Patents

Literature

38results about How to "Increased scale accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

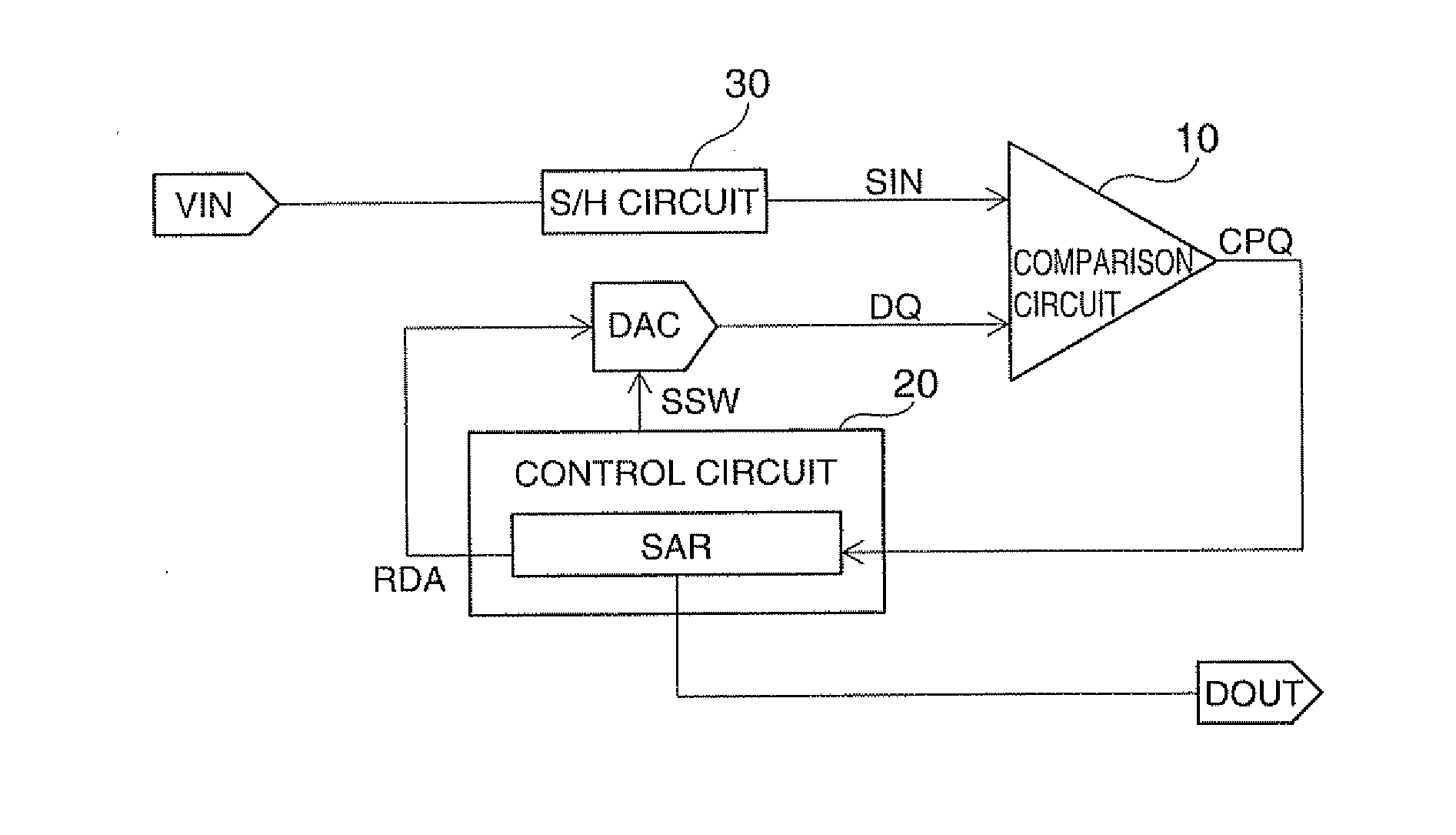

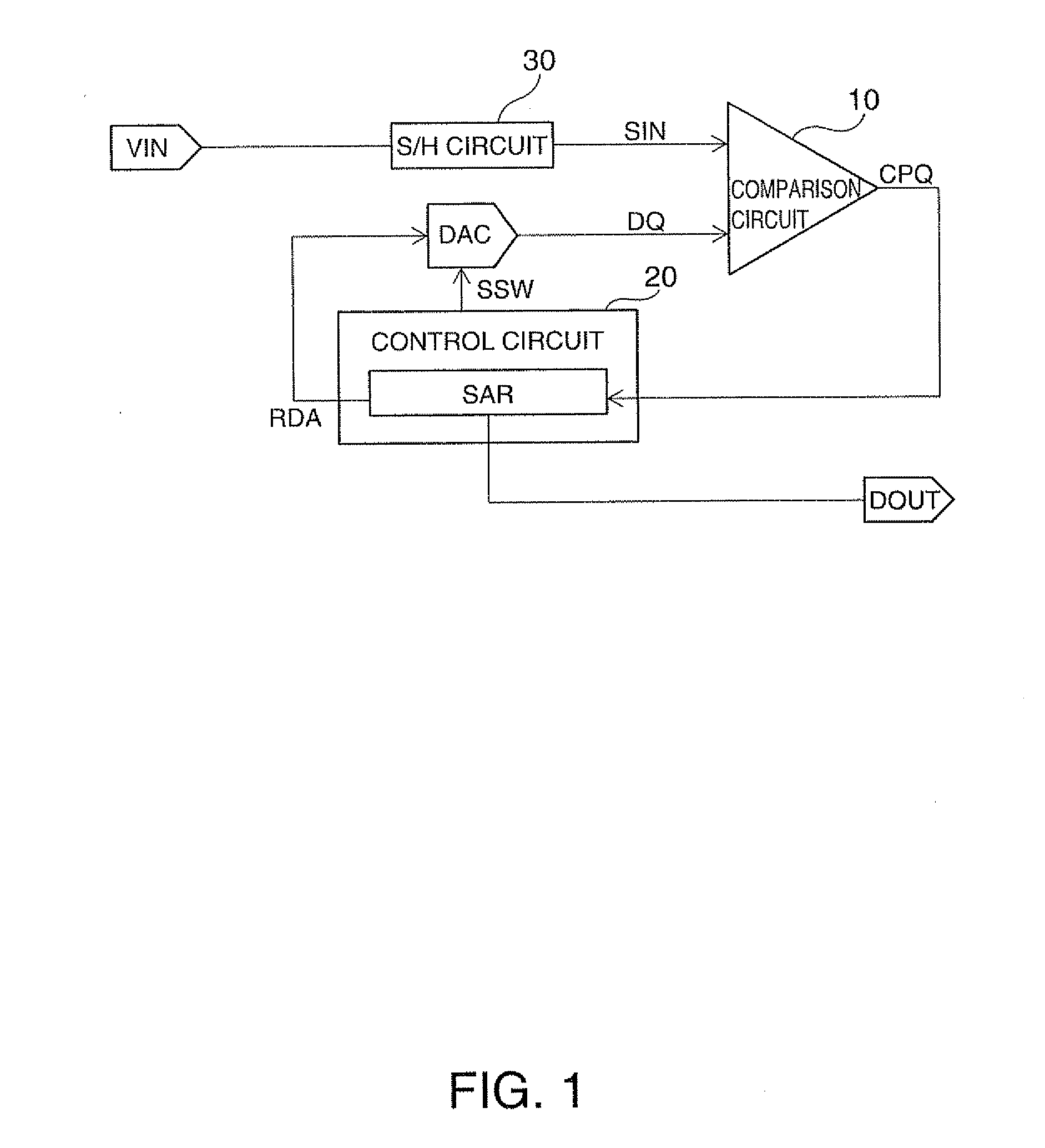

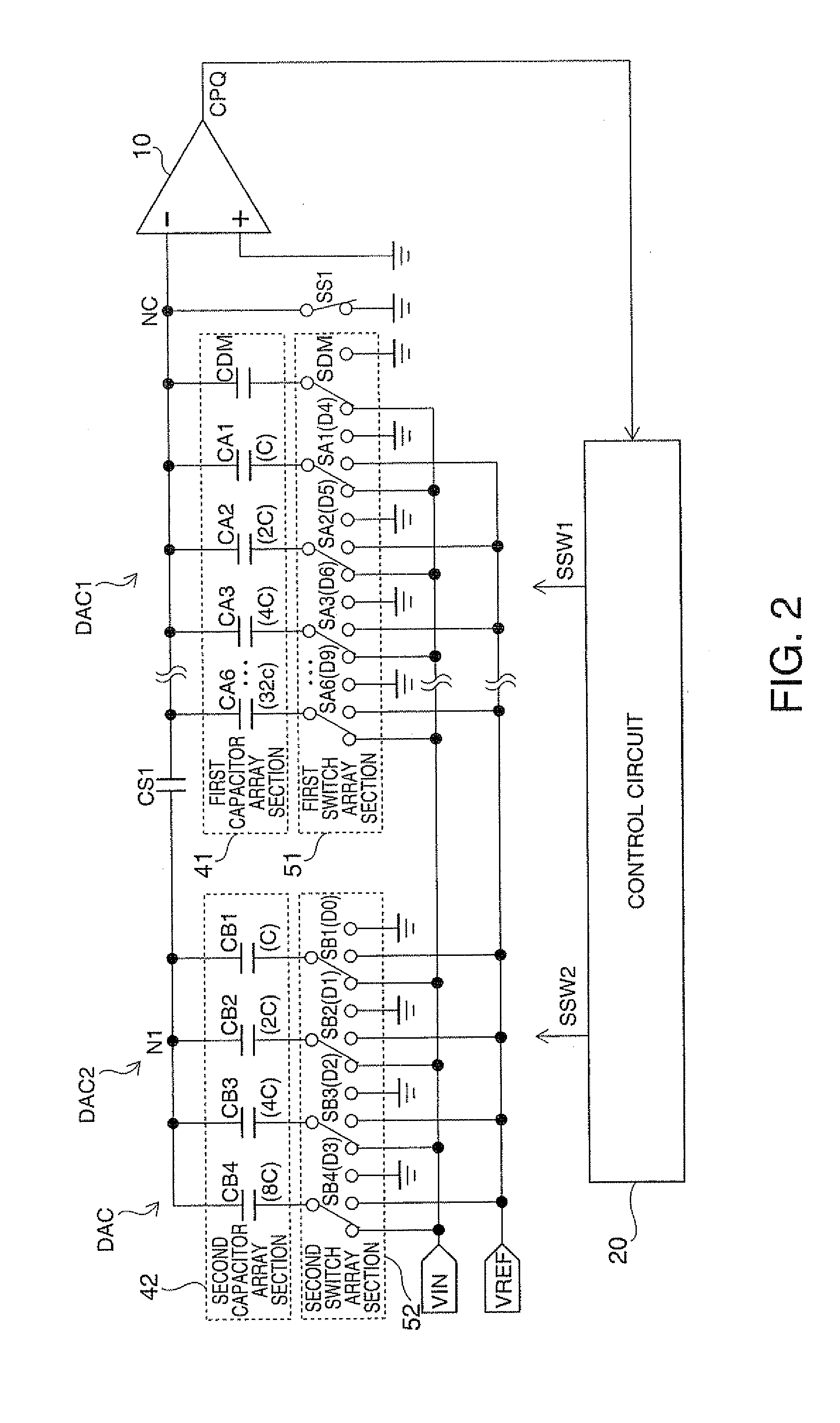

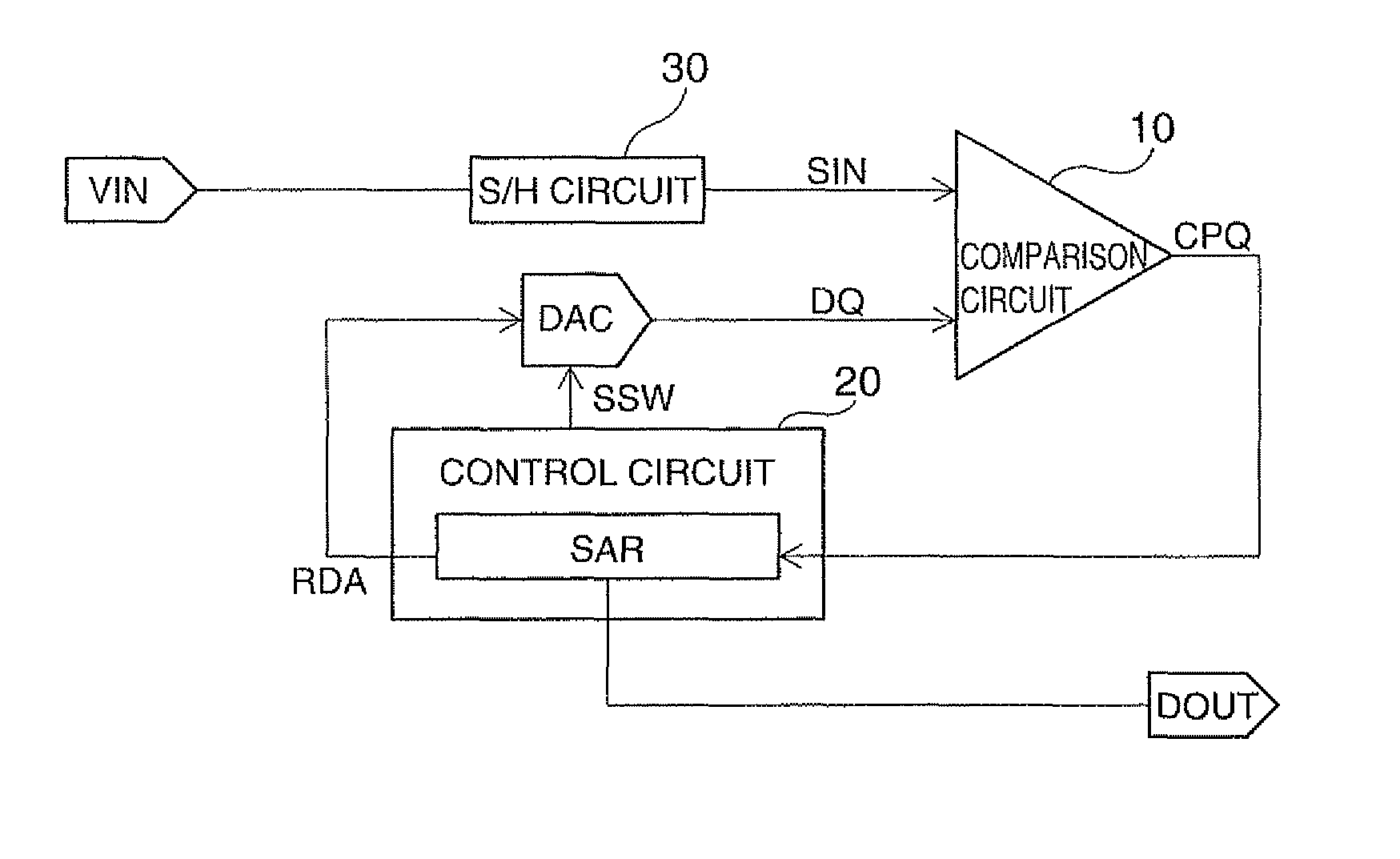

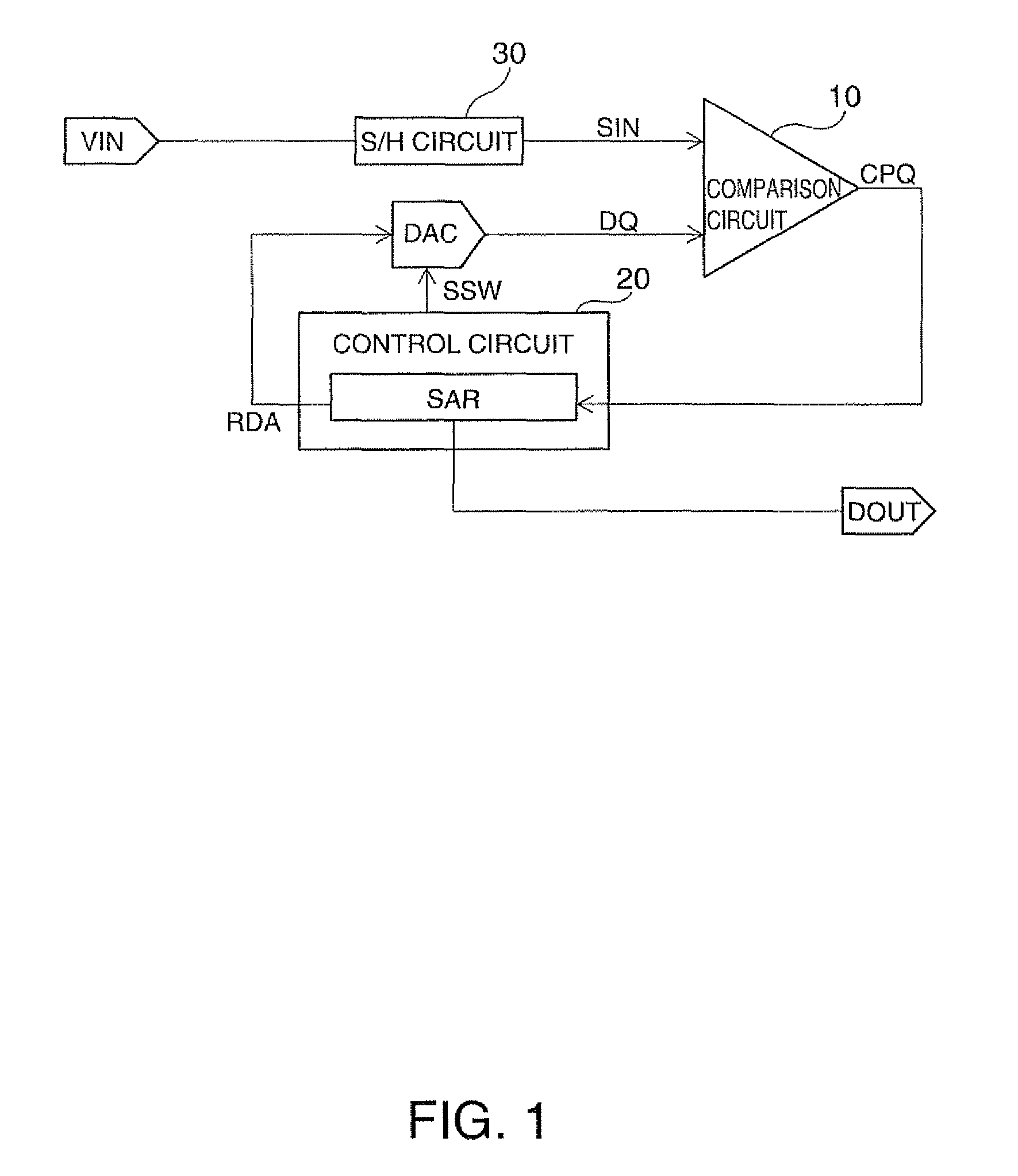

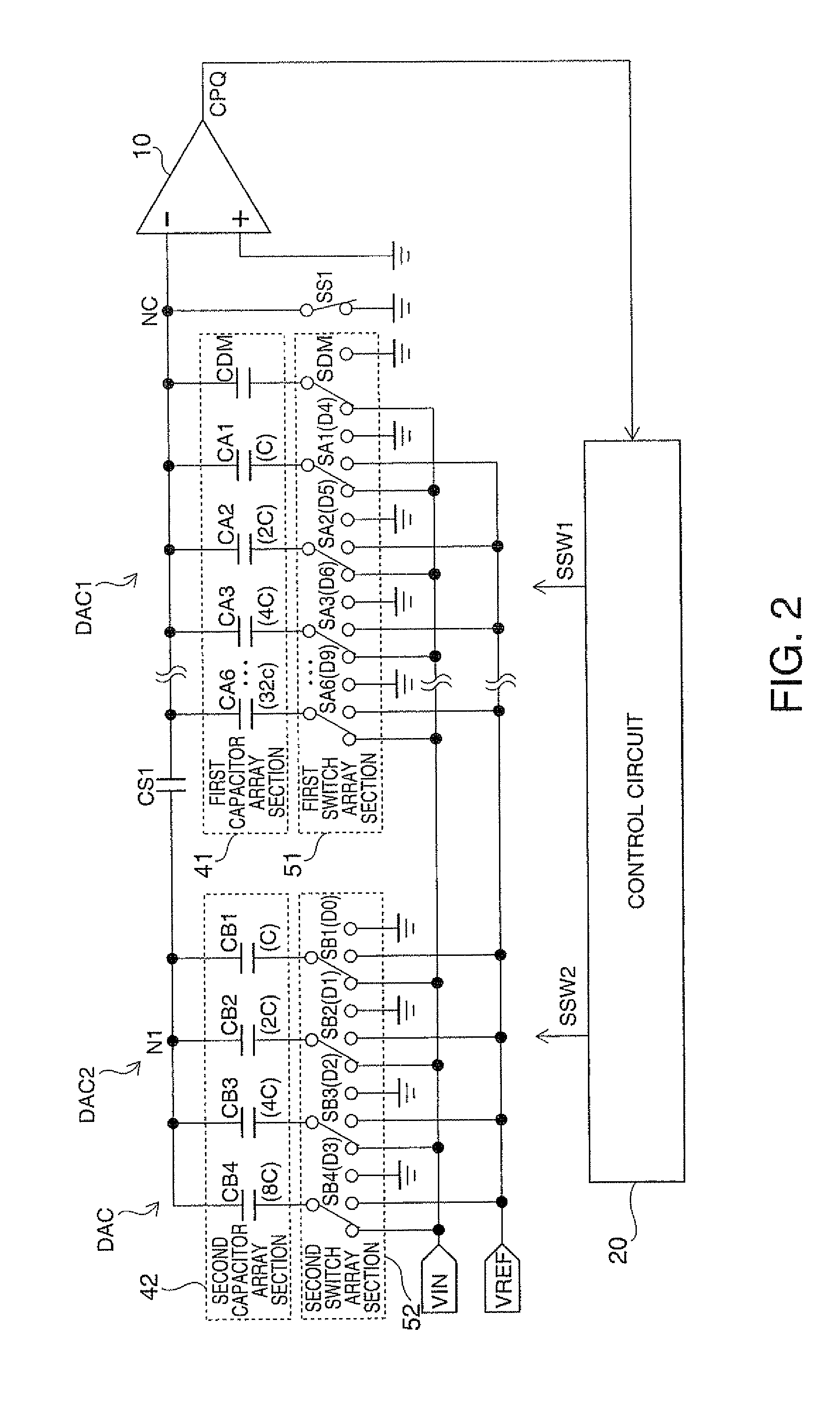

D/a conversion circuit, a/d conversion circuit and electronic apparatus

ActiveUS20120212357A1Enhancing apparent capacitance ratio accuracyImprove conversion accuracyElectric signal transmission systemsAnalogue-digital convertersDigital dataControl circuit

A D / A conversion circuit includes a first D / A converting section which is connected with an output node, a first serial capacitor which is disposed between the output node and a first node, a second D / A converting section which is connected with the first node, and a control circuit. The first D / A converting section includes a first capacitor array section and a first switch array section. The second D / A converting section includes a second capacitor array section and a second switch array section. The control circuit performs a switch control for dynamically changing allocation of the capacitors to the respective bits of input digital data for the first switch array section of the first D / A converting section.

Owner:SEIKO EPSON CORP

Method for preparing copper indium gallium selenide film and photovoltaic film battery based on selenium plasma

InactiveCN101956164ALower the temperature of selenizationHigh material ratio accuracyFinal product manufactureVacuum evaporation coatingIonizationIndium

The invention discloses a method for preparing a copper indium gallium selenide film and a photovoltaic film battery based on a selenium plasma, comprising the following steps of: 1, ionizing work gas by an ion source to enable the work gas to be in a plasma state and providing the plasma in an evaporation source chamber; 2: evaporating a selenium material by using an electron gun to generate selenium stream in the evaporation source chamber; 3: enabling electron cloud generated by the work gas in the ionization process to mutually impact the selenium steam by connecting a crucible with positive bias to generate the selenium plasma; and 4. heating the plated substrate to the preset selenizing temperature and respectively evaporating copper, indium, gallium and selenide metal materials by using an evaporation source arranged in the evaporation source chamber in the selenium plasma atmosphere backpressure environment so as to deposit a copper indium gallium selenide photovoltaic film on the substrate. According to the method, the selenizing temperature of the copper indium gallium selenide film in the growing process is reduced, the ratio precision of various materials of the copper indium gallium selenide film is improved and the large-area preparation of the copper indium gallium selenide film is realized.

