Metal surface crack monitoring based on RFID antenna sensor

A metal surface and sensor technology, applied in the direction of instruments, measuring devices, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 Working principle of microstrip antenna sensor

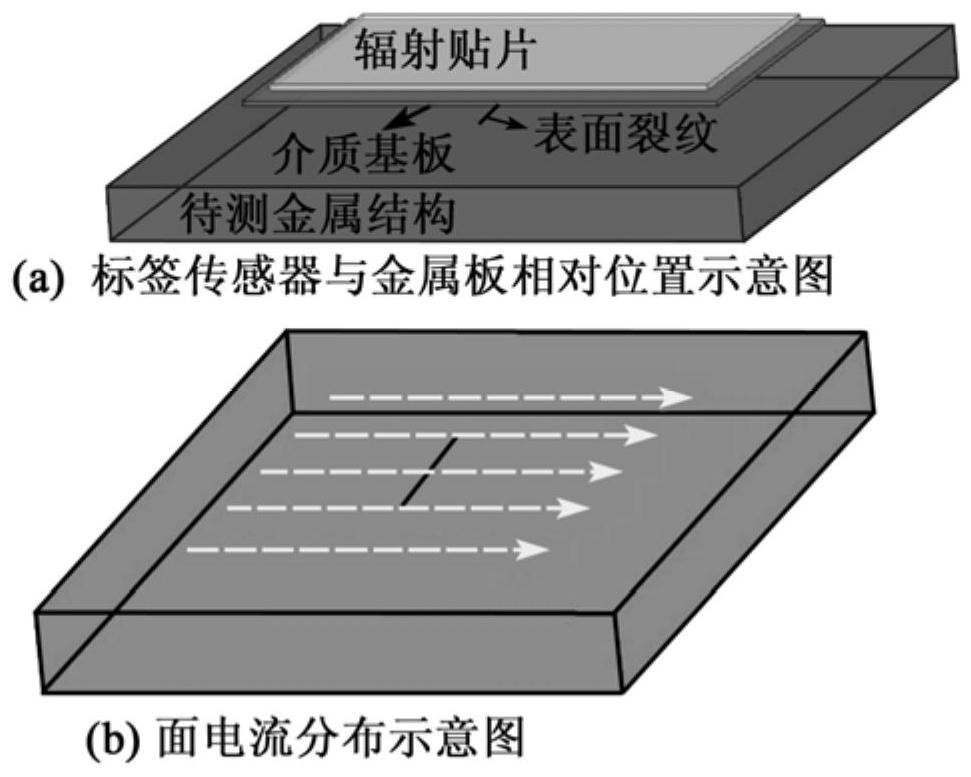

[0020] When the tag sensor is placed on the surface of the metal structure to work, the metal structure to be tested becomes the new grounding plate of the tag, and its surface will form an induction surface current parallel to the polarization direction of the tag, and distribute it on the lower surface of the tag radiation patch and the metal structure on flat surface. In this paper, the direction of the label surface current is perpendicular to the surface crack and parallel to the length direction of the label sensor, such as figure 1 shown.

