Preparation method and application of carbon-based carbon dioxide adsorbent

A technology for carbon dioxide and carbon dioxide adsorption, applied in chemical instruments and methods, separation methods, other chemical processes, etc., to achieve excellent adsorption performance and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

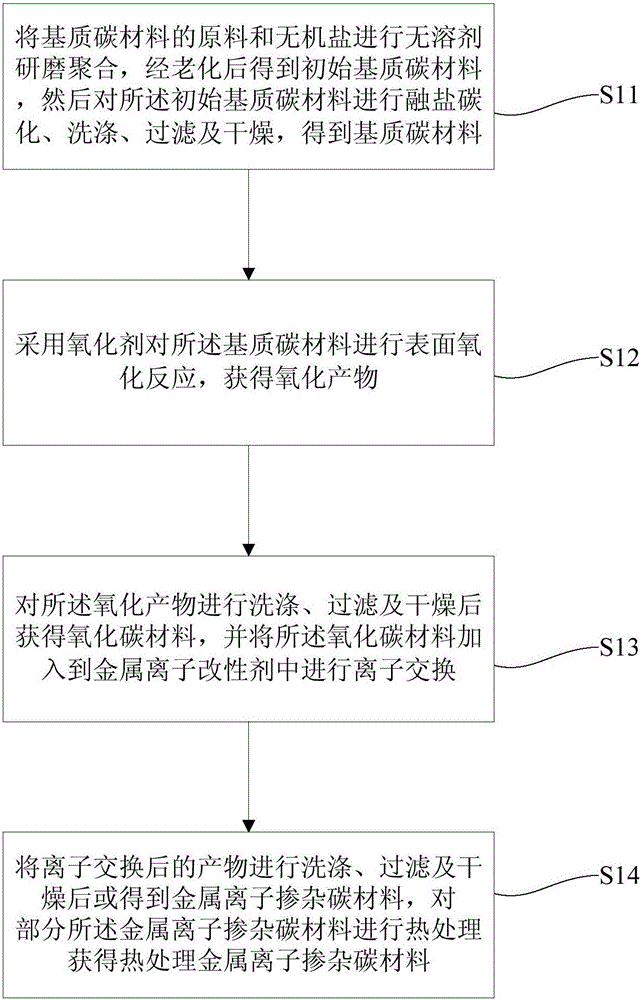

[0037] like figure 1 As shown, the present embodiment provides a preparation method of a carbon-based carbon dioxide adsorbent, the preparation method comprising steps:

[0038] Step 1) S11, carrying out solvent-free grinding and polymerization of the raw material of the matrix carbon material and the inorganic salt, and obtaining the initial matrix carbon material after aging, and then performing molten salt carbonization, washing, filtering and drying on the initial matrix carbon material to obtain the matrix carbon materials;

[0039] Step 2) S12, using an oxidant to perform a surface oxidation reaction on the matrix carbon material to obtain an oxidation product;

[0040] Step 3) S13, washing, filtering and drying the oxidized product to obtain a carbon oxide material, and adding the carbon oxide material to a metal ion modifier for ion exchange;

[0041] Step 4) S14, washing, filtering and drying the ion-exchanged product or obtaining a metal ion-doped carbon material, ...

Embodiment 2

[0052] This embodiment provides a method for preparing a carbon-based carbon dioxide adsorbent, the preparation method comprising steps:

[0053] Step 1), weigh 0.88g resorcinol, 1.07g terephthalaldehyde and 9.75g zinc chloride and grind them fully in a mortar. The temperature is 5°C / min, and the holding time is 5h. The carbonized product was stirred in an excess of 1 mol / L dilute hydrochloric acid for 24 hours, then washed with deionized water to neutral filter and dried at 100° C. for 8 hours to obtain a matrix carbon material.

[0054] Step 2), add 120mL of concentrated nitric acid into a three-necked flask, then add 3g of matrix carbon material, oxidize vigorously at 90°C for 8 hours, then wash with deionized water until neutral, filter and dry at 100°C for 8 hours to obtain carbon dioxide material.

[0055] Step 3), weigh 1g of carbon oxide material and add it to 200mL NaOH aqueous solution with a concentration of 2mol / L and stir for 8 hours, then wash with deionized wa...

Embodiment 3

[0058] This embodiment provides a method for preparing a carbon-based carbon dioxide adsorbent, the preparation method comprising steps:

[0059] Step 1), take by weighing 0.48g urea, 1.07g terephthalaldehyde, 4g potassium nitrate and 6g sodium nitrate and carry out thorough grinding in mortar, the product obtained carries out molten salt carbonization, and the temperature of carbonization is 700 ℃, and heating rate is 5°C / min, holding time is 5h. The carbonized product was stirred in an excess of 1 mol / L dilute hydrochloric acid for 24 hours, then washed with deionized water to neutral filter and dried at 100° C. for 8 hours to obtain a matrix carbon material.

[0060] Step 2), add 120mL of hydrogen peroxide solution in a three-necked flask, then add 3g of matrix carbon material, oxidize at 25°C for 8 hours, then wash with deionized water until neutral, filter and dry at 100°C for 8 hours Obtain carbon dioxide material.

[0061] Step 3), weigh 1 g of carbon oxide material a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com