Owner:何整风

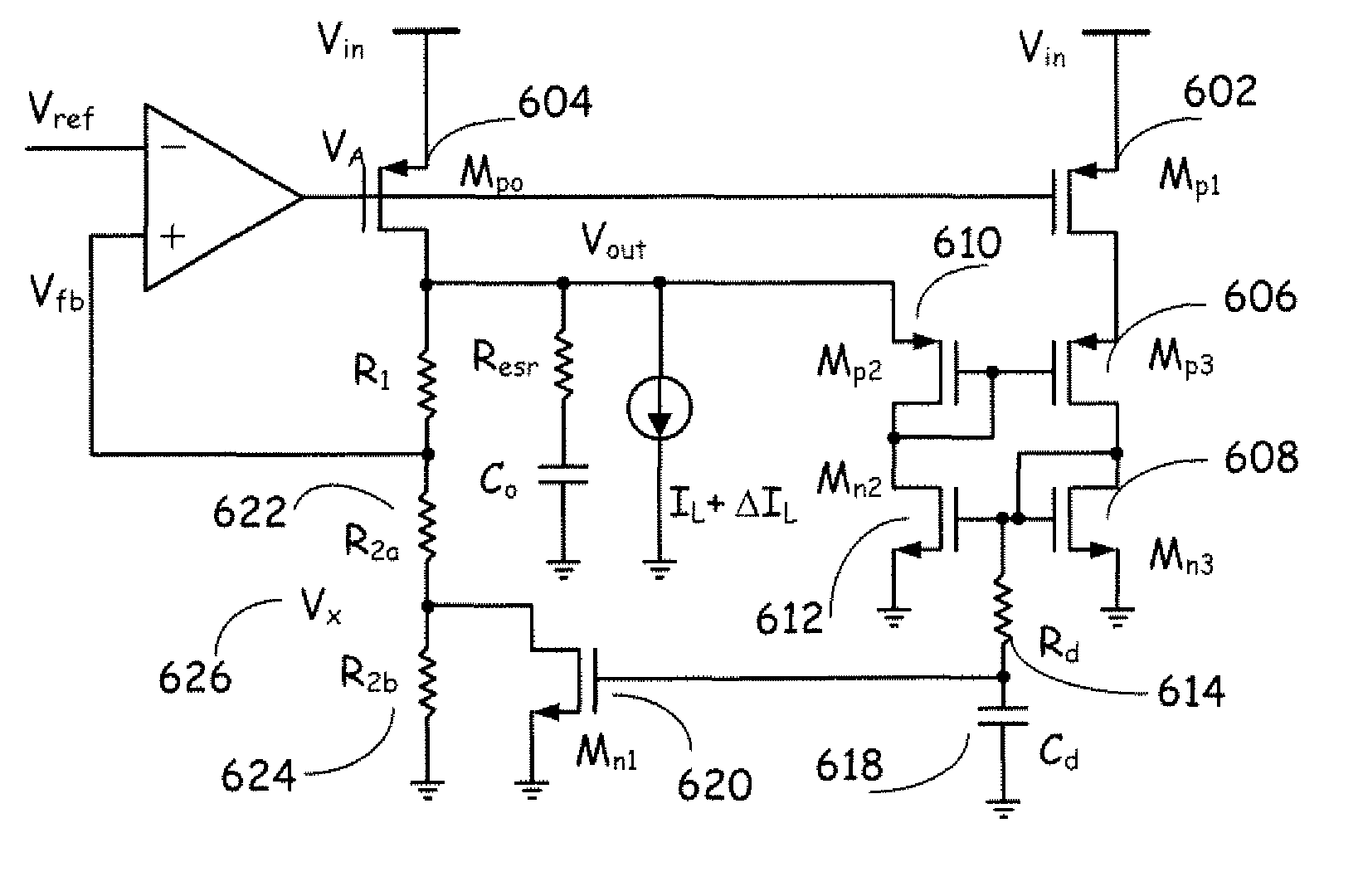

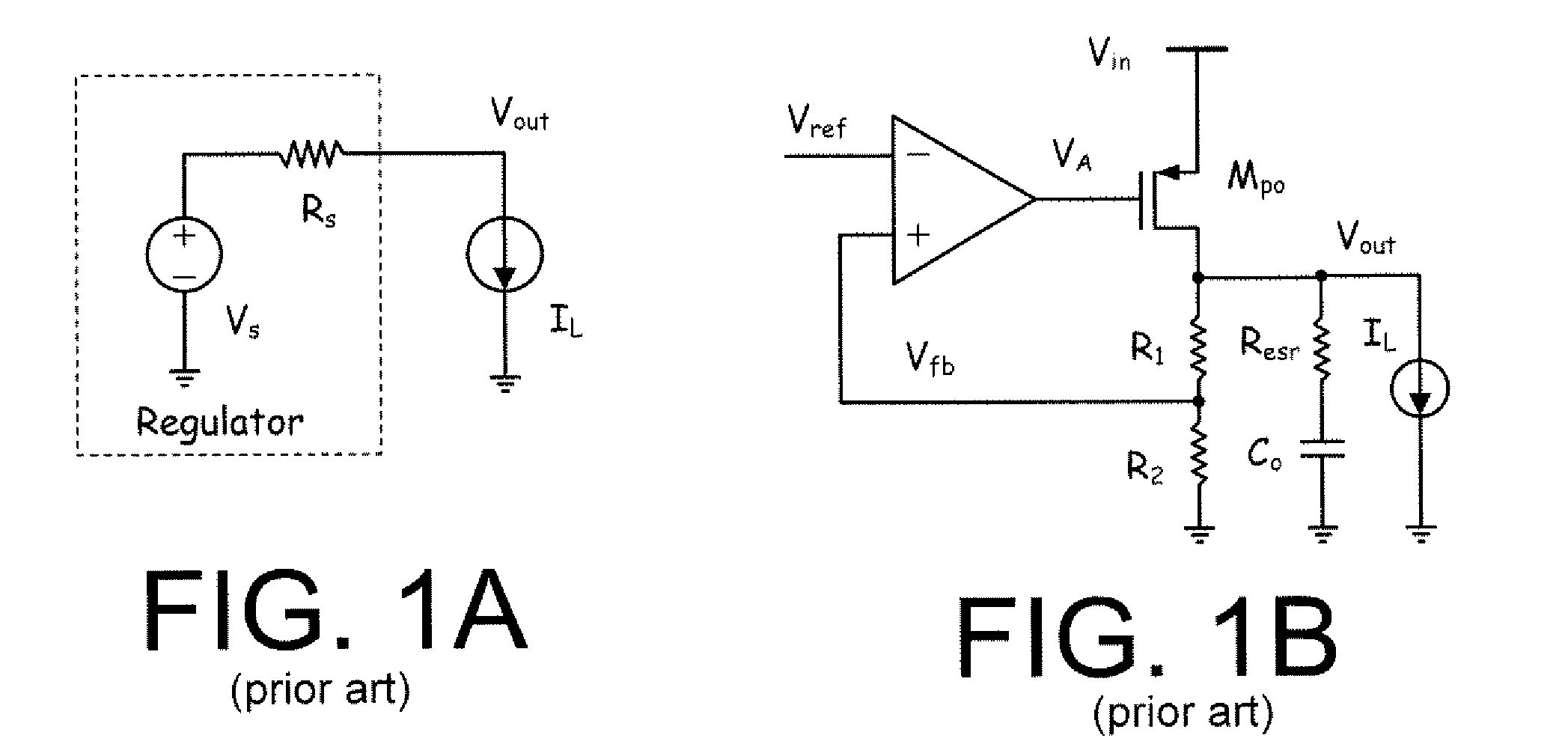

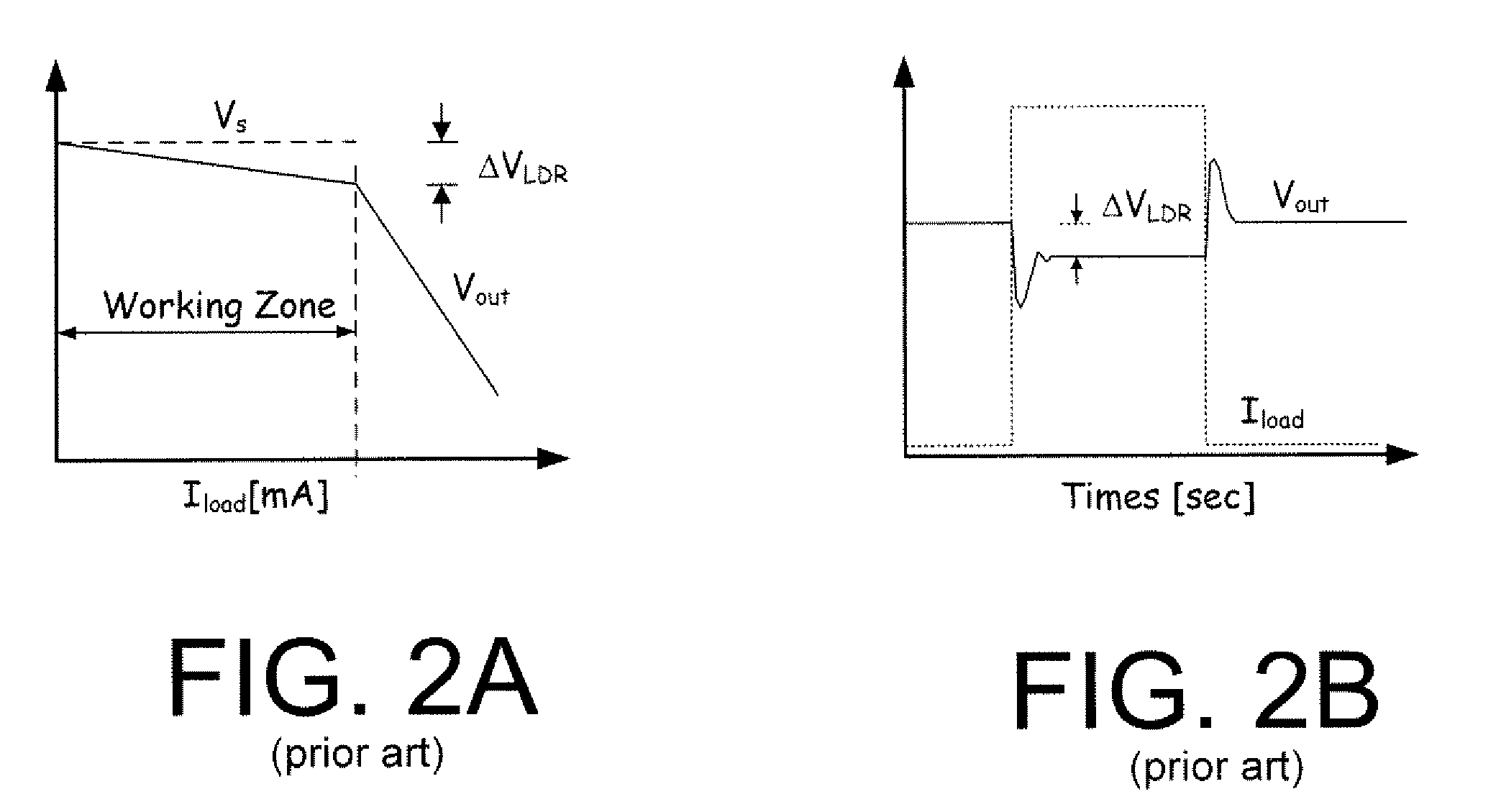

Systems, methods, and apparatuses for implementing a load regulation tuner for linear regulation

InactiveUS7772816B2Increased scale accuracyReduce impactElectric variable regulationConstant loadLinear regulator

Embodiments of the invention may provide for a load regulation tuner that reduces the load regulation effect. The load regulation tuner may include a load current controlled current source that is responsive to a load current from a power transistor of a linear regulator, where the load current controlled current source includes a sensing transistor that generates a fraction of the load current as a sensed partial load current. The load regulation tuner may also include a resistor in parallel with a load current controlled current source, and where the paralleled resistor and the load current controlled current source form at least a portion of a feedback block that adjusts an operation of the linear regulator to provide a substantially constant load voltage.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

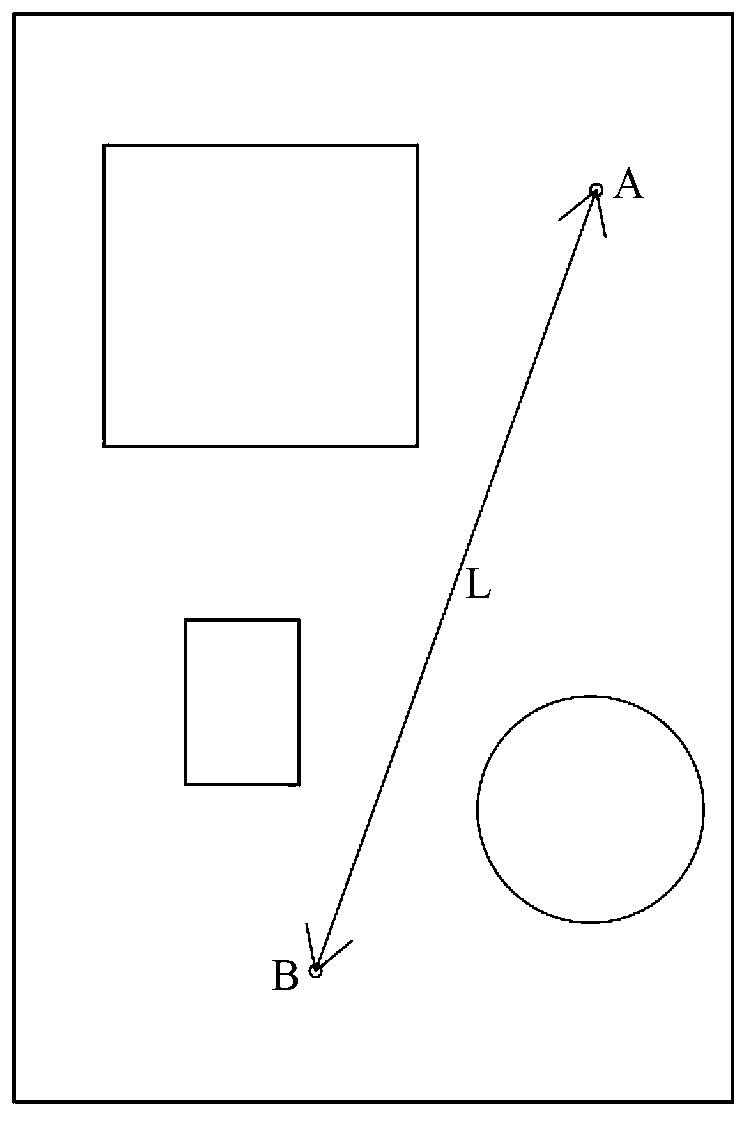

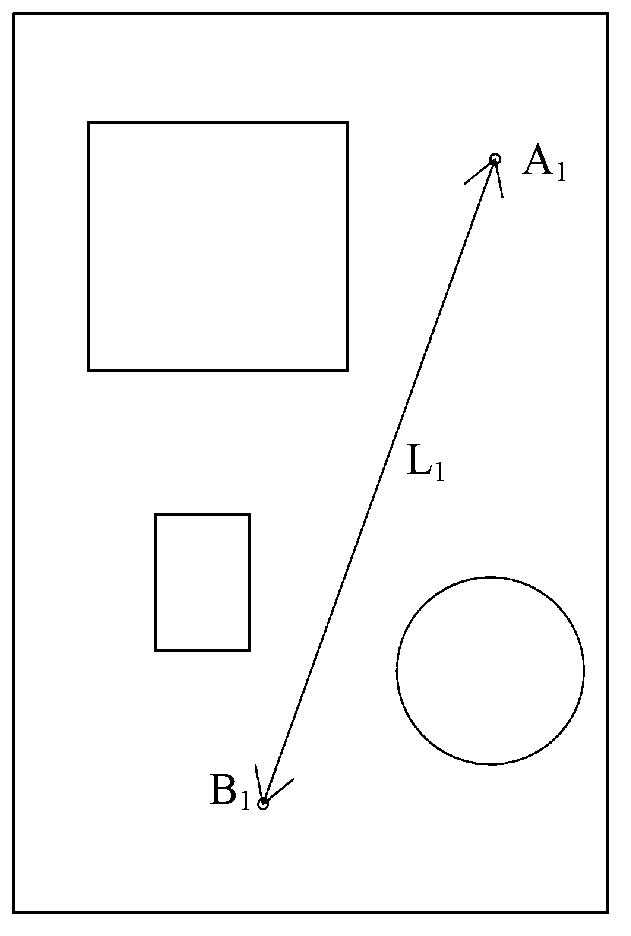

Correction method for aerial surveying and mapping images

ActiveCN102706331ASimple stepsEasy to operateHeight/levelling measurementPicture interpretationAerial photographyComputer vision

The invention discloses a correction method for aerial surveying and mapping images, which comprises the following steps: setting two reference points in a to-be-measured area, and measuring the horizontal distance between the two points; measuring idealistic distance between two final image points in a final image corresponding to a target scale according to the target scale and the obtained horizontal distance; carrying out aerial photography for to-be-measured area, butting the obtained images so as to obtain an integral original image of the to-be-measured area, and measuring the actual distance between two original image points; and calculating the ratio of the idealistic distance to the actual distance to scale the original image according to the ratio, so as to obtain the final image. Due to the adoption of the method provided by the invention, the image of the target scale can be obtained without conforming to the accurate aerial photography height, accordingly, the precision requirement for the aerial photography height is reduced, and the operation is simpler.

Owner:天津建岩岩土工程有限公司

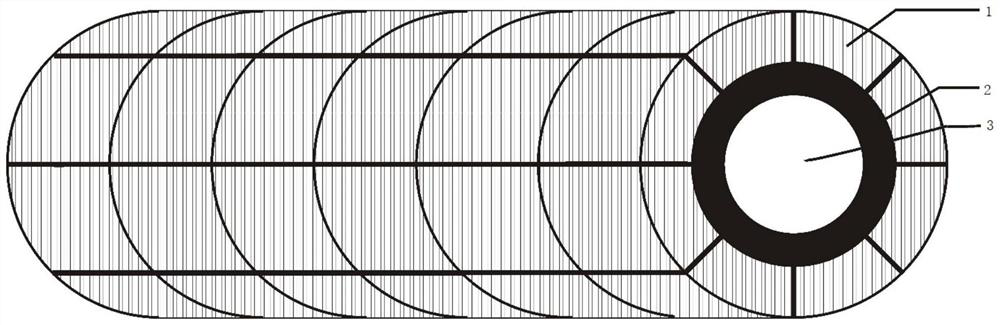

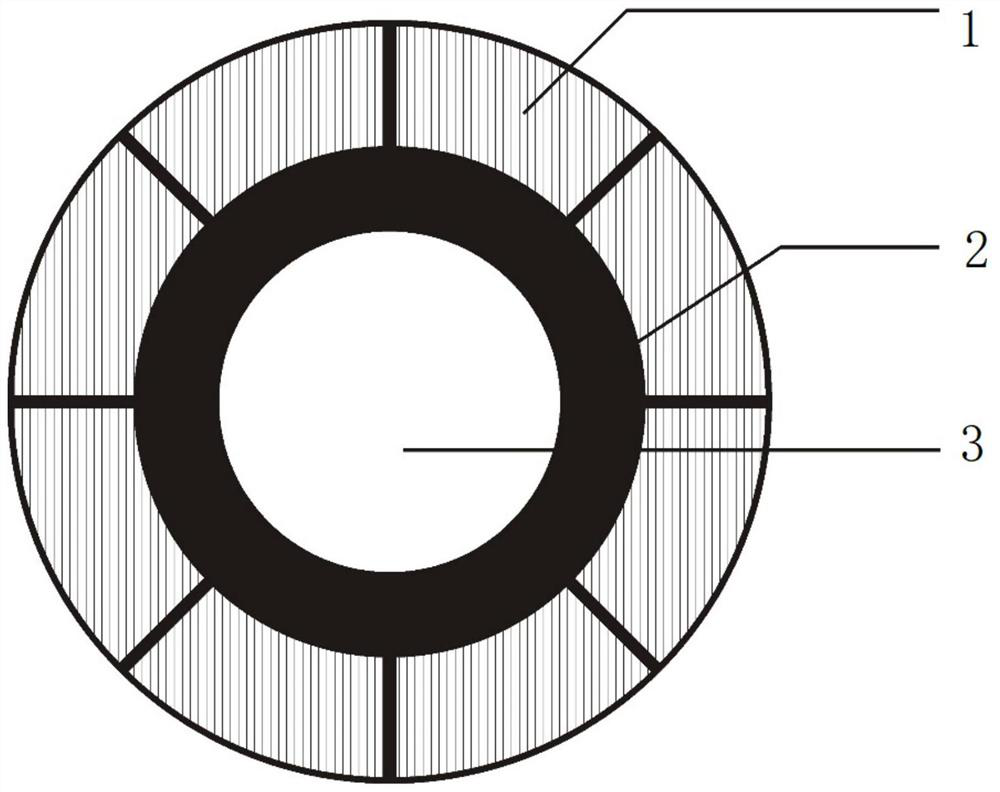

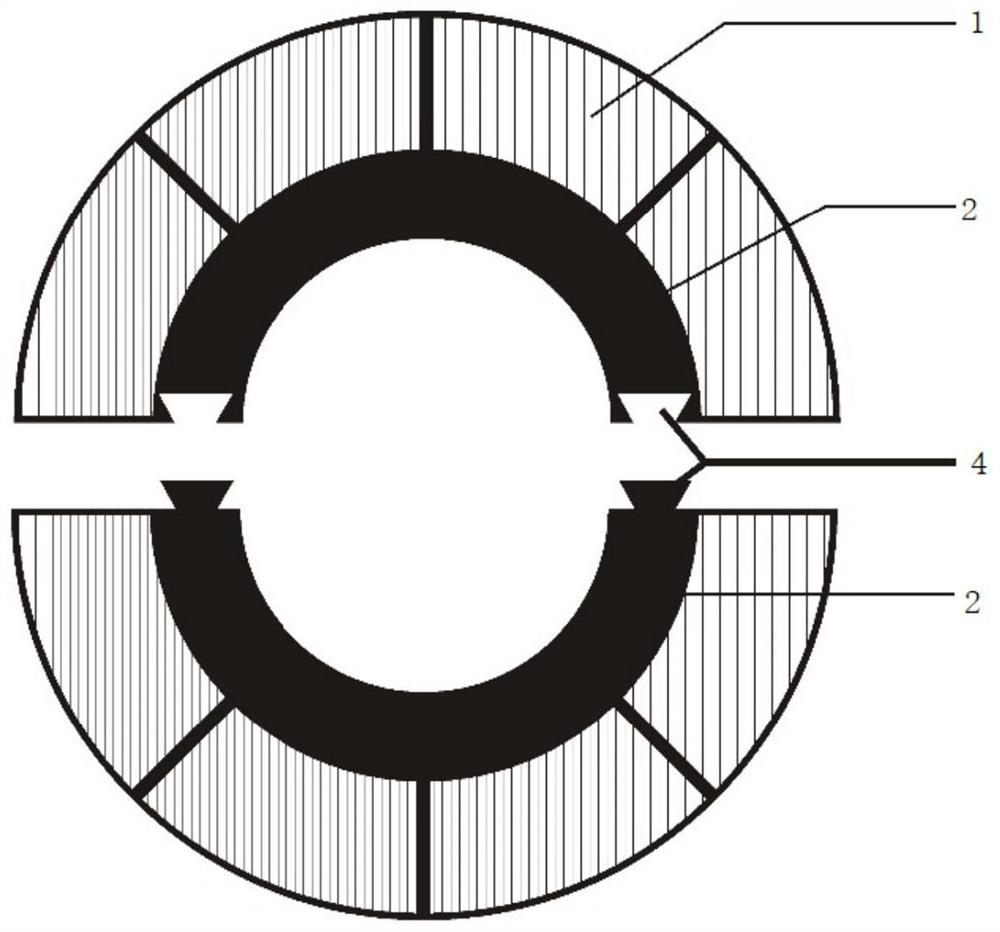

Preparation technology of copper and aluminum combined flat wire

InactiveCN105206351AAdjustable thicknessPrevent oxidationCable/conductor manufactureProduction lineCopper

The invention provides a preparation technology of a copper and aluminum combined flat wire. Firstly, copper and aluminum combined blanks are formed through horizontal continuous casting direct combination, and the area proportion of a wrapping copper layer is 15-50%. The preparation technology includes the following steps that firstly, rolling is performed, wherein a hole shape rolling technology is adopted, and the machining rate reaches 75-85% after rolling ends; secondly, drawing is performed, wherein drawing speed is controlled within 3-40 m / min, the thickness reduction amount of each pass is controlled to be 0.1-1.5 mm, the width reduction amount of each pass is controlled to be 0.1-2 mm, and the cross area total reduction amount is controlled to be 40-99% after drawing; thirdly, annealing is performed. The copper and aluminum combined flat wire can be prepared just through the horizontal continuous casting composite forming technology of copper and aluminum combined rod blanks, rolling, drawing and annealing, and efficient, short-process, high-yield and low-cost production of the copper and aluminum combined flat wire is achieved. The thickness of the copper layer of the copper and aluminum combined flat wire produced through the method is adjustable, the interface bonding strength is high and is larger than or equal to 40 Mpa, and a ten-thousand-ton-level industrialized production line and large-scale production of the copper and aluminum combined flat wire can be achieved through the method.

