Switching device and inflating device for free piston shock tunnel compression pipe

A technology of shock tunnel and transfer device, which is applied in the direction of measurement device, pipe/pipe joint/pipe fitting, connection with fluid cut-off device, etc., can solve the problems affecting the flow field of the wind tunnel, etc. High vacuum suction is difficult, and the effect of meeting the needs of various operating states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

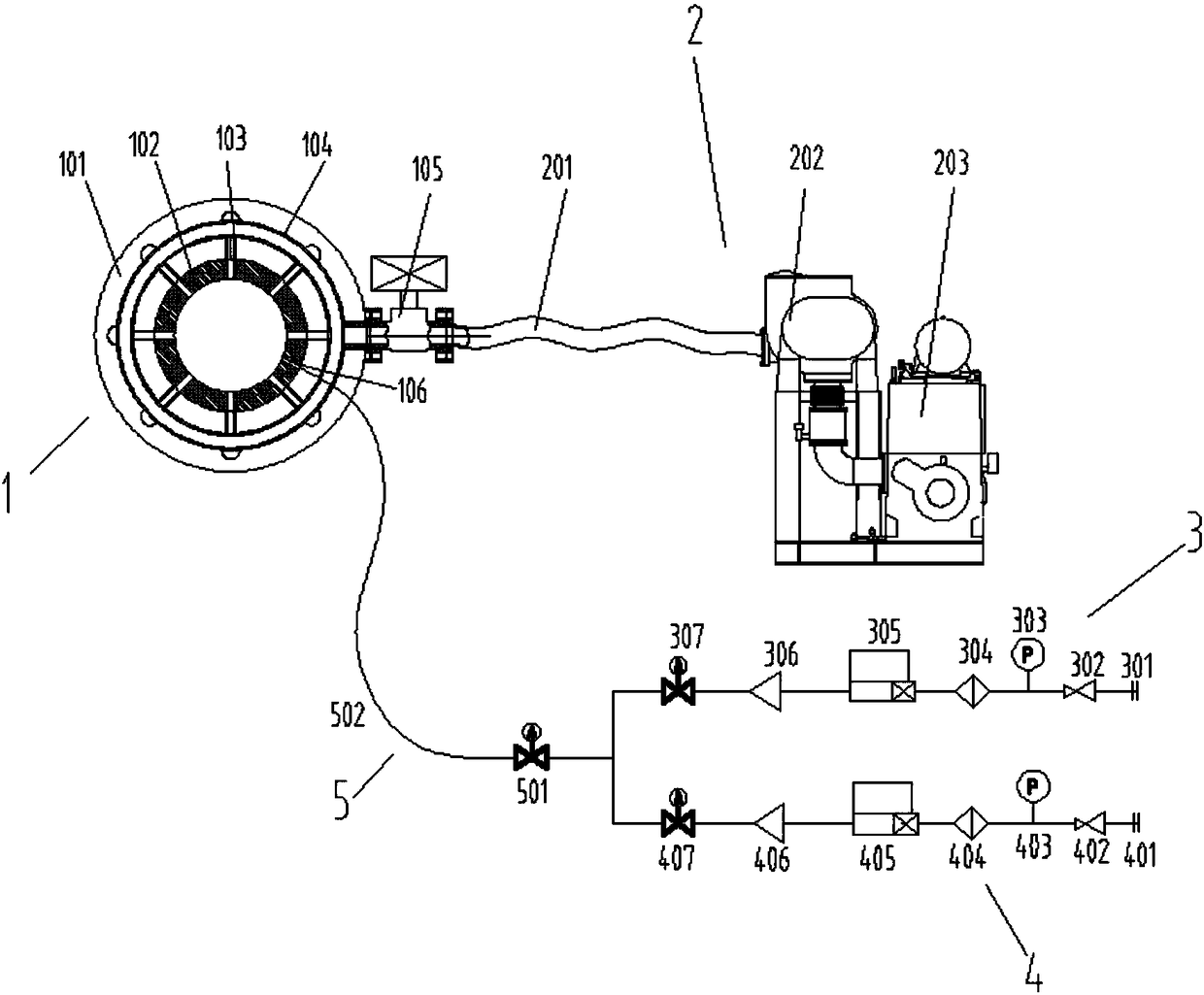

[0055] A compression tube inflation device adapting to various operating states of a free piston shock tunnel such as figure 1 As shown, it consists of an adapter device 1, a vacuum system 2, a helium filling branch 3, an argon filling branch 4, and a summary gas path 5.

