High-precision fiber grating force sensor for measuring puncture force of minimally invasive surgery

A minimally invasive surgery, fiber grating technology, applied in the measurement of force, the measurement of force by measuring the change of the optical properties of the material when it is stressed, surgery, etc., can solve problems such as poor detection sensitivity, achieve small size, avoid chirp phenomenon, the effect of improving the ability to resist lateral interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

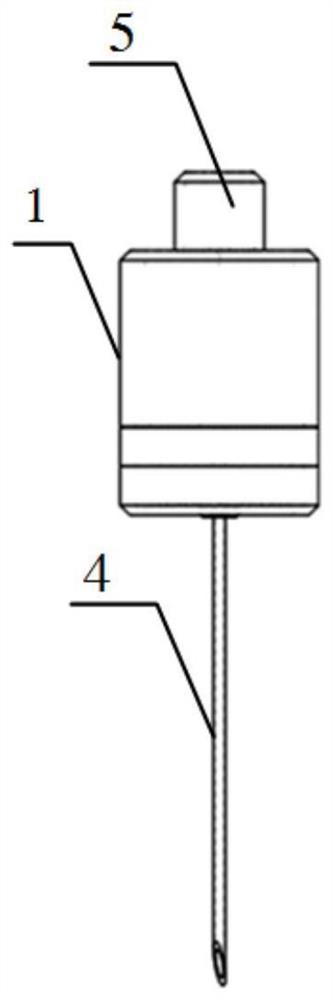

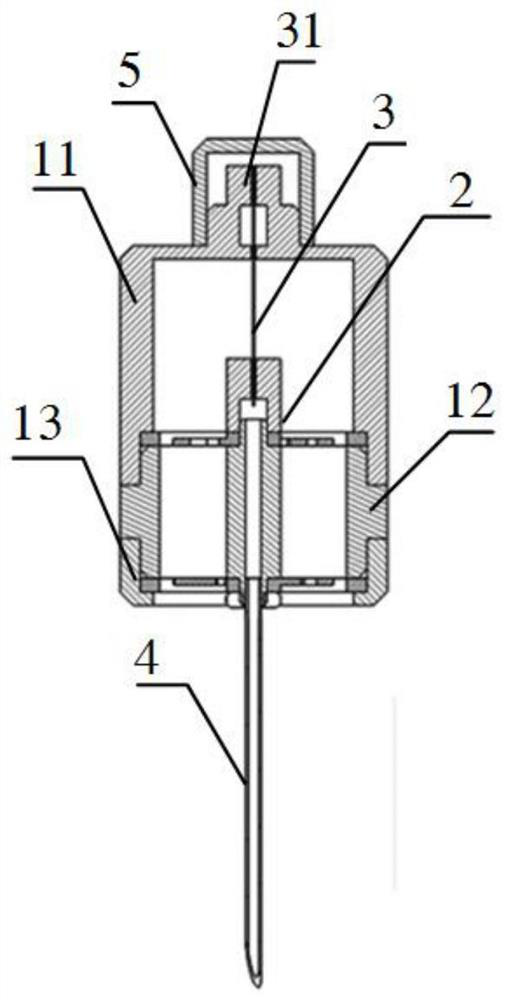

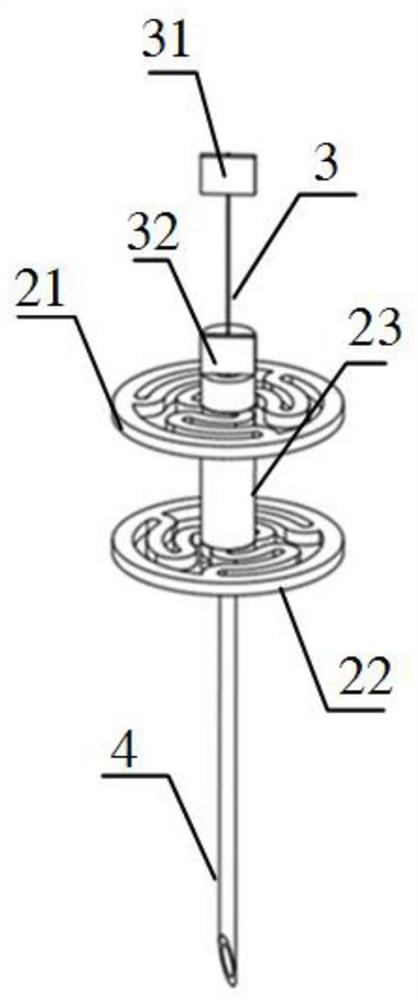

[0037] Embodiment 1: as Figures 1 to 7 As shown, a high-precision fiber grating force sensor for puncture force measurement in minimally invasive surgery is mainly composed of a sensor housing 1, a planar spring assembly 2, a fiber Bragg grating 3, a puncture needle 4, and a signal processing unit, wherein:

[0038] The interior of the sensing housing 1 is hollow, and the top of the sensor housing 1 is provided with a first optical fiber fixing part 31, and the first optical fiber fixing part 31 is provided with a first optical fiber installation groove 311, and the first optical fiber installation The groove 311 communicates with the inside of the sensor housing 1;

[0039] The planar spring assembly 2 is arranged inside the sensor housing 1 and is fixed to the side wall of the sensor housing 1; the planar spring assembly 2 is composed of two planar springs arranged in parallel and a connection and fixation of the two planar springs. The spring connector 23 is composed of; ...

Embodiment 2

[0047] Embodiment 2: as Image 6 As shown, a high-precision fiber grating force sensor for puncture force measurement in minimally invasive surgery is a preferred embodiment of embodiment 1, the difference is that the sensor housing 1 in this embodiment consists of a first housing 11, The second housing 12 and the third housing 13 are assembled together by screw connection; wherein: the first optical fiber fixing part 31 is arranged on the top of the first housing 11, and the first housing 11 and the second housing A first annular groove is provided between the body 12, and the first planar spring 21 is assembled in the first annular groove; a second annular groove is provided between the second shell 12 and the third housing 13, and the first Two planar springs 22 are assembled in the second annular groove.

[0048] Specifically, such as Image 6 As shown, the first housing 11 is a hollow cylindrical structure provided with internal thread segments; the second housing 12 is...

Embodiment 3

[0049] Embodiment 3: A high-precision fiber grating force sensor used for puncture force measurement in minimally invasive surgery. The difference from Embodiment 2 is that a hollow thread is provided between the first optical fiber fixing part and the first housing 11 of the 31 Section 14, the hollow threaded section 14 is provided with a central through hole connected with the first optical fiber installation groove 311; the force sensor is also provided with an external protective nut 5 connected with the hollow threaded section 14 , used to protect the fiber splicing point.

[0050] In the high-precision fiber grating force sensor described in Embodiment 3, the fiber Bragg grating 3 can be drawn out by an external protective nut 5 and connected to a signal processing unit, and the signal processing unit includes a fiber grating demodulator and a computer A system for converting an optical wavelength signal into a digital signal.

[0051] The specific working principle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com