Patents

Literature

73results about How to "High image precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

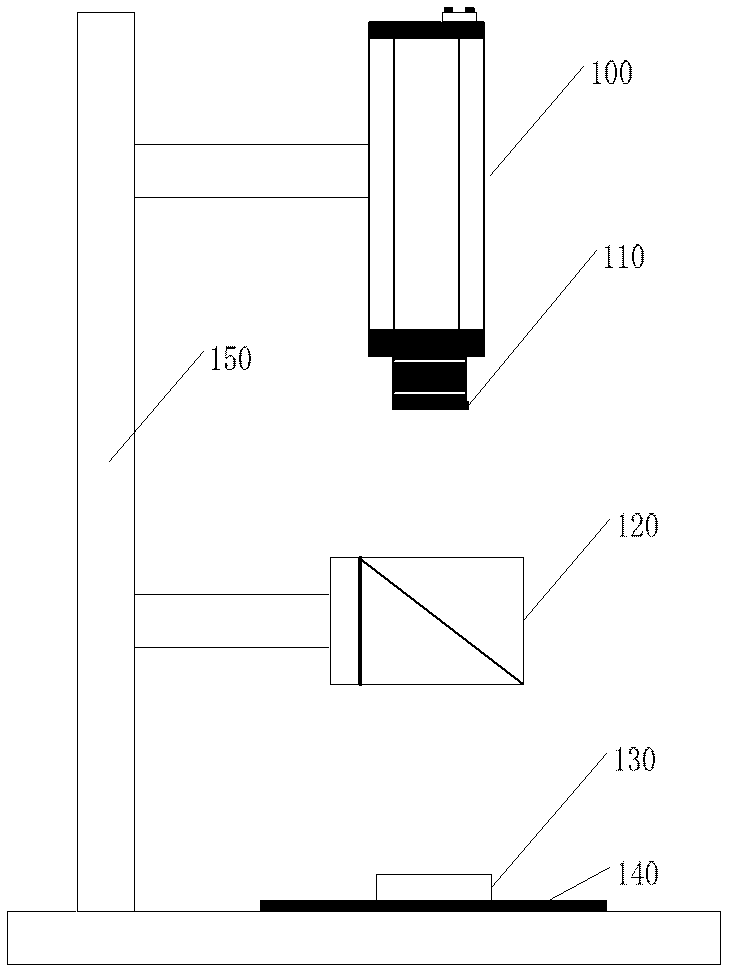

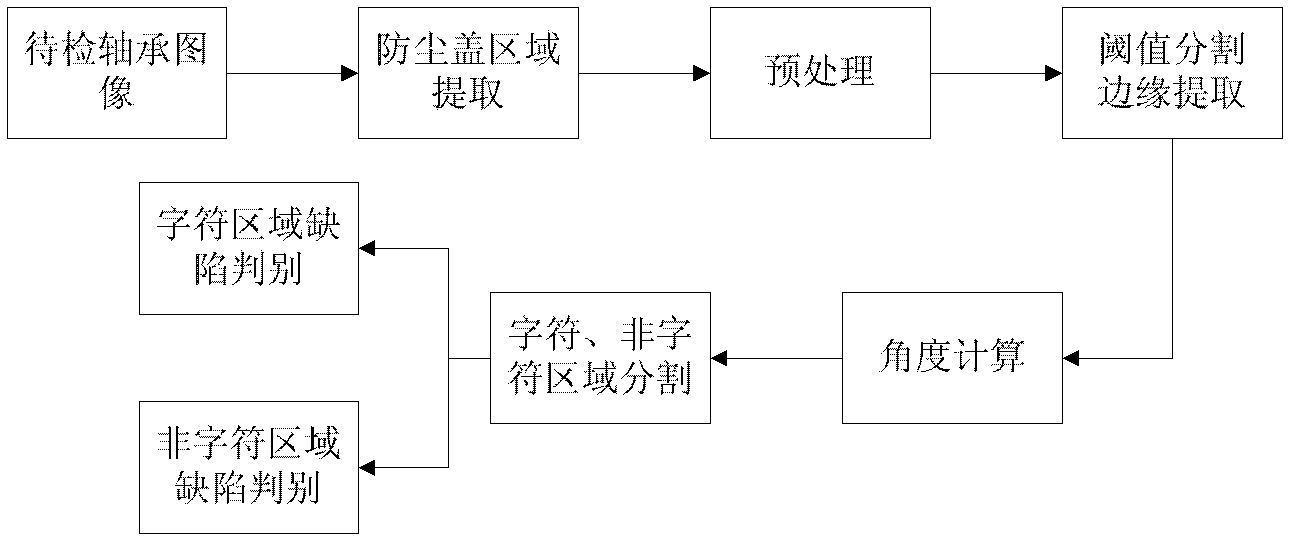

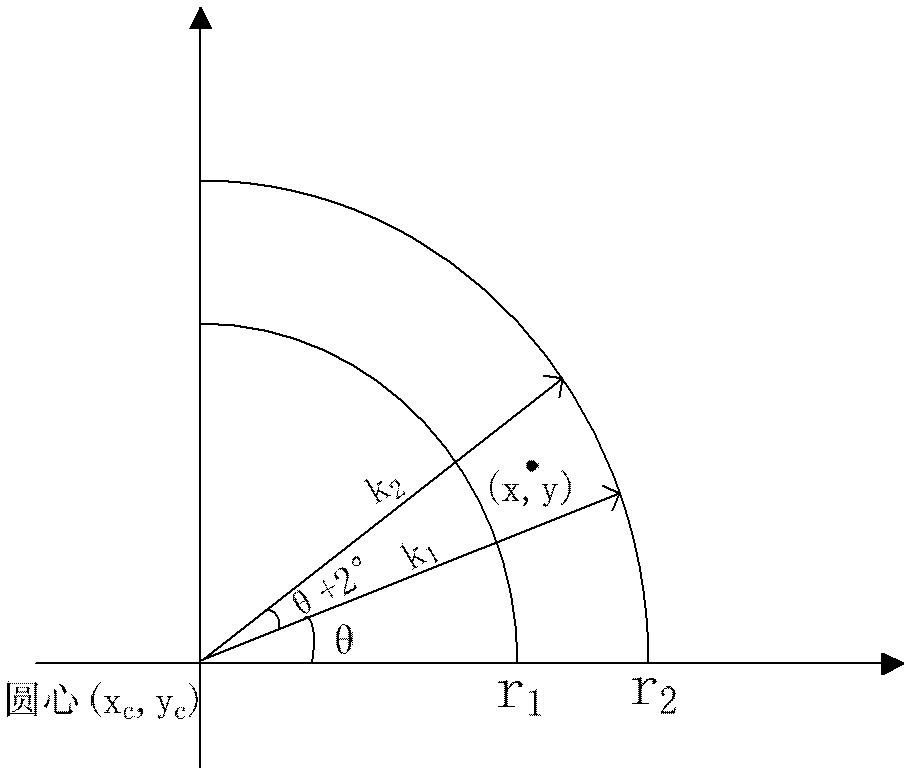

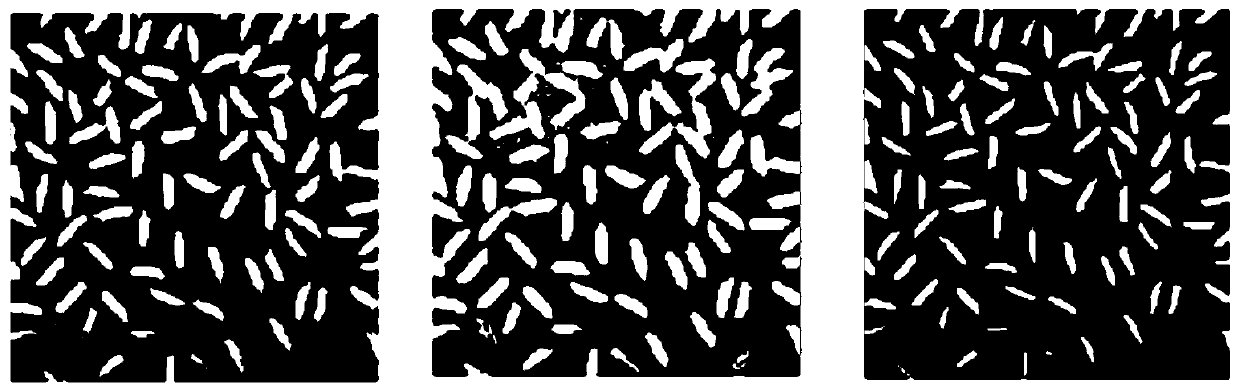

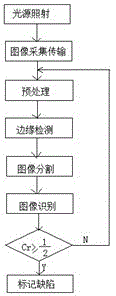

Method for detecting surface defects of dustproof cover of bearing based on machine vision

ActiveCN102636490AHigh speedAcquisition speed is fastOptically investigating flaws/contaminationMachine visionGrey level

The invention relates to a method for detecting surface defects of a dustproof cover of a bearing based on machine vision, which comprises the following steps: a, obtaining a gray level image of a to-be-detected bearing; b, carrying out separation on the gray level image so as to obtain a ring image of the dustproof cover of the bearing; c, carrying out grey level transformation and adaptive median filtering preprocessing on the ring image; d, carrying out threshold segmentation on the ring image by using a maximum interclass variance method, extracting an edge of the ring image of the dustproof cover of the bearing after threshold segmentation by using a Roberts edge detection operator; e, calculating the numbers of which the numerical values are 1 in the image area every two degrees for the ring image of the dustproof cover of the bearing; f, providing a template bearing image, and obtaining a deflection angle sigma through calculating; g, carrying out separation on the image so as to obtain character areas and non-character areas of the ring image of the dustproof cover of the bearing; and h, carrying out surface defect judgment on corresponding character areas and non-character areas in the ring image of the dustproof cover of the bearing according to the number of connected areas and the defect area. By using the method disclosed by the invention, automatic detection can be achieved, the visual detection workload of artificial detection is reduced, the detection efficiency is improved, and the method is safe and reliable.

Owner:JIANGNAN UNIV +1

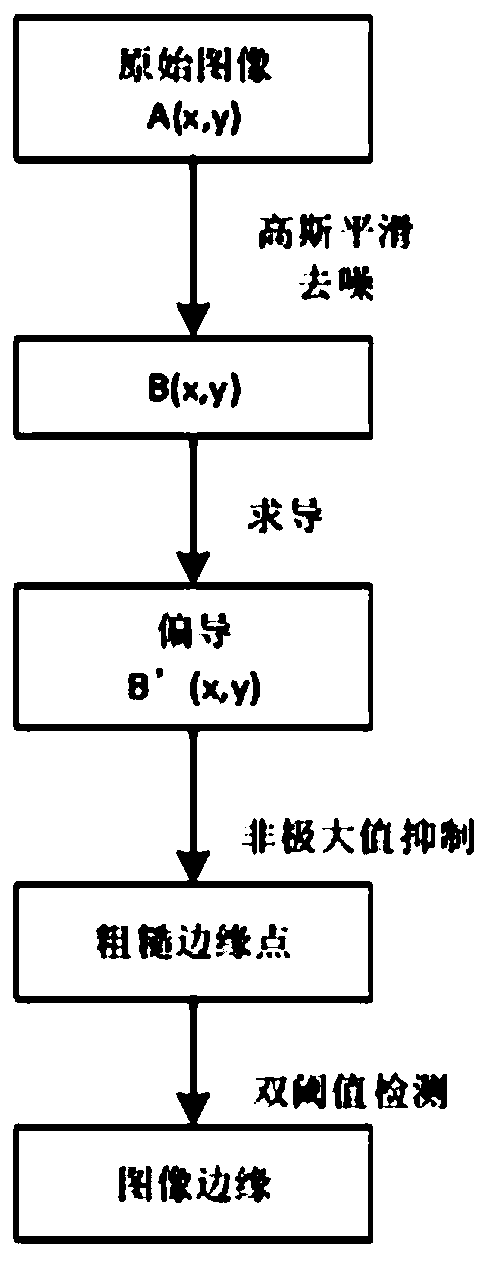

An intelligent identification and analysis method for an examination answer sheet system

InactiveCN109711284AIdentify intelligent high-speedHigh image precisionImage enhancementImage analysisImage denoisingImage detection

The invention discloses an intelligent identification and analysis method for an examination answer sheet system. The method comprises the following steps: carrying out item-by-item decomposition operation on image gray scale, image binaryzation, image denoising and morphological processing in an image preprocessing technology; an independent peak point is formed by using a monitoring image inclination and rotation correction technology, and an image is read for binaryzation; Edge monitoring operator monitoring is constructed by using an edge monitoring technology and through an original imagedifferential technology, and image filtering, image enhancement, image detection, a Canny operator and a Canny edge recognition algorithm are formed; and data image recognition analysis is carried out by adopting image recognition point positioning and affine transformation. The method can achieve the intelligent high-speed recognition of the answer sheet, is higher in image precision, is high inefficiency, is not limited to specific scanning equipment, achieves the mining and analysis of large data of batch scanning results, can intelligently recognize specific wrong knowledge points, and can achieve the intelligent statistical induction.