Owner:YANTAI FISEND BIMETAL

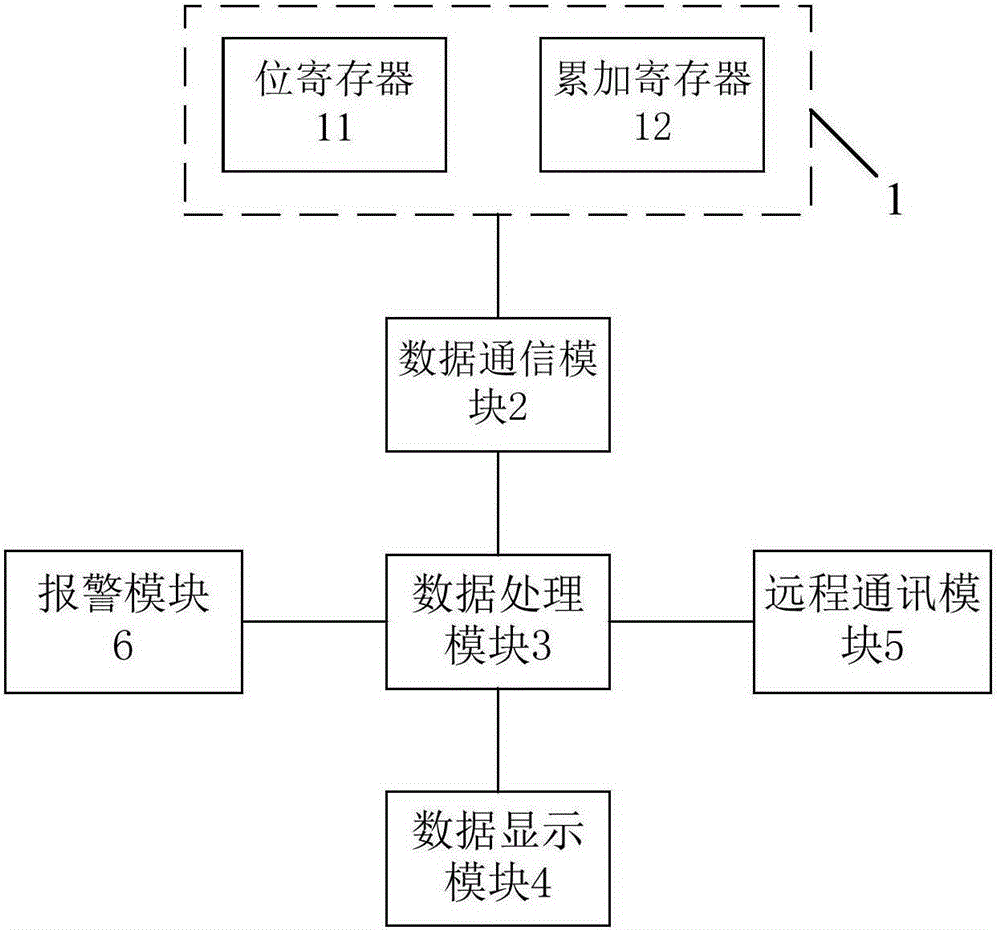

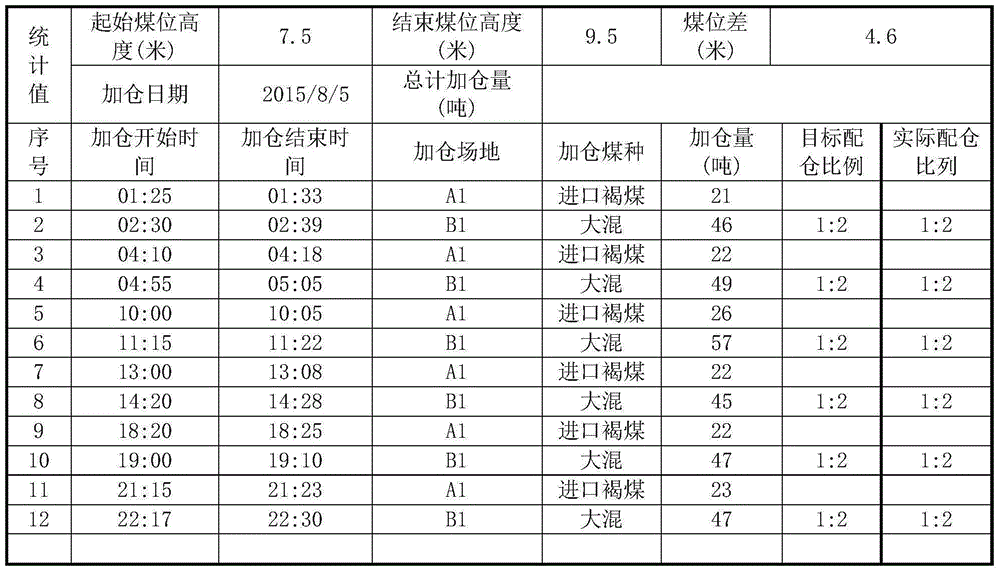

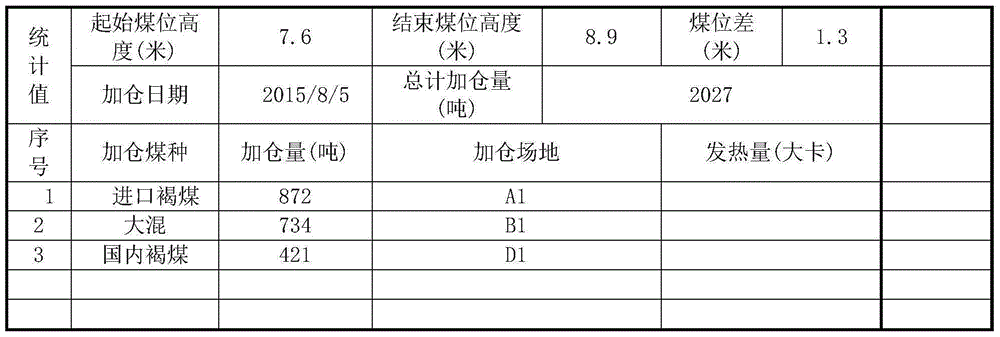

As-fired coal separate bin metering system of coal conveying system

InactiveCN105203194AIn line with operating habitsAccurate measurementSpecial purpose weighing apparatusData displayData acquisition module

The invention relates to an as-fired coal separate bin metering system of a coal conveying system. The as-fired coal separate bin metering system comprises added-to-bin amount data collection modules, a data communication module, a data processing module and a data display module. The added-to-bin amount data collection modules are arranged on all raw coal bins and used for collecting real-time coal addition amount information and accumulated coal addition amount information of each raw coal bin. The data communication module is connected with the added-to-bin amount data collection module and used for receiving the real-time coal addition amount information and the accumulated coal addition amount information which are conveyed by the data communication module. The data display module is connected with the data processing module and used for displaying current coal addition amount information and the accumulated coal addition amount information of all the raw coal bins. Compared with the prior art, the as-fired coal separate bin metering system has the advantages that the added-to-bin amount for mixed burning of each boiler is accurately reflected, and operation is convenient.

Owner:SHANGHAI WAIGAOQIAO POWER GENERATION

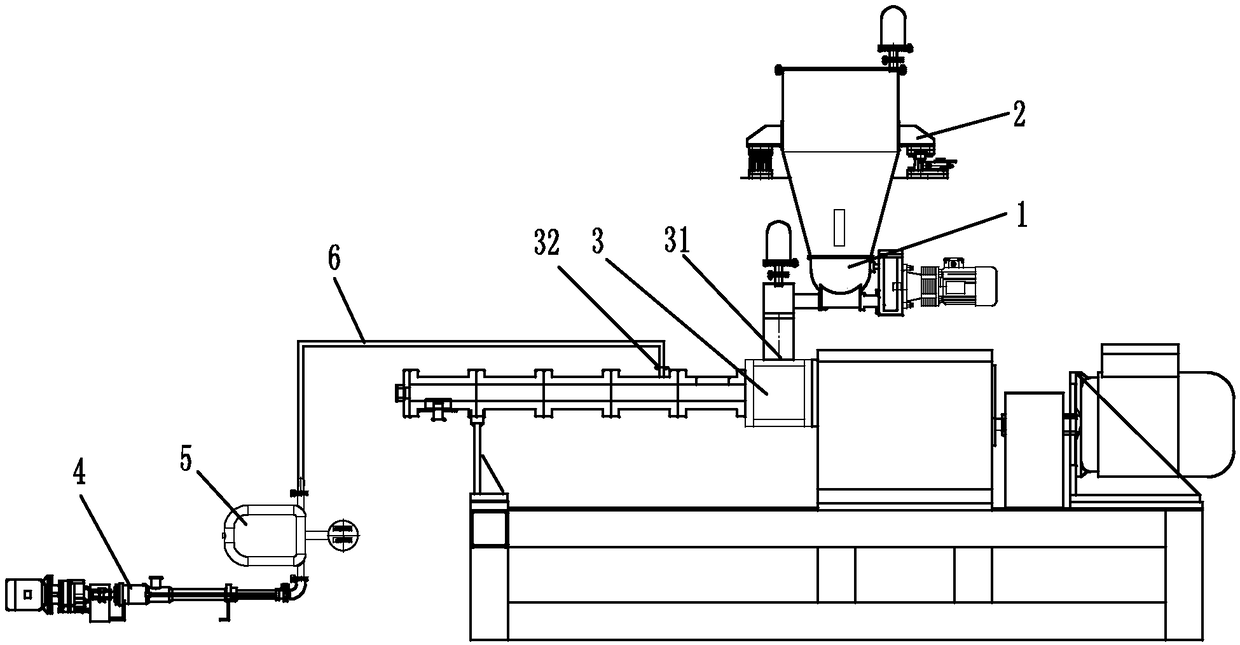

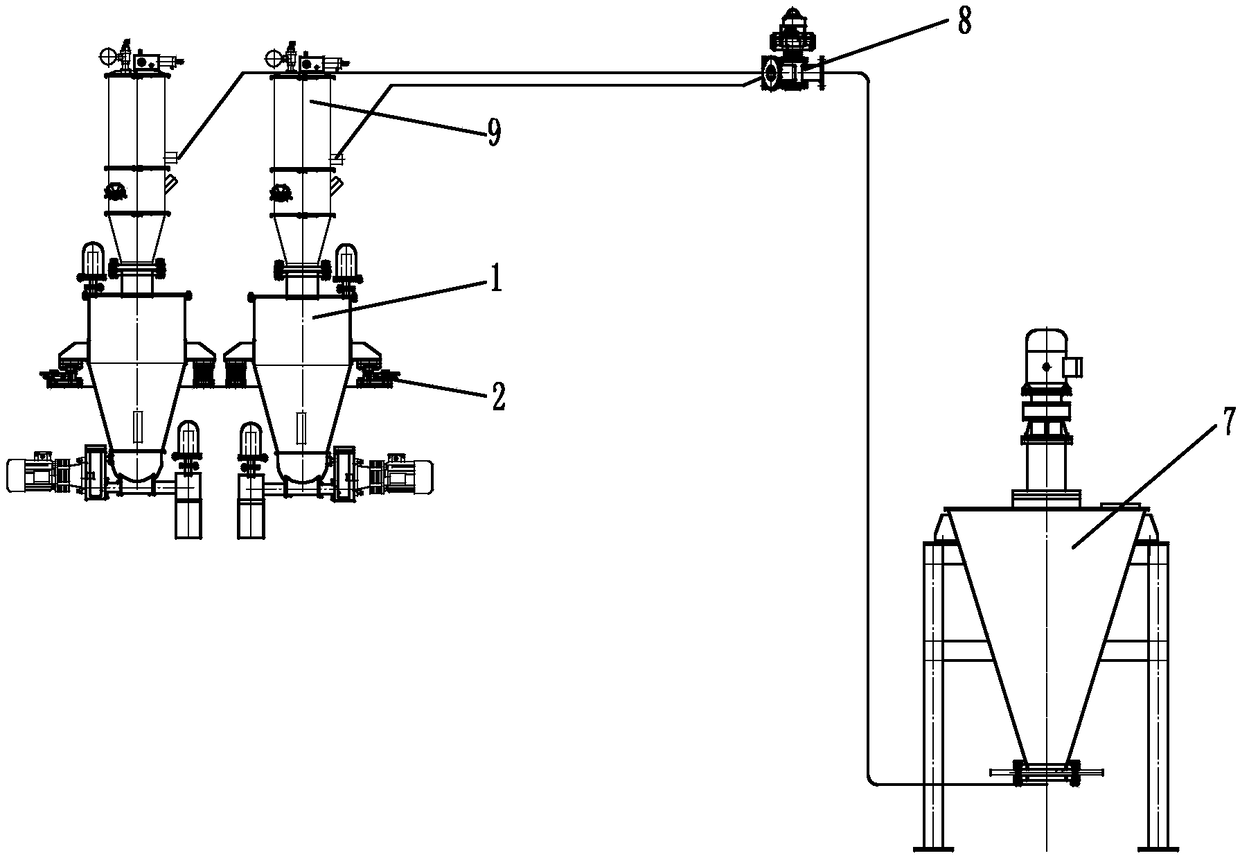

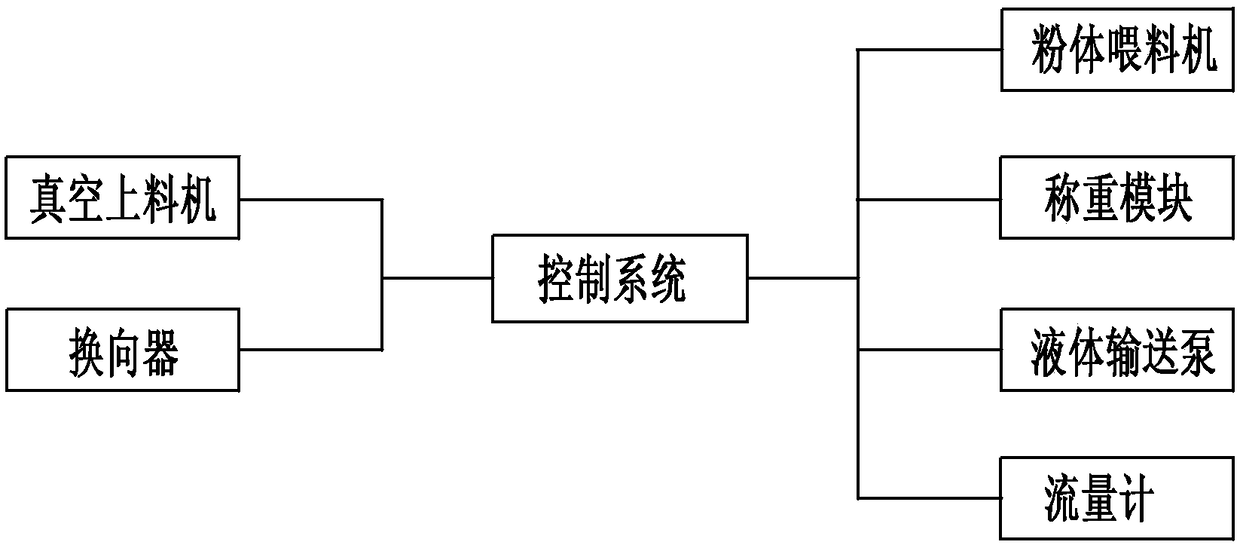

Feeding system and method for further improving proportioning precision in continuous production and feeding of chemical slurry

InactiveCN109464959AReduce mistakesImprove the accuracy of feeding ratioMixing methodsTransportation and packagingControl systemSlurry

The invention relates to a feeding system and method for further improving proportioning precision in continuous production and feeding of chemical slurry. The feeding system comprises a control system, a powder measuring and feeding device, a twin-screw mixer, a liquid conveying pump and a flow meter, wherein at least two powder measuring and feeding devices are provided; each powder measuring and feeding device is composed of a powder feeder and a weighing module; the powder feeder is communicated with the twin-screw mixer; the liquid conveying pump is communicated with a liquid inlet of thetwin-screw mixer through a liquid conveying pipe; the flow meter is mounted on the liquid conveying pipe; the control system is used for monitoring liquid feeding flow fed back by the flow meter in real time, monitoring the weight of power materials in the powder feeder fed back by the weighing module in real time and calculating a power feeding flow. The feeding system and method provided by theinvention can automatically calculate and adjust dosages of other materials according to a set feeding proportion by monitoring an actual dosage of the materials and using one of the materials as a reference, and achieves a purpose of further improving the proportioning precision of finished materials.

Owner:LIUZHOU HUT CHEM MACHINERY

D/A conversion circuit, A/D conversion circuit and electronic apparatus

ActiveUS8653998B2Increased scale accuracyImprove conversion accuracyElectric signal transmission systemsDigital-analogue convertorsDigital dataEngineering

A D / A conversion circuit includes a first D / A converting section which is connected with an output node, a first serial capacitor which is disposed between the output node and a first node, a second D / A converting section which is connected with the first node, and a control circuit. The first D / A converting section includes a first capacitor array section and a first switch array section. The second D / A converting section includes a second capacitor array section and a second switch array section. The control circuit performs a switch control for dynamically changing allocation of the capacitors to the respective bits of input digital data for the first switch array section of the first D / A converting section.

Owner:SEIKO EPSON CORP

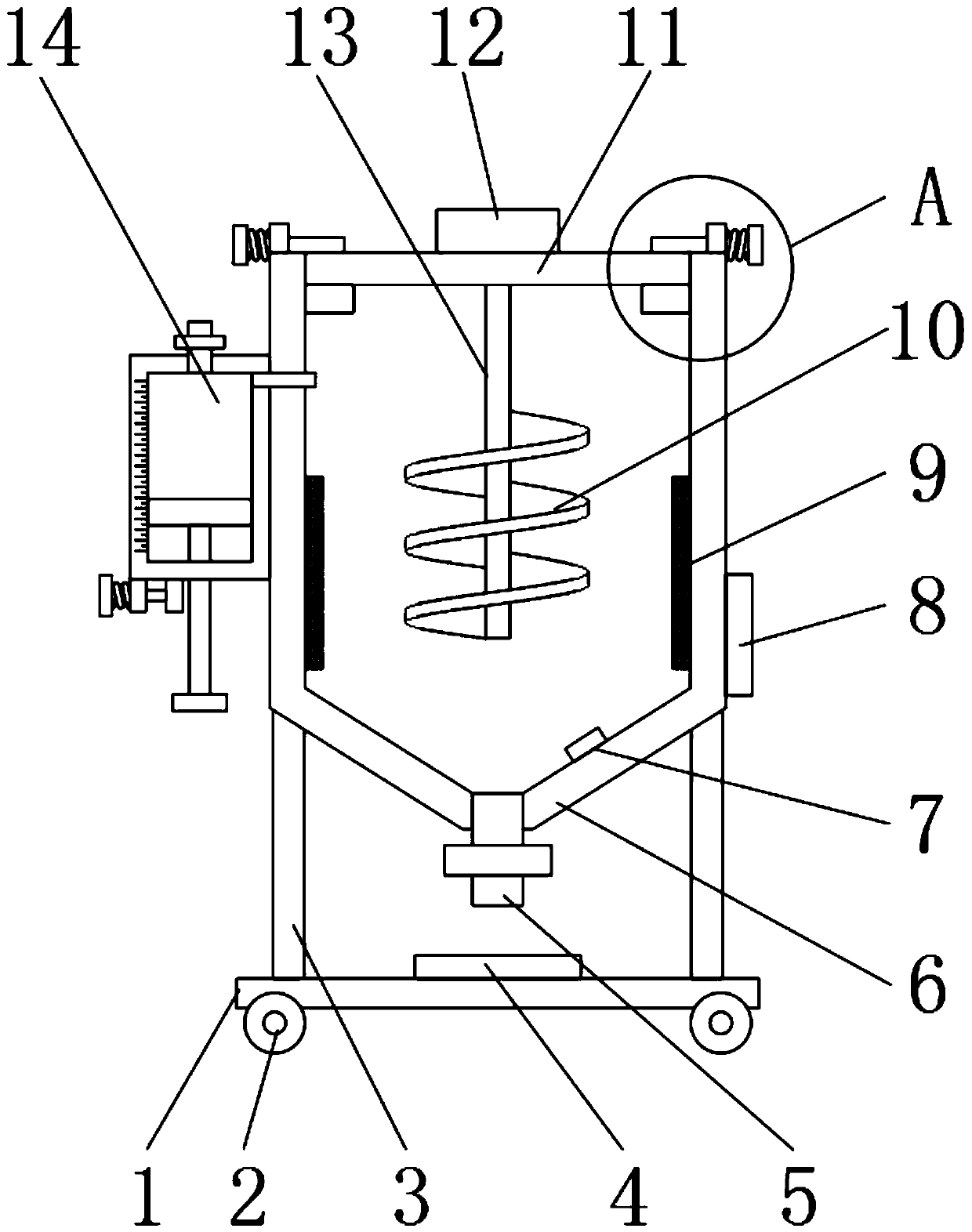

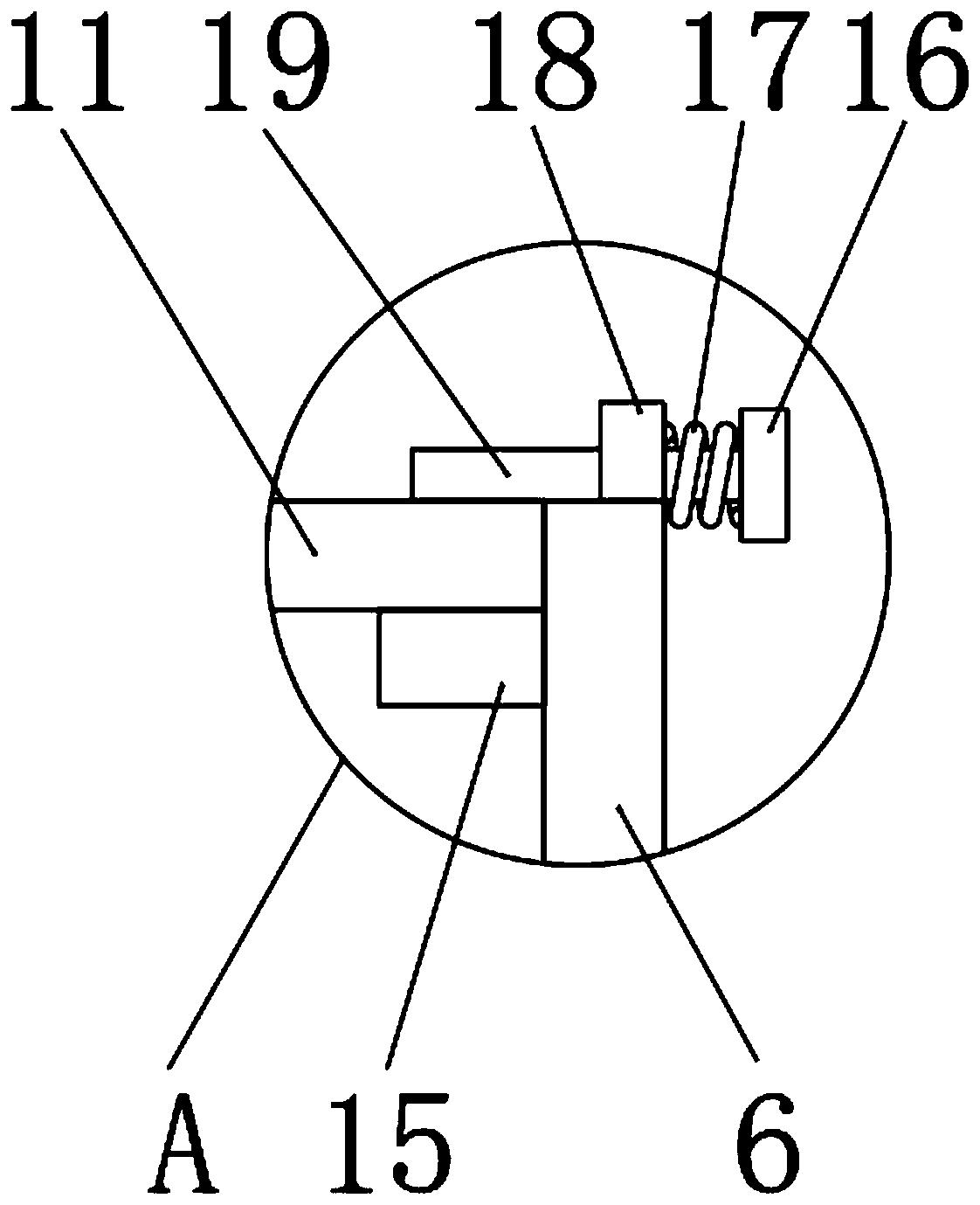

Coating material mixing device and use method thereof

InactiveCN110813148AEasy to moveLower center of gravityRotary stirring mixersTransportation and packagingProcess engineeringGravity center

The invention discloses a coating material mixing device and a use method thereof, and relates to the field of coating materials. The coating material mixing device specifically comprises a base, walking wheels, a support rod, a counterweight block, a material outlet, a mixing tank, a temperature sensor, a control panel, heating plates, a spiral stirring blade, a sealing cover, a motor, a stirringshaft and a material inlet device. In the implementation process of the coating material mixing device, the walking wheels are installed on the bottom surface of the base, so the mixing device can conveniently move; the counterweight block is arranged on the base, so the gravity center of the mixing device is lowered so as to improve the stability of the mixing device; the temperature in the mixing tank is controlled through the cooperation of the temperature sensor, the heating plates and the control panel, so the temperature in the mixing tank is always within a stable range so as to improve the mixing effect and the mixing efficiency of the coating material; and the coating material mixed material entering the mixing tank is quantified through the material inlet device, so that the ratio precision of the coating material mixing amount is improved, and the practicability of the mixing device is improved.

