Manufacturing technology for improving resistance precision of conductive carbon oil printed circuit board

A technology of printed circuit board and conductive carbon oil, which is applied in directions including printed resistors, printed circuit manufacturing, printed circuits, etc. High resistance value accuracy, fast processing speed, and the effect of reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

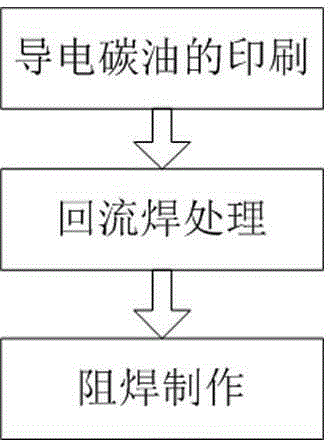

[0029] Such as figure 1 As shown, the present invention discloses a manufacturing process for improving the resistance accuracy of a printed circuit board with conductive carbon oil. Printing conductive carbon oil on one side of the circuit board includes the following steps:

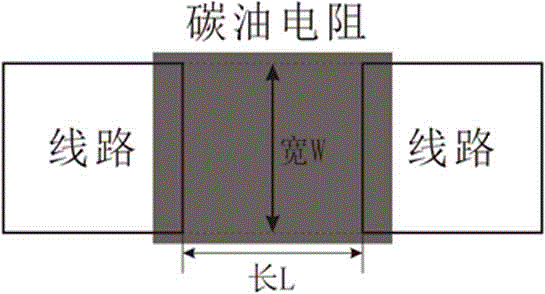

[0030] The first step is the printing of conductive carbon oil. After the circuit board completes the pre-production process of the conventional outer layer circuit, according to the resistance value and line width, the printing size of the conductive carbon oil is designed and printed on the circuit board to form a conductive carbon oil resistance. Both ends of the conductive carbon oil resistor are circuit board lines.

[0031] Such as figure 2 As shown, the printed size of the conductive carbon oil is calculated according to the following relationship: R=αL / W, wherein, R represents the resistance of the conductive carbon oil, α is the resistance value of the conductive carbon oil when the effective...

Embodiment 2

[0035] Such as figure 1 As shown, the present invention discloses a manufacturing process for improving the resistance precision of a printed circuit board with conductive carbon oil. Printing conductive carbon oil on both sides of the circuit board includes the following steps:

[0036] The first step is the printing of conductive carbon oil. After the circuit board completes the pre-production process of the conventional outer layer circuit, according to the resistance value and line width, the printing size of the conductive carbon oil is designed and printed on the circuit board to form a conductive carbon oil resistance. Both ends of the conductive carbon oil resistor are circuit board lines.

[0037] Such as figure 2 As shown, the printed size of the conductive carbon oil is calculated according to the following relationship: R=αL / W, wherein R represents the resistance of the conductive carbon oil, α is the resistance value of the conductive carbon oil when the effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com