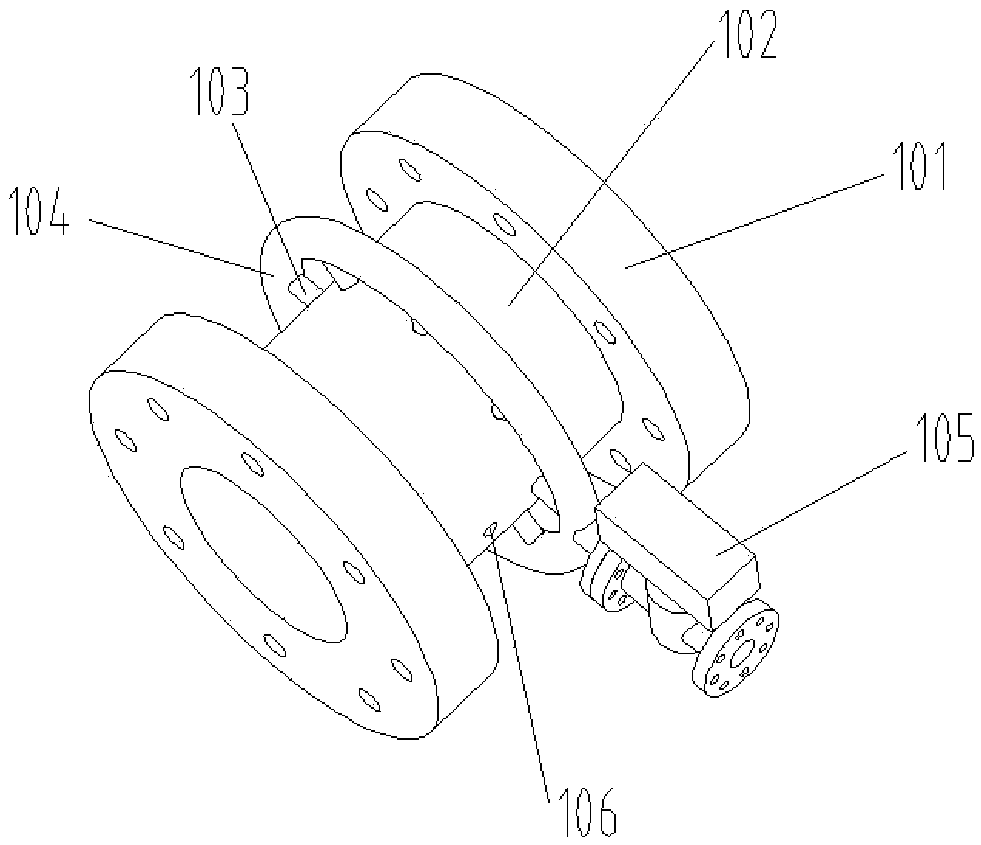

[0056] Such as figure 1 , figure 2 As shown, the adapter device 1 includes a flange 101, a pipe body 102, a suction column 103, a suction ring 104, and a first high-pressure pneumatic valve 105, and an air charging port 106 is provided on the pipe body. The suction column 103 is connected to the pipe body by welding, and then connected to the suction ring 104 by welding, and the suction ring 104 is connected to the first high-pressure pneumatic valve 105 through a flange. This structure improves the flow conductance of the vacuum suction pipeline, so that the compression tube can be sucked to a lower vacuum before helium and argon are inflated, ensuring the purity of the gas in the compression tube. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com