Owner:江苏博墨教育科技有限公司

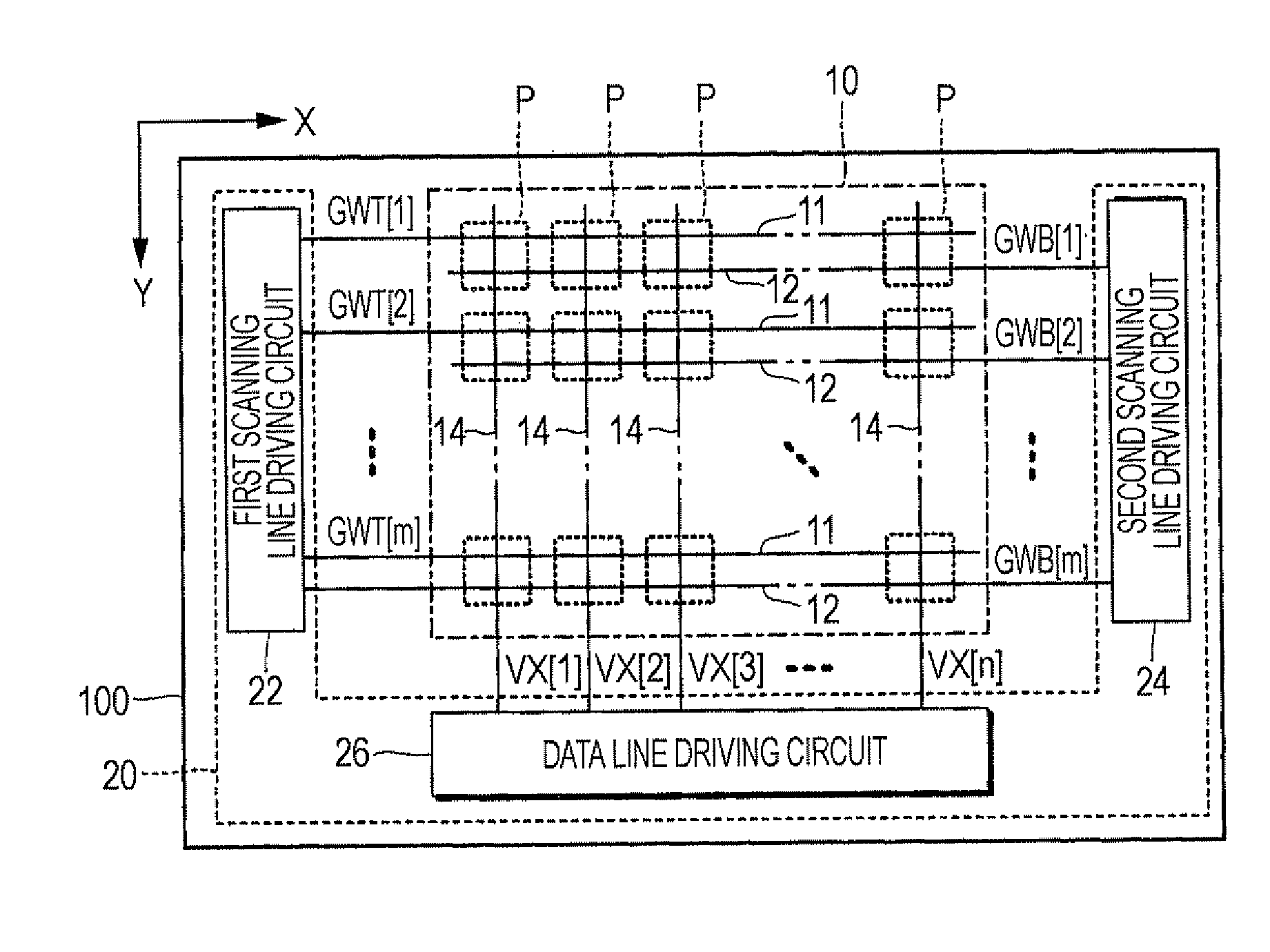

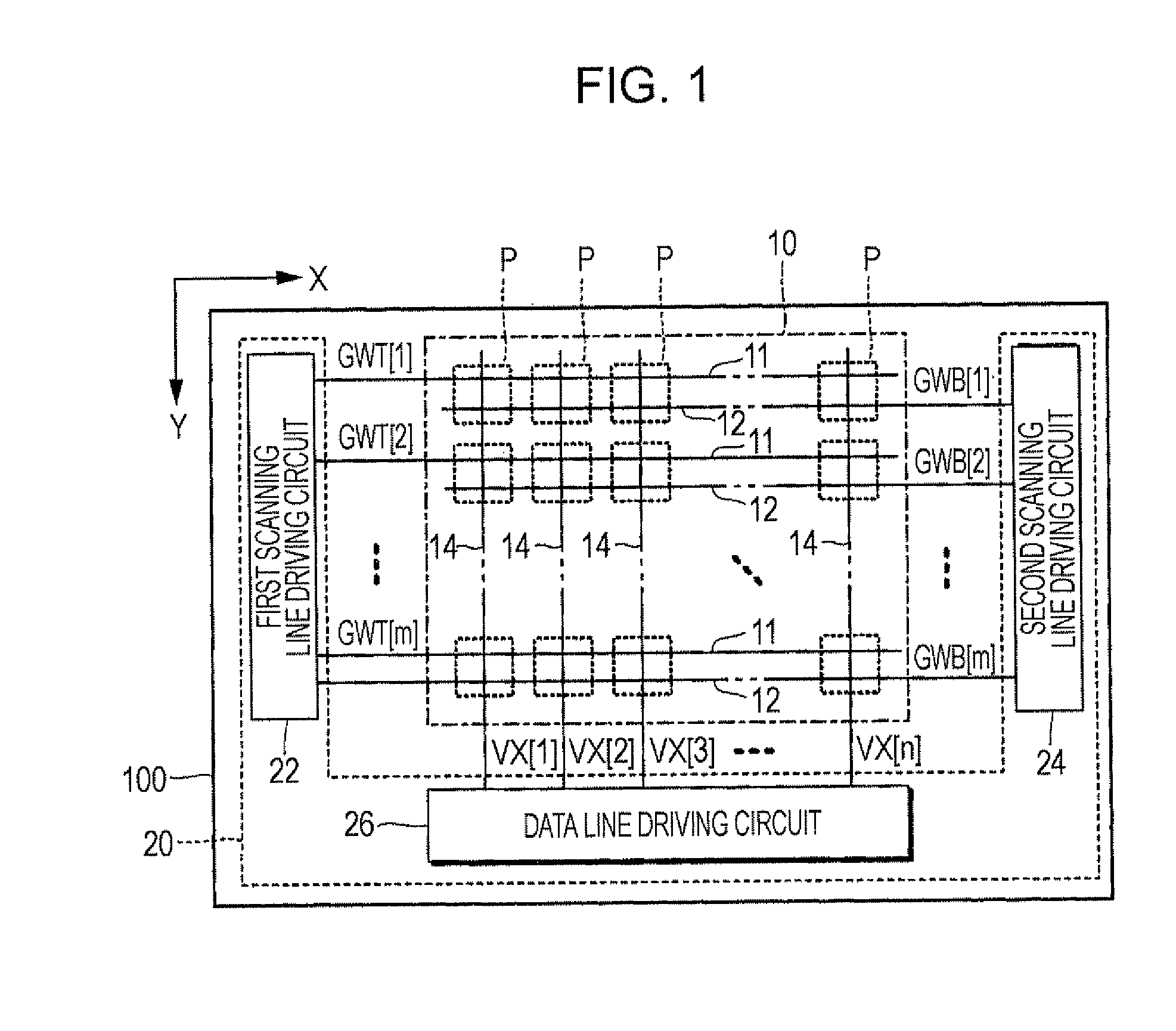

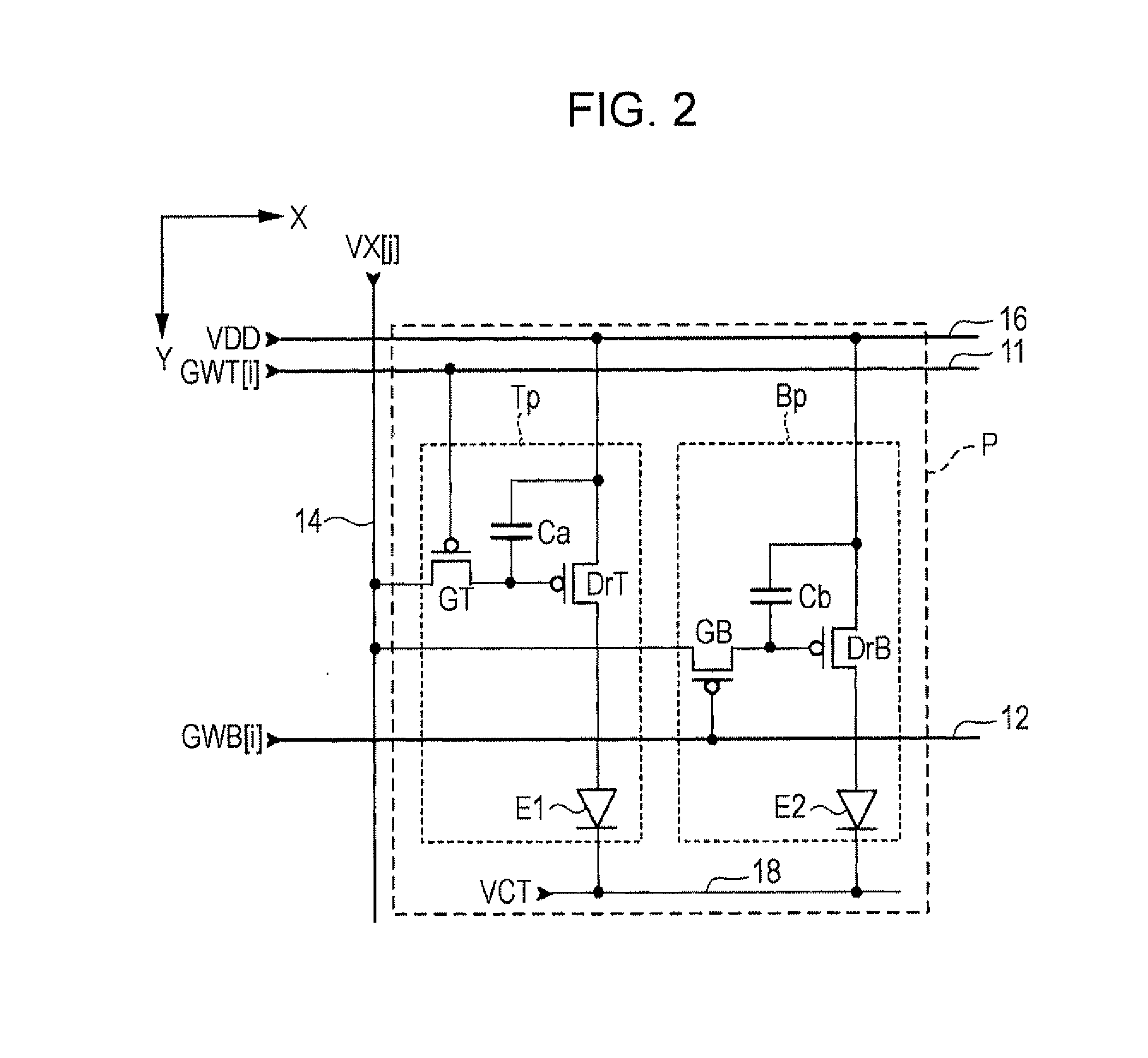

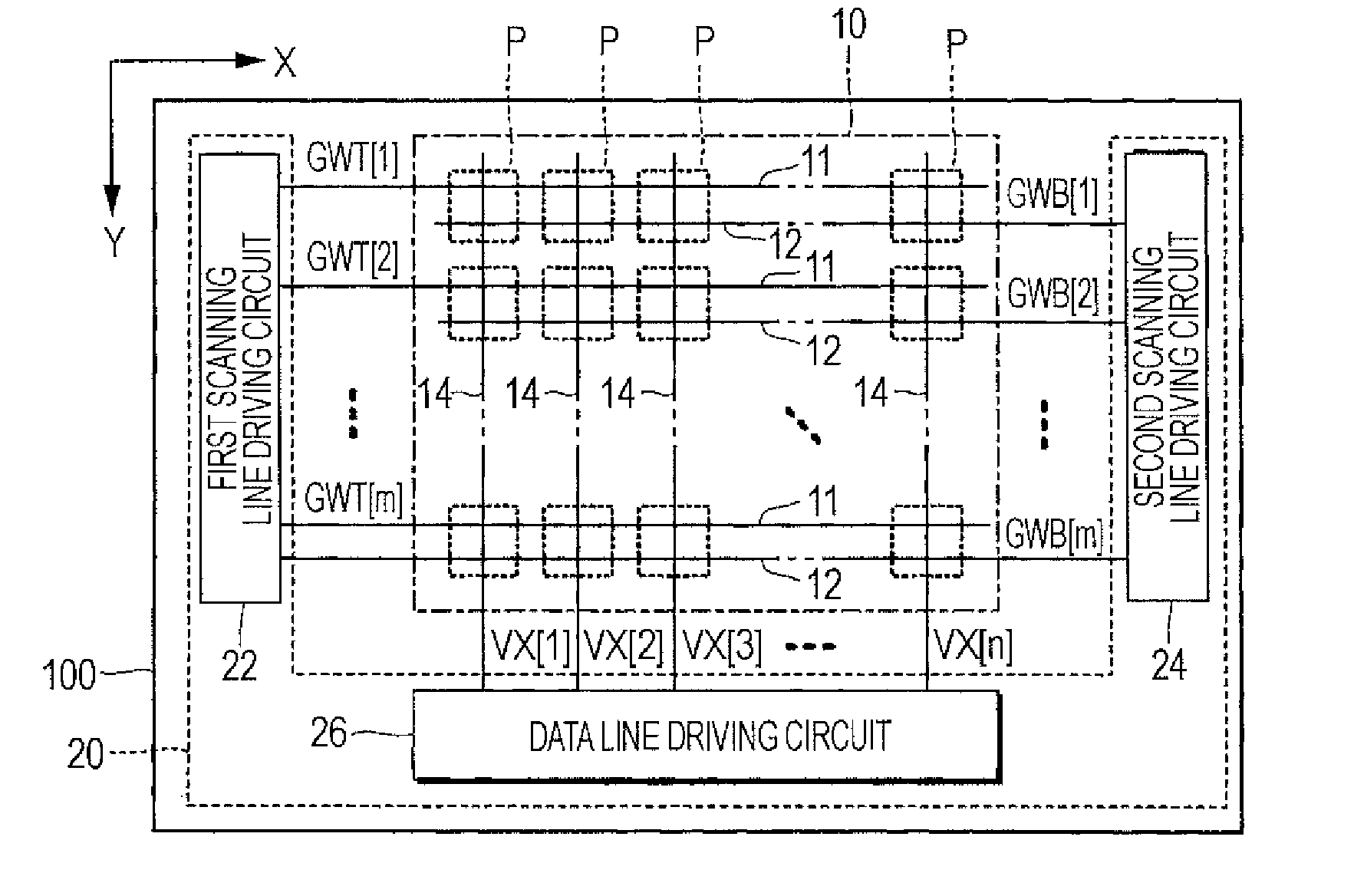

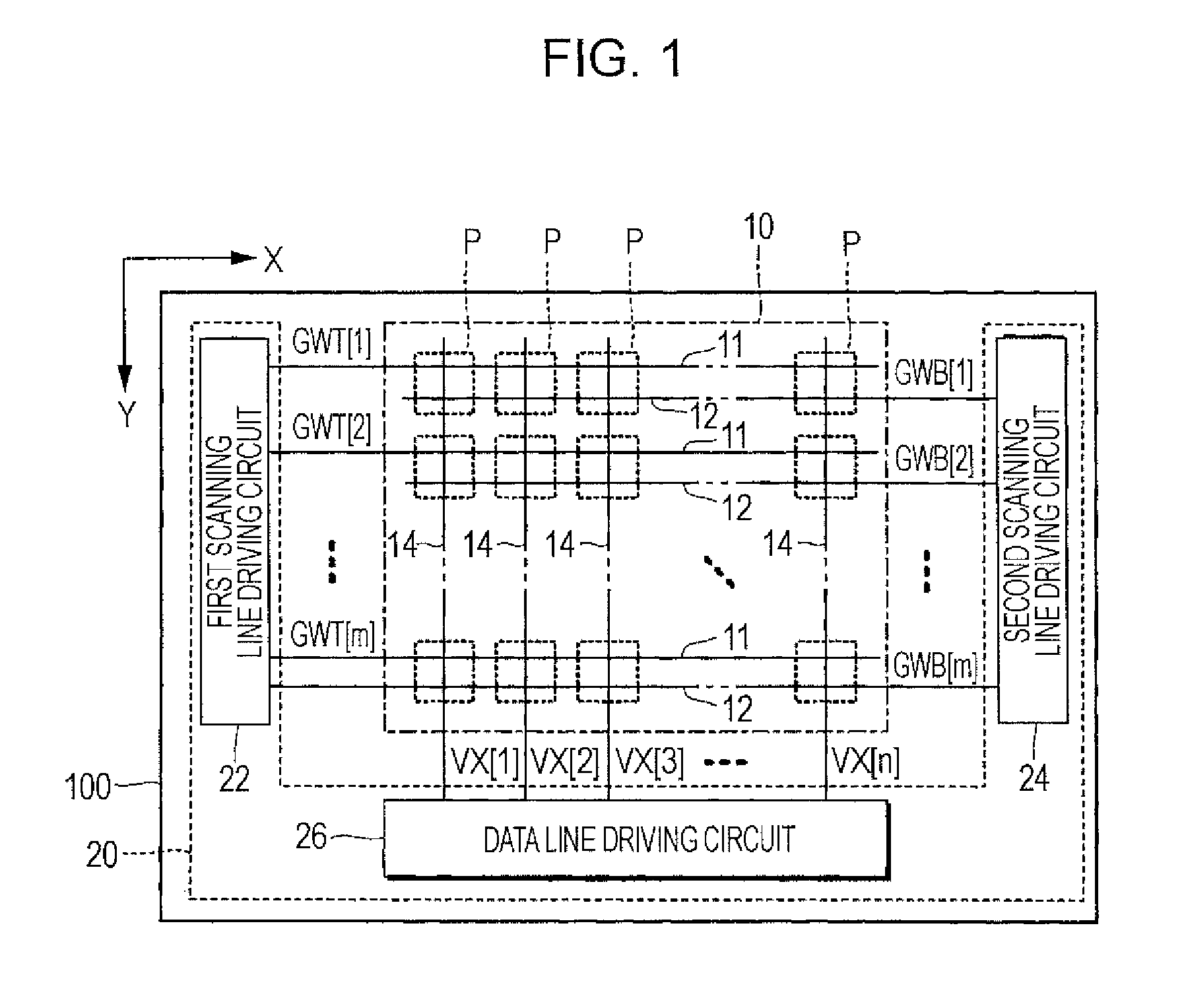

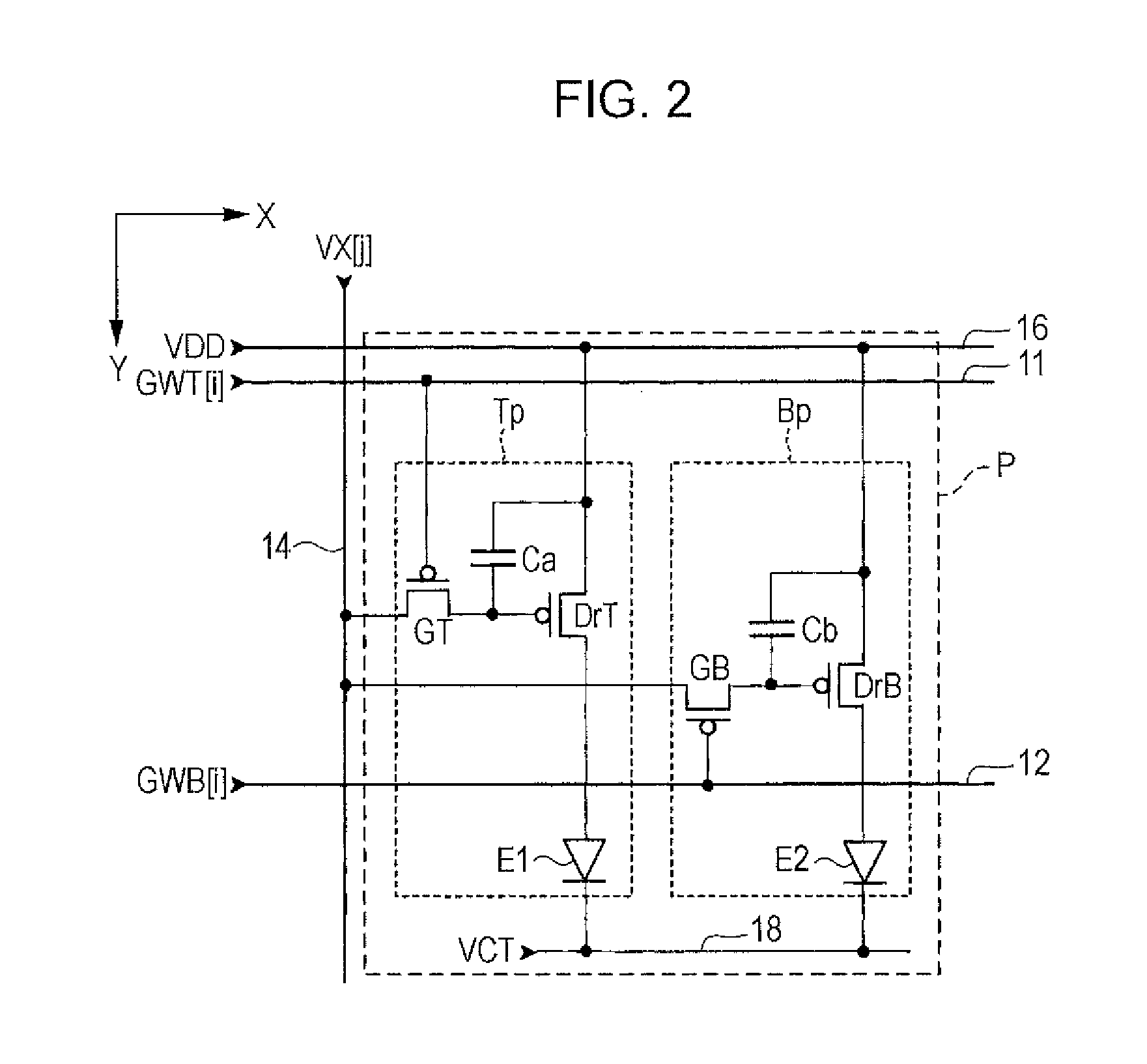

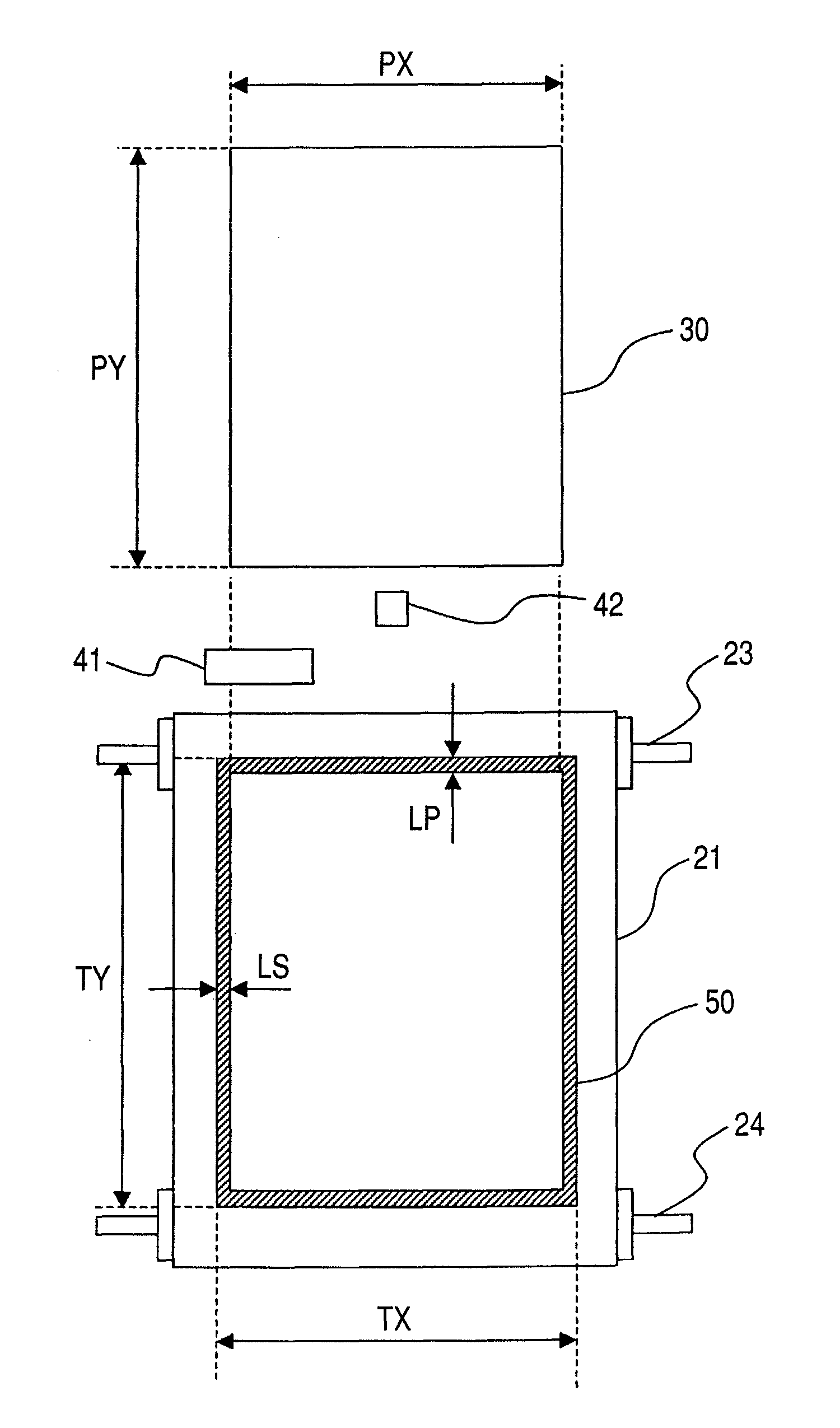

Light emitting device, electronic apparatus, and method of driving light emitting device

InactiveUS20110221789A1Improve accuracyHigh image precisionSolid-state devicesCathode-ray tube indicatorsEngineeringLight emitting device

A light emitting device includes a pixel circuit and a data line provided between a first substrate and a second substrate opposed to each other. The pixel circuit includes a first circuit and a second circuit, the first circuit includes a first light emitting element and a first driving transistor connected in series to each other, and a first switching element provided between a gate of the first transistor and the data line, and outgoing light of the first light emitting element is output from the first substrate side. The second circuit includes a second light emitting element and a second driving transistor connected in series to each other, and a first switching element provided between a gate of the second driving transistor and the data line, and outgoing light of the second light emitting element is output from the second substrate side.

