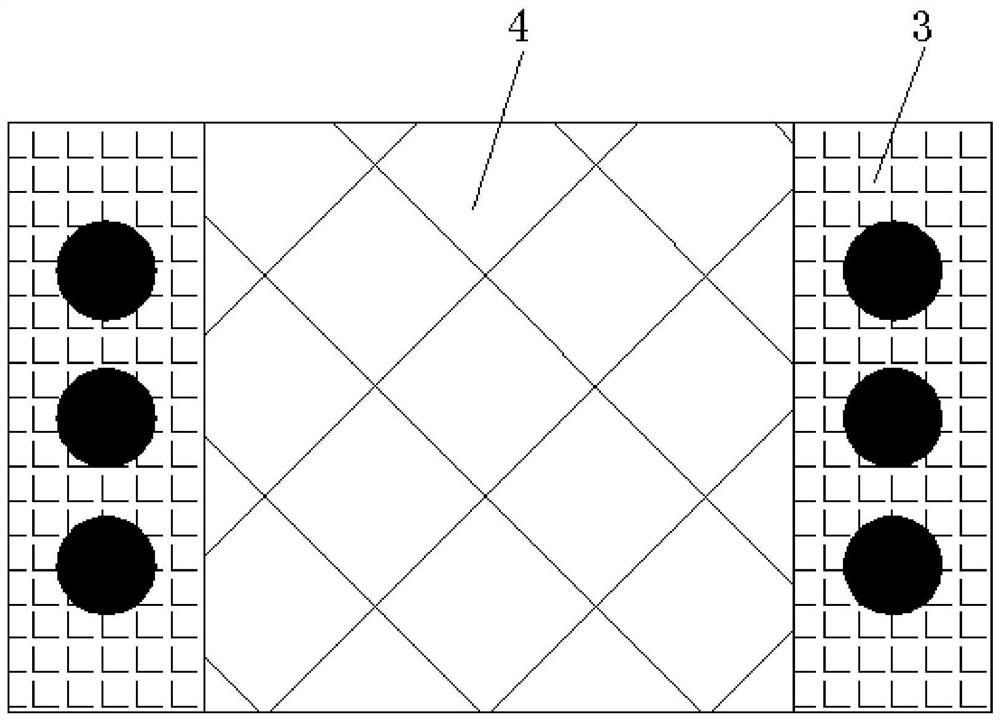

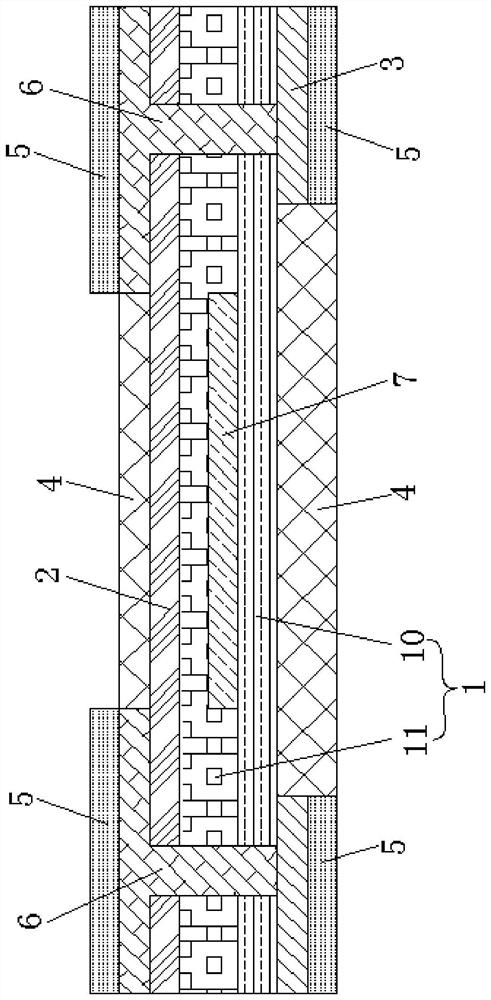

[0041] Please refer to the attached image 3 As shown, it is a schematic cross-sectional structure diagram of the chip heater of the present invention. The chip heater includes a carrier layer 1, a heating layer 2 and a copper foil welding layer 3. The carrier layer 1 has a plurality of carrier substrates arranged one after the other, and each of the carrier substrates is made of high temperature resistant glass fiber cloth. 10 and a colloid layer 11 positioned on the front of the high temperature resistant glass fiber cloth 10; the heating layer 2 is positioned on the front of the carrier layer 1, and the copper foil welding layer 3 is positioned on the On the back side of the carrier layer 1, and the heating layer 2 is also connected to the copper foil welding layer 3; in addition, the heating layer pattern is etched on the front side of the heating layer 2, and the heating layer pattern is etched on the copper foil welding layer The soldering layer pattern is etched on the...

preparation example 1

[0050] The manufacturing process of the chip heater is carried out as follows:

[0051] a. Cut out a piece of high-temperature-resistant glass fiber cloth 10 according to the design. The high-temperature-resistant glass fiber cloth 10 has a front side and a back side. On the front side of the high-temperature-resistant glass fiber cloth 10, a layer of polyimide modified ring is scratch-coated. epoxy resin, and after the polyimide modified epoxy resin is dried and aged, a colloid layer 11 with a solid content greater than 99% is formed; wherein, the high temperature resistant glass fiber cloth 10 connected together and the colloidal layer 11 are collectively referred to as the carrier matrix;

[0052] b. Placing a plurality of said carrier substrates sequentially, and after pressing treatment, a carrier layer 1 is obtained, that is, after pressing treatment, the colloid layer 11 of another said carrier substrate located below will infiltrate into an upper one. In the gap of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com