Owner:TIANJIN BAOLIJIE CO LTD

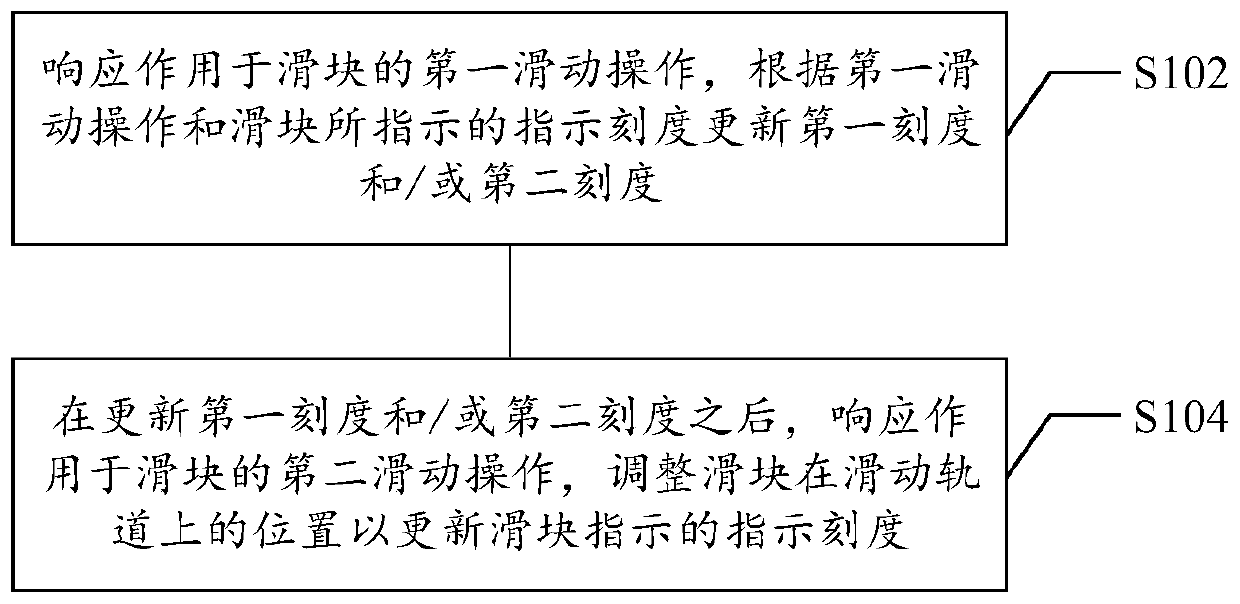

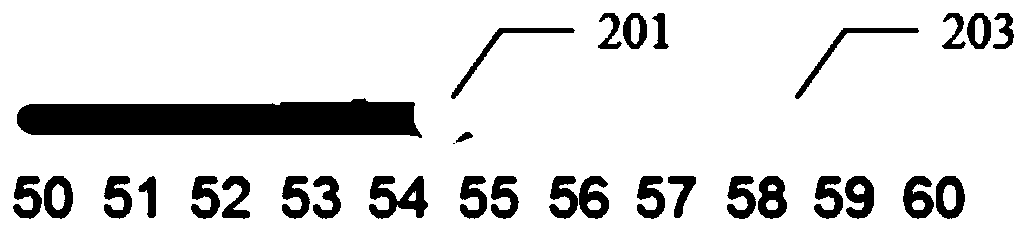

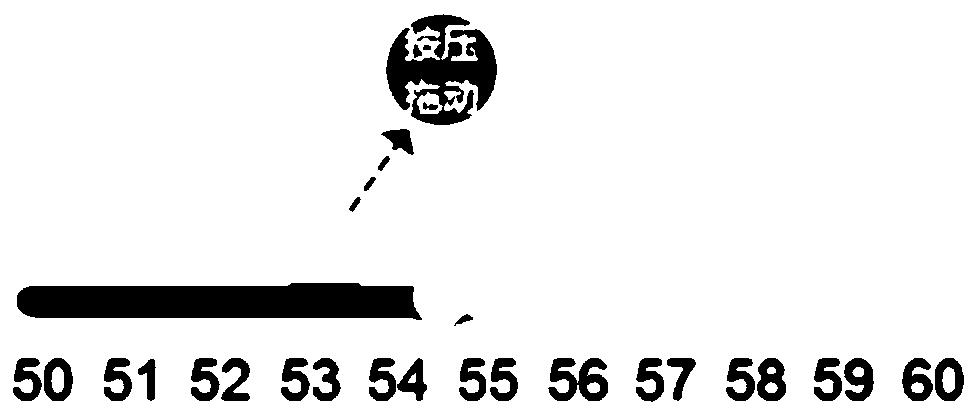

Sliding control controlling method and device, storage medium and electronic equipment

ActiveCN111552430AIncreased scale accuracyIncrease profitInput/output processes for data processingControl engineeringTerminal equipment

The invention provides a sliding control controlling method, a sliding control controlling device, a computer readable storage medium and electronic equipment, and relates to the technical field of human-computer interaction. The controlling method of the sliding control is applied to terminal equipment, the sliding control comprises a sliding block and a sliding rail, the sliding block is used for indicating scales on the sliding rail, and the scale range indicated by the sliding rail is from a first scale to a second scale. The method comprises the following steps: in response to a first sliding operation acting on the sliding block, updating the first scale and / or the second scale according to the first sliding operation and the indicating scale indicated by the sliding block; and afterthe first scale and / or the second scale are / is updated, responding to a second sliding operation acting on the sliding block, and adjusting the position of the sliding block on the sliding rail so asto update the indication scale indicated by the sliding block. The scale precision of the sliding control can be improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

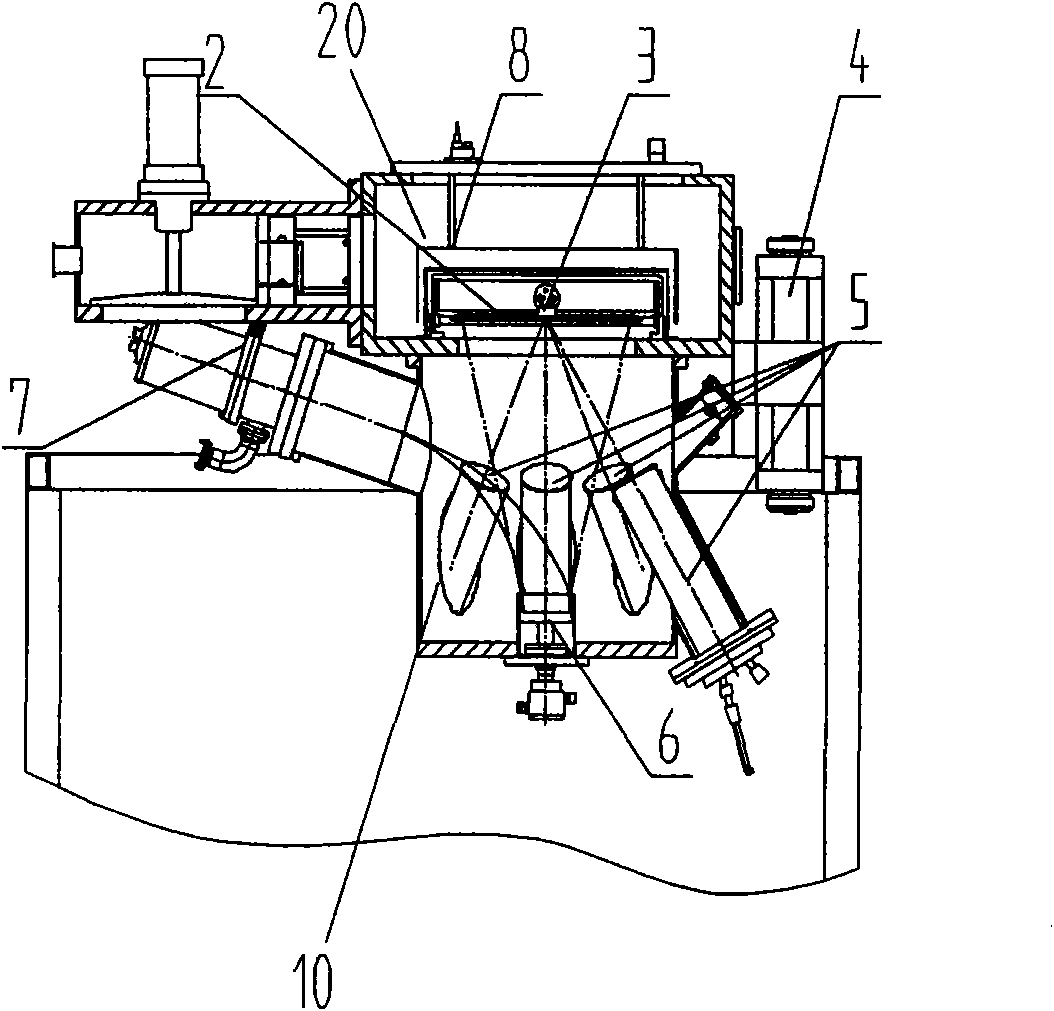

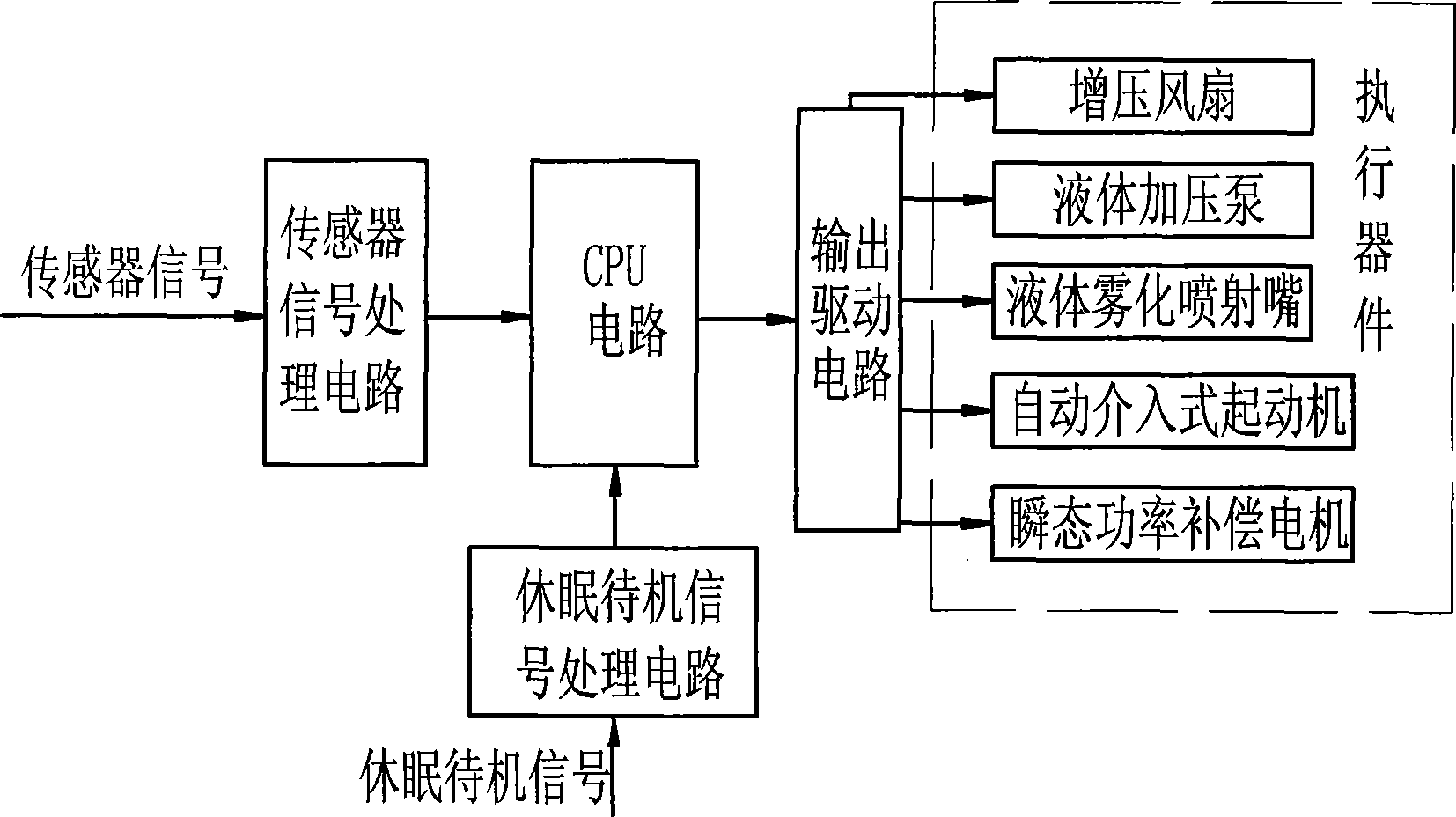

Energy-saving synergistic device for automobile

InactiveCN101503085AHigh expansion pressureOptimize fuel supply modeNon-fuel substance addition to fuelCombustion enginesCombustion chamberFuel oil

The invention discloses an automobile energy-saving and efficiency-increasing system, comprising an ECU control circuit, a sensor, an expander ECU control circuit, an engine air-entering and a pressure-increasing compensating mechanism, an engine liquid atomization compensating mechanism, an automatic intrusive starter, a transient power compensating mechanism and an electric machinery, wherein, the engine air-entering and pressure-increasing compensating mechanism, the engine liquid atomization compensating mechanism, the automatic intrusive starter, the transient power compensating mechanism and the electric machinery are controlled by the expander ECU control circuit. The invention can improve transient required ratio precision between air and fuel oil, transient transporting proportioning precision and the power of original automobile engine; the invention has the advantages of fast start and acceleration; the engine liquid atomization compensating mechanism can be used for increasing the expansion pressure of a combustion chamber after combusting, thereby the kinetic energy of the engine can be correspondingly improved and large amount of fuel oil can be saved when the engine outputs equivalent power; and the invention not only improves engine power but also reduces oil consumption, which is excellently characterized in that the purification degree of exhaust emission is high and has the rate of economizing gasoline which is more than 10%. The power is improved by more than 5% and the environmental protection function is superior to the original state-IV Europe.

Owner:HEBEI FEIER POWER SCI & TECH DEV

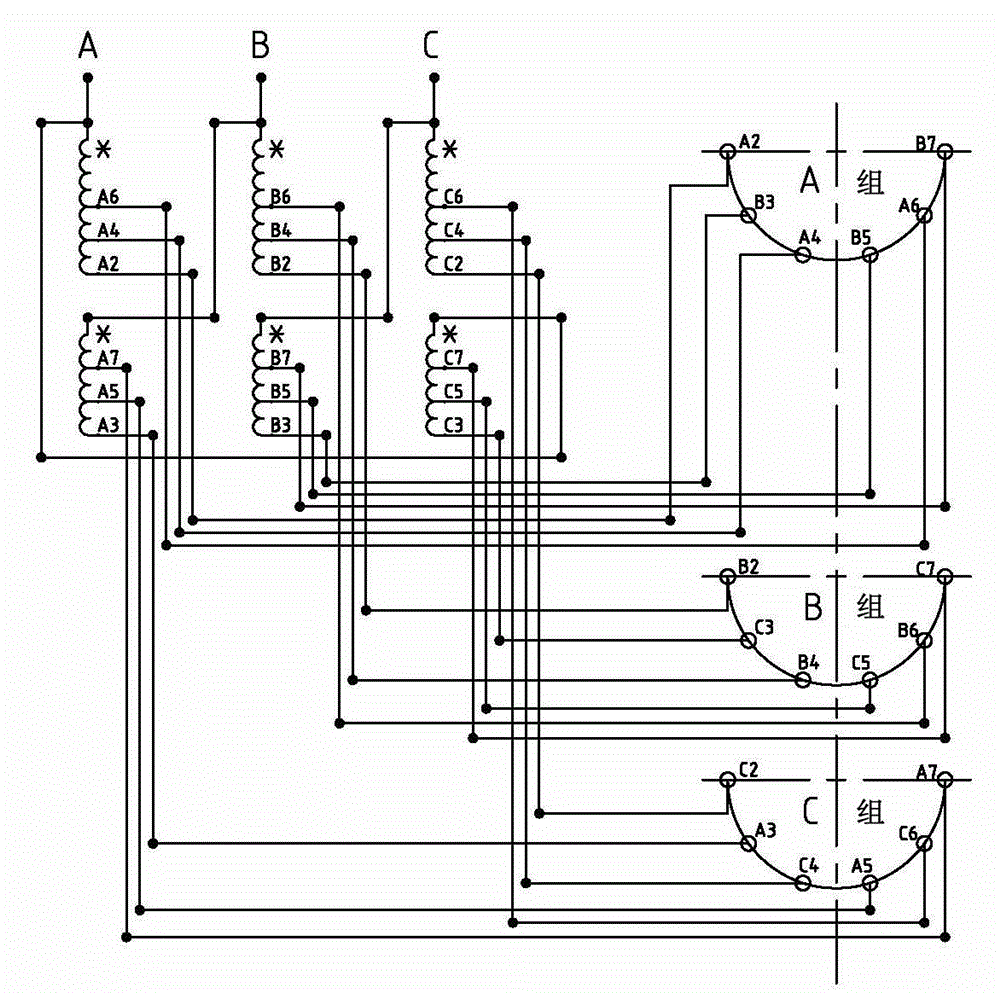

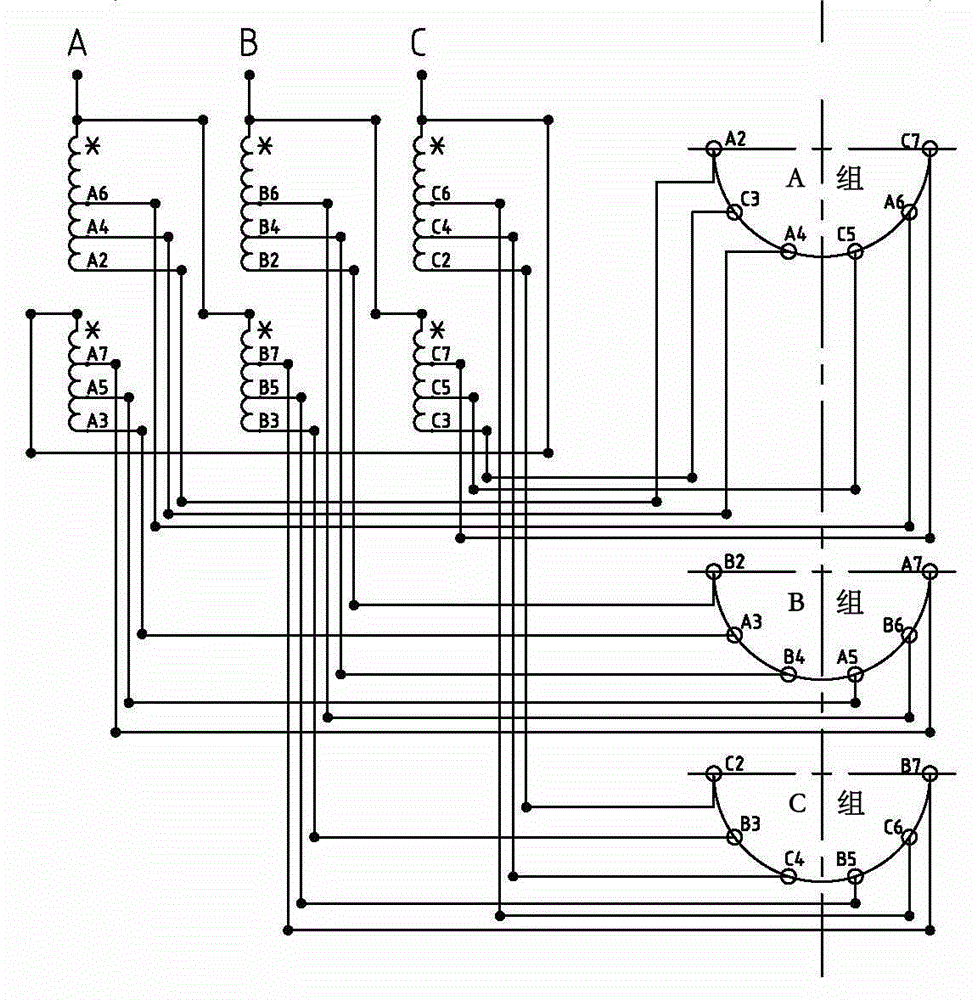

Phase-shifting winding type voltage-regulating rectifier transformer and voltage regulating method thereof

InactiveCN104882259AReduce cost lossReduce running lossTransformers/inductances coils/windings/connectionsVariable inductancesPhase shiftedLow voltage

The invention belongs to the technical field of transformers and discloses a phase-shifting winding type voltage-regulating rectifier transformer and a voltage regulating method thereof. A transformer cabinet internally comprises a phase-A core limb, a phase-B core limb and a phase-C core limb which are wound by two groups of phase-A windings, phase-B windings and phase-C windings respectively. A long-side dotted terminal of a high-voltage-side base winding in each group of three-phase windings is serially connected with a short-side dotted terminal of an adjacent-phase phase-shifting winding, and a shunting tap of a high-voltage-side long-side terminal is serially connected with an opposite adjacent-phase short-side terminal via a tap switch, so that a closed phase-shifting loop is formed; shunting taps at the terminals of the windings are serially connected via tap switches to achieve switching voltage regulation; the low-voltage-side windings in star connection and in angular connection output multi-pulse electric energy definite in phase-shifting angle and regulatable in voltage to a rectifier. The phase-shifting winding type voltage-regulating rectifier transformer and the voltage regulating method thereof have the advantages that phase-shifting angles are definite, voltage regulating range and the number of winding tapping turns are matched well, and the voltage-regulating rectifier transformer is compact in structure and good in manufacturability, so that manufacturing cost and operating loss of the transformer are reduced.