Owner:SEIKO EPSON CORP

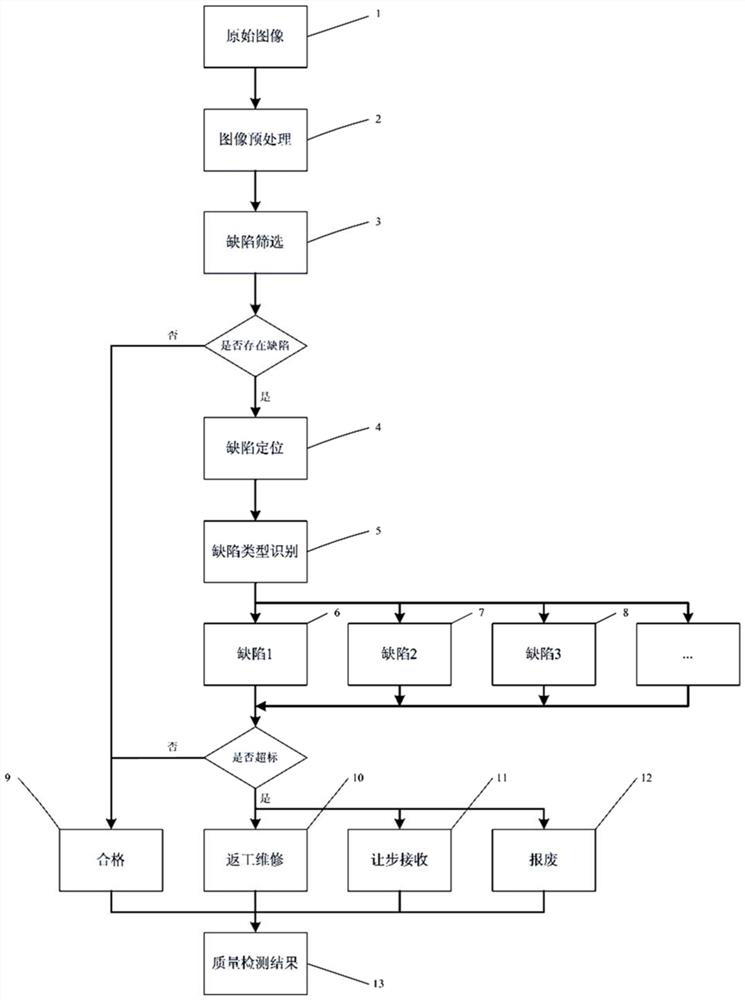

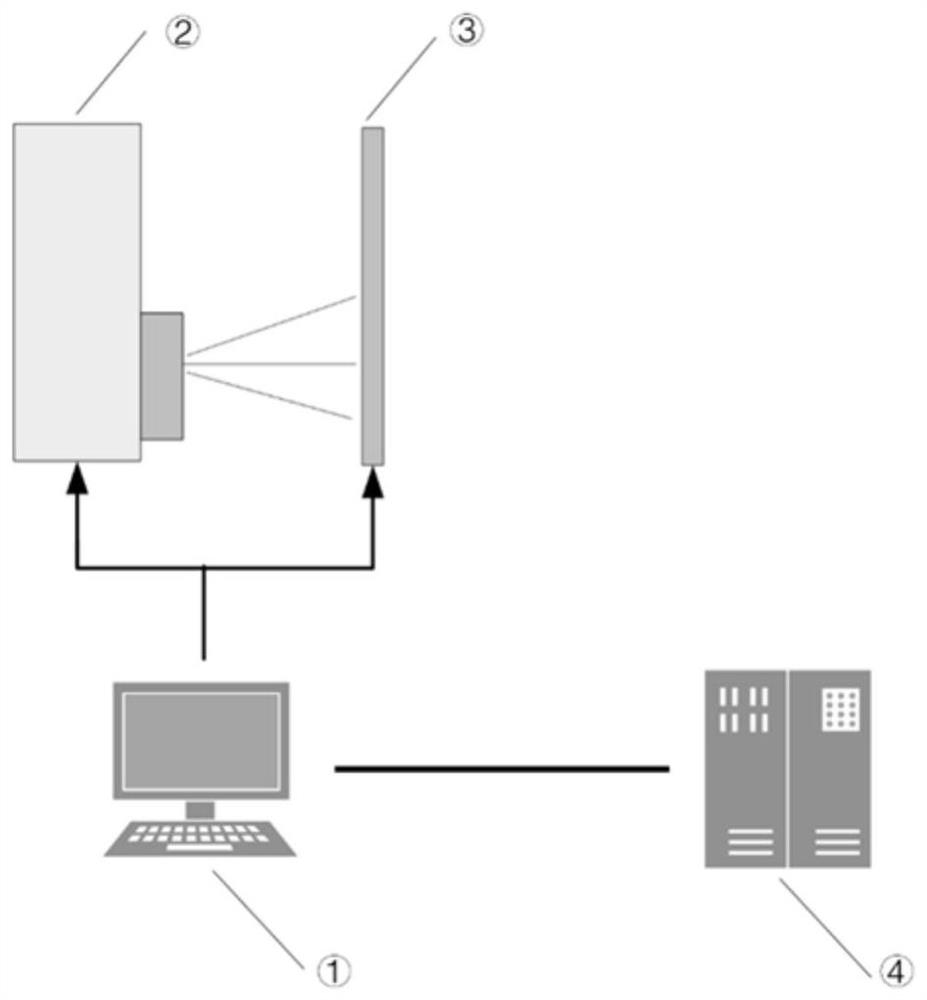

Weld joint internal defect intelligent detection device and method and medium

PendingCN112083017AHigh image precisionHigh sensitivityImage enhancementImage analysisImage evaluationControl cell

The invention provides a weld joint internal defect intelligent detection device and method and a medium, X-rays emitted by an X-ray tube irradiate a weld joint to obtain a digital image containing weld joint internal quality information on an imaging plate, optimal imaging is realized through an optical path simulation and control unit, and after the generated image is automatically uploaded to acloud platform server, a digital image processing technology and a deep learning neural network algorithm are adopted to carry out intelligent preprocessing on the image, whether defects exist or notis judged, defect positioning, defect type identification and defect rating are carried out, and detection of image characterization quality is achieved. According to the invention, the precise control of the complex structure weld joint detection process is realized in the detection process; in the image evaluation process, a manual film evaluation process is replaced by intelligent defect identification, so that the manual detection duration is effectively shortened, personal errors are avoided on the premise of ensuring the defect identification accuracy, and the welding seam quality detection working efficiency is improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

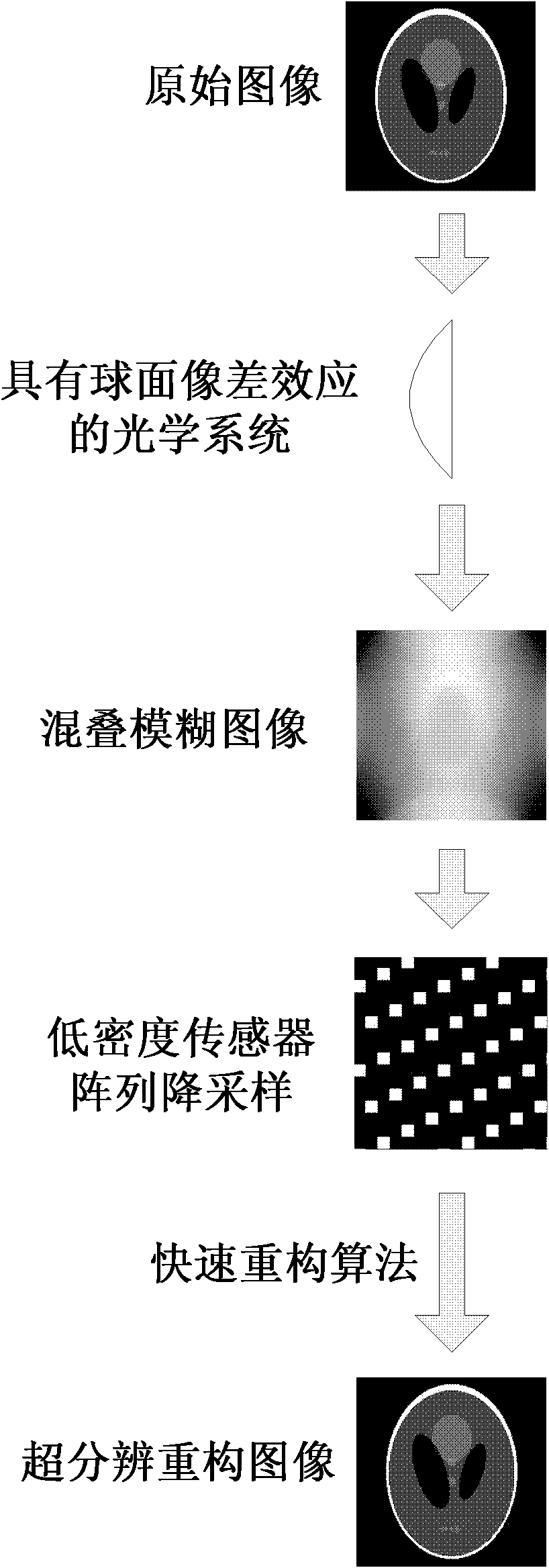

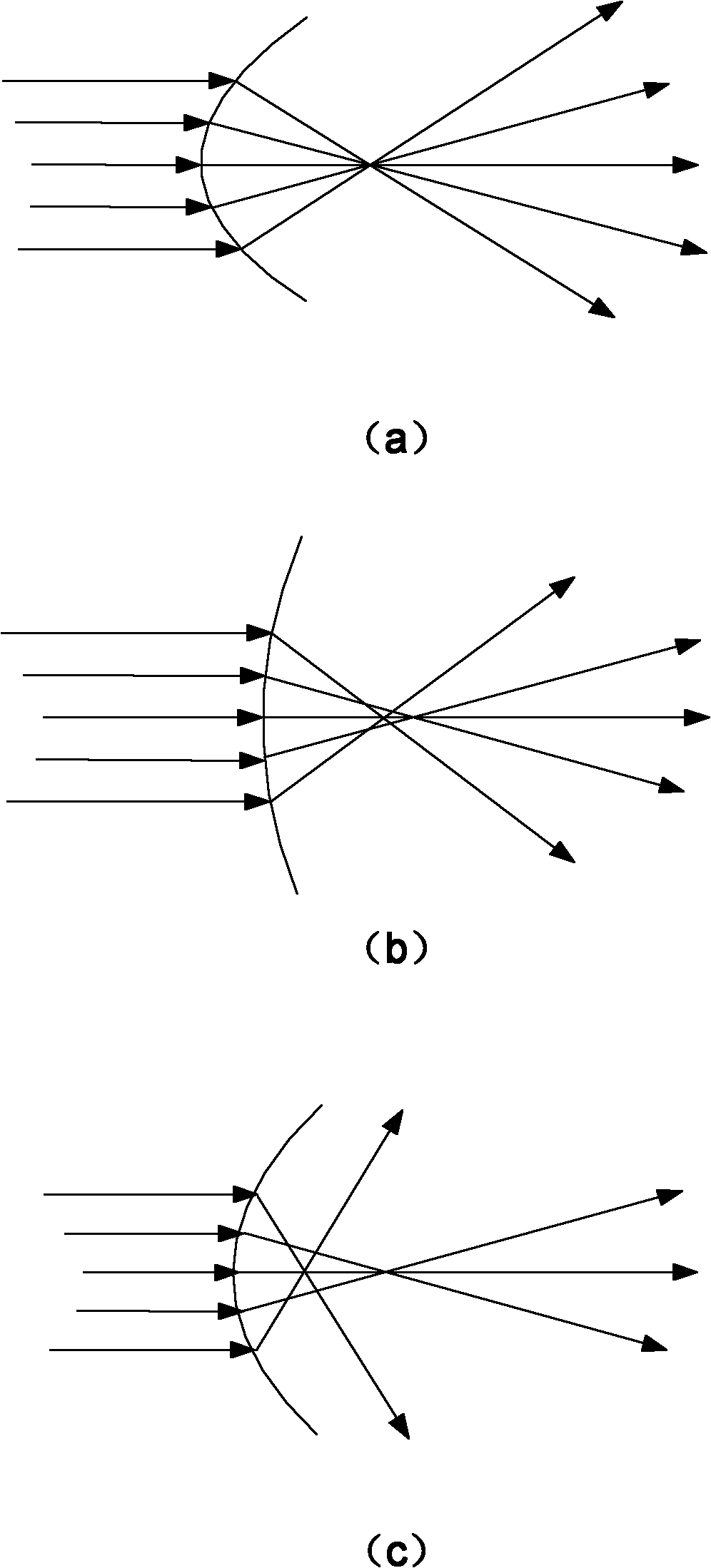

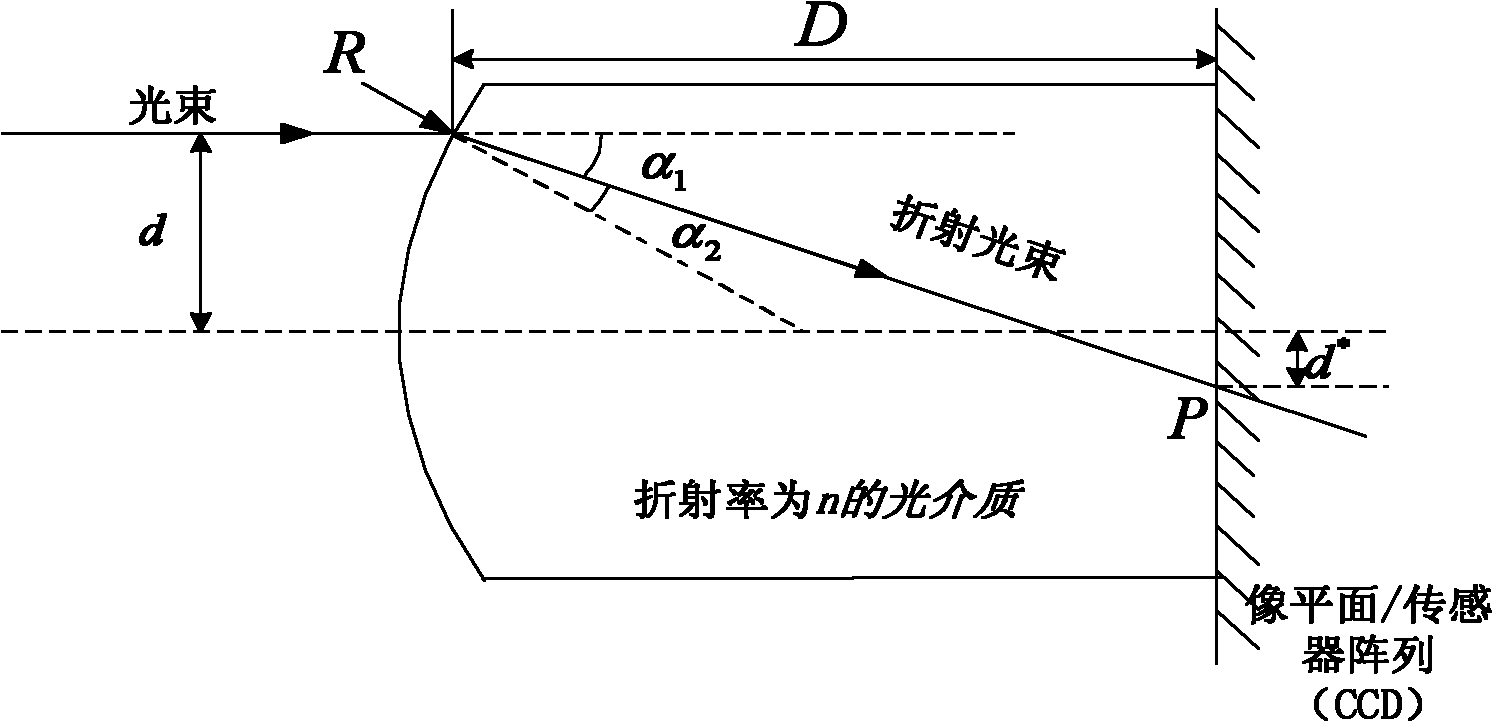

Super-resolution imaging method based on spherical aberration aliasing observation

InactiveCN102186016ASimple structureReduce volumeTelevision system detailsImage enhancementSensor arrayComputation complexity

The invention discloses a super-resolution imaging method based on spherical aberration aliasing observation, which mainly aims to solve the problems of low imaging accuracy, structural complexity and high computational complexity of the conventional method. The method comprises the following steps of: (1) establishing an optical system with remarkable spherical aberration effects; (2) obtaining a point spread function of the optical system by utilizing a theoretical deviation or simulation or experimental measurement method, and constructing a sampling matrix according to the point spread function; (3) performing aliasing observation on target optical signals by utilizing the established optical system, and performing sampling by using a low-resolution sensor array to obtain a low-resolution aliased image; and (4) reconstructing the low-resolution aliased image by using a rapid iterative optimization algorithm according to a compressive sensing theory in combination with the samplingmatrix to obtain a high-resolution image. The method has the advantages of simple system structure, small volume, low manufacturing cost, high image reconstruction accuracy and high reconstruction speed, and can be used for the acquisition and high-resolution reconstruction of the image in a small-scale sampling array.

