Optical Fiber Bragg Grating Sensing Device and Its Monitoring System Used to Detect the Forced State of Water-lubricated Bearings

A water-lubricated bearing and fiber grating technology, which is used in measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve problems such as unfavorable manufacturing, complex structure, and inconvenient manufacturing, so as to reduce manufacturing costs and reduce manufacturing costs. The effect of reducing production difficulty and real and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further explained:

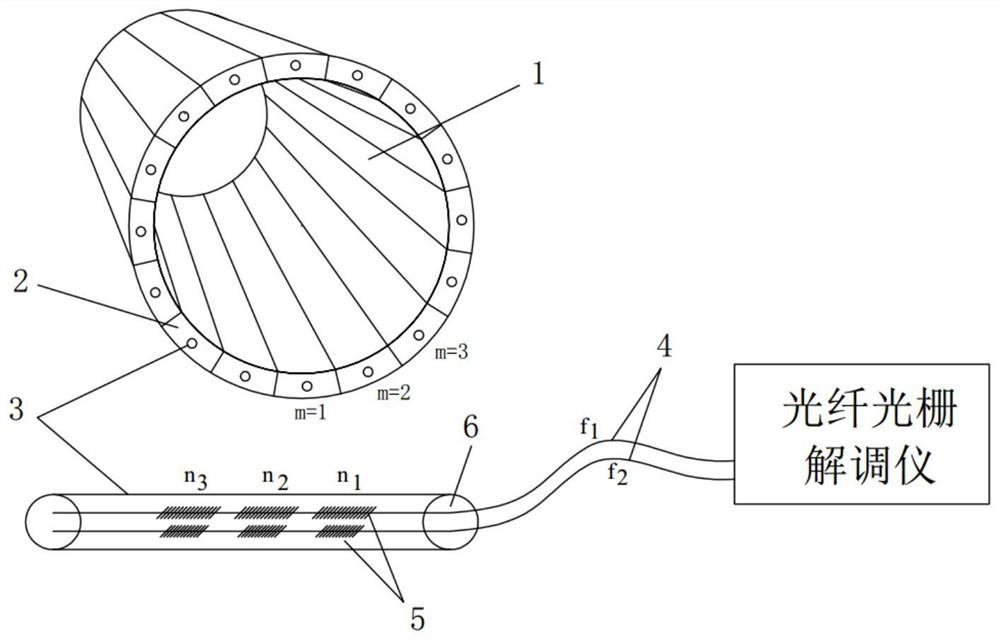

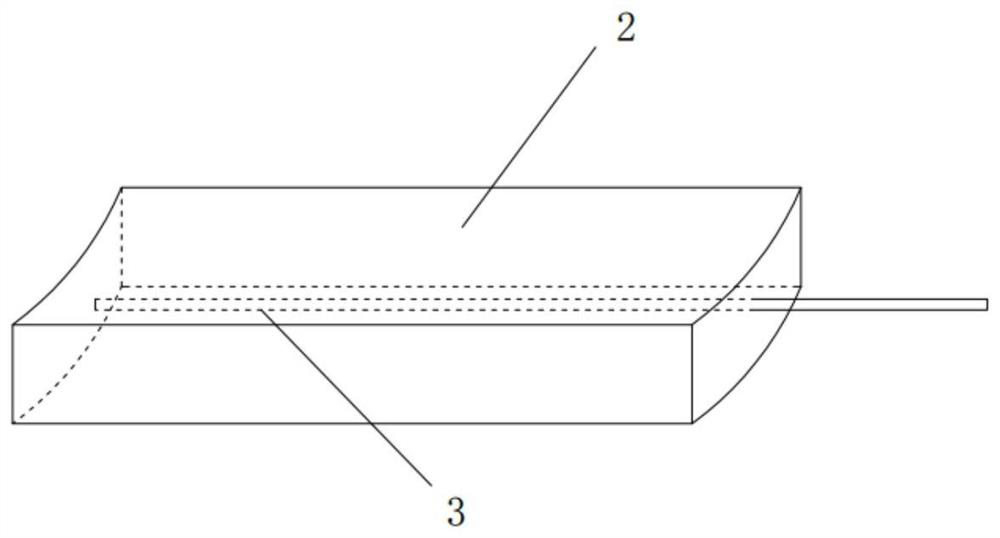

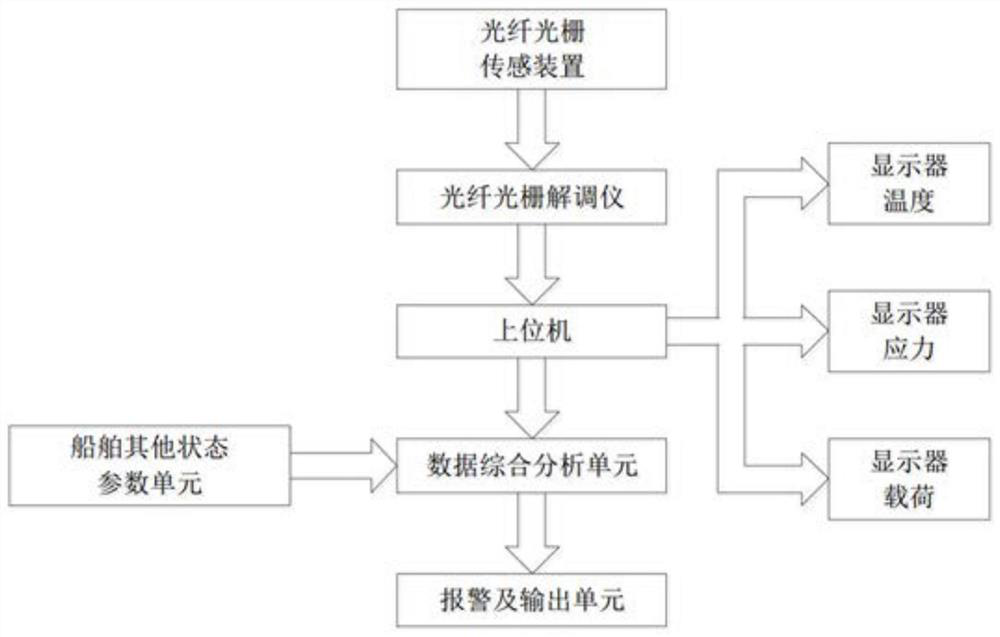

[0035] see figure 1 and figure 2 , the optical fiber grating sensor device used for the detection of the force state of the water-lubricated bearing, including a rubber bearing 1 composed of a plurality of rubber bearing strips 2, at least one rubber bearing strip 2 is embedded with an optical fiber grating sensing unit, the said The fiber grating sensing unit includes a capillary 3 axially embedded in the rubber bearing strip 2, an optical fiber 4 encapsulated in the capillary 3, and a filler 6 filled between the capillary 3 and the optical fiber 4; the optical fiber 4 A plurality of gratings 5 are arranged on it, and the gratings 5 are uniform fiber Bragg gratings.

[0036] Preferably, two parallel optical fibers 4 are packaged in the capillary 3, and a plurality of gratings 5 are arranged at different axial positions on each optical fiber 4 to form a grating st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com