Owner:江山市玉兰变压器有限公司

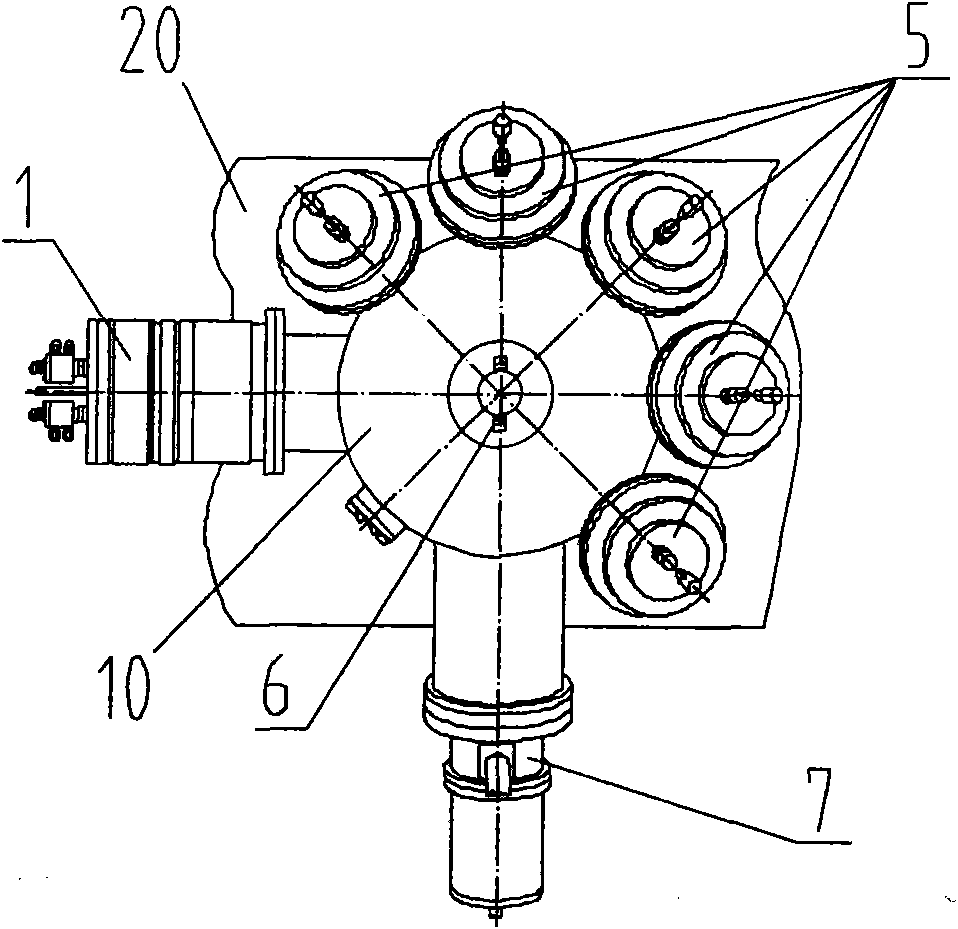

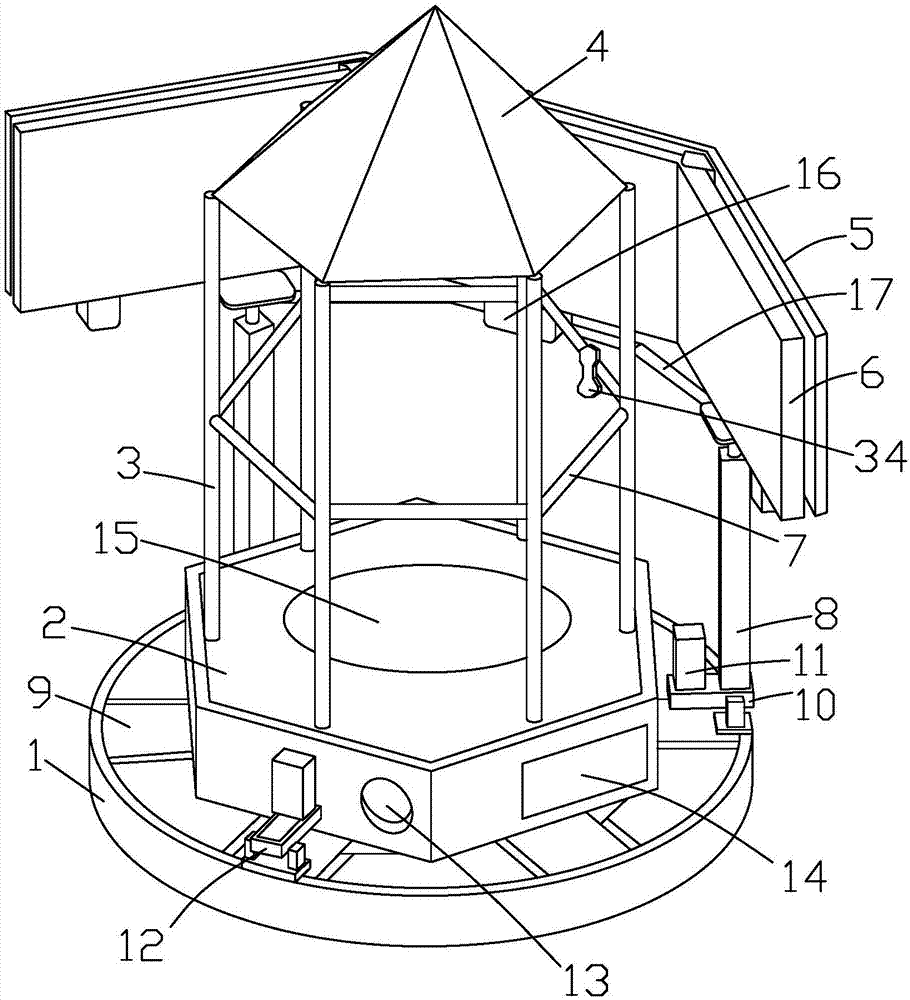

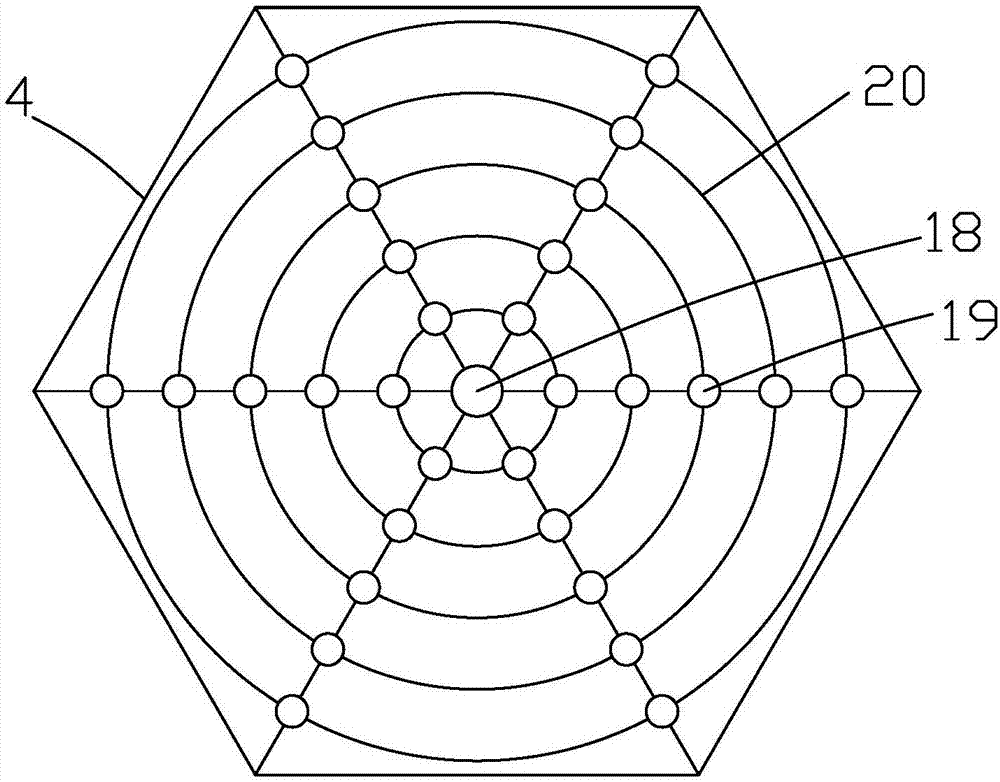

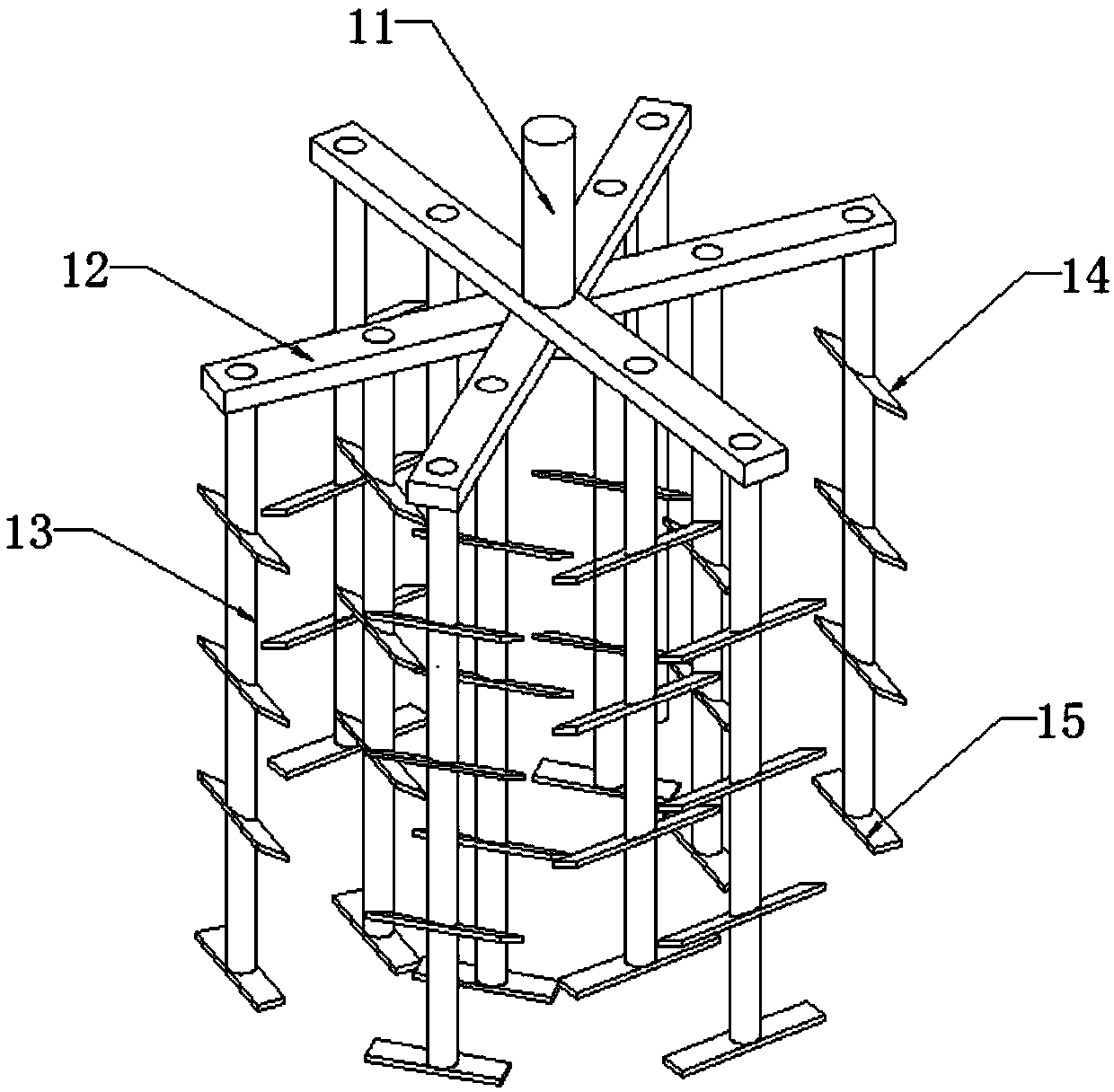

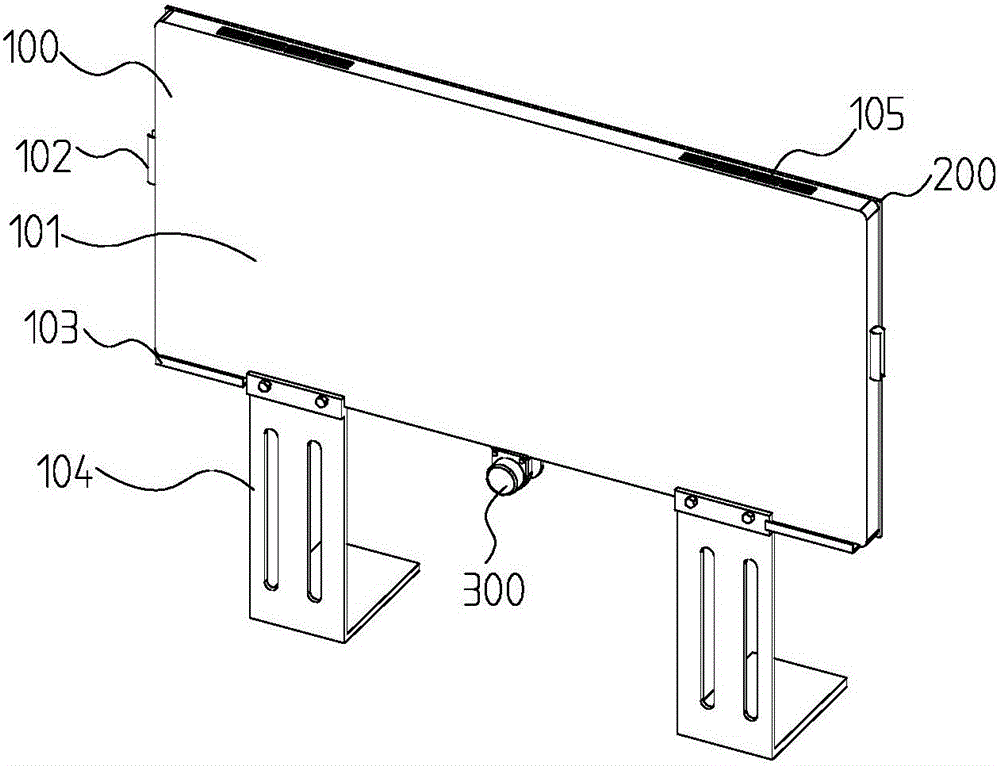

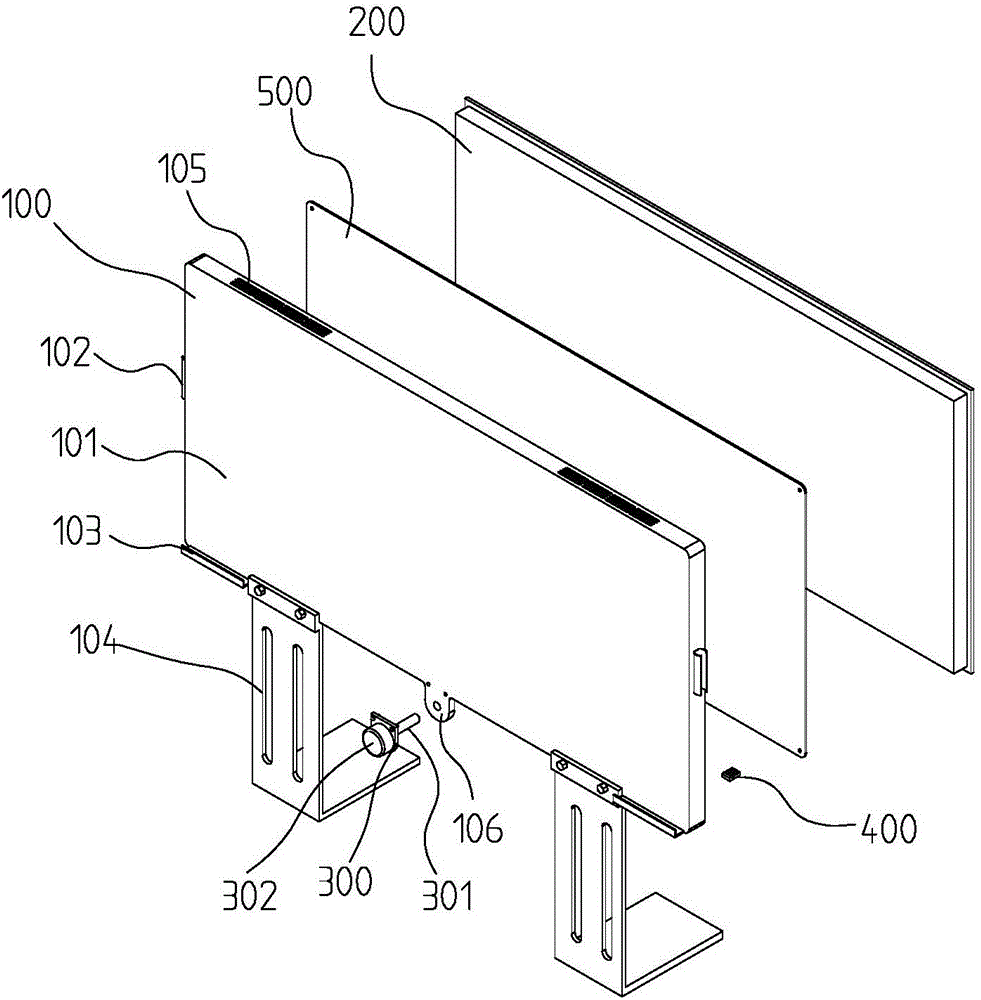

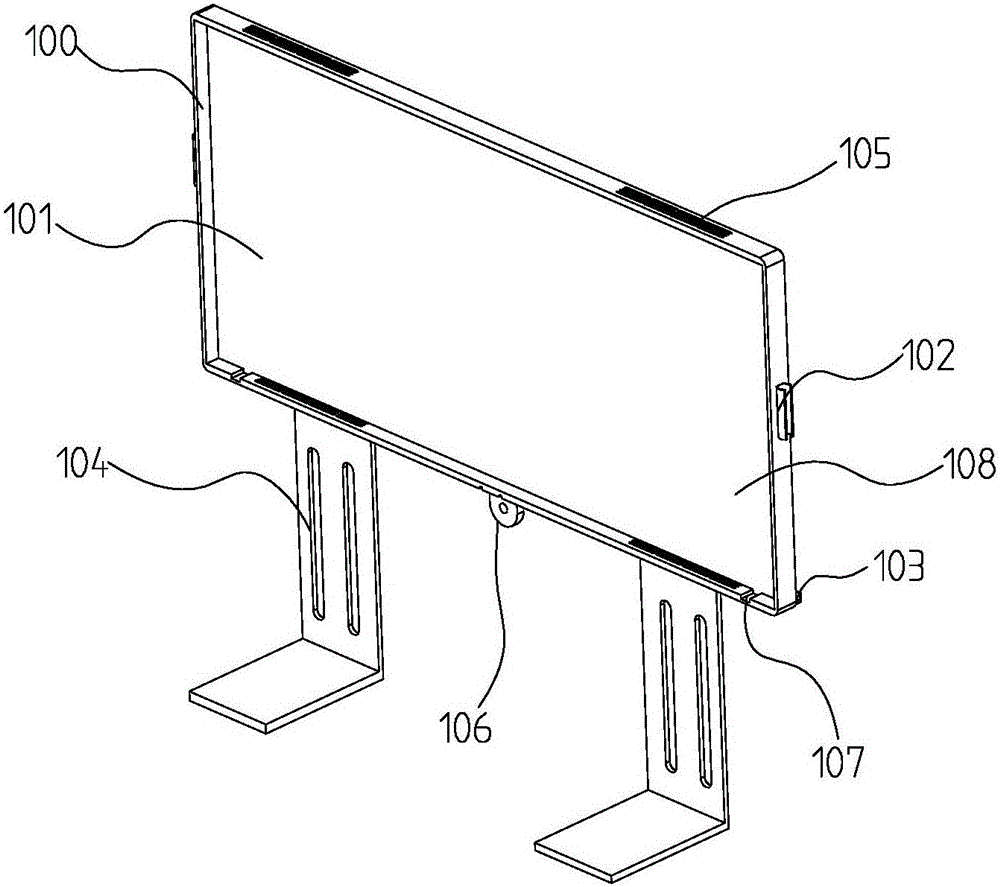

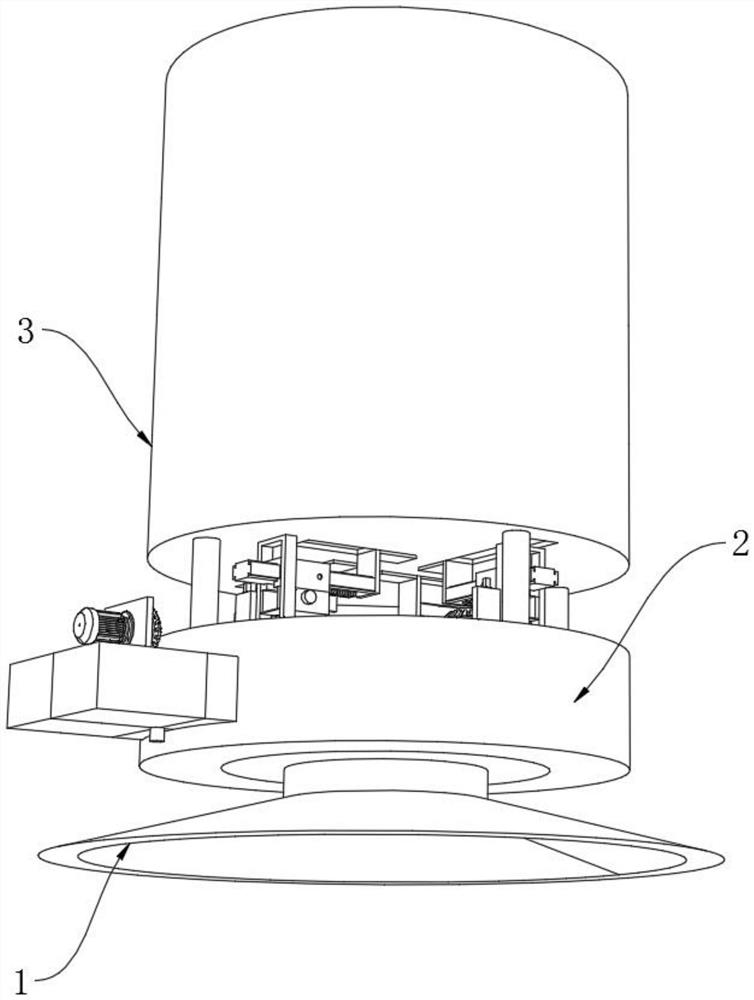

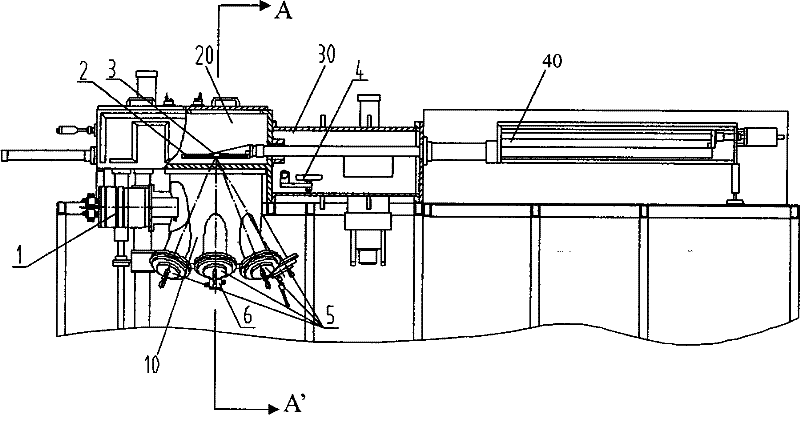

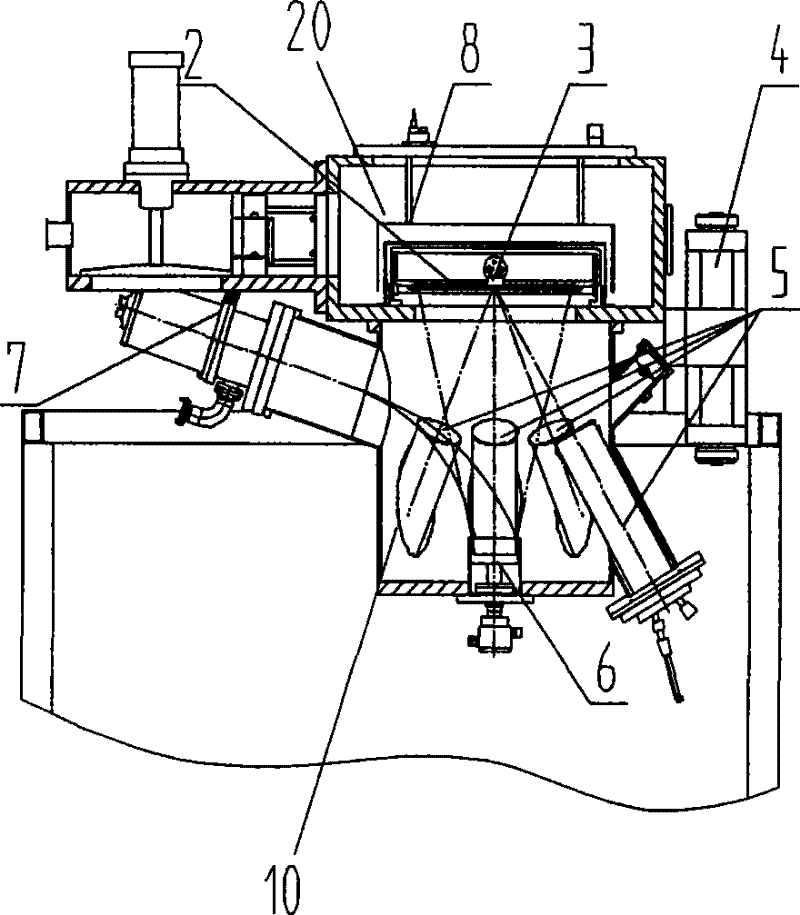

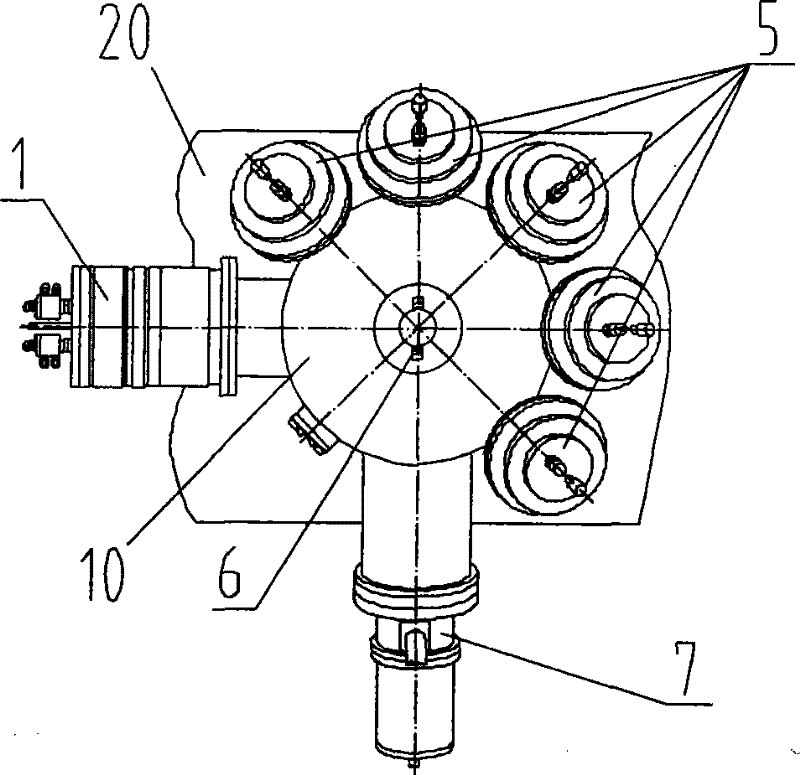

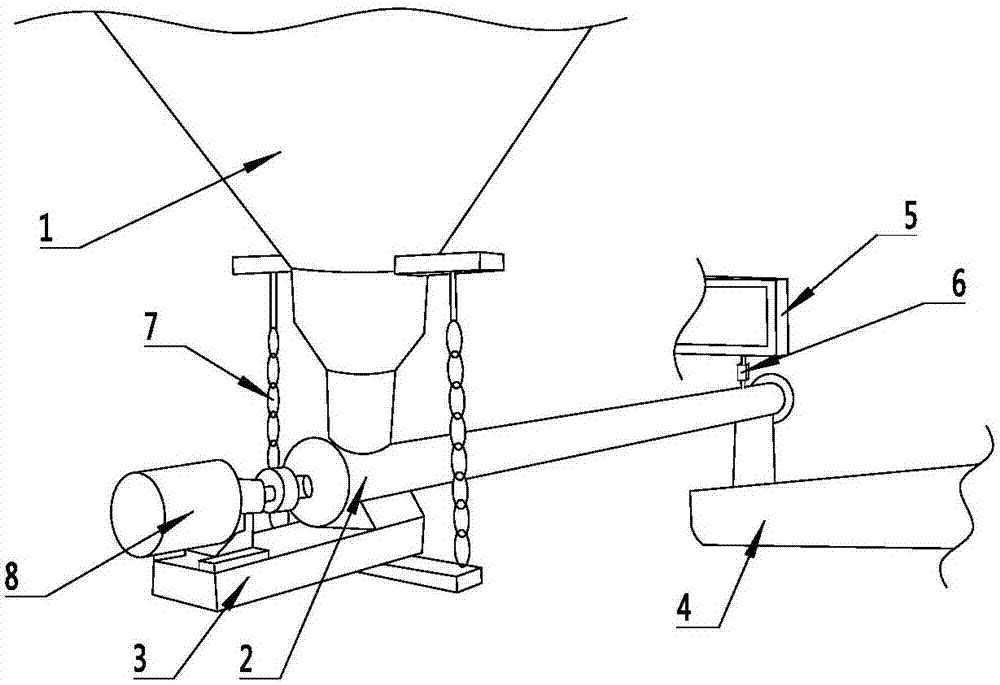

Architecture teaching system based on VR technology

PendingCN107545793AAvoid dizzinessImprove comfortEducational modelsElectrical appliancesEngineeringControl system

The invention discloses an architecture teaching system based on a VR technology. The architecture teaching system comprises a base, a hexagonal base plate, a VR display system and a VR control system, wherein an umbrella-shaped scanner is arranged above the hexagonal base plate and comprises an umbrella cover, a main sensor and an auxiliary sensor are arranged on the inner side face of the umbrella cover, the umbrella cover is fixedly connected to the hexagonal base plate through supporting rods, a connecting rod is arranged between the two adjacent supporting rods, at least two groups of shooting systems are arranged on the inner side faces of the supporting rods and are movably connected to the supporting rods through threaded rods, and a turntable is arranged on the hexagonal base plate. The architecture teaching system is simple in structure and good in practicability, makes the proportion of the human body to a VR scene achieve the purpose that the proportion is consistent to thereal proportion and meets the demand of actual architecture teaching, the safety is improved, parameters in the building process can be also verified through the VR scene, the manufacturing cost is greatly reduced, and the construction quality is improved.