Owner:XIDIAN UNIV

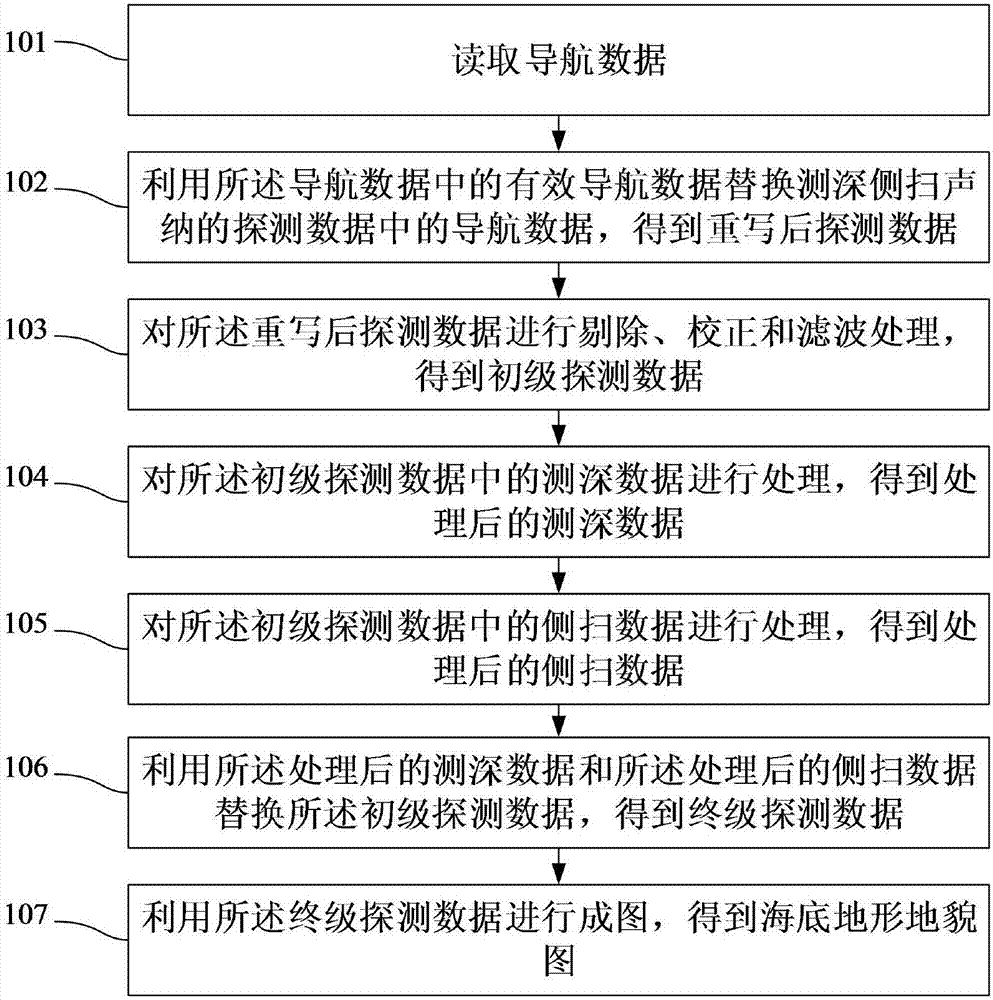

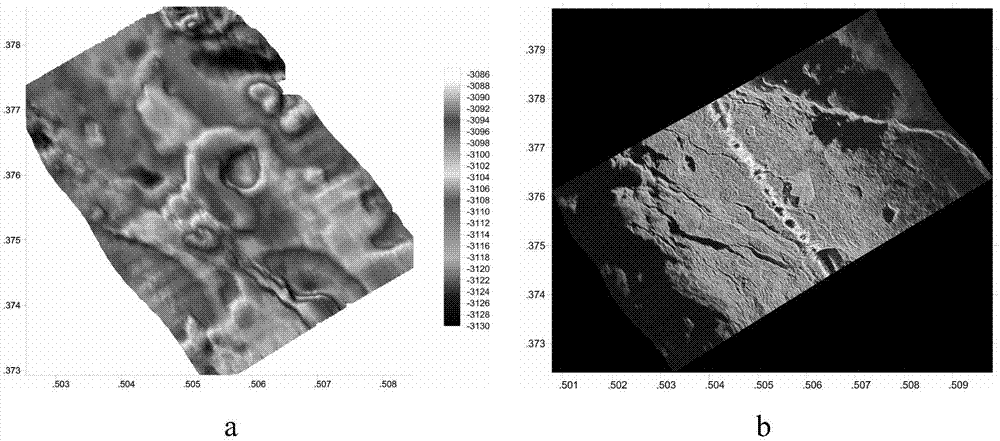

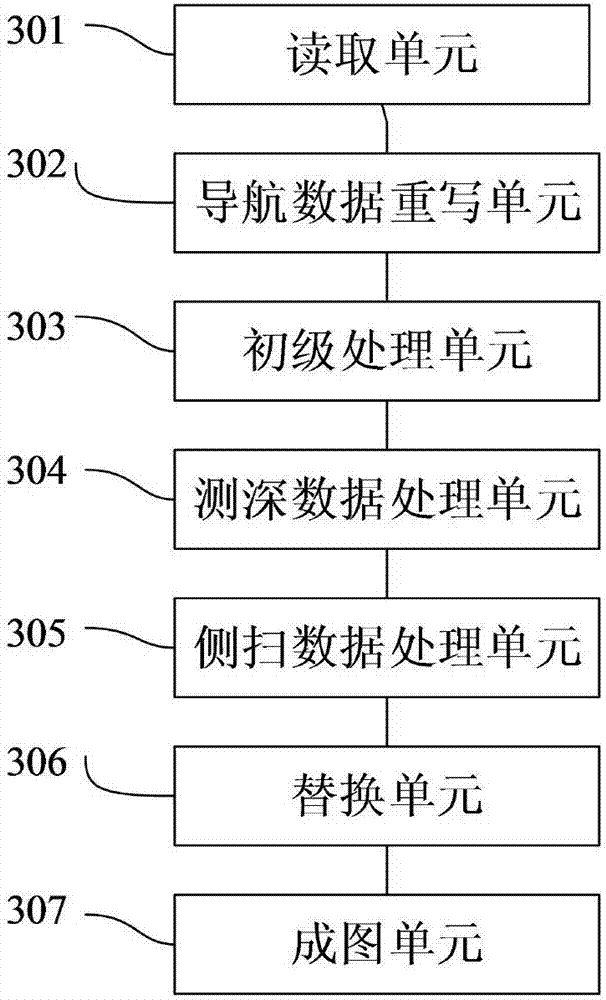

Method and system for acquiring high-precision submarine topographic and geomorphologic map

ActiveCN107219529AHigh image precisionAvoid the impact of image qualityAcoustic wave reradiationSonarOcean bottom

The invention discloses a method and device for acquiring a high-precision submarine topographic and geomorphologic map. The method comprises the steps of acquiring navigation data, replacing navigation data in detection data of bathymetric sidescan sonar by using effective navigation data in the navigation data, acquiring rewritten detection data, and performing rejection, correction and filtering processing on the written detection data to acquire primary detection data; processing bathymetric data in the primary detection data to acquire processed bathymetric data; processing sidescan data in the primary detection data to acquire processed sidescan data; replacing the primary detection data by using the processed bathymetric data and the processed sidescan data to acquire final detection data; and mapping by using the final detection data to acquire a submarine topographic and geomorphologic map. The submarine topographic and geomorphologic map acquired according to the invention is closer to the real submarine topography and geomorphology, the image precision is higher, and the mapping speed is high.

Owner:NAT DEEP SEA CENT

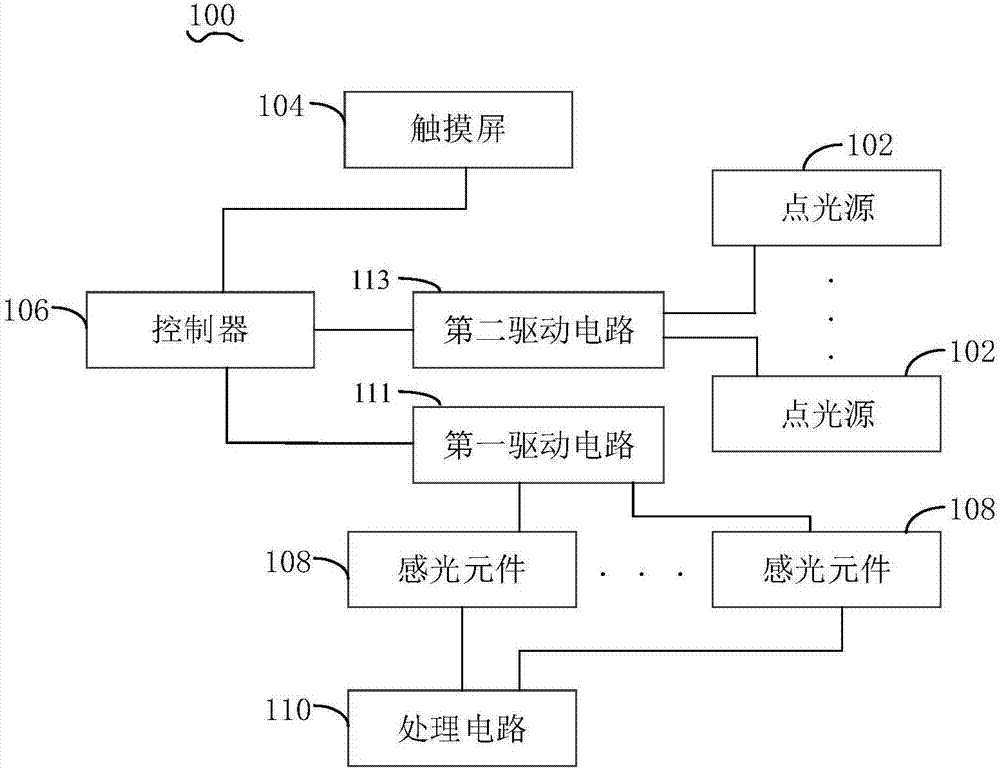

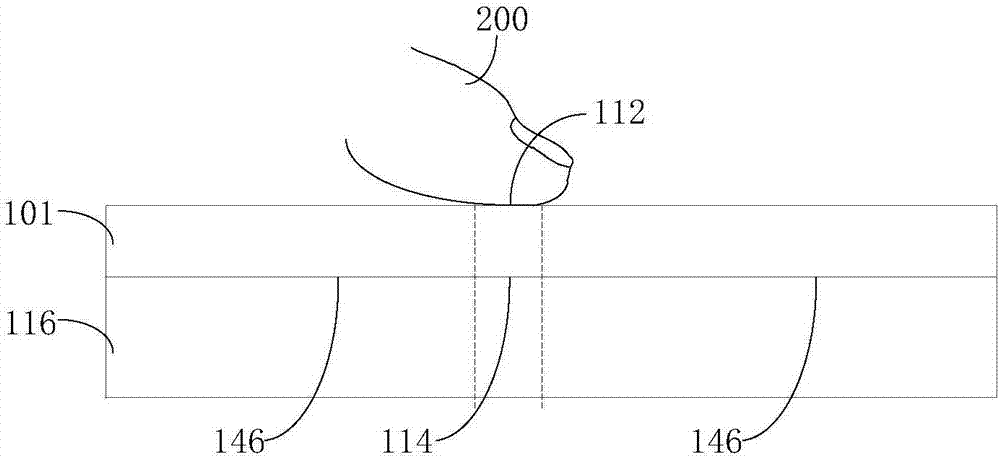

Display device and electronic device

ActiveCN107958145AImprove user experienceHigh image precisionDigital data authenticationInput/output processes for data processingDisplay deviceTouchscreen

The invention discloses a display device and an electronic device. The display device is used for executing image display and is also used for executing biological characteristic information sensing.The display device comprises a plurality of point light sources, a touch screen, a controller, a plurality of photosensitive elements and a processing circuit, wherein the touch screen is used for determining the contact area of a target object on the display device; the controller is used for controlling the plurality of point light sources corresponding to the contact area to be turned on at different time to emit an optical signal to the target object; the plurality of photosensitive elements are used for receiving the optical signal reflected by the target object and converting the received optical signal into a corresponding electrical signal; and the processing circuit is used for determining the biological characteristic information of the target object according to the electrical signal. The electronic device comprises the display device.

Owner:柳州梓博科技有限公司

Device and method for detecting surface defects of perforated plate workpiece

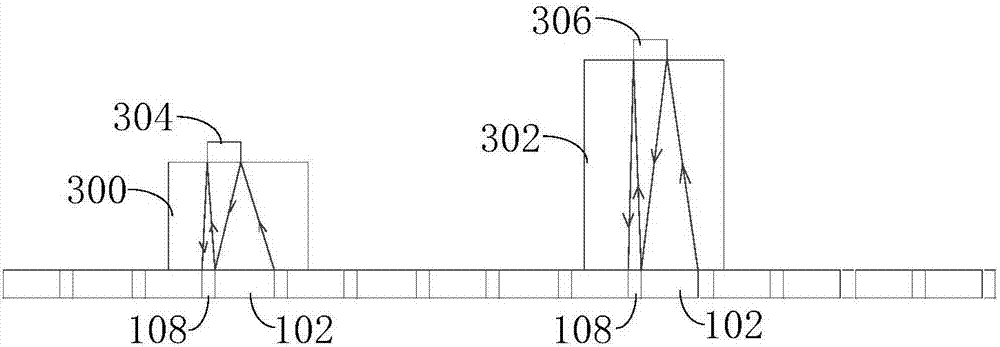

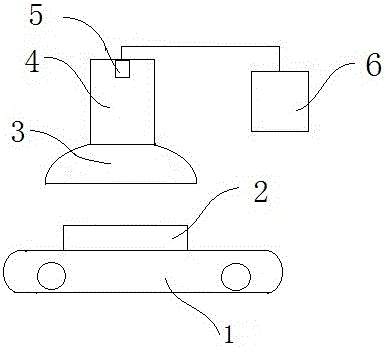

PendingCN106442556AImprove interchangeabilityUniform irradiationOptically investigating flaws/contaminationImaging processingTransfer system

The invention discloses a device and method for detecting surface defects of a perforated plate workpiece. The system comprises a transfer system, a special-shaped illuminating light source, an industrial charge coupled device (CCD) image sensor, an image acquisition card and a processor. A to-be-detected perforated plate workpiece is horizontally arranged in the transfer system; the special-shaped illuminating light source adopts a shed-shaped structure light source of which the top is arc-shaped and the horizontal section is rectangular, and is arranged at the periphery of a lens of the industrial CCD image sensor; the industrial CCD image sensor comprises a camera main body, a lens and an interface C; the camera main body adopts an industrial CCD camera and is connected with the lens through the interface C; the lens is arranged on the inner side of the special-shaped illuminating light source and is perpendicular to the to-be-detected perforated plate workpiece; the image acquisition card serves as the connector of an image acquisition part and an image processing part; the processor is used for realizing the operation of corresponding codes in a programming environment, calculating and marking the defect positions and intuitively displaying the defect positions. According to the detection device disclosed by the invention, the surface defect positions can be accurately displayed, and the workpiece defect information is acquired instead of human eyes, therefore, the detection accuracy is high.

