Fiber grating vibration sensor

A technology of vibration sensor and optical fiber grating, which is applied to instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of high fatigue life, achieve the effects of improving fatigue life, avoiding chirp, and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, structure and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

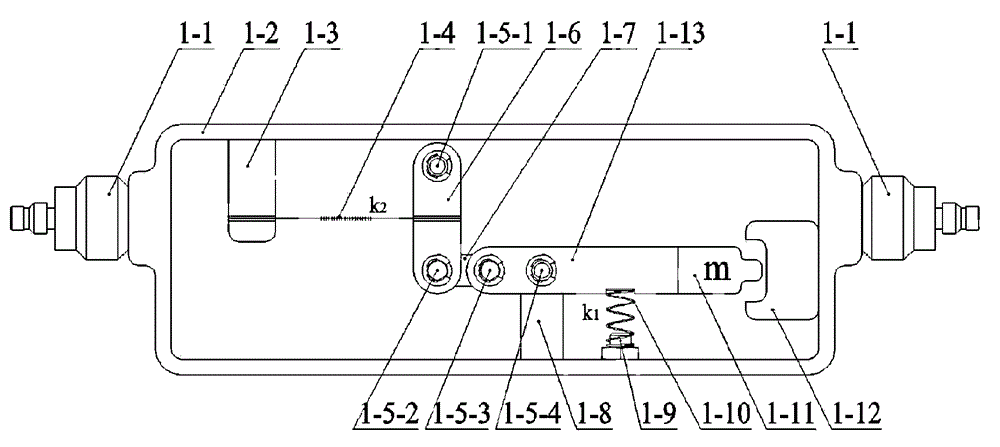

[0029] refer to figure 1 , according to one embodiment of the present invention, the fiber grating vibration sensor includes:

[0030] Support shell 1-2;

[0031] The link mechanism is located in the support housing 1-2, and the link mechanism includes a first link 1-6, a second link 1-7, a third link 1-13, a first fixed shaft 1 -5-1. The first movable shaft 1-5-2, the second movable shaft 1-5-3, and the second fixed shaft 1-5-4; wherein, the first fixed shaft 1-5-1, The rotation axis directions of the first movable rotating shaft 1-5-2, the second movable rotating shaft 1-5-3, and the second fixed rotating shaft 1-5-4 are parallel to each other and perpendicular to the length direction of the strained fiber grating 1-4; The first fixed rotating shaft 1-5-1 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com