Intelligent monitoring system of foamed cement component production line

An intelligent monitoring system and foamed cement technology, applied in cement mixing devices, control devices, clay preparation devices, etc., can solve the problems of no data processing and communication functions, long design cycle, large volume, etc., and achieve high proportioning accuracy , Improve production efficiency and maintain good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

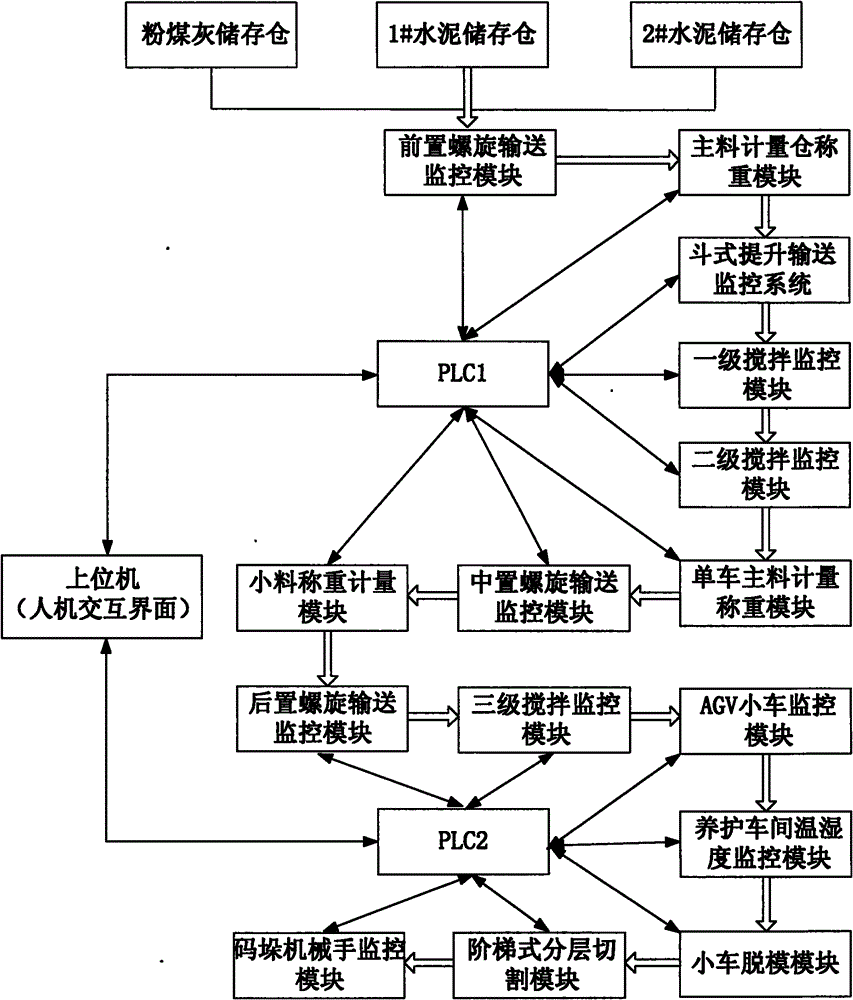

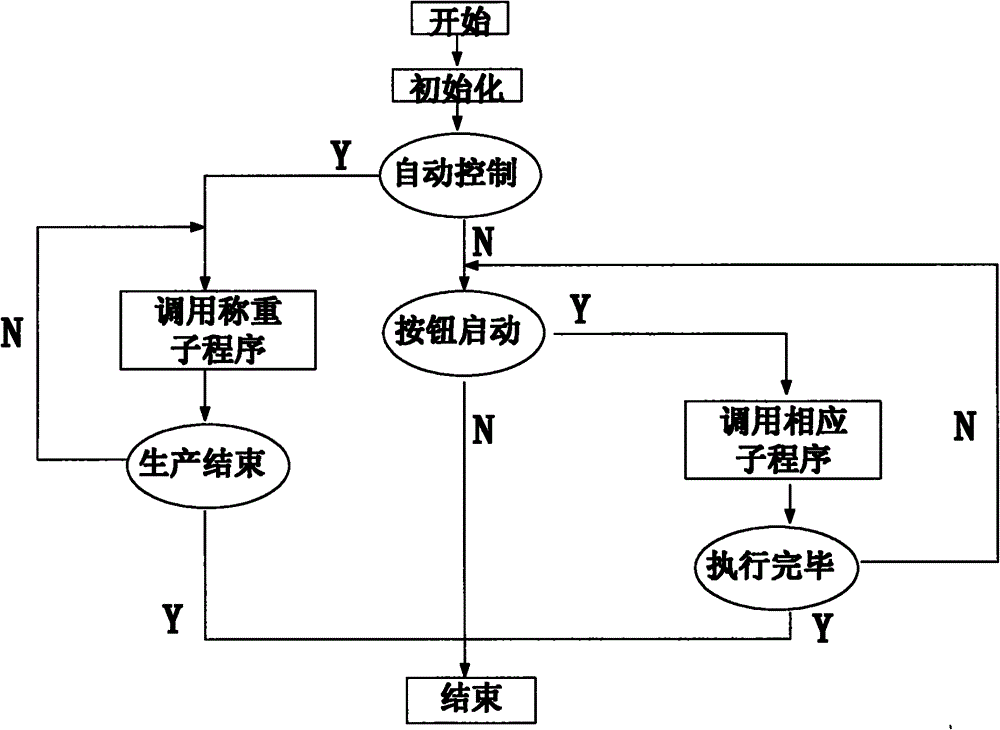

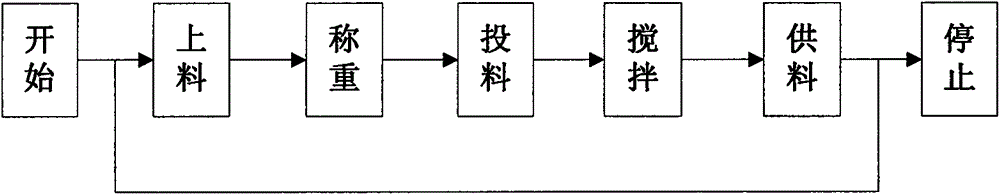

[0011] The PLC of this system is connected with the upper computer through the communication module, and the PLC sends instructions to the front screw conveying monitoring module, and the main material is loaded to the main material metering warehouse through the front screw conveyor. After the weighing and metering module measures the main material, when After the measured weight is reached, the weighing module sends a feedback signal to the PLC to stop feeding; then the PLC sends an instruction to the central screw conveying monitoring module to feed the material to the first-stage mixing tank, and the stirring monitoring module controls the first-stage mixing. After the mixing monitoring module controls the secondary mixing, the butterfly valve is opened to feed the material to the storage bin, and the PLC sends instructions to the rear screw conveying module to deliver to the third-level mixing and metering bin for single-vehicle metering. After weighing, stop feeding. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com