Owner:HARBIN UNIV OF SCI & TECH

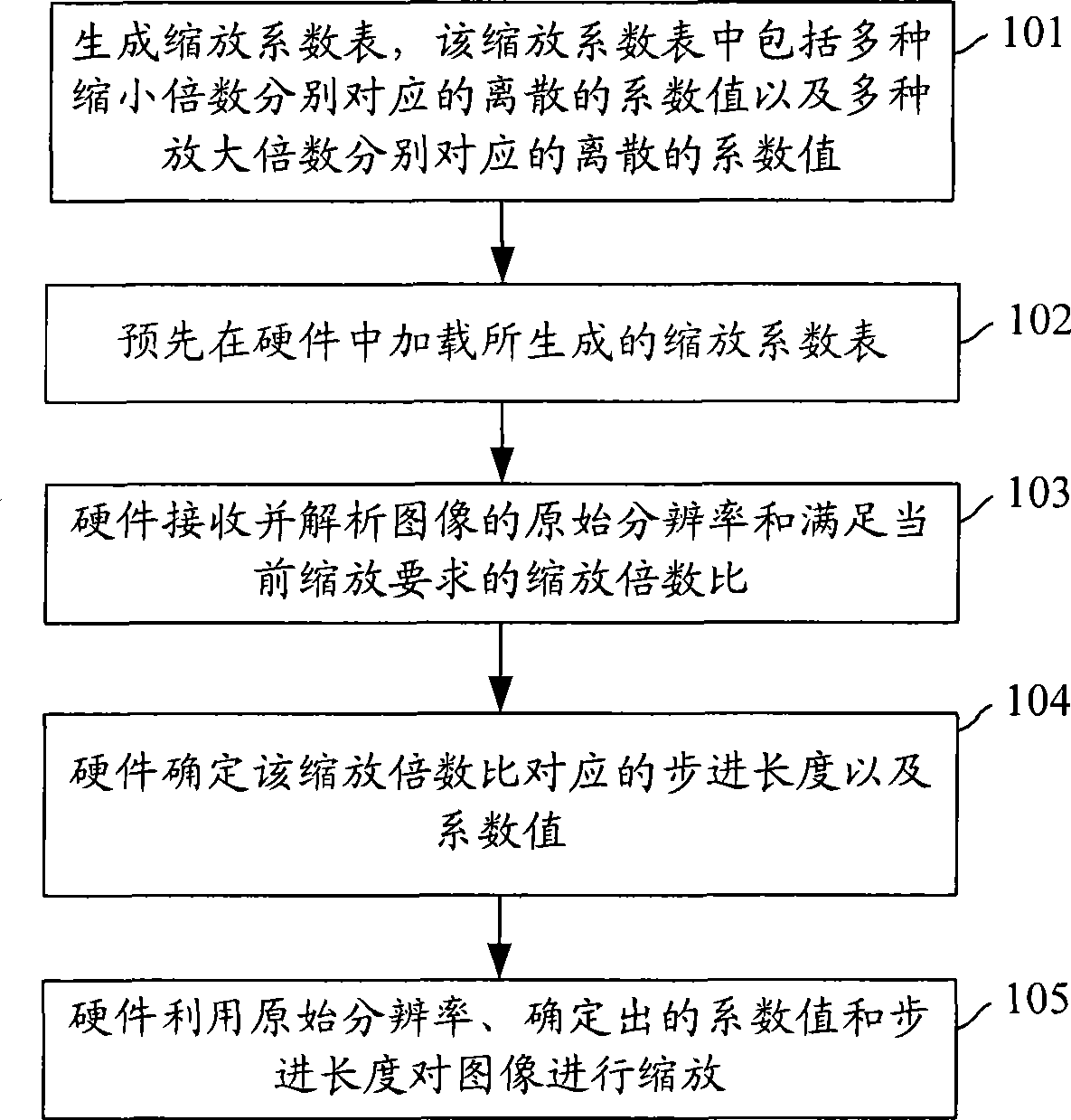

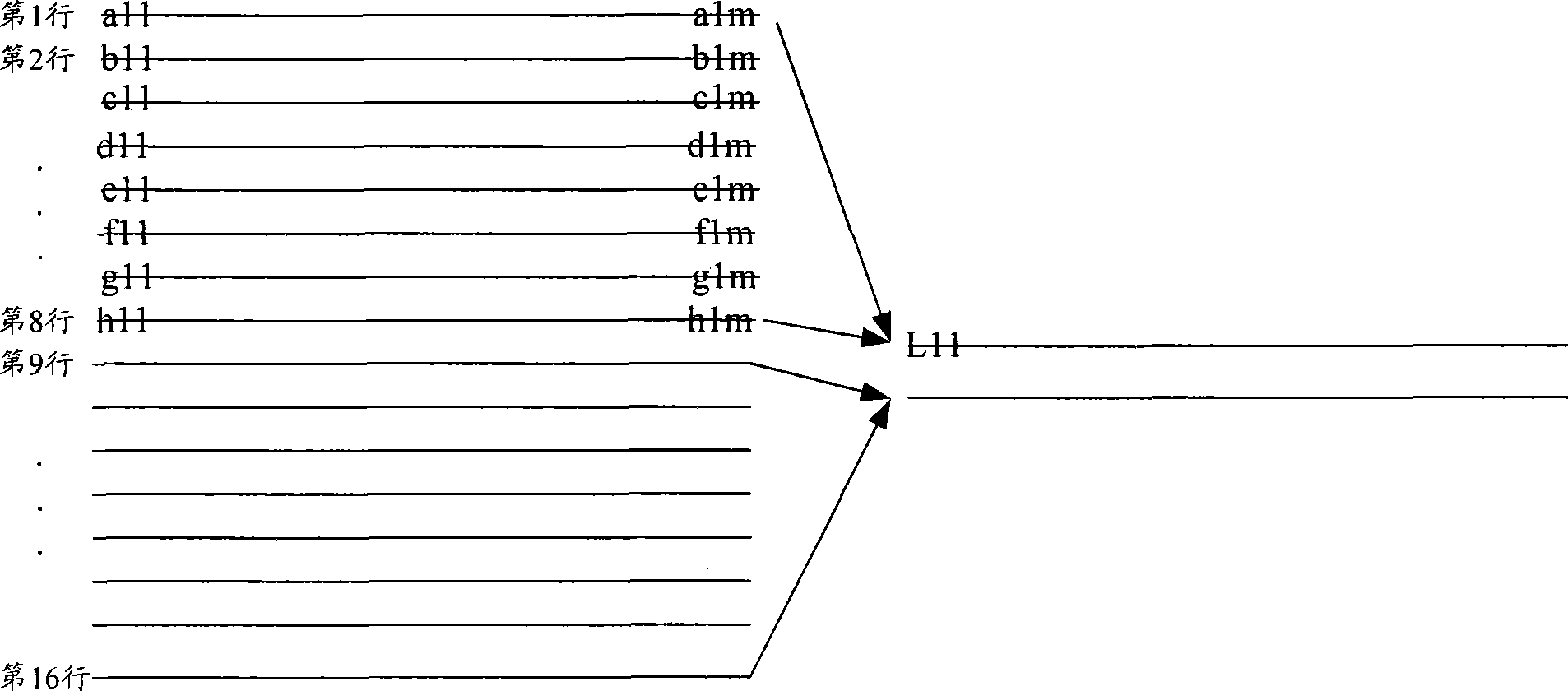

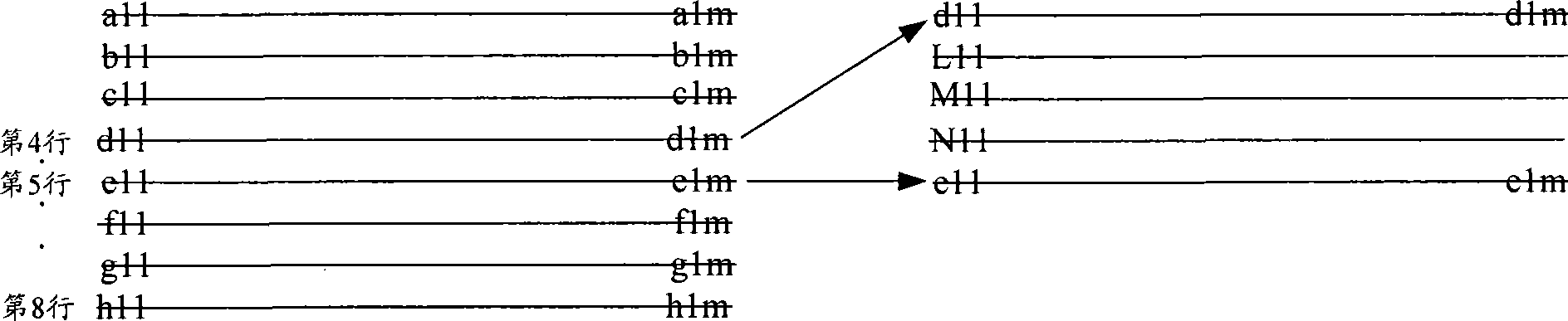

Method and device for zooming image

ActiveCN101465954AImprove practicalityMeet flexibility requirementsTelevision system detailsColor television detailsImage resolutionTime ratio

The invention discloses an image zooming method and device. The method comprises: a pre-generated zooming coefficient table is loaded and the zooming coefficient table comprises discrete coefficient values respectively corresponding to a plurality of reduction times and the discrete coefficient values respectively corresponding to a plurality of magnification times; the original resolution rate is received and a zooming times ratio required by the present zooming is satisfied; according to the zooming times ratio, the zooming coefficient table is searched and the stepping length as well as the coefficient value corresponding to the zooming times ratio are determined; by utilizing the determined stepping length, rows or columns of the original pixel which participates in each zooming are controlled, the pixel value of the original pixel in the rows or columns of the original pixel which participates in the zooming is multiply-accumulated with the determined coefficient value, the zoomed rows or columns are obtained, and the zooming is finished until the present image is determined according to the original resolution rate.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

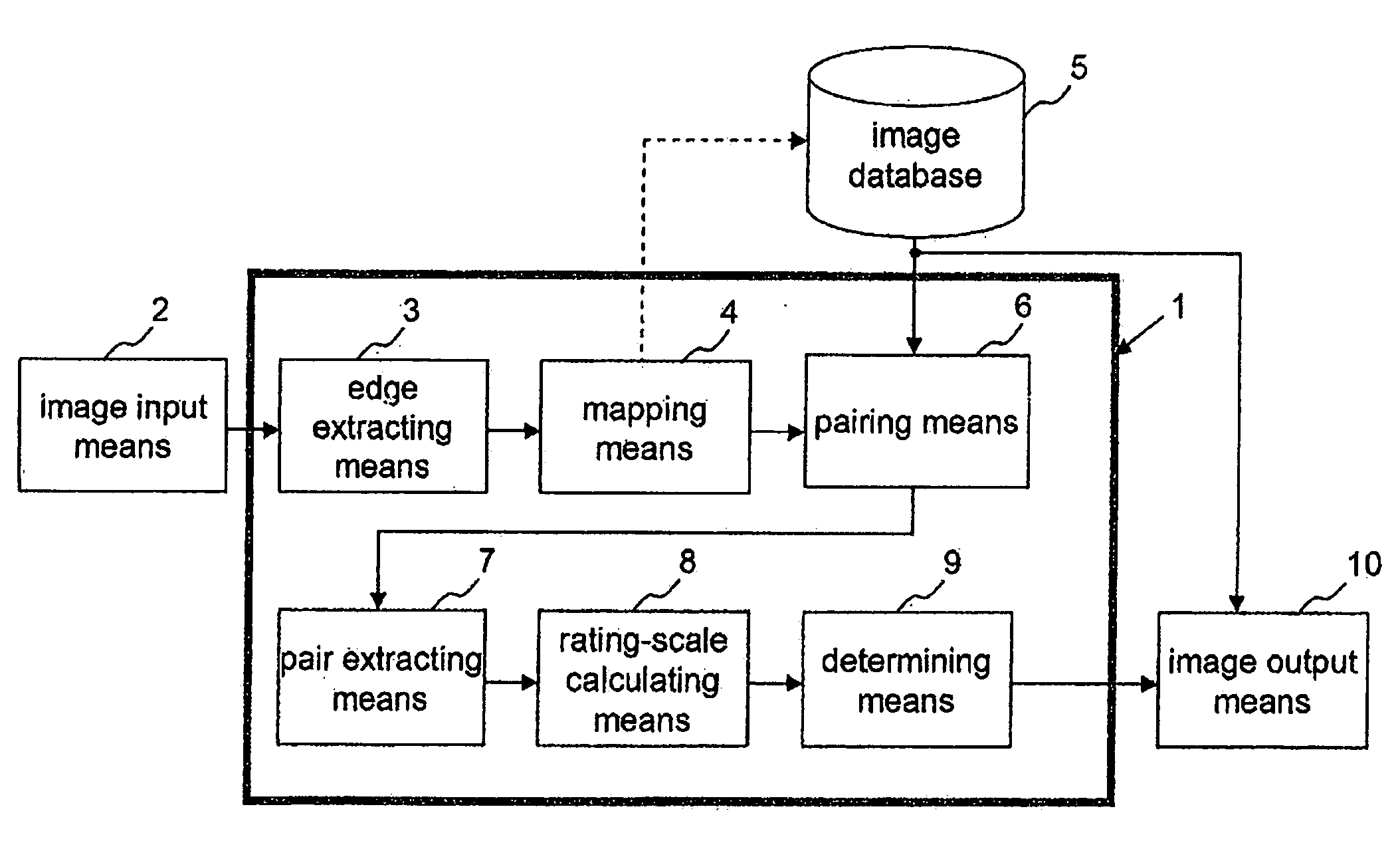

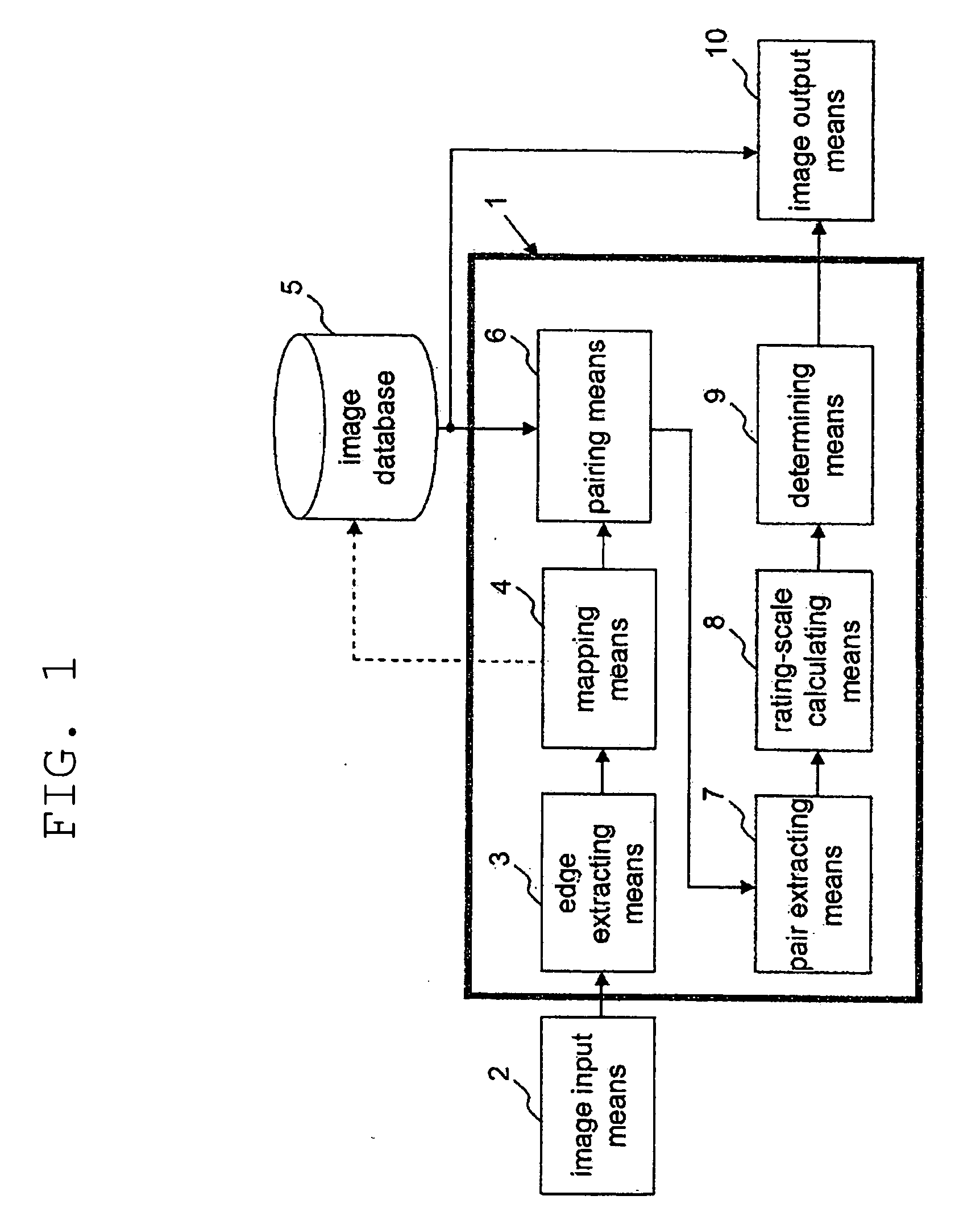

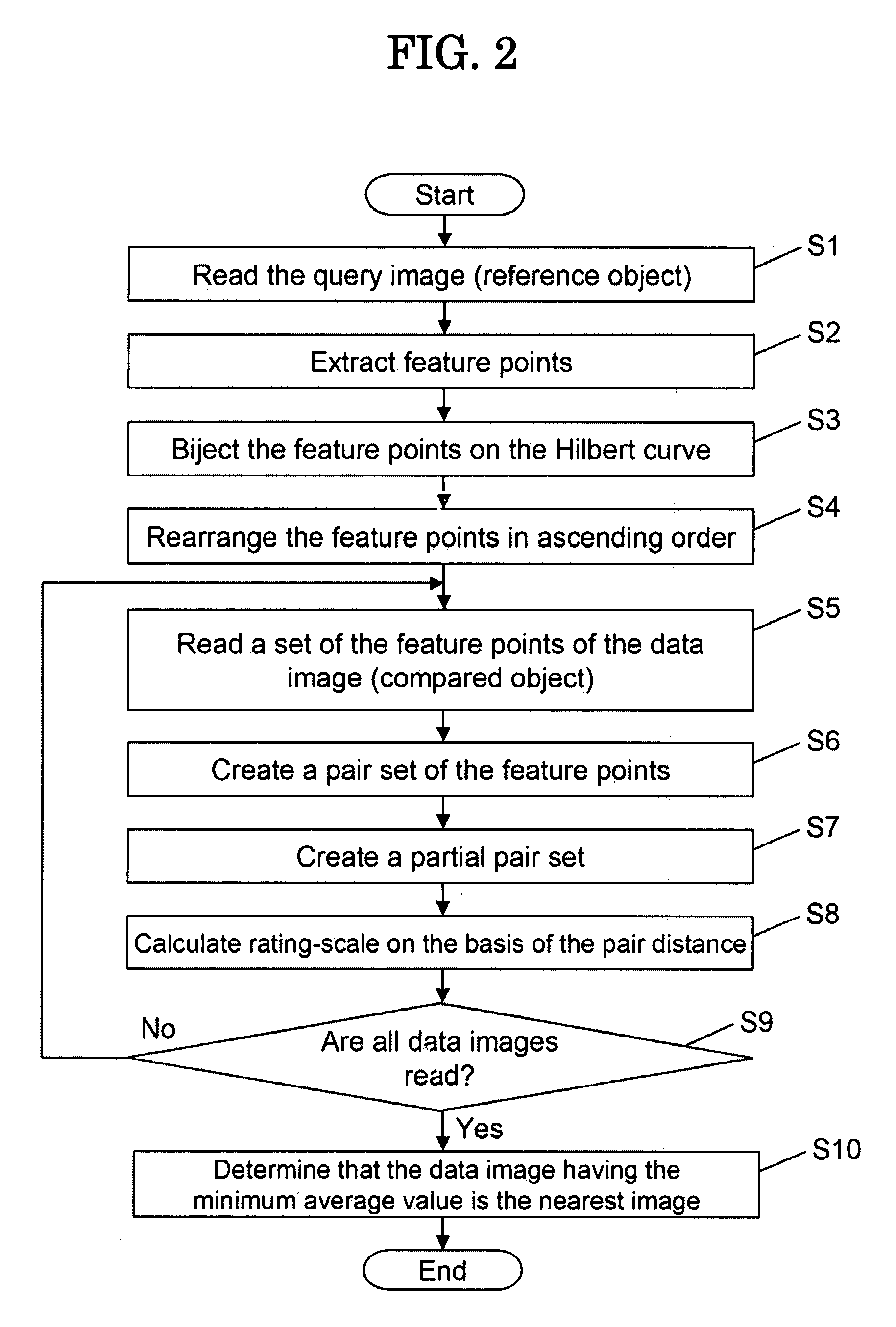

Matching apparatus, image search system, and histogram approximate restoring unit, and matching method, image search method, and histogram approximate restoring method

InactiveUS20080193029A1Easy to calculateQuick matchCharacter and pattern recognitionRestoration methodMatching methods

To provide a matching technology for determining the similarity between two objects at high velocity with high precision.A matching method for comparing a set of feature points of two objects projected to an N-dimensional space and determining the similarity between the two objects, includes a mapping step (S3) of mapping the set to a one-dimensional space, a pairing step (S6) of creating a set of pairs of a feature point of first object that is the most approximate to a feature point of second object, a partial-set creating step (S7) of partly extracting the pairs in small order of the pair distance from the set of the pairs of the feature points and creating a partial set of the pairs of the feature points, an average-value calculating step (S8) of calculating a rating-scale of the pair belonging to the partial set of the pair of the feature points, and a determining step (S10) of determining the similarity between the first object and the second object on the basis of an average value of the distance.

Owner:KITAKYUSHU FOUND FOR THE ADVANCEMENT OF IND +1

Biological electrical impedance tomography method

InactiveCN103462605AHigh precisionOvercome the disadvantage of initial value sensitivityDiagnostic recording/measuringSensorsElectrical impedance tomographyParticle swarm algorithm

The invention discloses a biological electrical impedance tomography method based on the particle swarm optimization and the regularization Gauss-Newton iteration algorithm. The method comprises during biological electrical impedance tomography problem solving, generating an initial value approximating to a true value as the initial value of the regularization Gauss-Newton iteration algorithm through the particle swarm optimization, then solving an inverse problem through the regularization Gauss-Newton iteration algorithm. The biological electrical impedance tomography method has the advantages that uneven subdivision is utilized during direct problem calculation to improve the tomography precision; the standard particle swarm optimization is utilized for generating one initial value for the regularization Gauss-Newton iteration algorithm, accordingly the defect that Newton type algorithms are sensitive to initial values can be well overcome, and meanwhile, only one approximate value approximating to the true value needs to be generated, so that low precision requirements can be achieved, further a relatively small number of particles and times of iterations are needed and the calculation amount can be reduced largely; image reconstruction is performed through the regularization Gauss-Newton iteration algorithm, so that high image precision and accurate image positioning can be achieved.