Owner:ZHEJIANG COLLEGE OF CONSTR

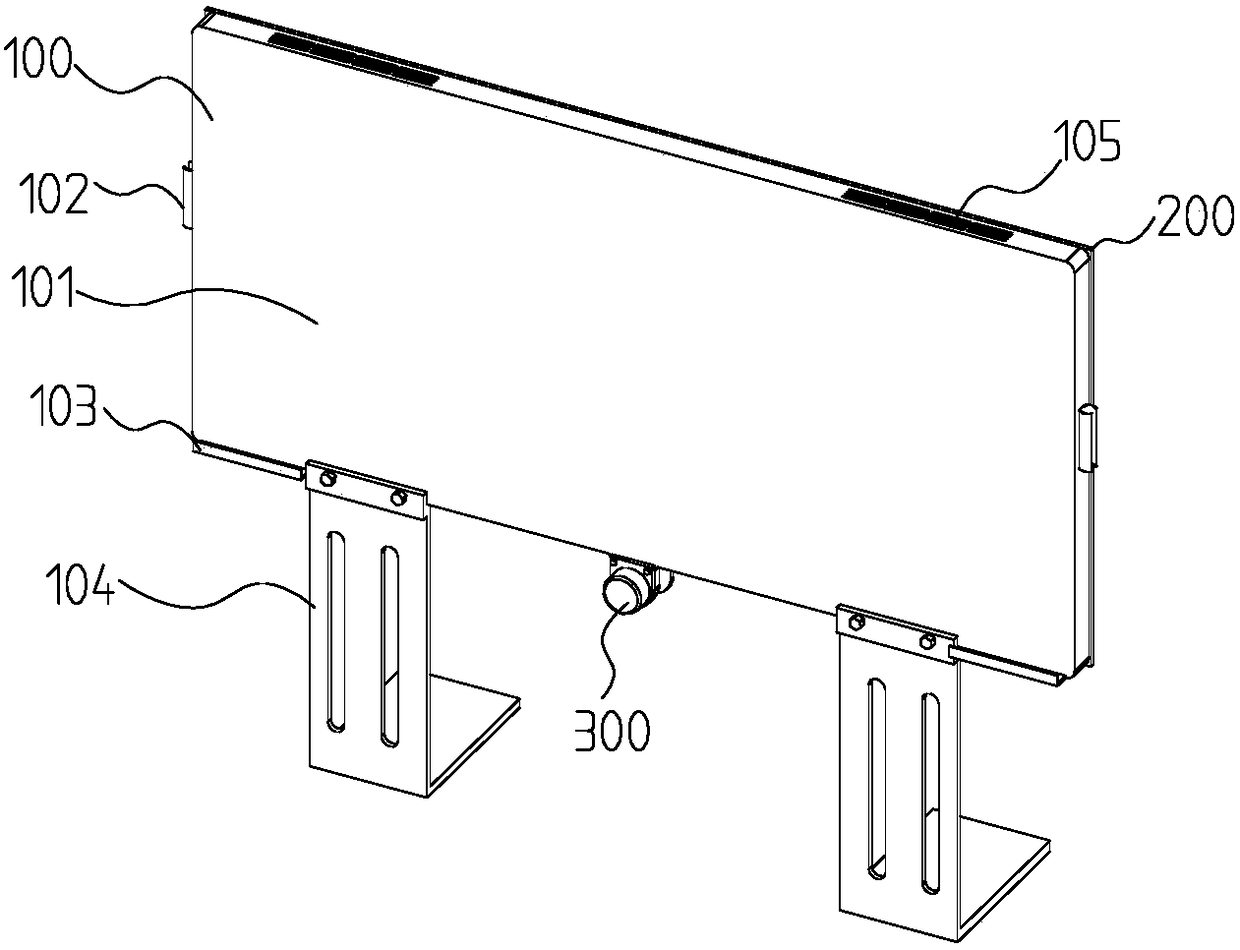

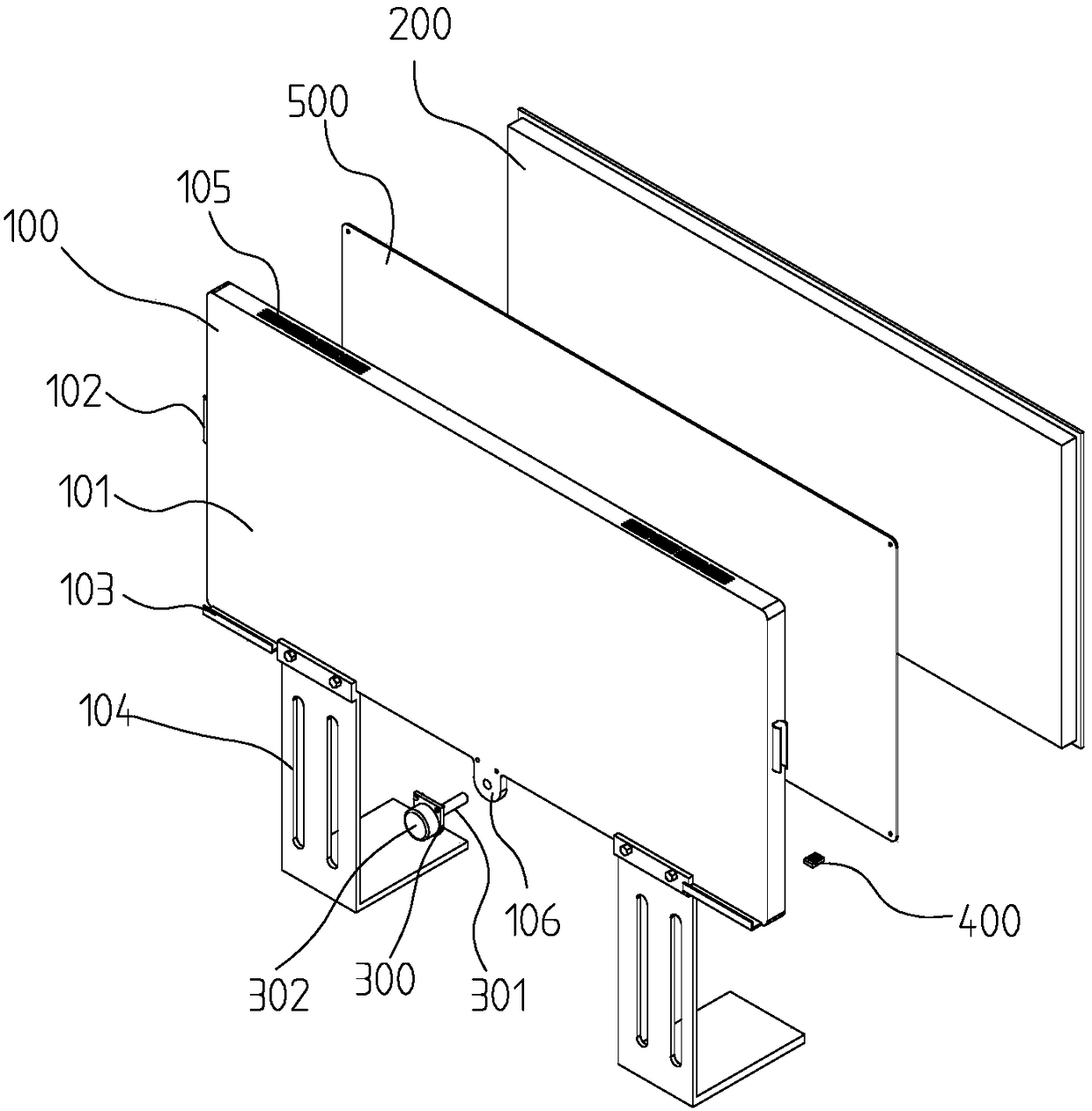

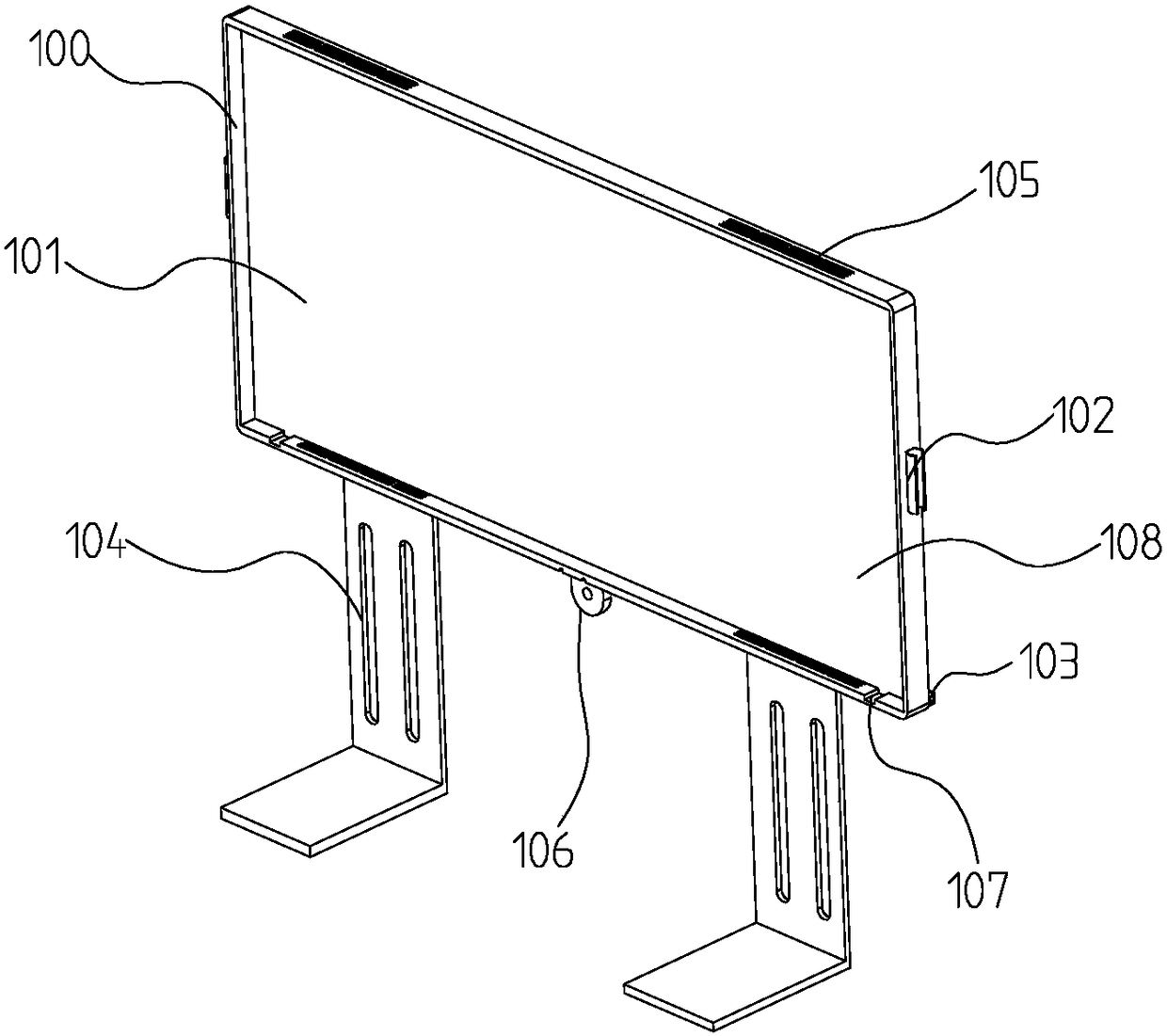

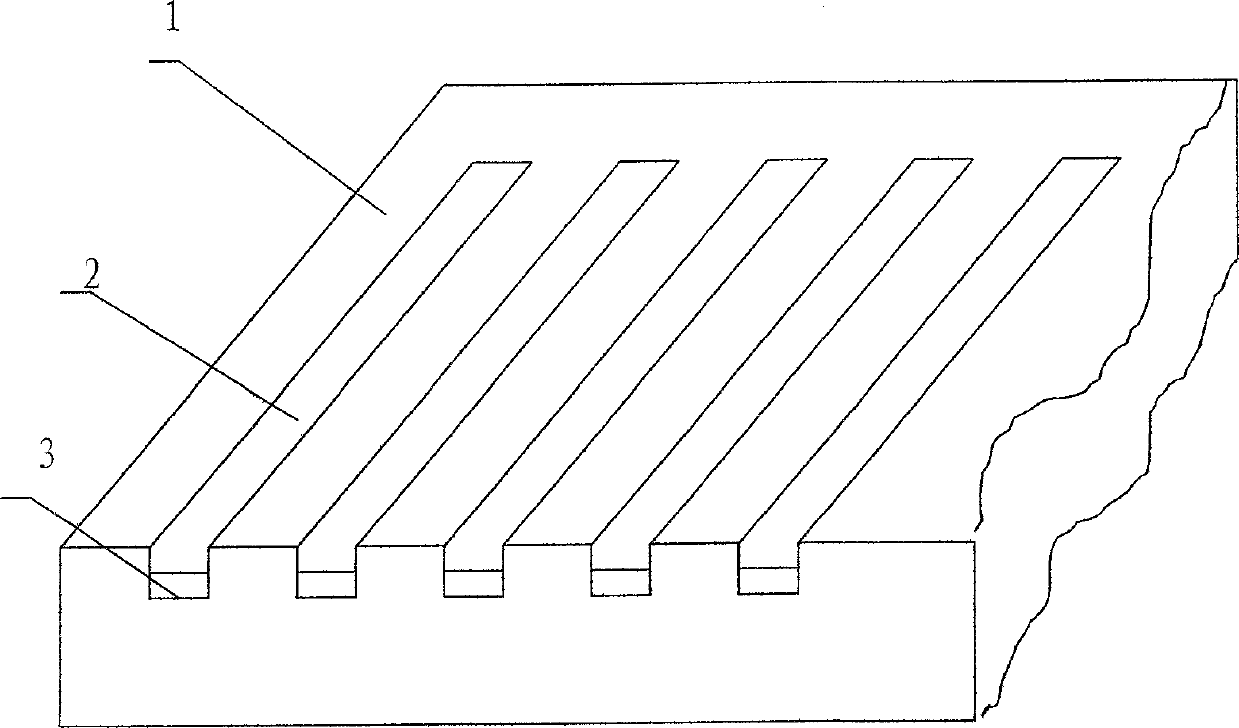

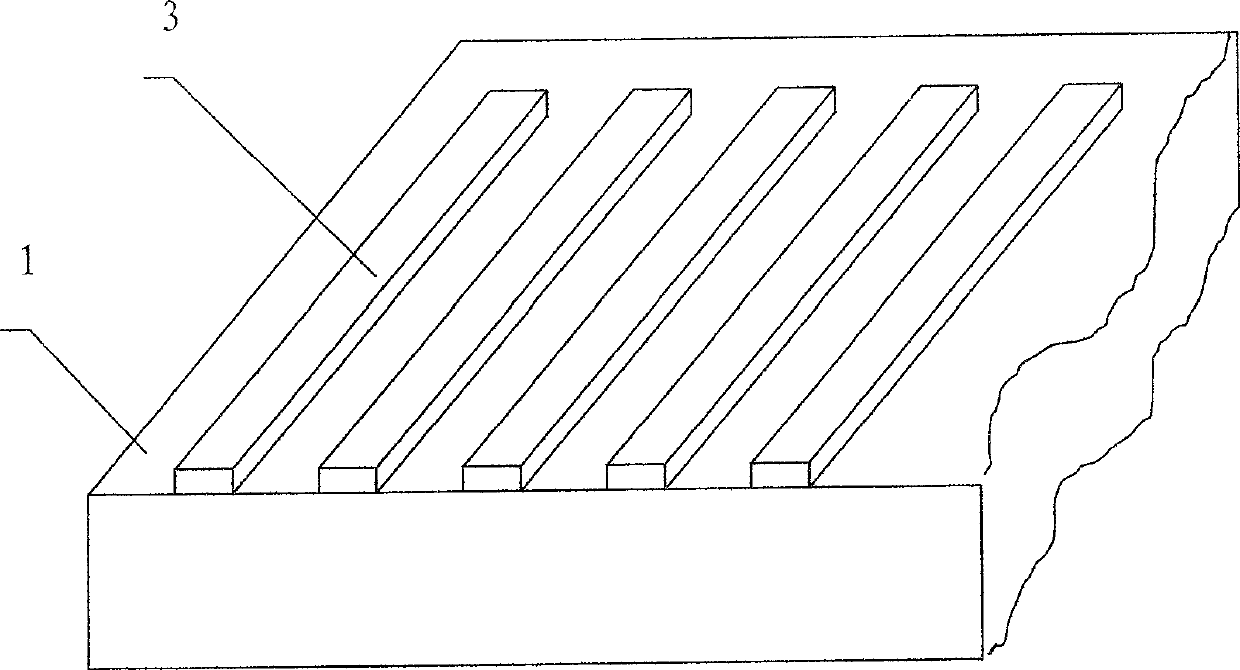

A teaching tool for advanced mathematics

InactiveCN105894869BReduce on-site drawingIncreased scale accuracyElectrical appliancesGraphicsTeaching tool

The invention provides a higher mathematic teaching aid. The higher mathematic teaching aid comprises a mounting frame, a movable board, a driving assembly, a sliding sleeve, a light emitting board and a light emitting board control device, wherein the mounting frame comprises a writing board, pen clips, board erasing frames, support legs, air holes, a motor mounting lug, sliding sleeve mounting grooves and a movable board mounting frame. The higher mathematic teaching aid has the advantages of simple structure and convenience in use, is capable of presenting prepared electronic courseware and coordinate graphics to students via the light emitting board, reducing the trouble of drawing the coordinate graphics by a teacher on site and improving proportion precision of the coordinate graphics; the writing board can also be used independently; different using effects can be achieved by adjusting the distance between the light emitting board and the writing board, so that the teaching efficiency can be improved.

Owner:JILIN INST OF CHEM TECH

Casting process for casting motorcycle engine cylinder block

InactiveCN106583649ALow costReduce finishing costsFoundry mouldsFoundry coresPressure systemPlastic film

The invention discloses a casting process for casting a motorcycle engine cylinder block. The evaporative pattern casting process is adopted for casting the motorcycle engine cylinder block, so that the traditional sand shakeout and decoring procedures are omitted thoroughly, treatment cost is lowered, mold cost is lowered, high-precision castings are produced repeatedly one hundred percent, and the wall thickness error is controlled within + / - 0.5 mm. The casting process includes the following specific steps that a foam plastic gasifiable pattern is manufactured; the motorcycle engine cylinder block pattern is subjected to foam plastic gasification, and then the foam plastic gasifiable pattern is combined and dried; fireproof paint is brushed or sprayed on the surface of the foam plastic gasifiable pattern, and then the foam plastic gasifiable pattern is dried again; a special sand box for containing the motorcycle engine cylinder block is placed on a three-dimensional vibration compacting table and filled with bottom sand, and then vibration compacting and strike-off are carried out; the dried foam plastic gasifiable pattern is placed on the bottom sand, layer-by-layer sand filling is carried out according to process requirements, and strike-off is carried out on the opening of the box after automatic vibration compacting; and the opening of the sand box is covered with a plastic thin film, a sprue cup is placed, and an evaporative pattern is obtained and connected with a negative pressure system.

Owner:重庆市合川区银窝铸造厂

Portable nuclear magnetic resonance logging calibration device and rapid calibration method

ActiveCN111963160APortableScale implementationWater resource assessmentBorehole/well accessoriesRock coreField conditions

The invention discloses a portable nuclear magnetic resonance logging calibration device and a rapid calibration method. The device comprises a cover, a shell and an inner cavity, wherein the cover ismatched with the shell, a sealing piece is arranged between the cover and the shell, the inner cavity is filled with a simulated geological layer medium and a fluid medium, the logging calibration device comprises a plurality of standard blocks, and the standard blocks are connected with one another to form a cylinder with an annular bottom surface. According to the calibration device and method,a rock skeleton medium is simulated by adopting glass beads, a real rock core and the like, a standard block is manufactured by adopting an oil and water simulated underground hydrocarbon reservoir fluid medium, and multi-point calibration is carried out under the conditions of simulating the pore structure of underground rock and oil bearing water; the multi-point calibration device has the characteristic of portability, and calibration of a logging field instrument is realized; through unified allocation of the detachable standard blocks, the difference of nuclear magnetic resonance loggingcalibration fluid caused by field condition limitation is avoided, unified calibration between different instruments in different areas is achieved, and the ground comparison cost of the instrument measurement effect is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

