Aero-engine labyrinth disc hot list processing thickness information extraction system

An aero-engine and information extraction technology, applied in the field of inspection, can solve problems such as rapid detection and evaluation of the coating surface of the grate tooth disc, hidden dangers, and product quality, and achieve the effect of eliminating various hidden dangers, improving efficiency, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

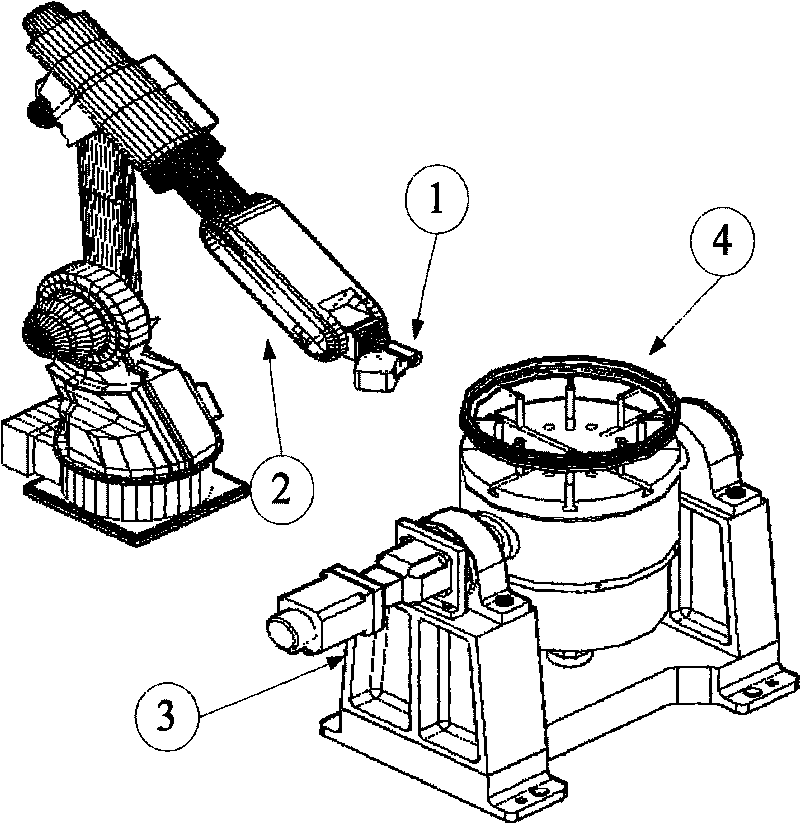

[0016] The present invention mainly comprises following three parts:

[0017] (1) Use an industrial robot and a non-contact laser scanning head to scan the three-dimensional surface of the grate plate of the aircraft engine to be sprayed.

[0018] (2) Scan the grate plate after spraying again

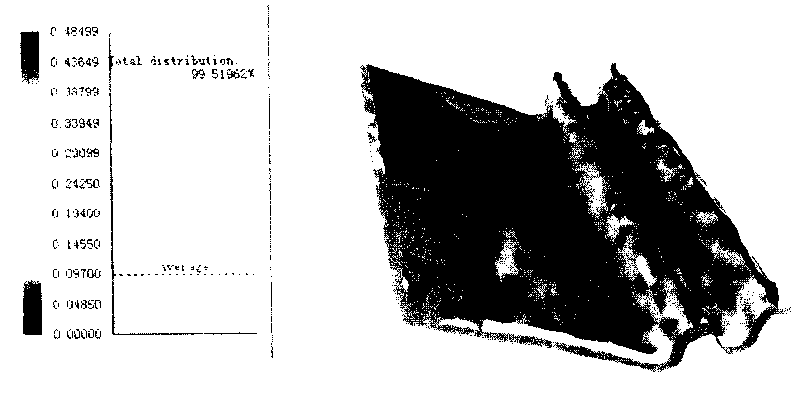

[0019] (3) Subtracting the two scanning data along the spraying direction to obtain the coating thickness information data of the spraying area.

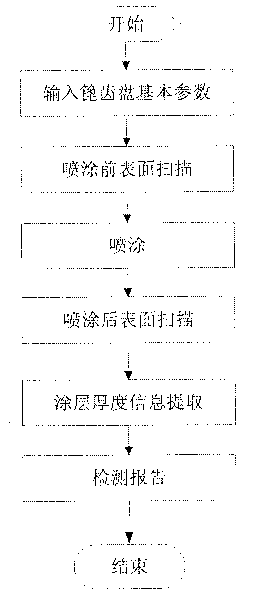

[0020] Combining the above two parts, the coating thickness detection process of a typical grate disc is introduced in detail below:

[0021] Step 1: Enter the basic parameters of the grate plate

[0022] Size: 30×20×12cm 3 ,

[0023] Material: carbon steel

[0024] Surface roughness: ≤0.5%.

[0025] Step 2: Surface scan before painting

[0026] The industrial robot drives the laser scanning head to scan the three-dimensional surface of the grate plate to be sprayed to generate three-dimensional data before spraying.

[0027] Step 3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com