Owner:NANJING UNIV OF POSTS & TELECOMM

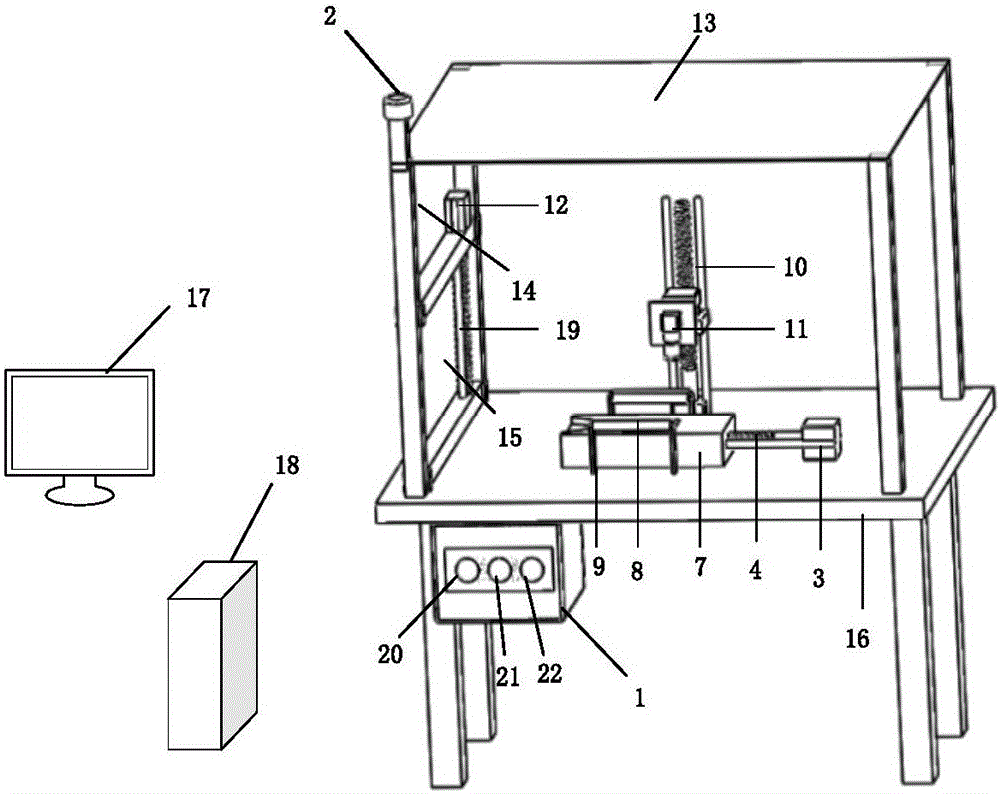

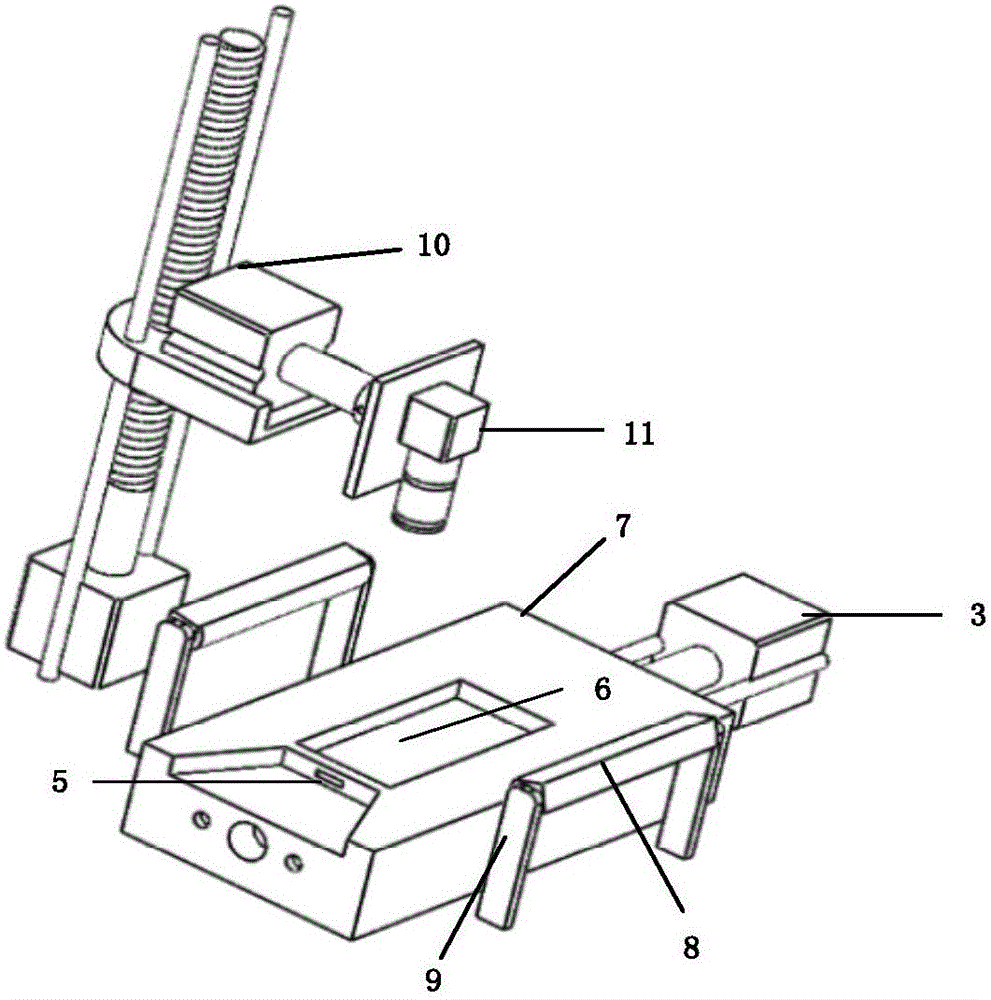

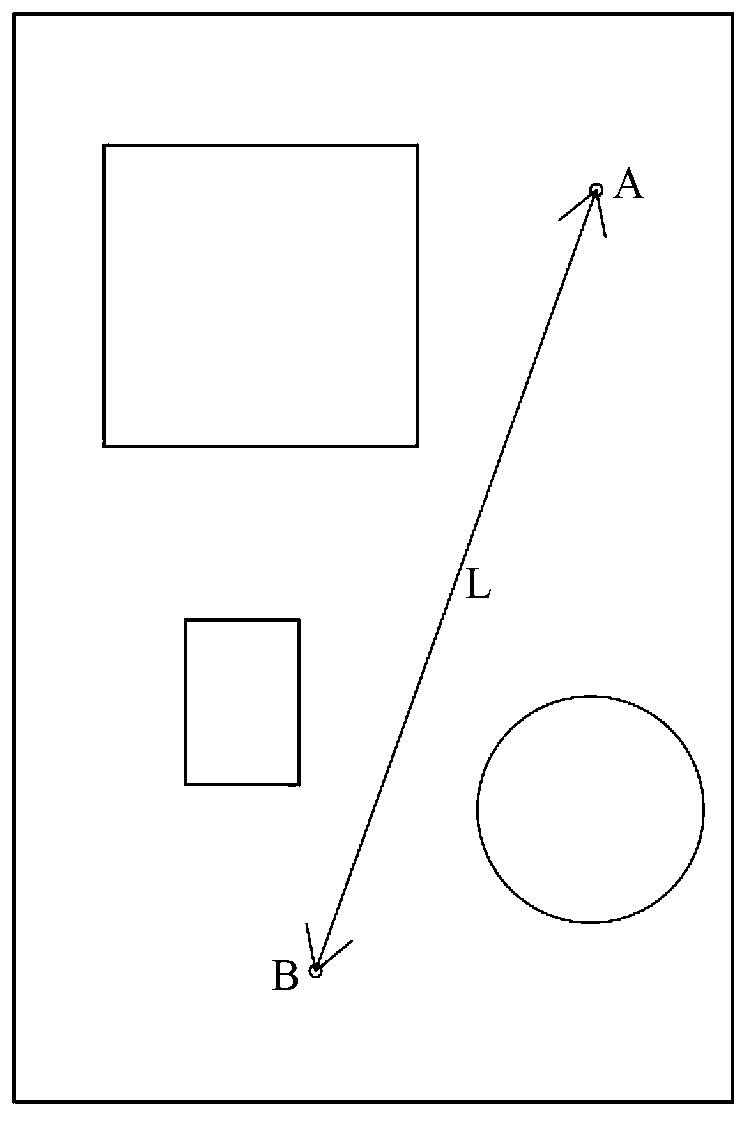

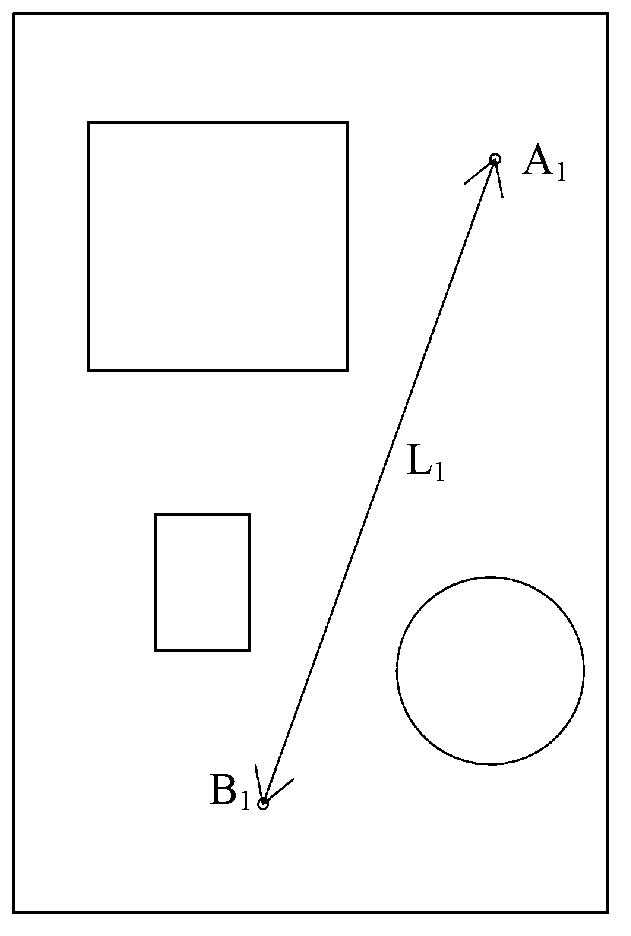

Device and method for detecting size of internal groove of small-size workpiece through asynchronous exposure of multipoint light source

InactiveCN106091926AOvercome the technical problems of large measurement errors and low efficiencyOvercome errorUsing optical meansMeasurement pointComputer vision

The invention discloses a device and method for detecting the size of an internal groove of a small-size workpiece through the asynchronous exposure of a multipoint light source. The device comprises an experiment table, a square framework, a small-size workpiece visual collection assembly, a control cabinet, and a buzzer. The method comprises the steps: enabling the lightproof square framework to be disposed on the experiment table in a covering manner and forming an internal dark box environment; placing the small-size workpiece visual collection assembly in the internal dark box environment; carrying out the calibration of an industrial camera, and obtaining the value of a pixel single quantity; taking a contour image, and marking a measuring point as a template image; placing a to-be-detected workpiece, respectively turning on parallel light sources at two sides for asynchronous exposure, collecting the upper and lower contour images, carrying out the matching with the template image, moving the measuring point of the template image to the lower contour image, carrying out the fusion of upper and lower contour images, calculating the distance between the lower and upper contour images, and obtaining a result. The device can method can carry out the multipoint detection of the size of the internal groove of a complex workpiece quickly and accurately, is high in detection efficiency, and is high in precision.

Owner:CHINA JILIANG UNIV

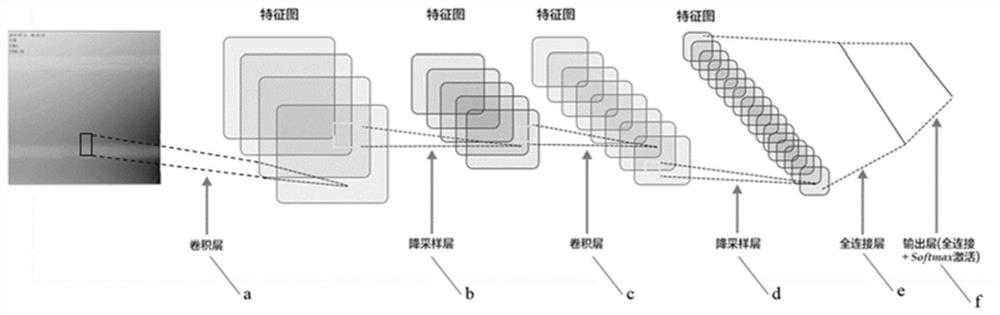

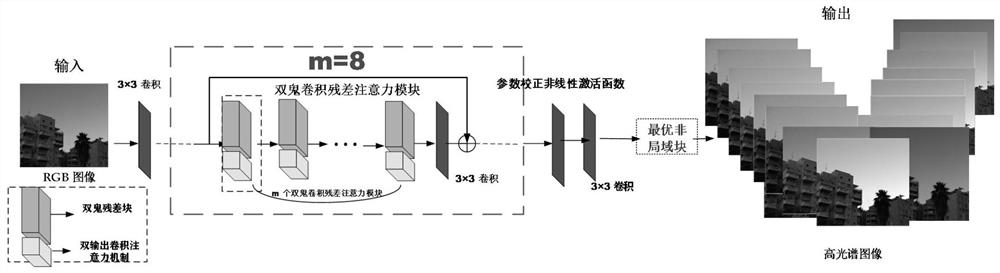

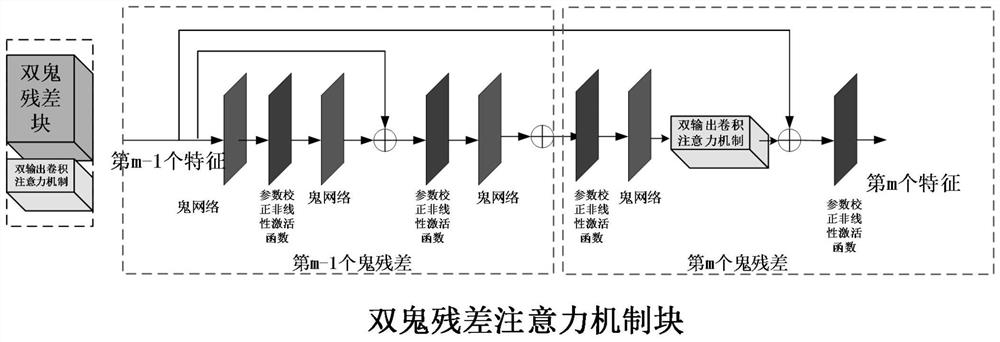

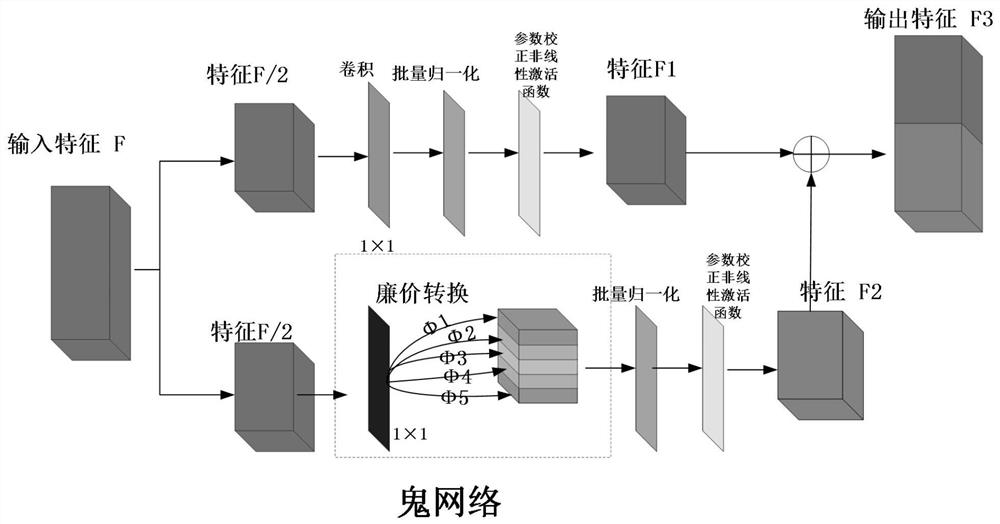

Hyperspectral image reconstruction method based on double-ghost attention mechanism network

ActiveCN112819910AActive connectionHigh image precision2D-image generationNeural architecturesPattern recognitionRgb image

The invention provides a hyperspectral image reconstruction method based on a double-ghost attention mechanism network, which is used for performing hyperspectral image reconstruction on a single RGB image, and comprises the following steps: step 1, inputting and processing an RGB image to obtain shallow feature information; 2, enabling the shallow feature information to enter a first double-ghost residual attention module, and obtaining deep feature information; 3, enabling the deep-level feature information to enter a dual-output feature convolution attention mechanism module to extract deeper-level feature information; 4, adding the deeper feature information and the shallow feature information to obtain new features; 5, putting the new features sequentially into subsequent m-1 series double ghost residual attention modules, and finally outputing one feature; 6, performing convolution on the features output in the step 5, and activating to obtain new features; and 7, enabling the feature map with the new features to enter an optimal non-local module, and outputting a hyperspectral image for visualization.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

