Electrode magnetron sputtering process of NTC temperature sensor

A temperature sensor, magnetron sputtering technology, applied in thermometers, sputtering plating, metal material coating processes, etc. High density, uniform particle size and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

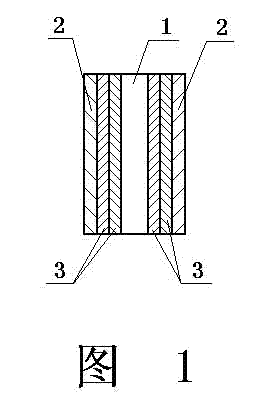

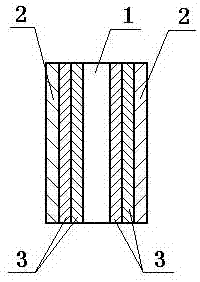

[0015] An NTC temperature sensor magnetron sputtering electrode process, including the following process steps: using a semiconductor sensitive ceramic substrate 1 with a thickness of 0.3mm, a length of 0.5mm, and a width of 0.5mm, the surface of the semiconductor sensitive ceramic substrate 1 is cleaned as follows : Soak and ultrasonically clean the semiconductor sensitive ceramic substrate 1 in a deionized aqueous solution, then soak the semiconductor sensitive ceramic substrate 1 in a high-purity IPA solution to remove surface stains, ultrasonically clean for 5 minutes, and finally rinse with ionized water, heat and bake the semiconductor sensitive ceramic substrate 1 Dry standby, temperature control 200±10℃;

[0016] Magnetron sputtering: Place the above semiconductor sensitive ceramic substrate 1 in the vacuum chamber of the multi-target facing target magnetron sputtering equipment, use argon gas with a mass purity of 99.99% as the working gas, and the working vacuum degre...

Embodiment 2

[0018] A magnetron sputtering electrode process for an NTC temperature sensor, comprising the following process steps: using a semiconductor sensitive ceramic substrate 1 with a thickness of 1 mm, a length of 2.5 mm, and a width of 2.5 mm, the surface of the semiconductor sensitive ceramic substrate 1 is cleaned as follows: Soak in deionized aqueous solution for ultrasonic cleaning, then soak the semiconductor sensitive ceramic substrate 1 in absolute ethanol solution to remove surface stains, ultrasonically clean for 5 minutes, and finally rinse with ionized water, heat and dry the semiconductor sensitive ceramic substrate 1 Standby, temperature control 200±10℃;

[0019] Magnetron sputtering: Place the above semiconductor sensitive ceramic substrate 1 in the vacuum chamber of the multi-target facing target magnetron sputtering equipment, use argon gas with a mass purity of 99.99% as the working gas, and the working vacuum degree is 0.1-1 Pa, the sputtering distance is 80-120m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com