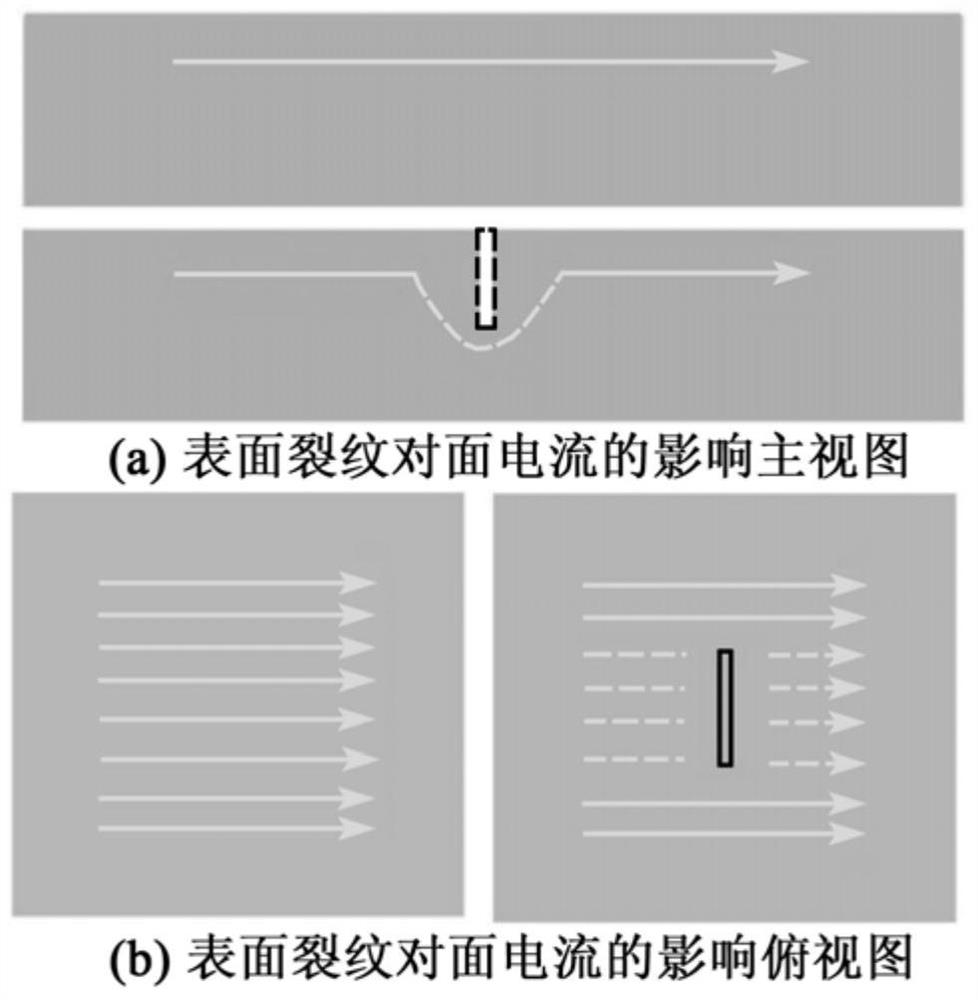

[0021] When surface cracks appear on the metal structure, the surface current passes through the concave part of the surface crack, and the surface current path length of the metal structure to be tested will increase with the increase of the surface crack depth. In addition, as the length of the surface crack increases, the proportion of the concave part passing ...

Embodiment 2

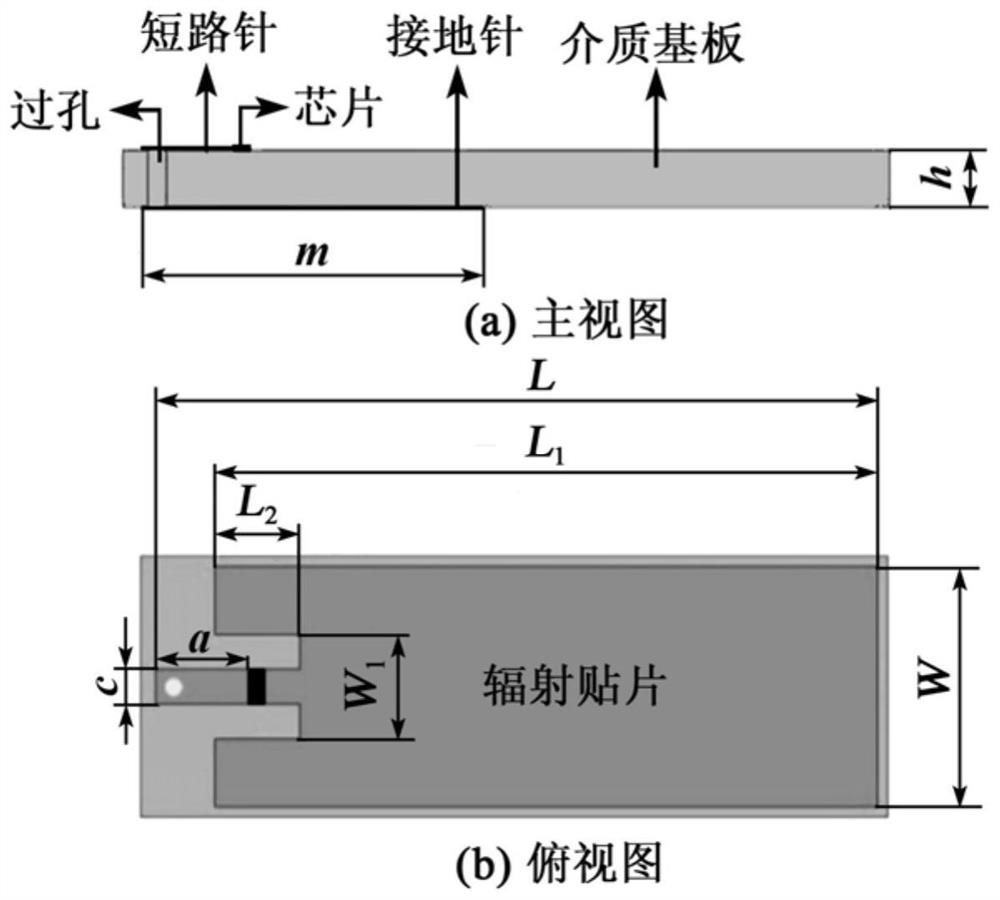

[0026] The structural composition of embodiment 2 microstrip antenna sensor

[0027] RFID-based label sensors are mainly composed of dielectric substrates, radiation patches and chips, such as image 3 shown. The radiation patch and the grounding plate are etched on the RF4 substrate with a relative permittivity of 4.4, and connected through a short-circuit pin; the label chip is Alien Higgs-3, and when the operating frequency is 915MHz, the input impedance Zchip=(27+j201)Ω , the right end of the chip is connected to the radiation patch, and the left end is connected to the transmission line. The specific dimensions of the label sensor are shown in Table 1. Compared with traditional fragile crack sensing tags, the sensor has the characteristics of realizing crack sensing without changing the physical structure of the tag, so the sensing tag can be reused, reducing the number of sensing units in the crack monitoring process. loss.

[0028] Table 1 Microstrip antenna sensor ...

Embodiment 3

[0035] Embodiment 3 Metal Surface Crack Monitoring Method Based on RFID Antenna Sensor

[0036] The main chemical composition of 5A06 aluminum alloy is selected as shown in Table 2. Its tensile strength is 315MPa and yield strength is 155MPa. The sample is processed according to GB / T228.1-2010 "Metal Tensile Test Method". At its center, a semi-elliptical surface defect is machined by EDM as a prefabricated crack. Sample size such as Figure 4 shown.

[0037] Table 2 Chemical composition of 5A06 aluminum alloy

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com