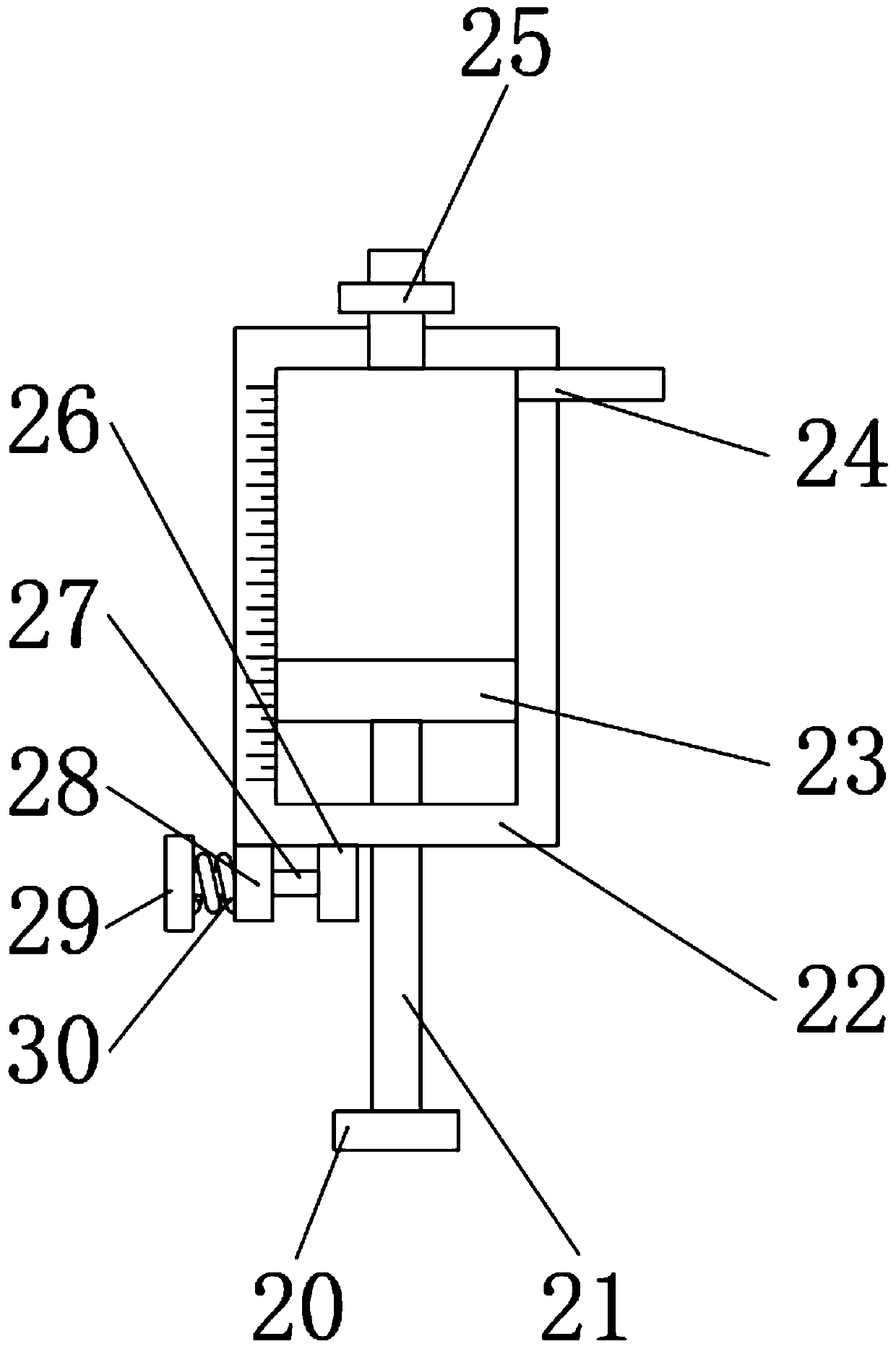

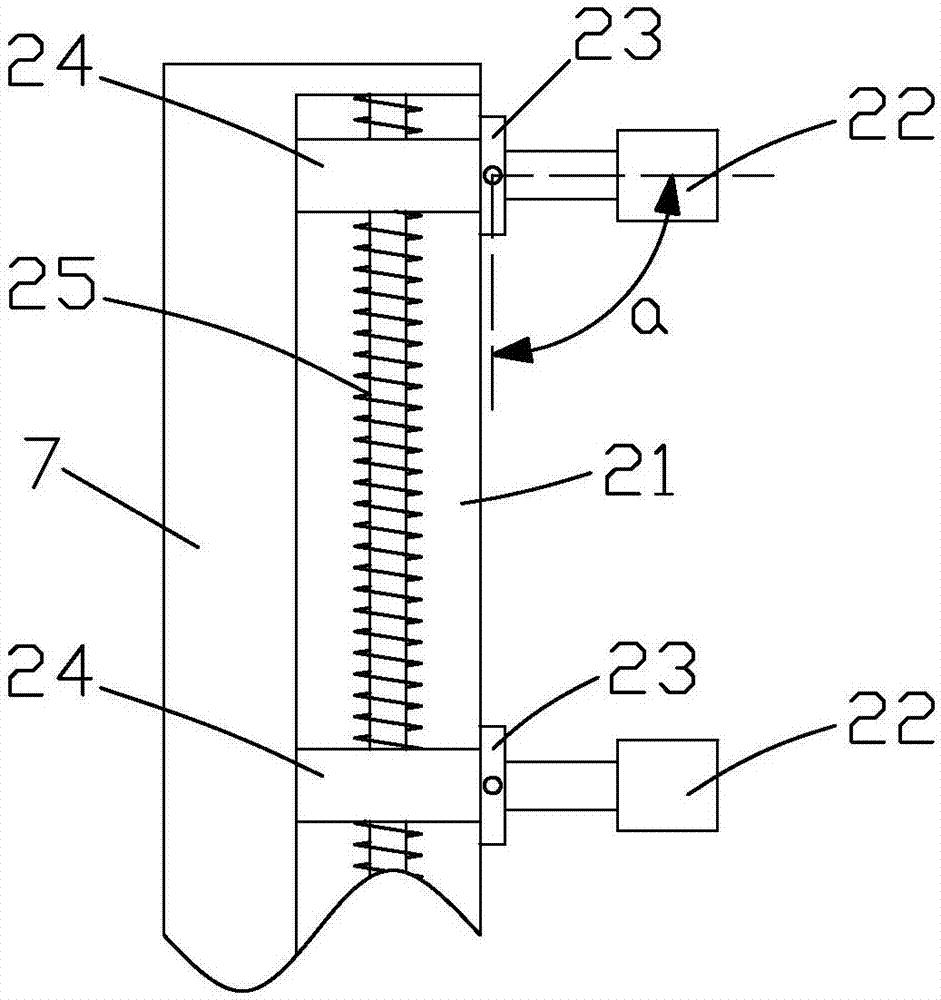

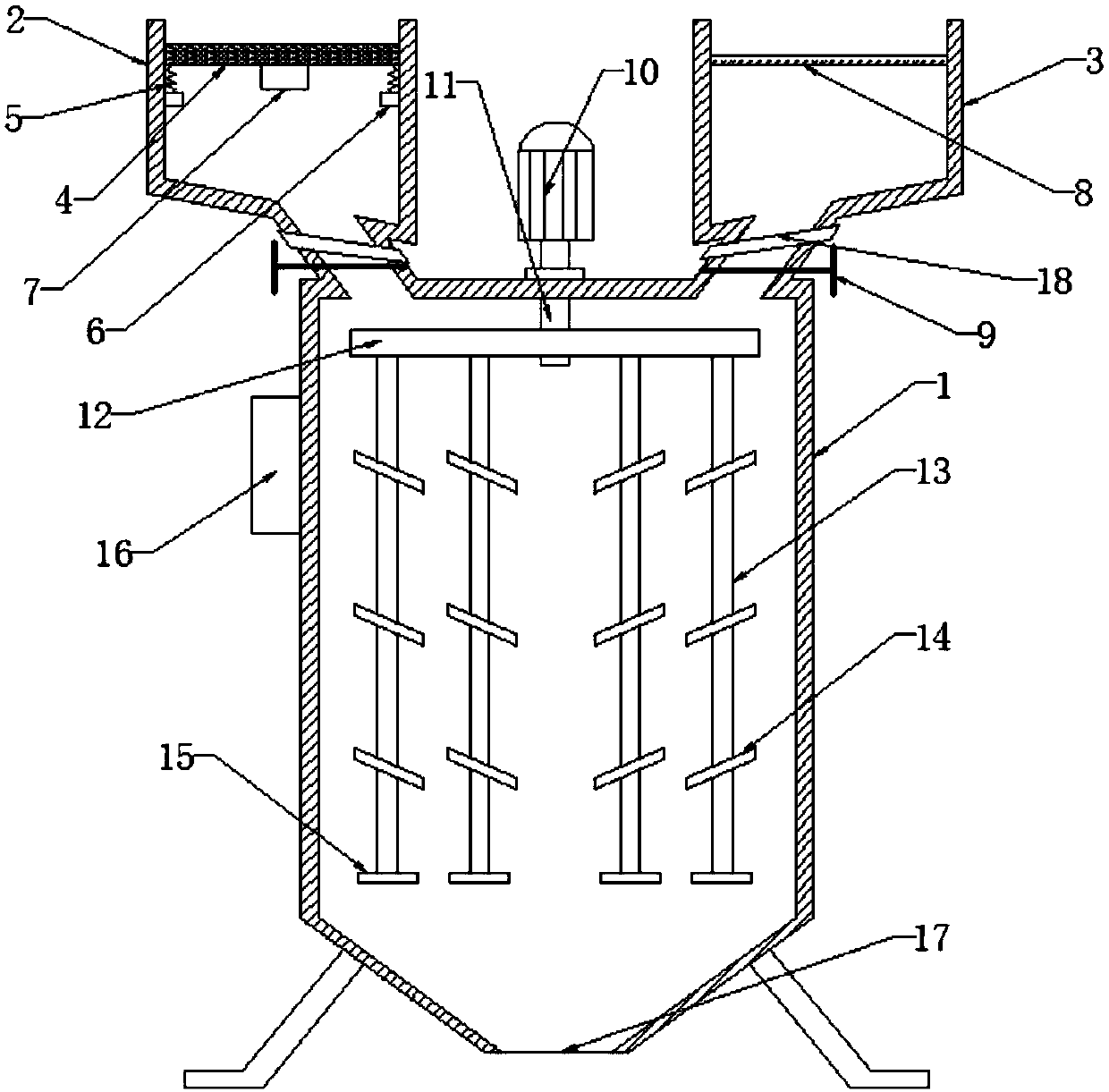

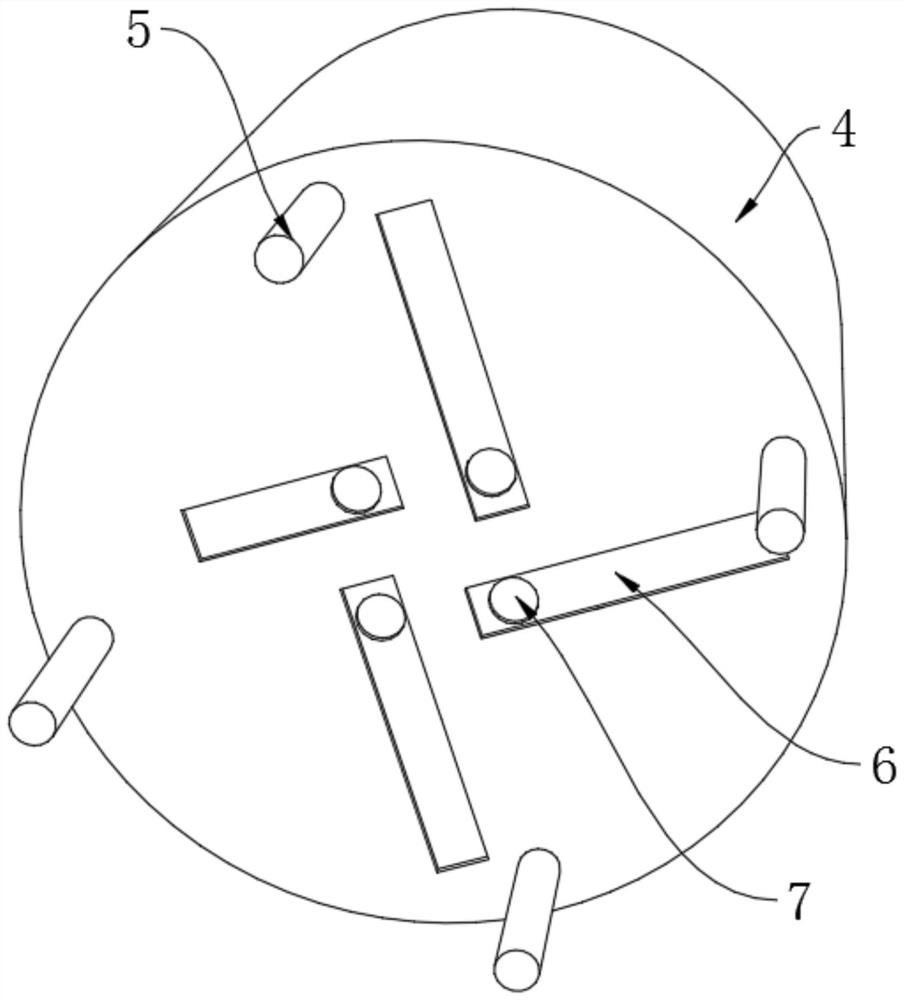

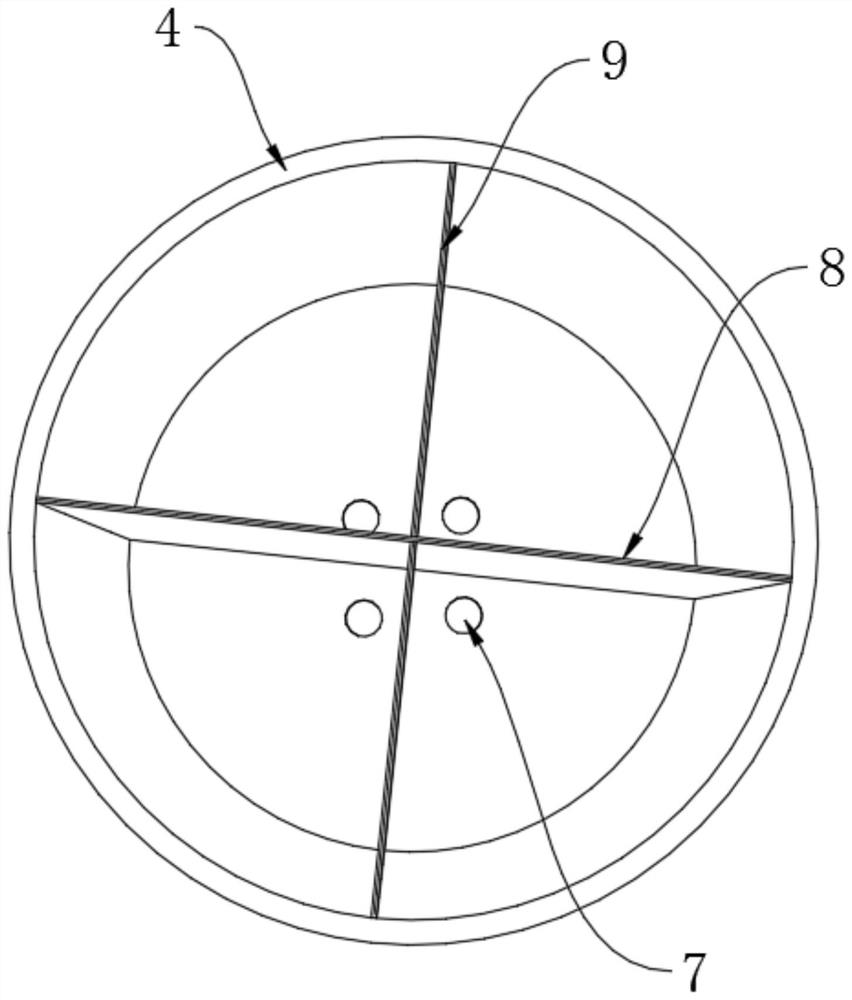

Multifunctional batching device

InactiveCN109718688AIncreased scale accuracyImprove stirring efficiencySievingRotary stirring mixersElectromagnetic valveMultiple function

The invention provides a multifunctional batching device comprising a stirring drum, a powder charging box and a liquid charging box; the powder charging box and the liquid charging box are located above the stirring drum and are in communication with the stirring drum by connecting channels; the connecting channels are connected with flow meters and electromagnetic valves, the stirring drum is provided with a controller, and the flow meters and the electromagnetic valves are connected with the controller; the top of the stirring drum is provided with an electric motor, and a vertically arranged rotating shaft is arranged in the stirring drum and is connected with the electric motor; the rotating shaft is provided with 2-8 supporting rods which are horizontally arranged, and the supportingrods are located at the upper part inside the stirring drum; 1-3 stirring rods are arranged below the supporting rods and are provided with a plurality of stirring blades, and the bottoms of the stirring rods are provided with stirring baseplates; and a feed opening is formed in the bottom of the stirring drum. The multifunctional batching device provided by the invention is capable of increasingthe stirring efficiency, more uniform in stirring and precise in batching.

Owner:新昌县永益包装有限公司

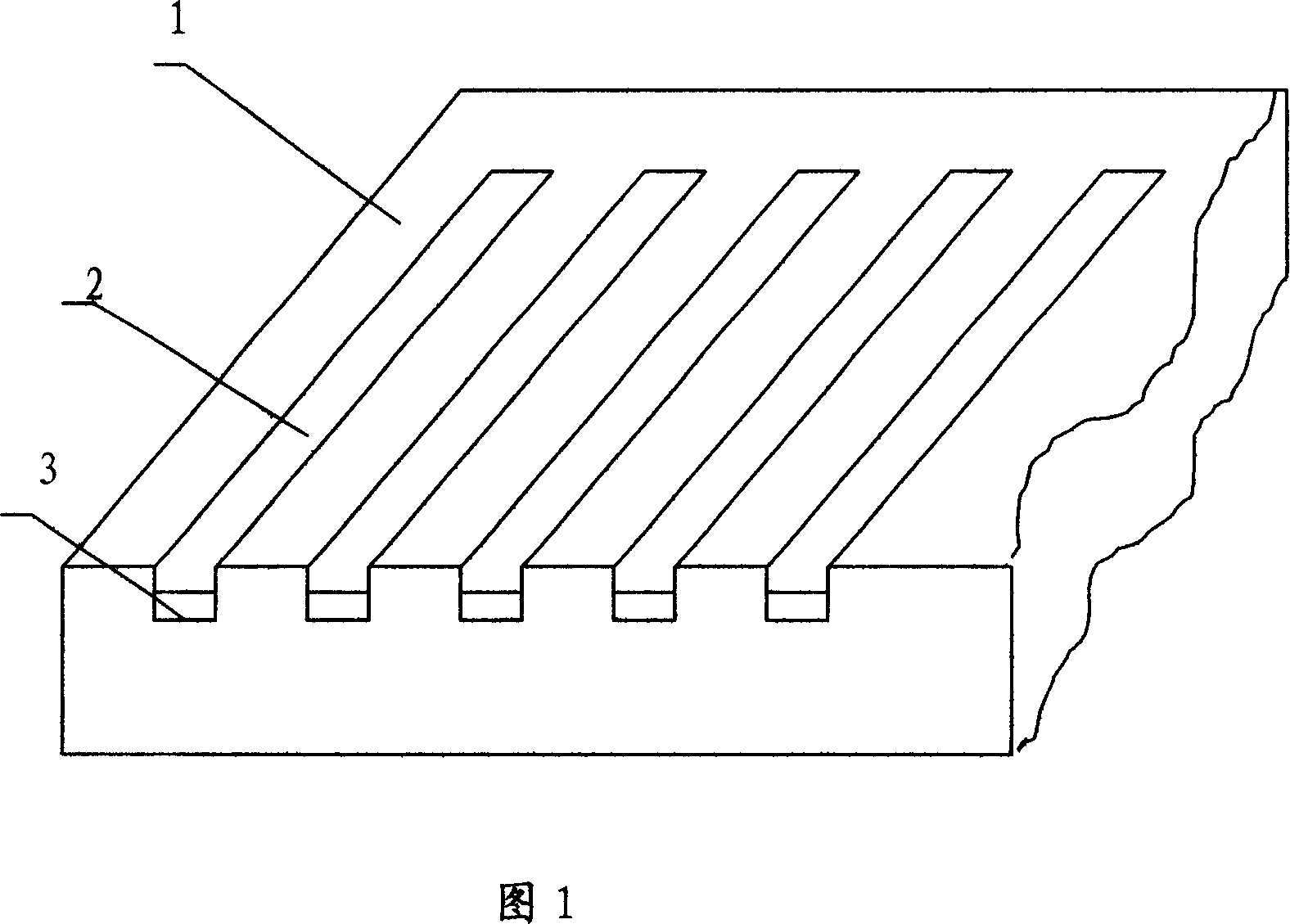

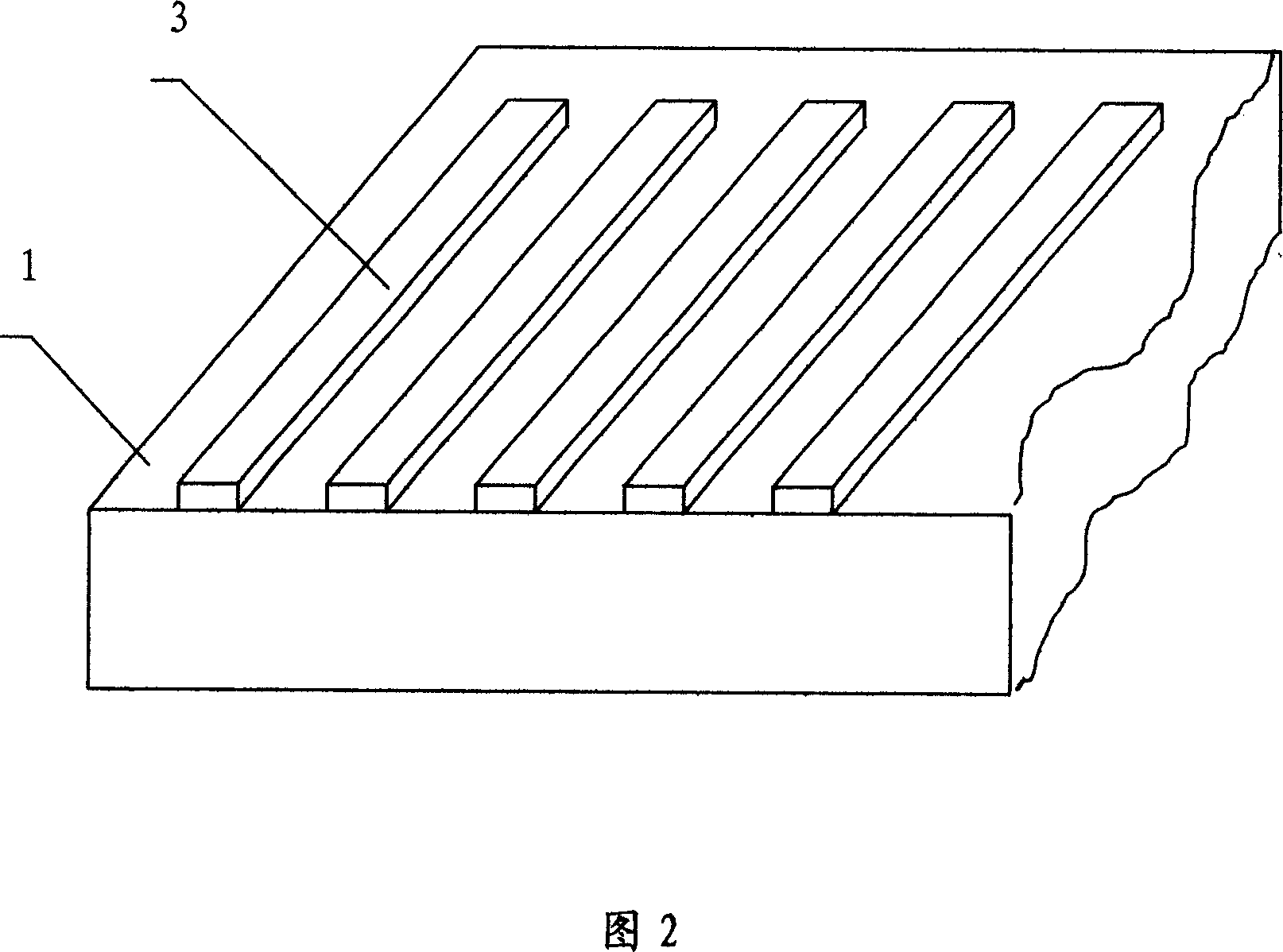

Hot stamping process for promoting meterage realia graduation precision

The invention involves a thermoprint art for increasing the scale accuracy of measuring teaching aid. Among them, the surface of printed object is equipped with groove and the scale mark is on the bottom of groove, the steps of thermoprint method as follows: getting ready thermoprint typograph with scales; putting the thermoprint paper between the thermoprint typograph and printed stock; starting thermoprinting machine to making the thermoprint heating component is heat pressed and contacted with thermoprint typograph, the printed stock is heated and distorted down forming groove during the thermoprinting process; the thermoprinting time is 3-60 seconds; thermoprinting temperature is 85-185 degree C; the scales on the thermoprint typograph is trans-printed with the thermoprinting paper on the groove bottom of printed object and forms scale marks; then preparing product. The advantages of the invention are: using proper thermoprinting art can improve the scale accuracy of measuring teaching aid and can make the scale accuracy of measuring teaching aid meet the requirements in QB / T1474.1-QB / T1474.7. The got product in the invention is very suitable for professional users such as mapping and drawing personnel.

Owner:南昌航天文化科技有限公司

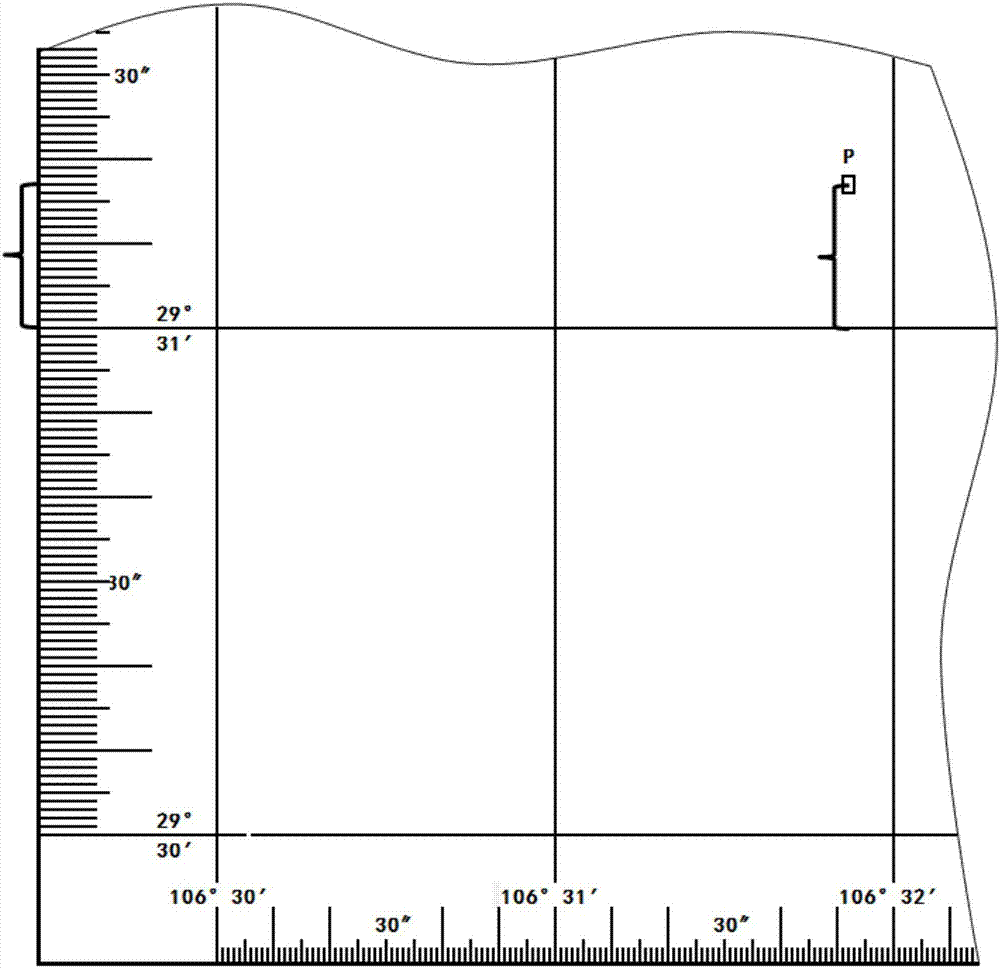

Geographic coordinate in large scale map application and measurement method and map for implementing same method

The invention relates to a geographic coordinate in large scale map application and measurement method and a map for implementing the same method. The method of reading the geometric coordinates of the large-scale map comprises the following steps: capturing a vertical distance from the target point to the left longitude or the lower parallel, and reading the geographical coordinates directly on the map edge line near the target point. The large-scale map for implementing the method employs the geometric coordinate network. The indexing zone difference of the adjacent latitude and longitude lines is one point. Each indexing zone is marked with the degree value. Each indexing zone is scaled by second values on the outer edge line. The method process is simplified and the efficiency is high. The line searching error, the line connection error and the reading error of the map user are reduced. The number reading and the formulation calculation are not required, the speed is increased, and the error is reduced. The dependence on the measurement tools such as long rulers and calculators of the personnel is reduced. The map loss is reduced, the manpower and material resources are saved, and wastes of map printing resources are reduced.

