A high-precision and high-reliability laminated thermistor chip and its manufacturing method

A technology of a thermistor chip and a manufacturing method, which is applied in resistance manufacturing, resistors with negative temperature coefficient, resistors, etc., can solve problems such as mutual diffusion, increase production cost, difference in sintering expansion rate, etc., and achieve higher resistance value. Accuracy, stable and reliable performance, avoiding the effect of quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

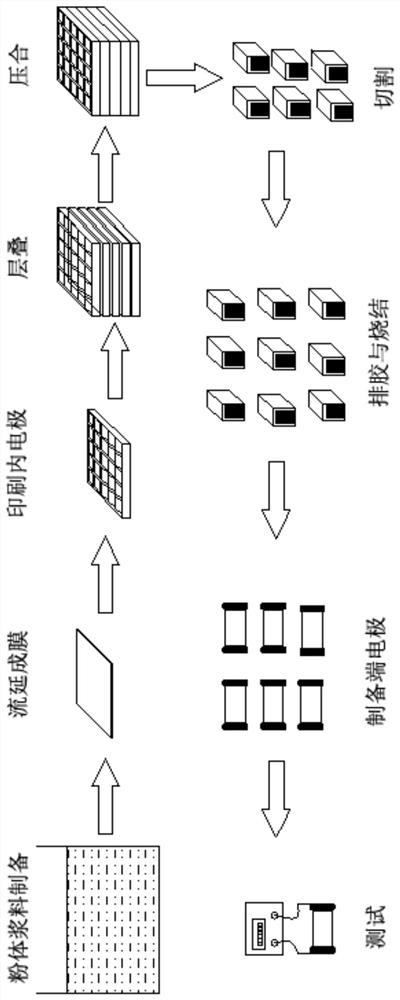

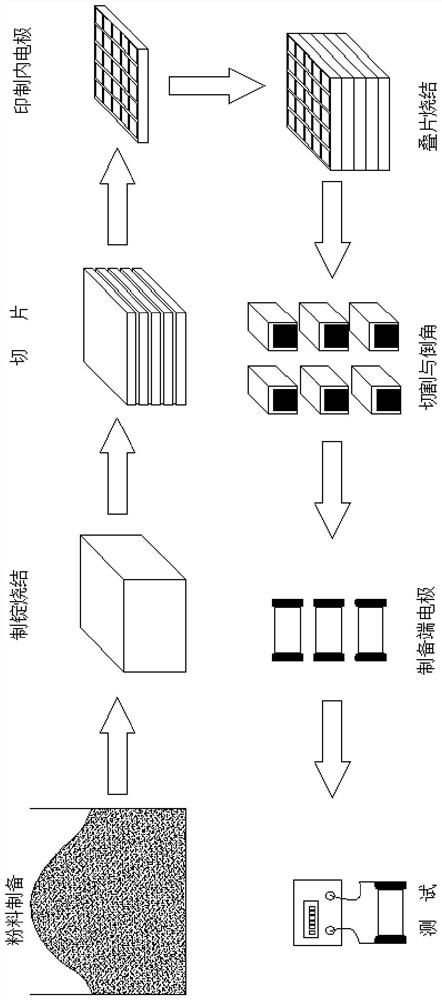

[0031] see figure 2 , the manufacture method of high-precision and high-reliability laminated thermistor chip of the present invention, comprises the steps:

[0032] (1) Preparation of thermistor ceramic powder:

[0033] According to the formula of NTC thermosensitive ceramic powder, use 30%~40% Mn by mass percentage 3 o 4 (manganese oxide), 25%~35% Co 3 o 4 (cobalt oxide), 25% to 35% Fe 2 o 3 (iron oxide), 5% to 10% NiO (nickel oxide), 0.3% to 3%% SrCO 3 (strontium carbonate), 0.3% to 3% ZrO (zirconia) and other raw materials to make thermistor ceramic powder.

[0034] Adding SrCO to the powder formulation 3 (strontium carbonate) and ZrO (zirconia) as a joint stabilizer can enhance the stability and reliability of the electrical properties of the NTC thermistor.

[0035] (2) Ingot making and sintering:

[0036] The obtained thermistor ceramic powder is pressed into an ingot, and then sintered at a high temperature to obtain a ceramic body.

[0037] Specifically, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com