Exhaust gear applied to automotive hydraulic braking system and control method

A technology of hydraulic brake and exhaust device, which is applied in the direction of brake safety system, brake transmission device, fluid pressure actuation device, etc., and can solve the problems of inability to complete the brake system pipeline inspection, complex structure, and high cost. Achieve the effect of simple structure, simple processing technology and small quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention is described in detail below in conjunction with accompanying drawing:

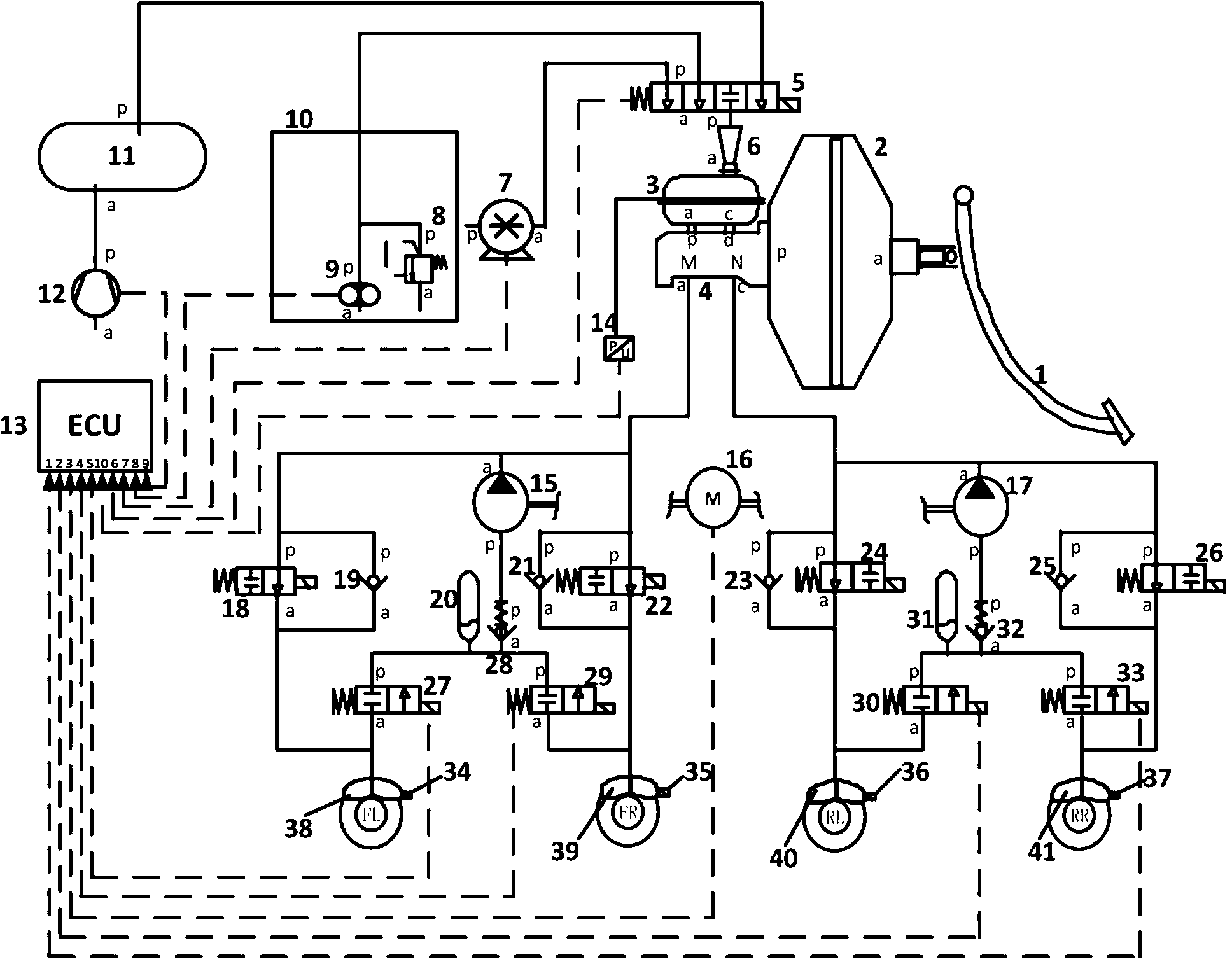

[0063] refer to figure 1 , the exhaust device applied to the automobile hydraulic braking system according to the present invention is mainly composed of a brake operating mechanism, exhaust filling equipment, a hydraulic adjustment unit, a brake actuator, an exhaust controller ECU13 and a pressure sensor 14.

[0064] The brake operating mechanism of the present invention includes a brake pedal 1 , a vacuum booster 2 , an oil pot 3 , and a brake master cylinder 4 . The exhaust filling equipment includes a four-position two-way solenoid valve 5 , a filling gun 6 , a vacuum pump 7 , a pressure limiting valve 8 , an oil pump 9 , an oil storage tank 10 , an air pressure tank 11 and an air compressor 12 .

[0065] The filling gun 6 is composed of a sealing joint, a vent valve and a gun body pipeline, and the sealing joint mainly ensures the sealing connection between the mouth of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com