Manufacturing method of platinum film thermal resistor

A technology of thin film thermistor and manufacturing method, which is applied in the direction of resistance manufacturing, resistors, coating resistance materials, etc., can solve the problems of high production cost of platinum resistors, poor resistance value accuracy, and large product volume, so as to reduce production costs , Improve production efficiency, improve the effect of resistance value accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

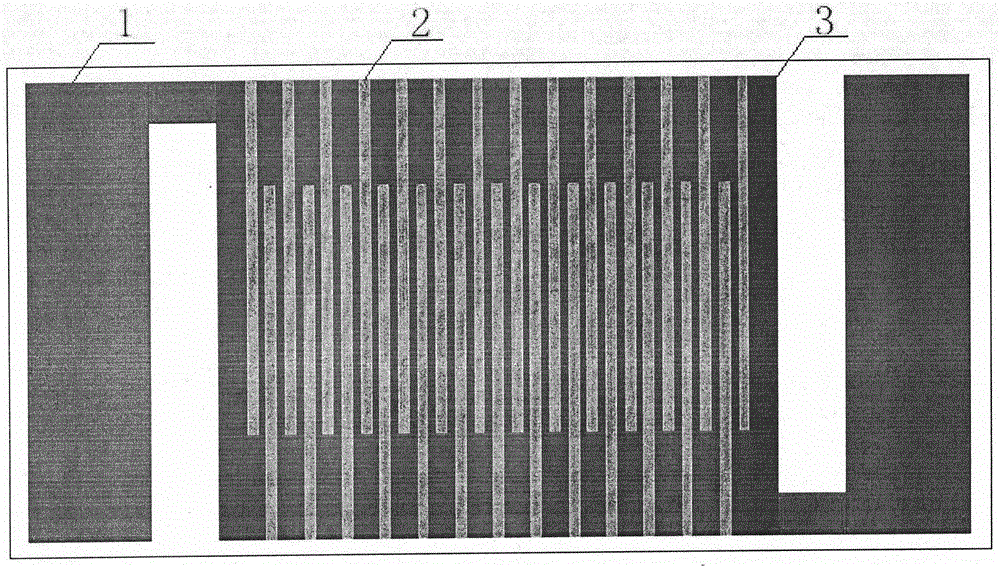

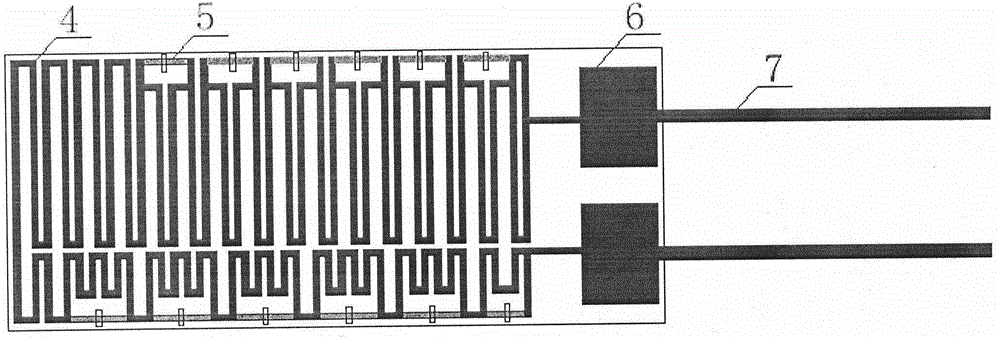

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments: a manufacturing method of a platinum thin-film thermistor, including ceramic substrate polishing, platinum film layer sputtering, film layer heat treatment, plasma etching, laser digital resistance adjustment, Resistor body encapsulation, sintering, manual splitting, lead welding, solder joint encapsulation and encapsulation layer curing; the specific methods are as follows:

[0031] 1) The upper and lower surfaces of the 99 ceramic substrate are polished, and the surface roughness is controlled at 0.10 μm to 0.15 μm;

[0032] 2) Soak the polished ceramic substrate with 5% NaOH solution for 15 minutes, and ultrasonically clean the substrate 3 times with deionized water for 5 minutes each time, remove the remaining NaOH solution on the substrate, and dry it with compressed air Water drops on the surface of the substrate, and the substrate was dried in an oven at 150°C for 60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com