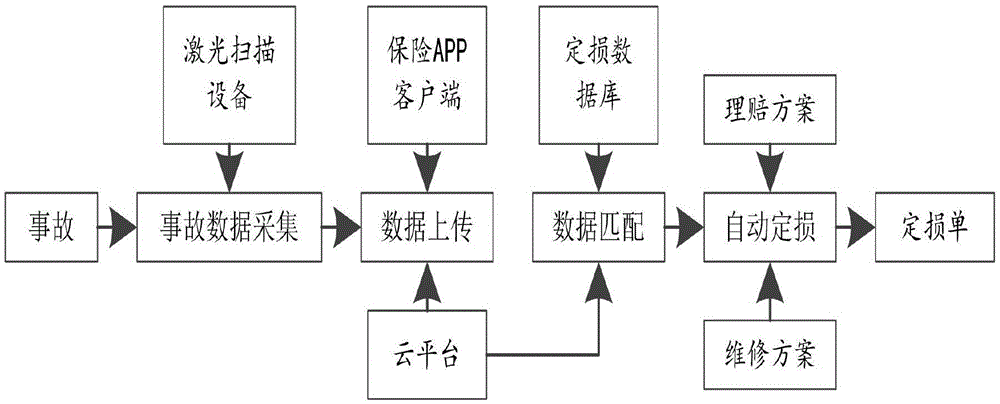

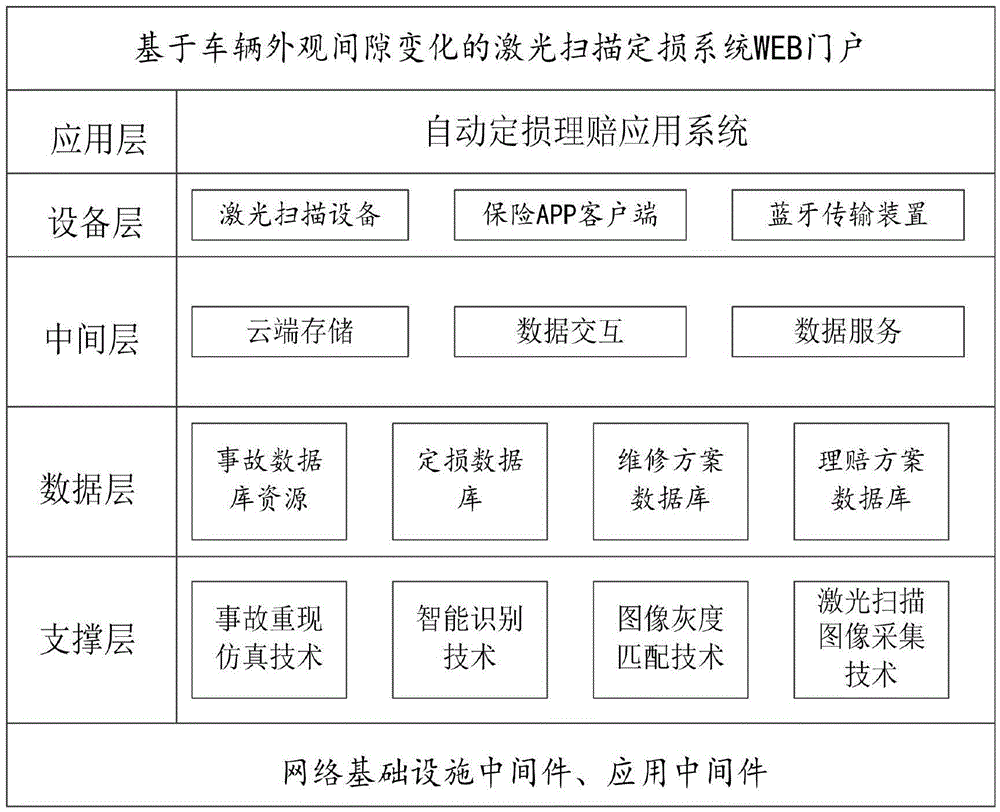

Vehicle appearance clearance change-based laser scanning automatic loss assessment method and system

InactiveCN105469312AAvoid the chance of accident fraudHigh image precisionFinanceCharacter and pattern recognitionLaser scanningEngineering

The invention relates to a vehicle appearance clearance change-based laser scanning automatic loss assessment method and system. With the method and system adopted, the problem of subjectivity and possibility of allied insurance cheating in loss assessment of loss assessors can be solved. The system includes portable Bluetooth driven laser scanning equipment, a loss assessment system, an insurance APP client, a Bluetooth transmission device, a cloud platform and a network system framework. With the method and system adopted, dismantling cost of vehicles involved in accidents can be omitted, and therefore, the satisfaction of insured customers and the standardization of the settlement of accident insurance claim can be greatly improved.

Owner:DALIAN ROILAND SCI & TECH CO LTD

Correction method for aerial surveying and mapping images

ActiveCN102706331ASimple stepsEasy to operateHeight/levelling measurementPicture interpretationAerial photographyComputer vision

The invention discloses a correction method for aerial surveying and mapping images, which comprises the following steps: setting two reference points in a to-be-measured area, and measuring the horizontal distance between the two points; measuring idealistic distance between two final image points in a final image corresponding to a target scale according to the target scale and the obtained horizontal distance; carrying out aerial photography for to-be-measured area, butting the obtained images so as to obtain an integral original image of the to-be-measured area, and measuring the actual distance between two original image points; and calculating the ratio of the idealistic distance to the actual distance to scale the original image according to the ratio, so as to obtain the final image. Due to the adoption of the method provided by the invention, the image of the target scale can be obtained without conforming to the accurate aerial photography height, accordingly, the precision requirement for the aerial photography height is reduced, and the operation is simpler.

Owner:天津建岩岩土工程有限公司

Light emitting device, electronic apparatus, and method of driving light emitting device

InactiveUS20140043219A1Improve accuracyHigh image precisionStatic indicating devicesEngineeringLight emitting device

A light emitting device includes a pixel circuit and a data line provided between a first substrate and a second substrate opposed to each other. The pixel circuit includes a first circuit and a second circuit, the first circuit includes a first light emitting element and a first driving transistor connected in series to each other, and a first switching element provided between a gate of the first transistor and the data line, and outgoing light of the first light emitting element is output from the first substrate side. The second circuit includes a second light emitting element and a second driving transistor connected in series to each other, and a first switching element provided between a gate of the second driving transistor and the data line, and outgoing light of the second light emitting element is output from the second substrate side.

Owner:SEIKO EPSON CORP

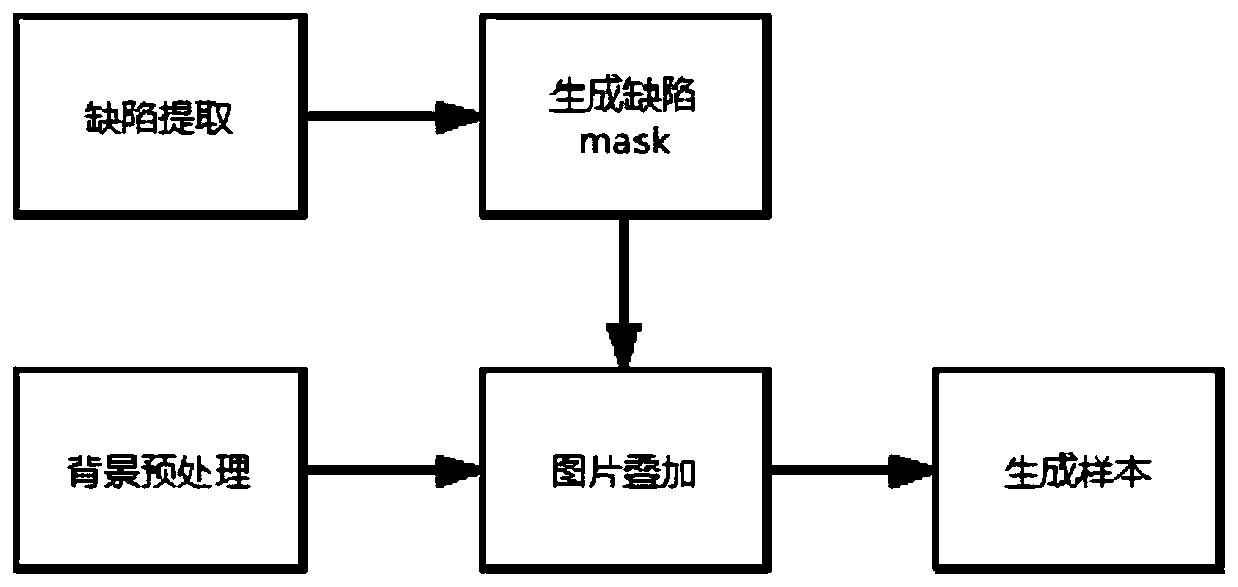

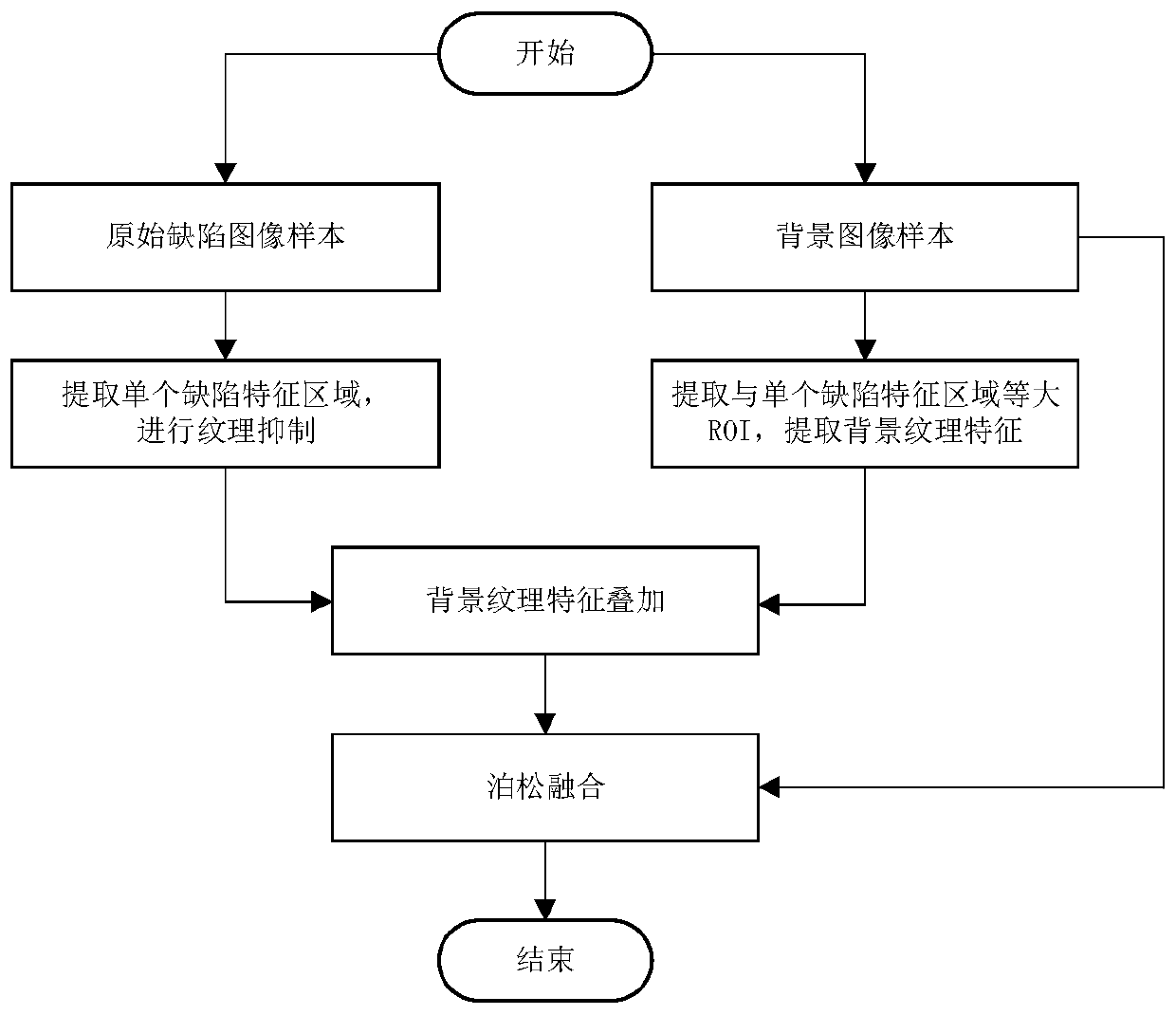

Defect image sample generation method and device and panel defect detection method

ActiveCN111524100AProminent visual defectGood fusion effectImage enhancementImage analysisRegion of backgroundDeep learning

The invention provides a defect image sample processing method and device and a panel defect detection method. The method comprises the following steps: extracting a defect feature region on an original defect image sample, and performing texture suppression on the defect feature region to obtain a first simulated defect image; extracting an ROI (Region Of Interest) equal to the defect feature region in area from the background image sample; extracting background texture features and superposing the background texture features into the first simulated defect image to obtain a second simulateddefect image; and finally, fusing the second simulated defect image and the background image sample to generate a defect image sample. According to the effective method for synthesizing the defect image sample by simulating any scene provided by the invention, the defect area is enabled to have the texture of the existing background through a background texture feature extraction and coverage method, the pixel distribution is closer to the background area, and the image is more natural; therefore, the generated defect image sample can meet the training requirement of a deep learning model, andthe problem of insufficient training samples is solved.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

