A fiber grating sensor packaging device and method

A fiber grating and packaging device technology, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, measuring devices, etc., can solve the problems of the influence of fiber grating sensor values and the inability to continuously control external forces, etc., to ensure stable and good performance Consistency, Avoiding Fiber Bragg Grating Chirp and Waveform Distortion, Effect of Avoiding Chirp and Waveform Distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

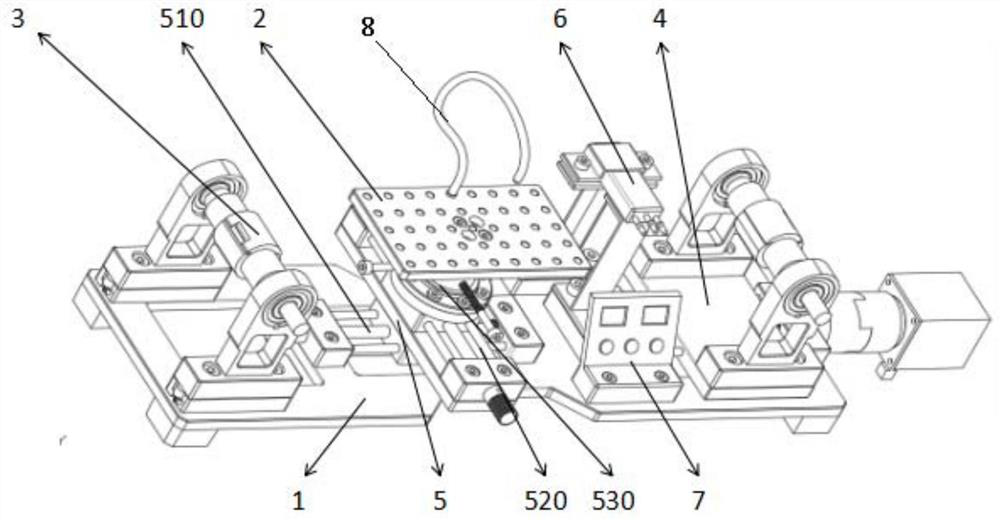

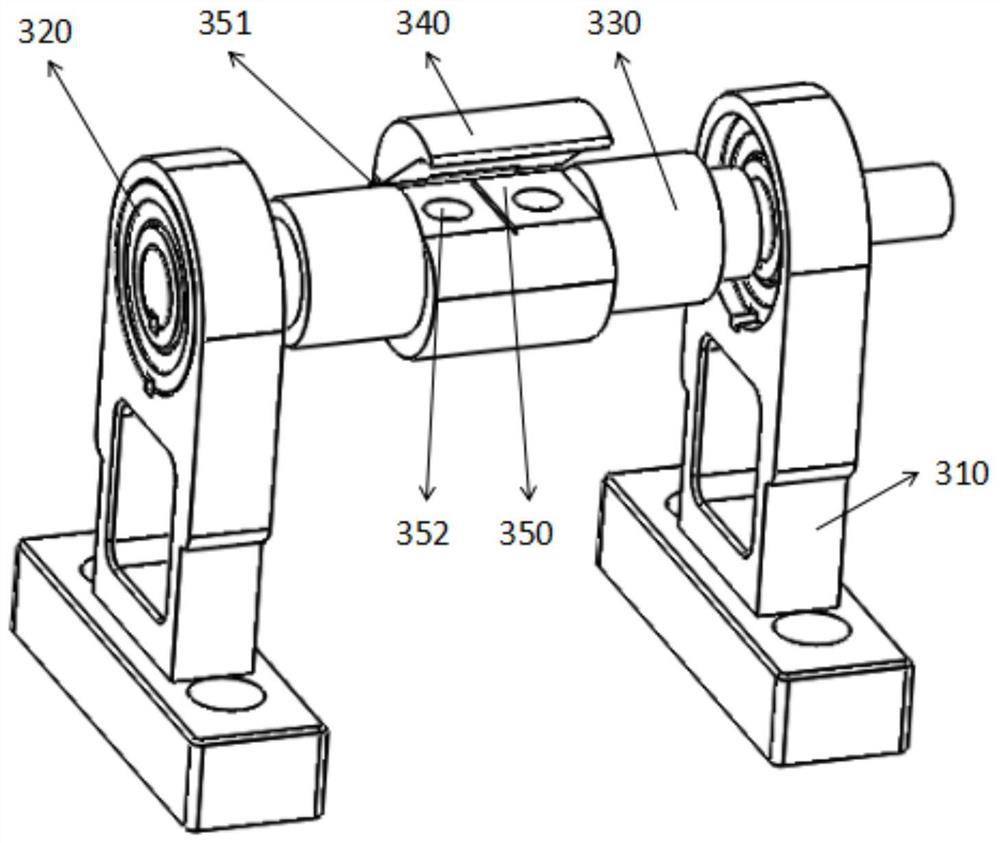

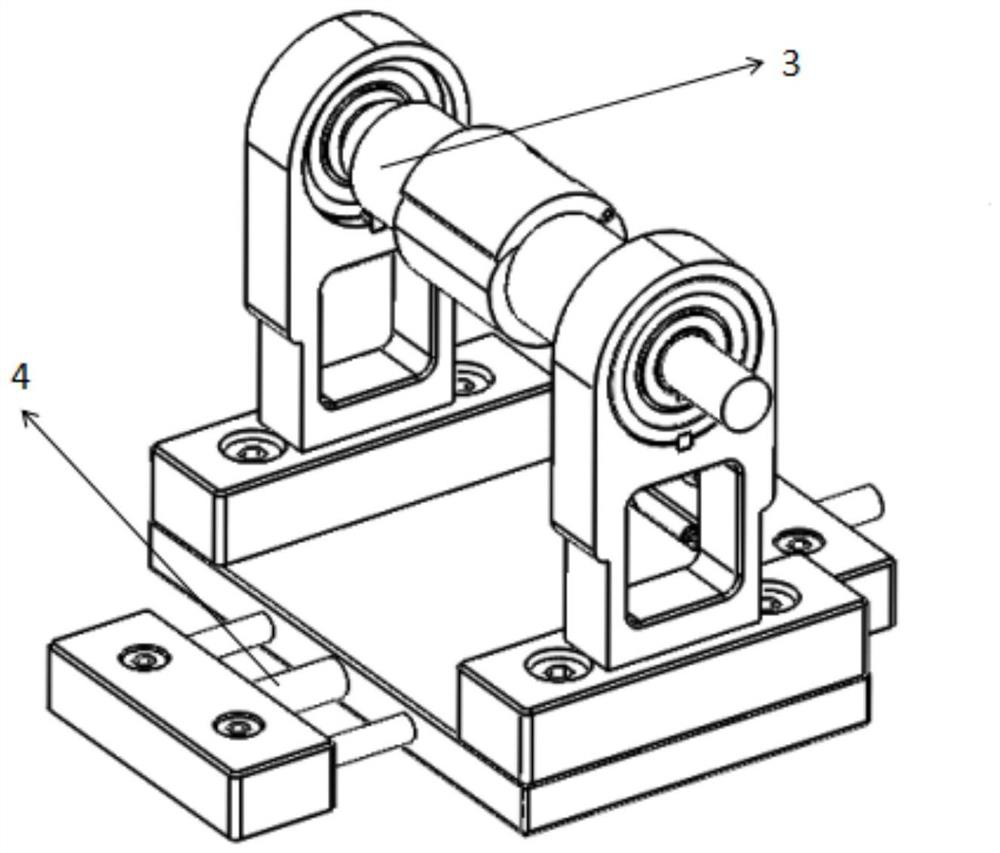

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a fiber grating sensor packaging device includes a base 1, a workbench 2, a heating device, a glue coating device, two optical fiber clamping mechanisms 3 and a prestress adjustment device 4, and the prestress adjustment device 4 is arranged on the base 1 , one of the two fiber clamping mechanisms 3 is set on the output end of the prestress adjusting device 4, the other is set on the base 1, and the fiber clamping mechanism 3 set on the output end of the prestress adjusting device 4 passes the prestress The function of the adjusting device 4 is to adjust the distance between it (the optical fiber clamping mechanism arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com