Owner:中国人民解放军69080部队

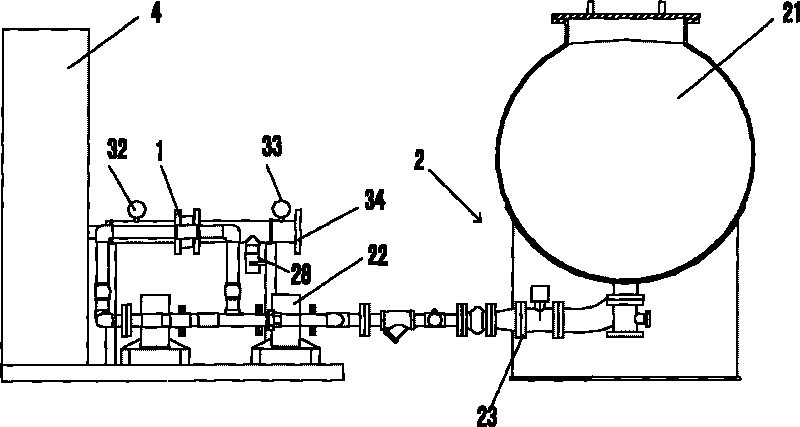

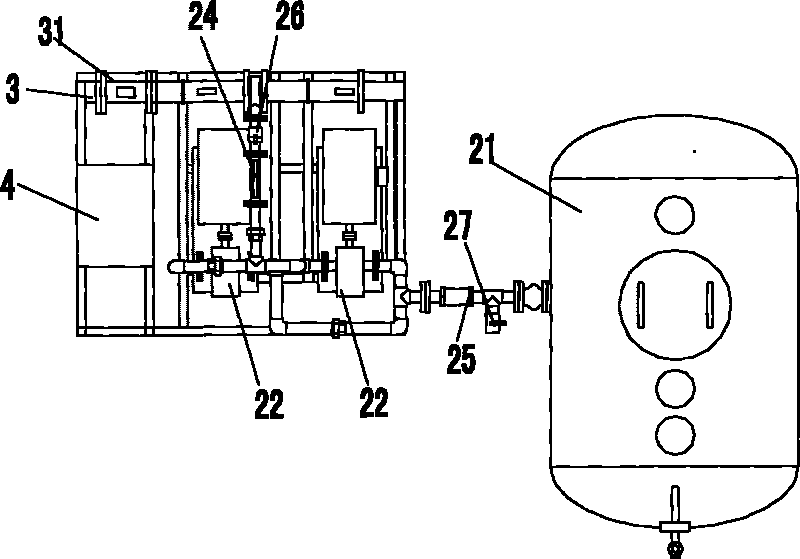

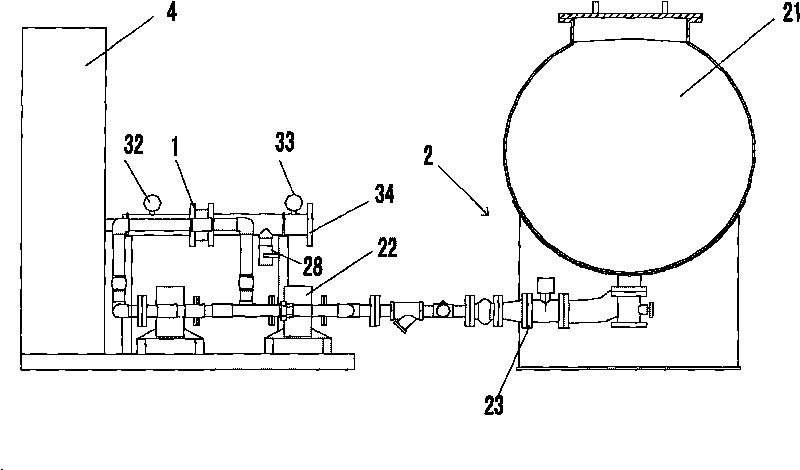

Measurement injecting type proportion mixing device

InactiveCN101721781AAutomatic adjustment of pump flowGood energy saving effectFire rescueMixer accessoriesFrequency changerMicrocomputer

The invention discloses a measurement injecting type proportion mixing device comprising a proportioner, a foam concentrate supply mechanism and a fire fighting water pipeline, wherein the foam concentrate supply mechanism and the fire fighting water pipeline are communicated with the proportioner; the foam concentrate supply mechanism comprises a foam concentrate storage tank, a foam concentrate delivery pump, a foam concentrate delivery pipeline, an engineering single board computer PC and a transducer, wherein the fire fighting water pipeline and the foam concentrate delivery pipeline are respectively provided with a fire fighting water flow sensor and a foam concentrate flow sensor; two flow sensors are respectively connected with the electrical signal of the engineering single board computer PC; the engineering single board computer PC is connected with the electrical signal of the transducer; the transducer is connected with the electrical signal of the foam concentrate delivery pump so as to control the revolving speed of the foam concentrate delivery pump. The measurement injecting type proportion mixing device of the invention takes automatic instrument measurement as a main control unit, uses a microcomputer transducer for controlling according to the flow change of a water supply system, can keep fire fighting water and foam liquid in a stable proportion, has high precision degree of mixing ratio and is convenient to adjust the mixing ratio.

Owner:SHANGHAI HAIYUE SAFETY ENG EQUIP CO LTD

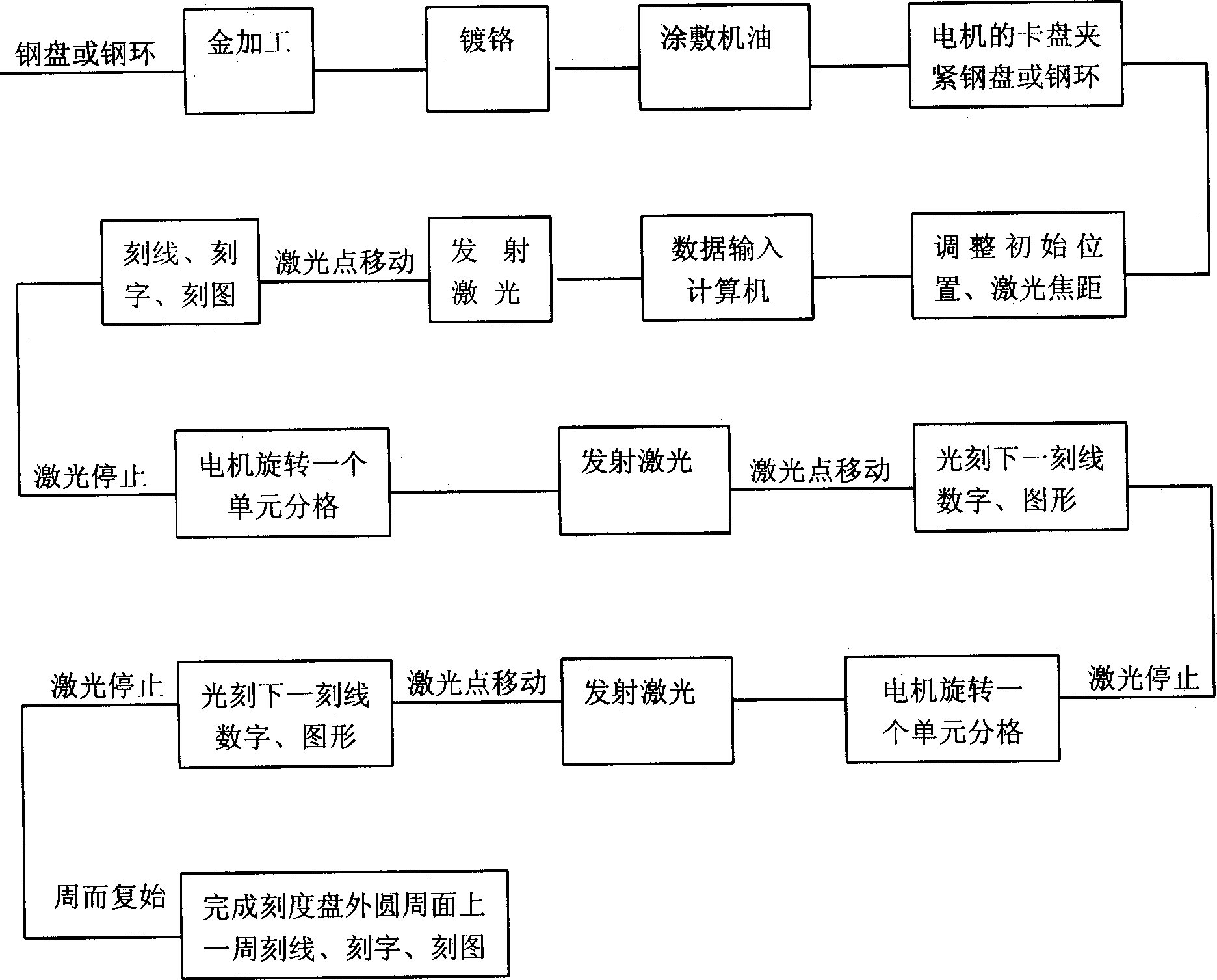

Photoetching method for dial of machine-tool

InactiveCN1381332AHigh scale accuracySimple processLaser beam welding apparatusAutomatic controlEngineering

A laser carving method for the dial scale of machine-tool features that after the machine oil is coated on the circumference surface of blank dial scale, the laser beam is used for carving lines, characters and graphics on the said surface while the blank dial scale is driven by a motor to rotate under the control of the computer. Its advantages are high precision, beautiful appearance, low cost,long service life and no environmental pollution.

Owner:张伟华

Higher mathematic teaching aid

InactiveCN105894869AReduce on-site drawingIncreased scale accuracyElectrical appliancesGraphicsEngineering

The invention provides a higher mathematic teaching aid. The higher mathematic teaching aid comprises a mounting frame, a movable board, a driving assembly, a sliding sleeve, a light emitting board and a light emitting board control device, wherein the mounting frame comprises a writing board, pen clips, board erasing frames, support legs, air holes, a motor mounting lug, sliding sleeve mounting grooves and a movable board mounting frame. The higher mathematic teaching aid has the advantages of simple structure and convenience in use, is capable of presenting prepared electronic courseware and coordinate graphics to students via the light emitting board, reducing the trouble of drawing the coordinate graphics by a teacher on site and improving proportion precision of the coordinate graphics; the writing board can also be used independently; different using effects can be achieved by adjusting the distance between the light emitting board and the writing board, so that the teaching efficiency can be improved.

Owner:JILIN INST OF CHEM TECH

Batch raw material feeding and manufacturing device based on laundry condensate bead production

InactiveCN113859797AImprove the ability to deliver in batchesImprove the accuracy of ingredient ratioLarge containersProcess engineeringMaterial distribution

The invention discloses a batch raw material feeding and manufacturing device based on laundry condensate bead production, and relates to the technical field of novel laundry condensate bead processing. The batch raw material feeding and manufacturing device comprises a liquid leakage prevention guide-out funnel, a batch feeding control structure used for controlling timed and quantitative feeding of raw materials is fixed at the top end of the liquid leakage prevention guide-out funnel, the top end of the batch feeding control structure is fixedly connected with a material distribution storage tank structure used for storing different raw materials in a separated mode, and the material distribution storage tank structure comprises a storage tank main body, an auxiliary supporting column, a reserved stroke groove, a discharging through hole, a first separation placing plate and a second separation placing plate. According to the batch raw material feeding and manufacturing device, the batch feeding control structure and the material distribution storage tank structure are designed in a matched mode, so that the device can conveniently and automatically carry out timed and quantitative feeding of the raw materials in batches into the laundry condensate bead production device, the capacity of feeding the raw materials in batches is greatly improved, and therefore the batching proportion accuracy in the production process and the execution performance of the feeding process at different times are improved.

Owner:安徽婧夫人生物科技有限公司

Hot stamping process for promoting meterage realia graduation precision

ActiveCN100506552CIncreased scale accuracyPracticalRotary pressesThermographyHot stampingLetterpress printing

Owner:南昌航天文化科技有限公司

Production method for calibration block of radioactive fluid density logging instrument

ActiveCN102606133ASolve the problem of excessive errorIncreased scale accuracySurveySpecific gravity measurementGround systemDensity logging

The invention discloses a production method for a calibration block of a radioactive fluid density logging instrument. The method includes: making density calibrated scales equal in length and width but unequal in height according to the dimension of the sampling channel of the radioactive fluid density logging instrument, calculating scale coefficients of the fluid density logging instrument in air and pure water respectively and storing; placing the radioactive fluid density logging instrument in air, placing the density calibrated scales equal in length and width but unequal in height into sampling chambers respectively, using a logging ground system to read the scale coefficients and record displayed values of fluid density, and setting up data tables of the density calibrated scales unequal in height and the corresponding density values; determining the height values of the density calibrated scales unequal in height according to the data tables when the density value error is zero; and making a density calibration block according to the height values of the density calibrated scales. Using the method can produce corresponding standard calibration blocks for various radioactive fluid density logging instrument, the problem that errors of the calibration block are out of standard is effectively solved, and scale precision of the instrument is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

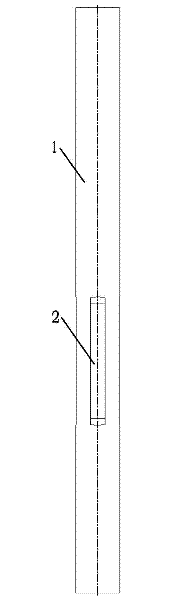

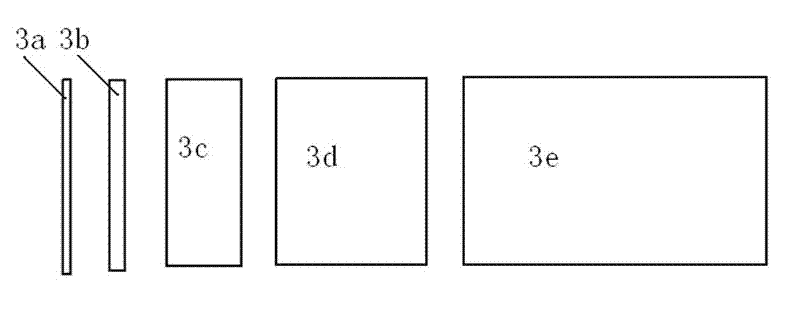

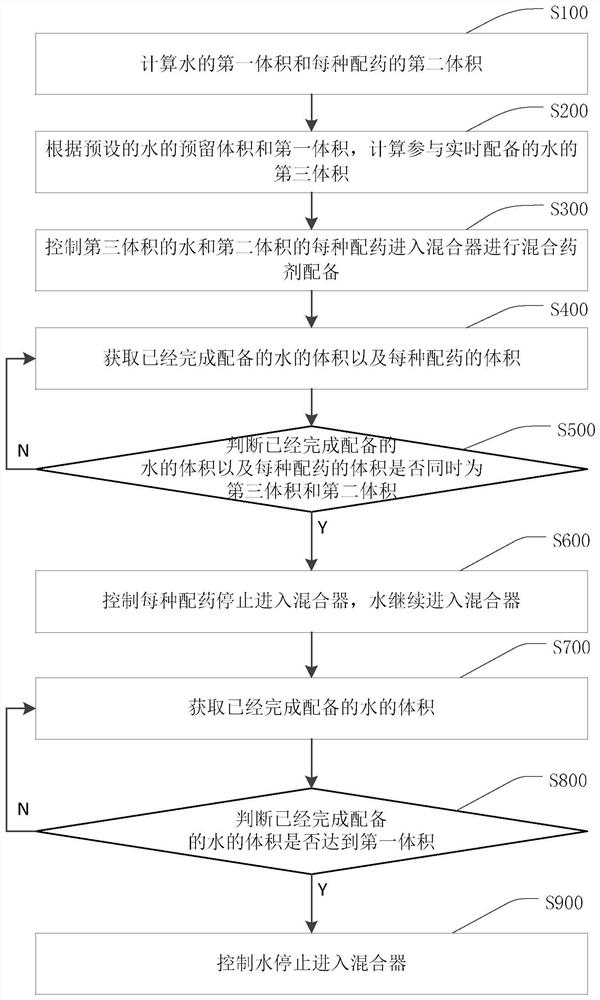

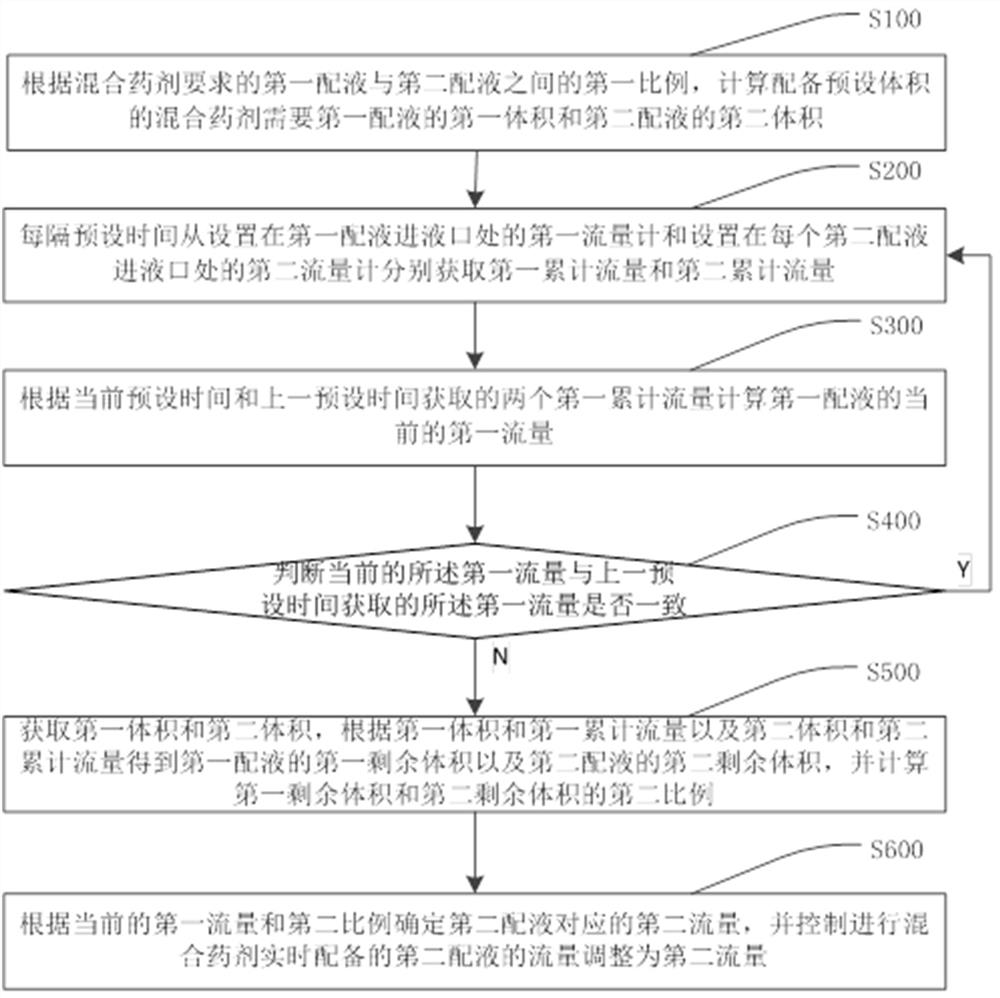

Control method for preparation of mixed medicament and control device

ActiveCN113244848AGuaranteed compliance with proportional requirementsGuaranteed ratio requirementsTransportation and packagingMixing methodsWater useProcess engineering

Owner:北京百瑞弘霖有害生物防治科技有限责任公司

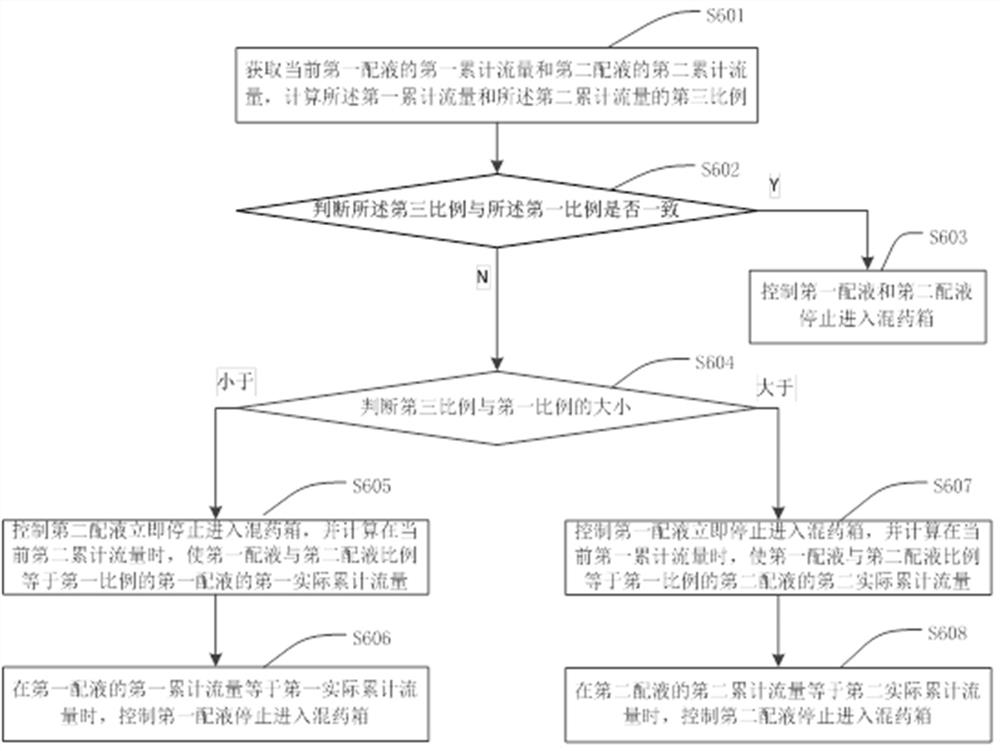

Method and device for monitoring preparation of mixed medicament

PendingCN113634185AMeet the first ratio requirementImprove reliabilityMixer accessoriesProcess engineeringIntensive care medicine

The invention relates to a method and device for monitoring preparation of a mixed medicament. The method comprises the following steps: acquiring a first accumulative flow of a first prepared solution and a second accumulative flow of a second prepared solution every preset time; calculating the current first flow of the first prepared solution according to the first accumulated flow obtained in the current preset time and the previous preset time; and when the current first flow is inconsistent with the first flow obtained in the previous preset time, calculating a first residual volume of the first prepared solution, a second residual volume of the second prepared solution and a second proportion of the first residual volume and the second residual volume, determining a second flow corresponding to the second prepared solution according to the current first flow and the second proportion, and controlling the flow of the second prepared solution to be changed into the second flow. The solution preparation flow can be monitored and adjusted in real time, it is guaranteed that the mixed medicament prepared in each time period meets the proportion requirement, and the reliability of preparation of the mixed medicament is effectively improved.

Owner:北京百瑞盛田环保科技发展有限公司

Method for preparing copper indium gallium selenium thin film and photovoltaic thin film battery based on selenium plasma

InactiveCN101956164BIncreased scale accuracyLower the temperature of selenizationFinal product manufactureVacuum evaporation coatingIndiumCopper indium gallium selenide solar cells

The invention discloses a method for preparing a copper indium gallium selenide film and a photovoltaic film battery based on a selenium plasma, comprising the following steps of: 1, ionizing work gas by an ion source to enable the work gas to be in a plasma state and providing the plasma in an evaporation source chamber; 2: evaporating a selenium material by using an electron gun to generate selenium stream in the evaporation source chamber; 3: enabling electron cloud generated by the work gas in the ionization process to mutually impact the selenium steam by connecting a crucible with positive bias to generate the selenium plasma; and 4. heating the plated substrate to the preset selenizing temperature and respectively evaporating copper, indium, gallium and selenide metal materials by using an evaporation source arranged in the evaporation source chamber in the selenium plasma atmosphere backpressure environment so as to deposit a copper indium gallium selenide photovoltaic film on the substrate. According to the method, the selenizing temperature of the copper indium gallium selenide film in the growing process is reduced, the ratio precision of various materials of the copper indium gallium selenide film is improved and the large-area preparation of the copper indium gallium selenide film is realized.

Owner:何整风

Powder output device capable of automatically controlling discharge amount

PendingCN106965327AControl work statusPrecise control of powder conveying volumeMixing operation control apparatusIngredients weighing apparatusAutomatic controlMechanical engineering

The invention discloses a powder output device capable of automatically controlling the discharge amount. The powder output device comprises a funnel-shaped powder cylinder and a feeding device communicating with the bottom of the powder cylinder. A mounting frame is mounted on the lower portion of the powder cylinder in a hoisting mode. One end of the feeding device is fixedly mounted on the mounting frame, and the other end of the feeding device is connected with a fixing frame and communicates with a mixing device. A tension sensor is mounted between the feeding device and the fixing frame. The mass of the feeding device is measured and controlled through the tension sensor, and the tension sensor can precisely control the powder conveying amount of the feeding device, improve the proportion precision of mixed powder and improve the quality of concrete production. The automation degree is high, the labor cost can be reduced, and resources are saved.

Owner:JIANGMEN ZHONGJIAN TECH DEV CO LTD

Correction method for aerial surveying and mapping images

ActiveCN102706331BSimple stepsEasy to operateHeight/levelling measurementPicture interpretationComputer visionAerial photography

The invention discloses a correction method for aerial surveying and mapping images, which comprises the following steps: setting two reference points in a to-be-measured area, and measuring the horizontal distance between the two points; measuring idealistic distance between two final image points in a final image corresponding to a target scale according to the target scale and the obtained horizontal distance; carrying out aerial photography for to-be-measured area, butting the obtained images so as to obtain an integral original image of the to-be-measured area, and measuring the actual distance between two original image points; and calculating the ratio of the idealistic distance to the actual distance to scale the original image according to the ratio, so as to obtain the final image. Due to the adoption of the method provided by the invention, the image of the target scale can be obtained without conforming to the accurate aerial photography height, accordingly, the precision requirement for the aerial photography height is reduced, and the operation is simpler.

Owner:天津建岩岩土工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com