Feeding system and method for further improving proportioning precision in continuous production and feeding of chemical slurry

A technology of feeding ratio and continuity, applied in the field of feeding system, can solve the problems of reducing work efficiency, flying powder in the workshop, and fluctuating the flow of input materials, so as to improve the accuracy of feeding ratio, avoid human injury, and improve the operating environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

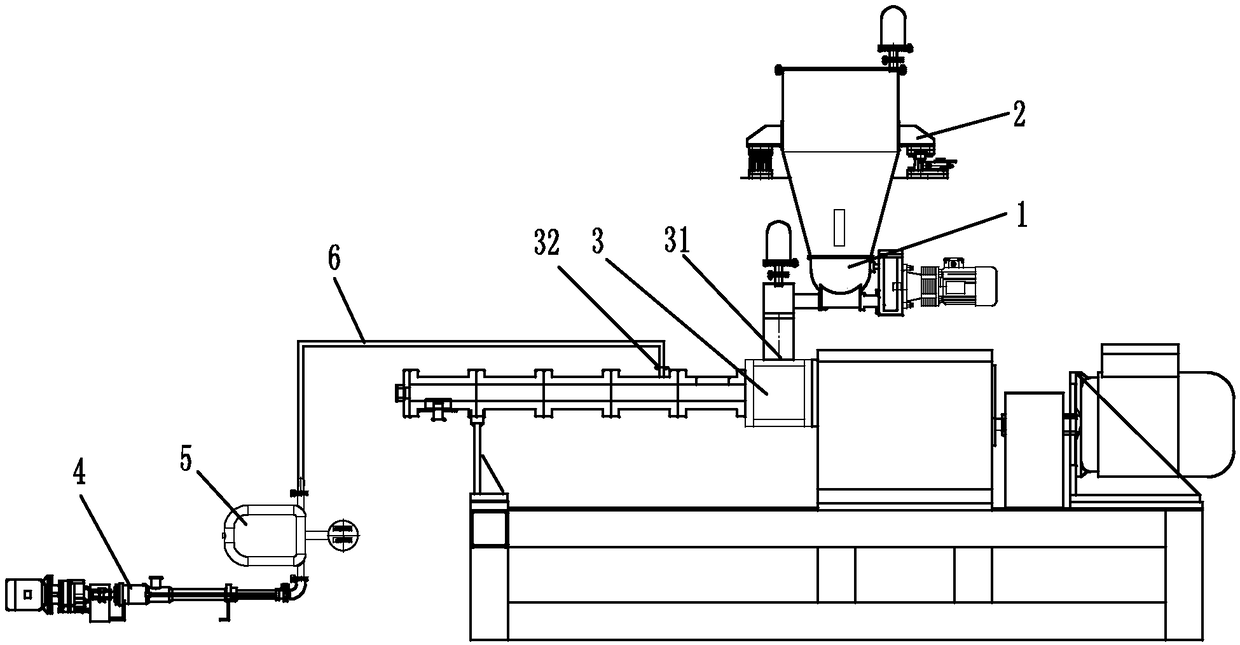

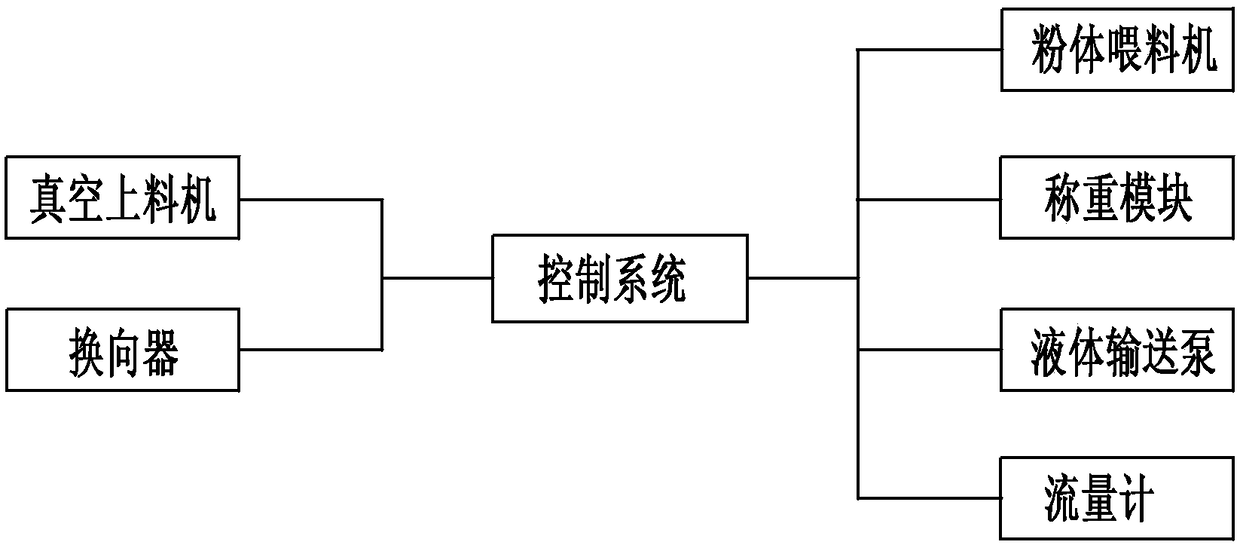

[0029] Embodiment 1: a kind of feeding system that further improves the precision of feeding ratio in the continuous production of chemical slurry, such as figure 1 As shown, it includes a control system, a powder metering and feeding device, a twin-screw mixer 3, a liquid delivery pump 4, and a flow meter 5 for measuring the liquid feeding flow and feeding back information to the control system. The powder metering and feeding device There are two (powder metering and feeding device I and powder metering and feeding device II), each powder metering and feeding device is composed of powder feeder 1 and used to weigh the weight inside the powder feeder and send information The weighing module 2 fed back to the control system is composed of the weighing module 2 installed on the powder feeder; the twin-screw mixer 3 is provided with a powder inlet 31 and a liquid inlet 32, and the outlet of the powder feeder 1 is connected to the twin-screw The powder inlet 31 of the mixer 3 is ...

