Optical-fiber grating sensor detecting pressure temperature simultaneously

A fiber grating and sensor technology, applied in the field of fiber grating sensors, achieves the effects of good safety, avoiding chirp phenomenon, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The measurement principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

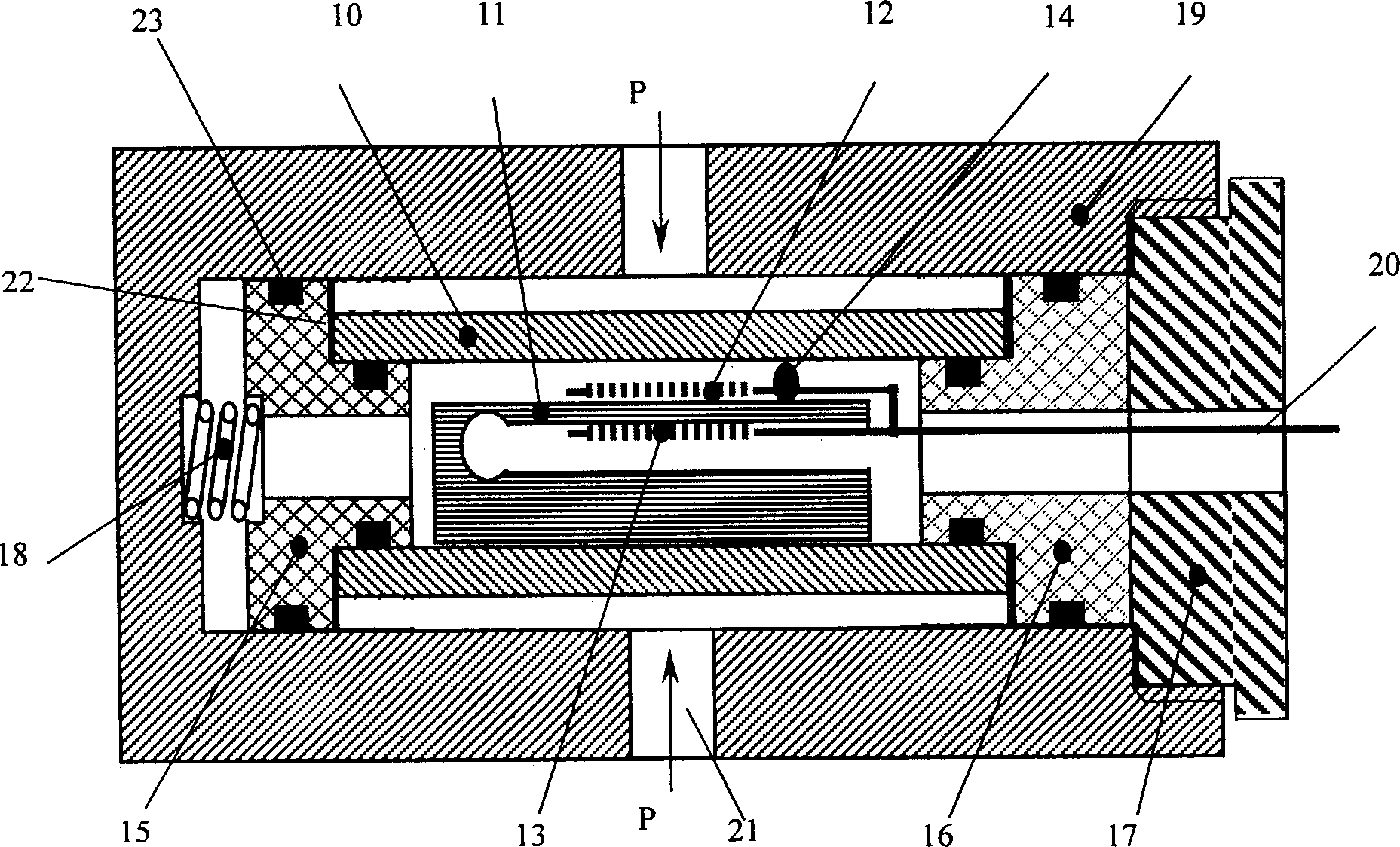

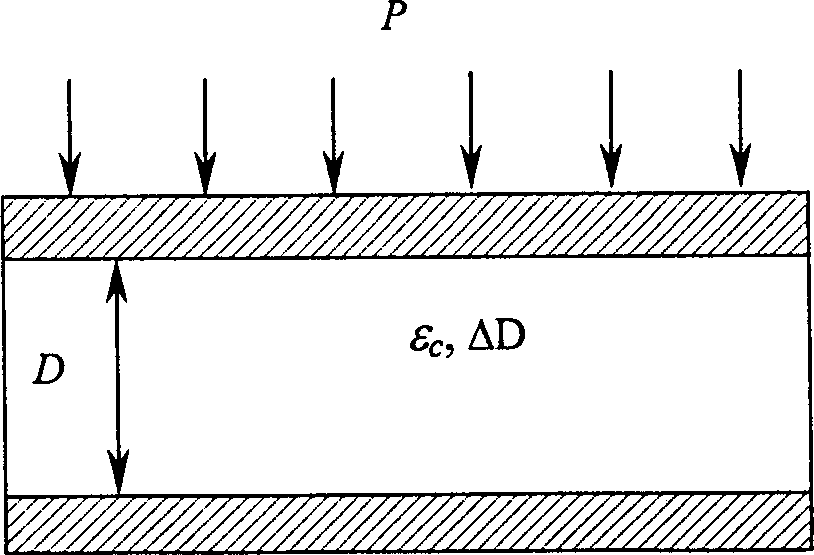

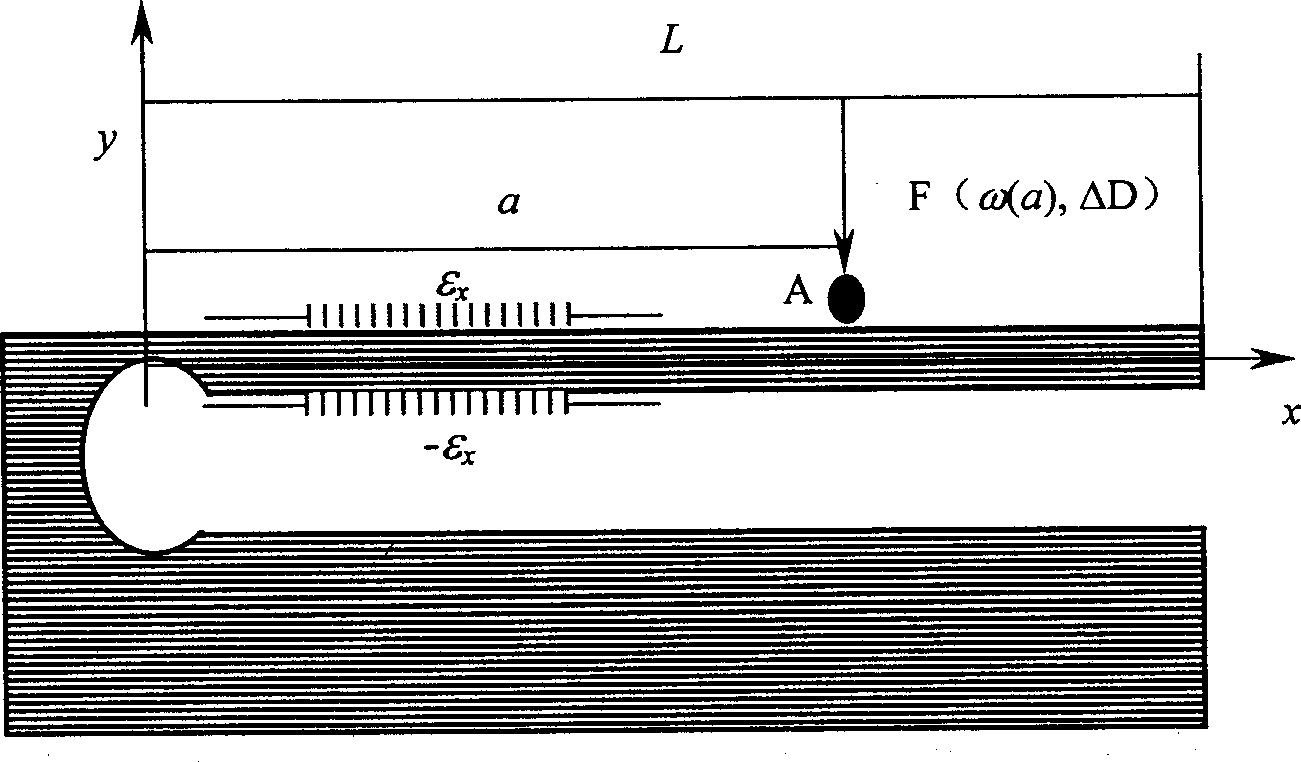

[0023] figure 1 It is a structural schematic diagram of the sensor of the present invention. The sensor mainly includes a free elastic cylindrical pressure transducer 10, a cantilever beam mechanism 11 placed in the free elastic cylindrical pressure transducer, a transmission optical fiber 20, sealing mechanisms 15, 16, pre-tension spring 18, belt There is an outer protective shell 19 with a pressure inlet hole 21 and an end element 17 for positioning. The cantilever beam mechanism 11 adopts an isosceles triangle structure of equal thickness (such as image 3 , 4 As shown), two fiber gratings 12 and 13 are fixed respectively on the corresponding positions of the upper and lower surfaces of the cantilever beam 11. These two fiber gratings have the same parameters and performance, and are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com