Torque sensor device based on fiber gratings

A technology of torque sensor and optical fiber grating, which is applied in the direction of measuring devices, instruments, torque measurement, etc., can solve problems affecting the stability and accuracy of measurement, measurement signal fluctuations, instability, etc., and achieve simple and easy measurement, overall High sensitivity and the effect of avoiding chirp phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

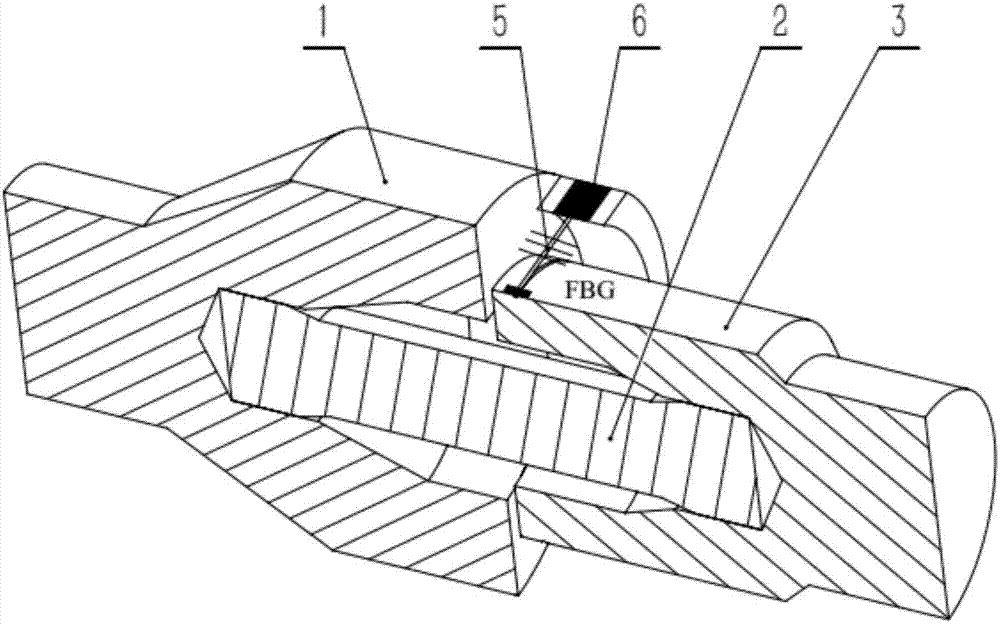

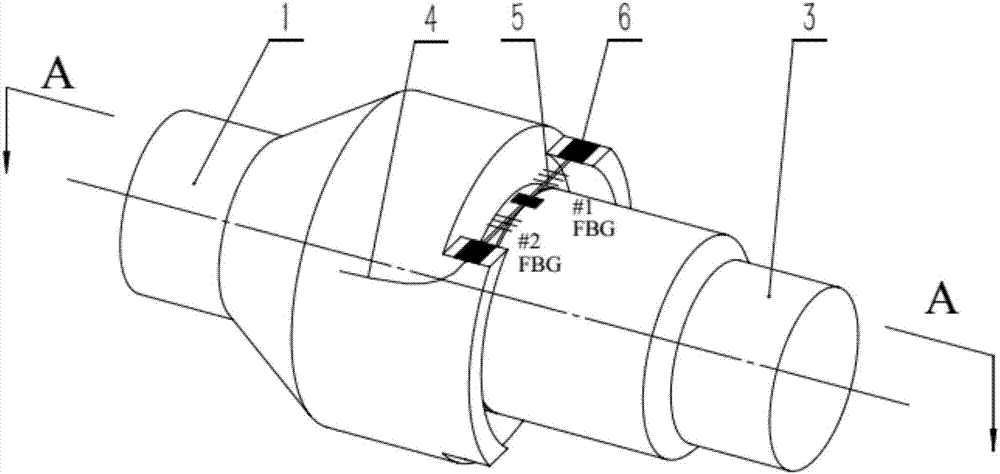

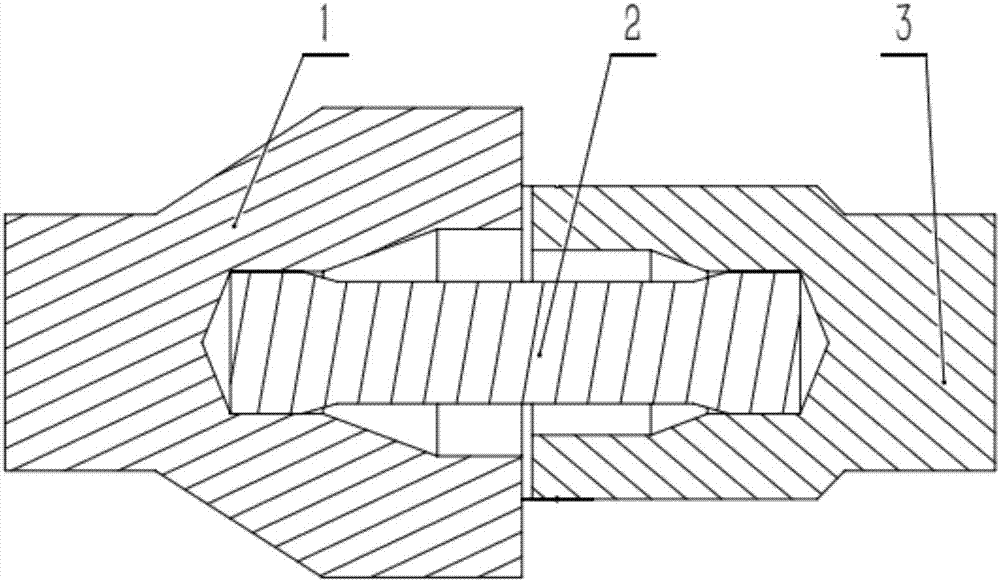

[0018] Such as Figure 1 to Figure 3 As shown, a torque sensor device based on a fiber grating 5 includes a fiber grating 5 and a coaxial input shaft 1, torsion bar 2 and output shaft 3, and the two ends of the torsion bar 2 are respectively connected to the input shaft 1 and the The output shaft 3 is connected. One end of the input shaft 1 is provided with a partial ring-shaped protrusion that is symmetrical about the axis. The outer surface of the output shaft 3 is provided with a groove. The optical fiber is tensioned in a straight line and is tangent to the output shaft 3. It is fixed on part of the ring-shaped protrusion by glue 6, and fixed on the groove by glue 6 in the middle. There are two suspended gratings evenly distributed between the three fiber fixing points. The pigtail 4 is close to and along the input axis 1. Lead out from the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com