Embodiment 2

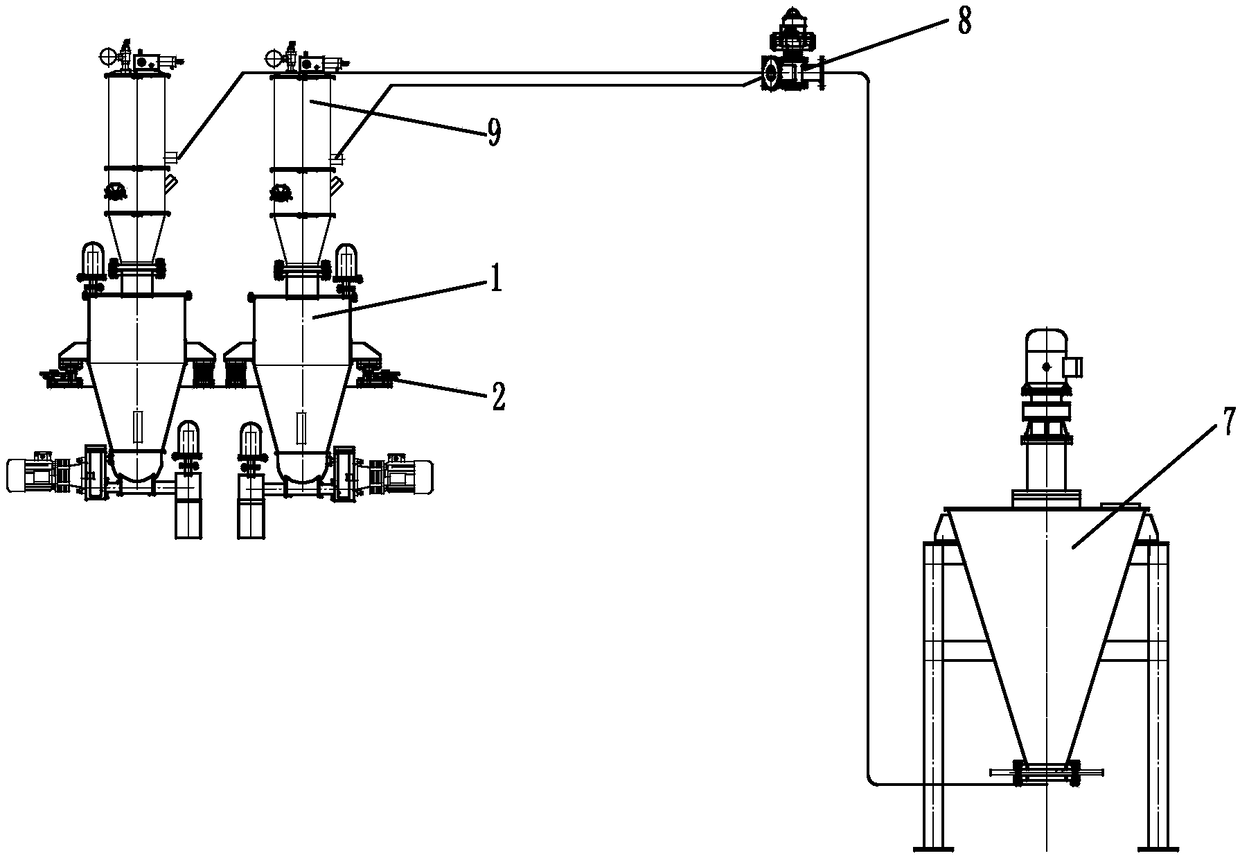

[0030] Embodiment 2: A feeding system for further improving the accuracy of feeding proportioning in the continuous production of chemical slurry, its basic structure is the same as that of Embodiment 1, the difference is that it also includes a powder storage device 7, a commutator 8 and Two vacuum feeders 9, the vacuum feeder is installed on the powder feeder 1, the vacuum feeder 9 communicates with the powder storage device 7 through the commutator 8, the vacuum feeder 9 and the commutator 8 are respectively connected with the control system (such as figure 2 , image 3 shown), the commutator in this embodiment is a three-way commutator.

Embodiment 3

[0031] Embodiment 3: a kind of feeding method that further improves the precision of feeding ratio in the continuous production of chemical slurry, adopts the feeding system described in embodiment 1, comprises the following steps:

[0032] (1) Set the ratio of the powder feeding flow rate to the liquid feeding flow rate in the control system;

[0033] (2) The control system controls the powder feeder 1 and the liquid delivery pump 4 of the powder metering and feeding device to feed powder materials and liquid materials into the twin-screw mixer 3 at a constant flow rate for continuous production; two powder feeders Machine 1 switches feeding to ensure continuous feeding of powder materials.

[0034] (3) The control system monitors the liquid feeding flow rate fed back by the flow meter 5 in real time and the weight of the powder material in the powder feeder 1 fed back by the weighing module 2 in real time, and calculates the powder feeding flow rate;

[0035] The calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com