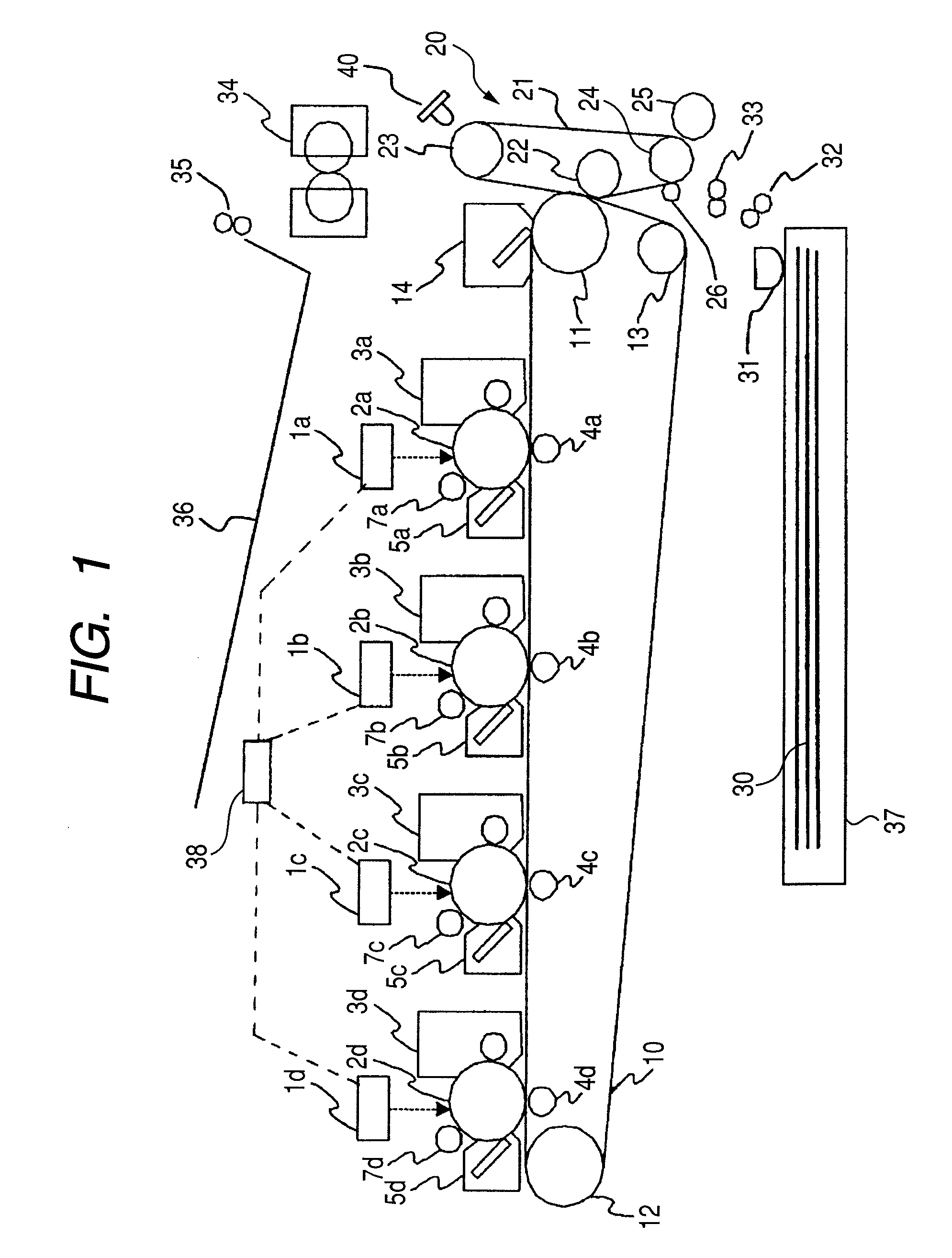

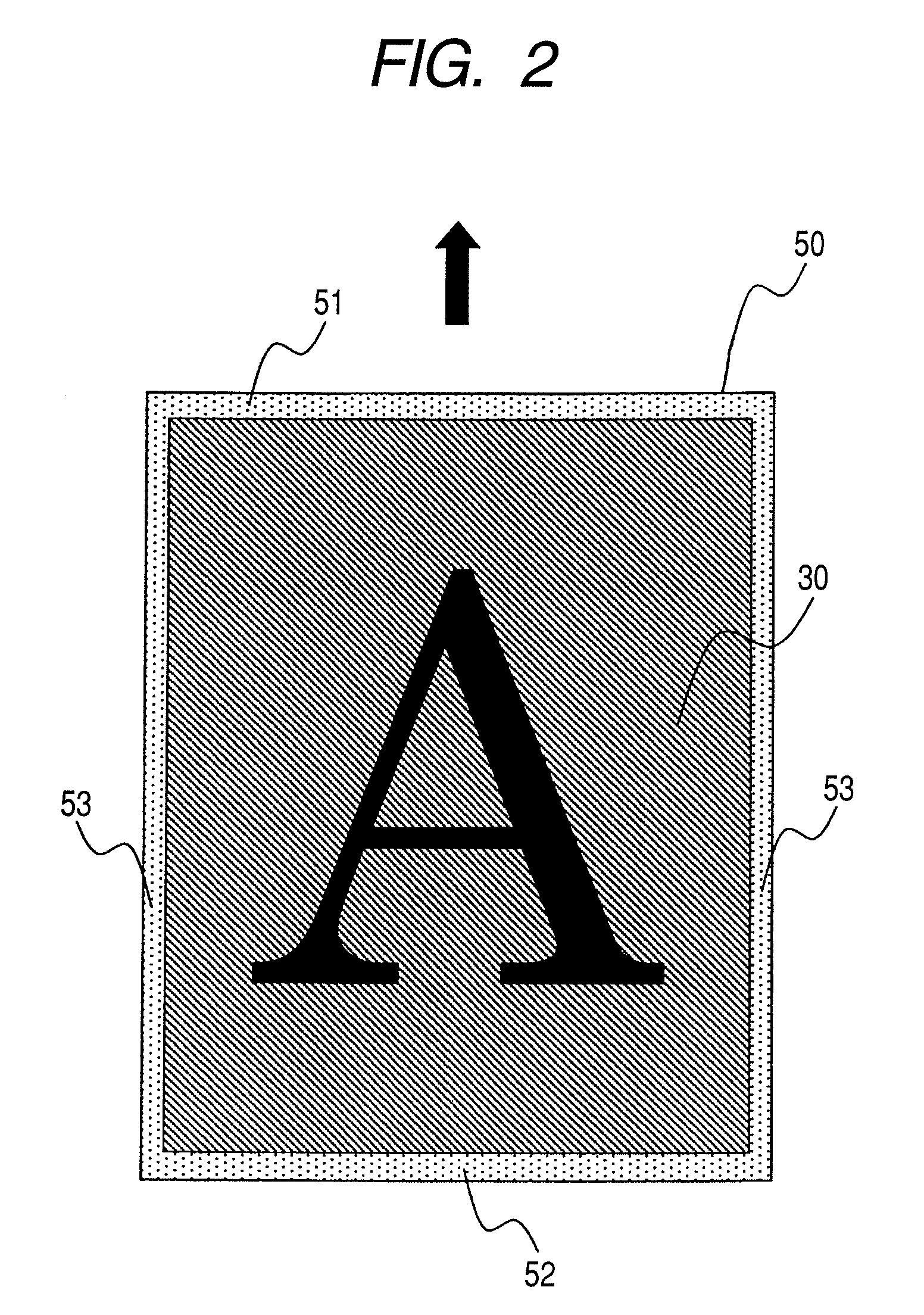

Image forming apparatus for marginless printing

Owner:CANON KK

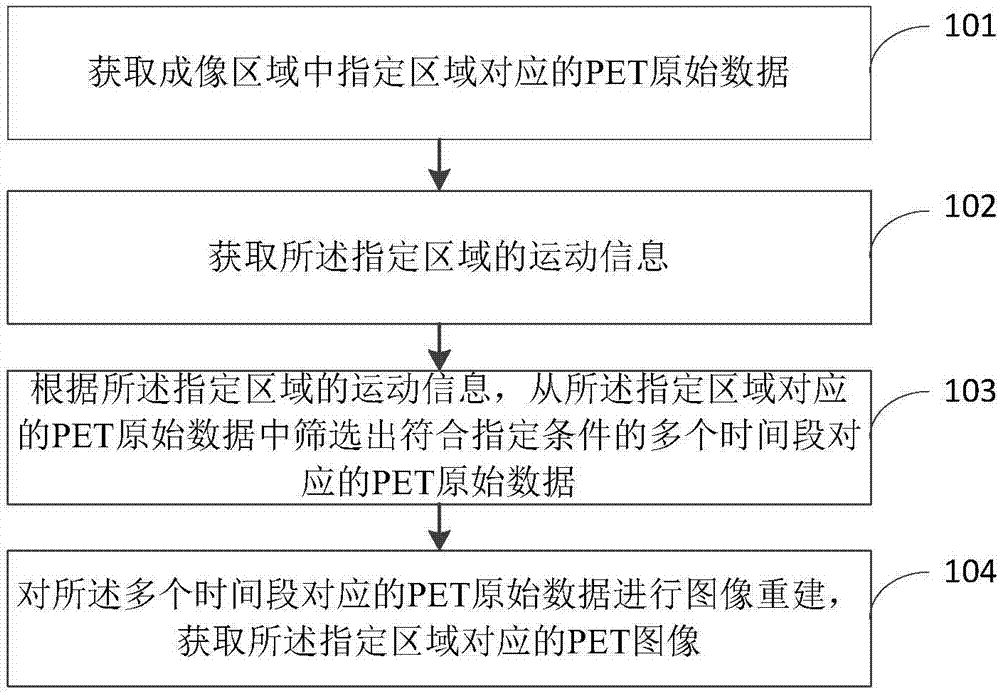

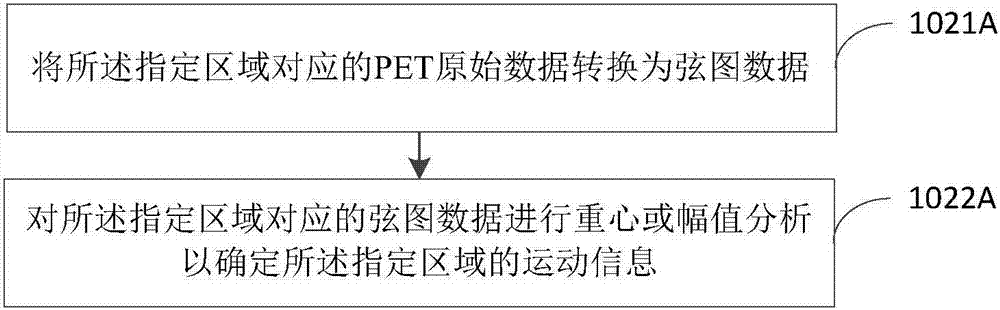

Medical imaging method and device

ActiveCN107016661AResolve ArtifactsAvoid Fusion BiasImage enhancementImage analysisOriginal dataMedical imaging

The embodiment of the invention provides a medical imaging method and a device, relates to the technical field of medicines and aims to solve the problem of PET image artifacts. The method comprises the following steps: firstly, acquiring a PET original data corresponding to an appointed area in an imaging area, and then acquiring motion information of the appointed area; screening the PET original data corresponding to multiple time periods that meet an appointed condition from the PET original data corresponding to the appointed area according to the motion information of the appointed area; and performing image reconstruction on the PET original data corresponding to multiple time periods, thereby acquiring a PET image corresponding to the appointed area. The technical scheme provided by the embodiment of the invention is suitable for medical imaging process.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

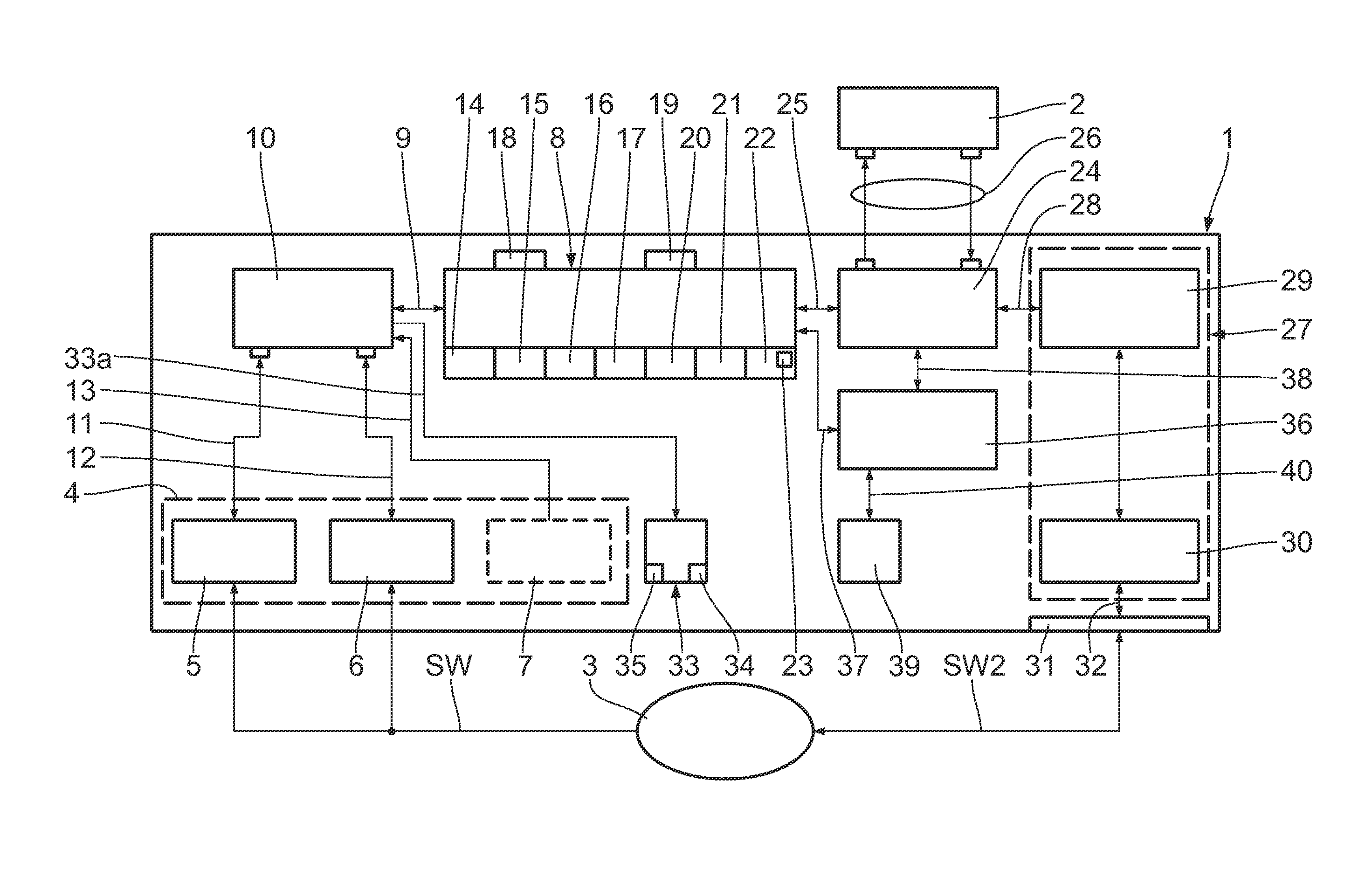

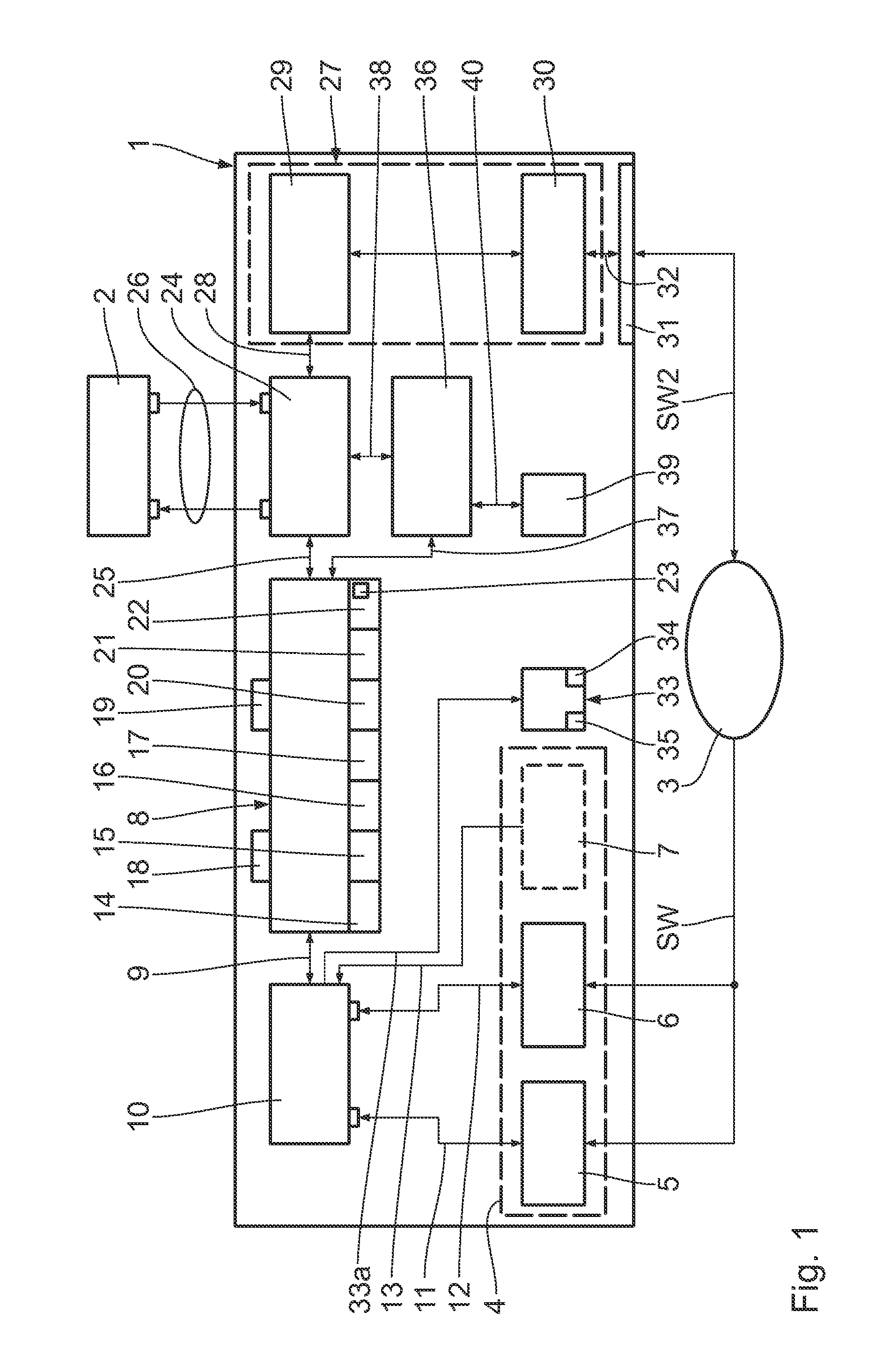

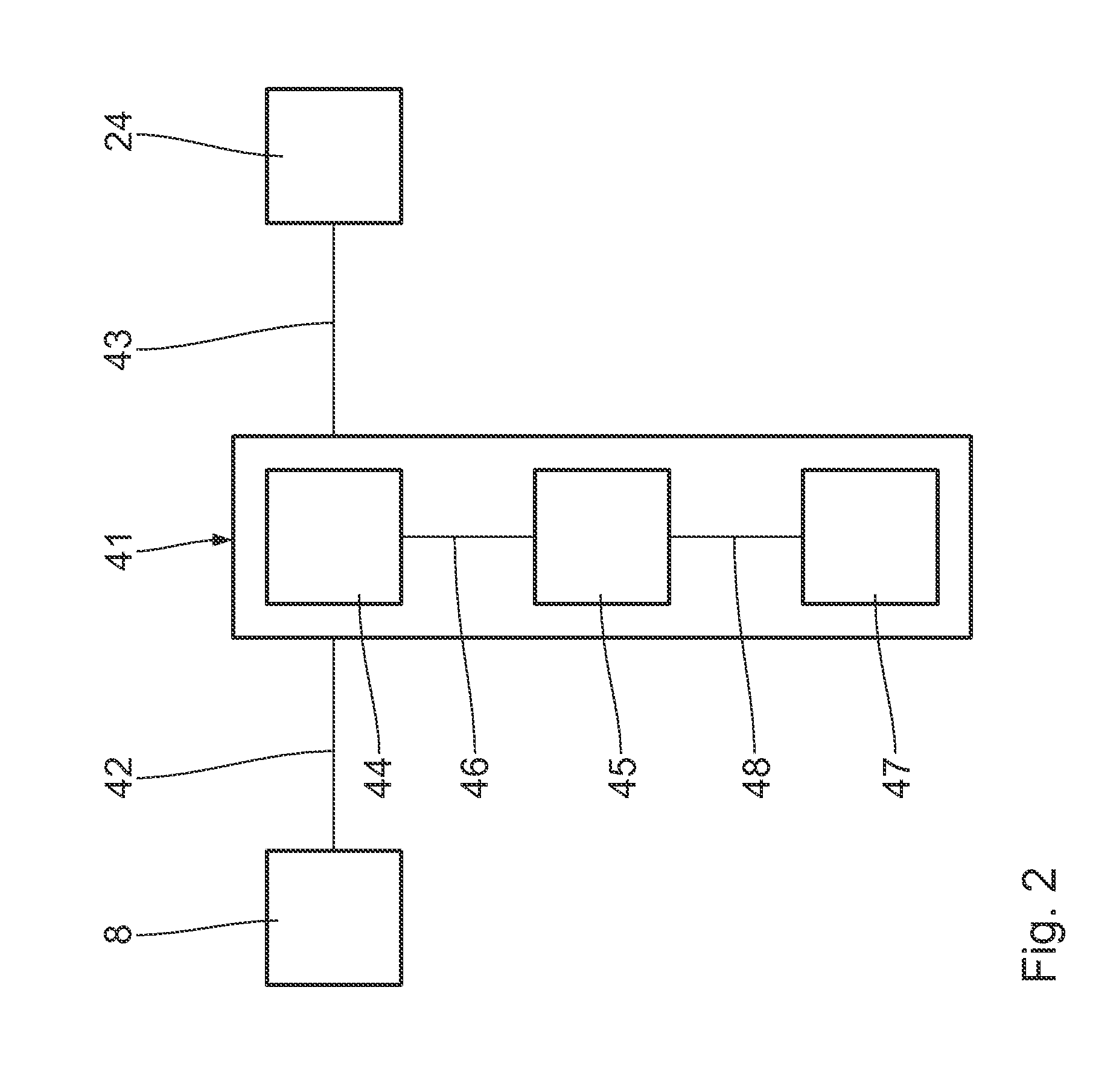

Remote control device for controlling a mechanism with the aid of a movable object and interface module for communication between modules of a remote control device of this type or between one of the modules and an external mechanism

ActiveUS20130293685A1Control be possibleHigh range resolutionInput/output for user-computer interactionImage analysisStereo imageImage evaluation

A remote control device is used to control a mechanism with the aid of a movement pattern and / or a distance pattern of at least one moved object. The remote control device has a camera module to receive a stereo image and to detect the moved object. An image evaluation module has a movement evaluation sub-module and a distance evaluation sub-module. A control and communication module of the remote control device, depending on the movement or distance values determined, generates at least one mechanism control signal and sends it to the mechanism to be controlled. An interface module has a data memory, a comparator sub-module and a communication sub-module. The latter, with adequate agreement between the respective actual parameter and one of the desired movement parameters, sends the control signal assigned in the table to the module of the remote control device or to the mechanism.

Owner:MYESTRO INTERACTIVE

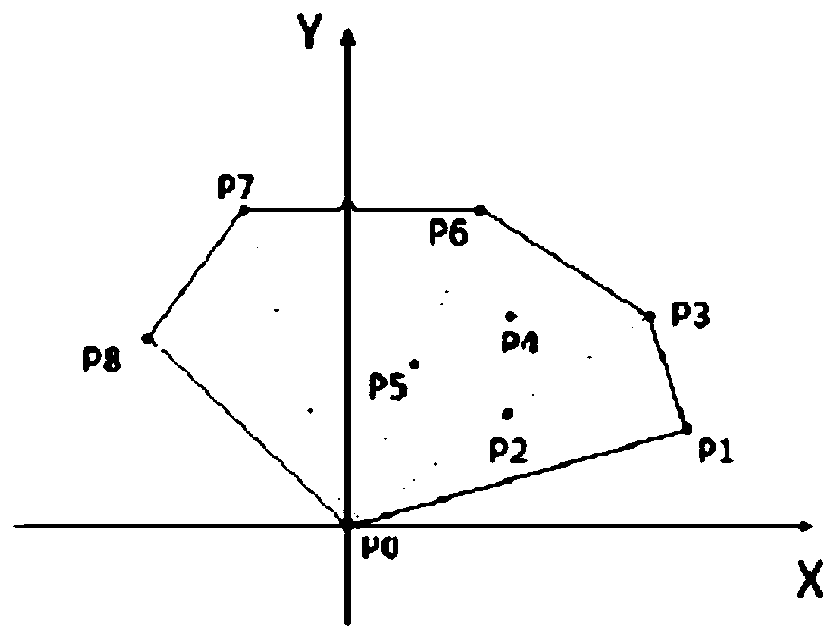

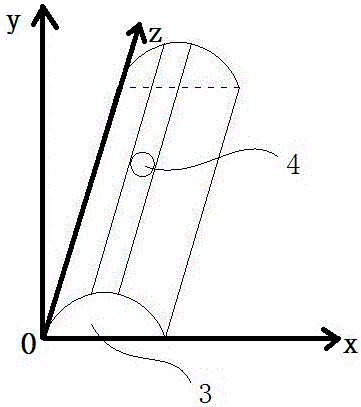

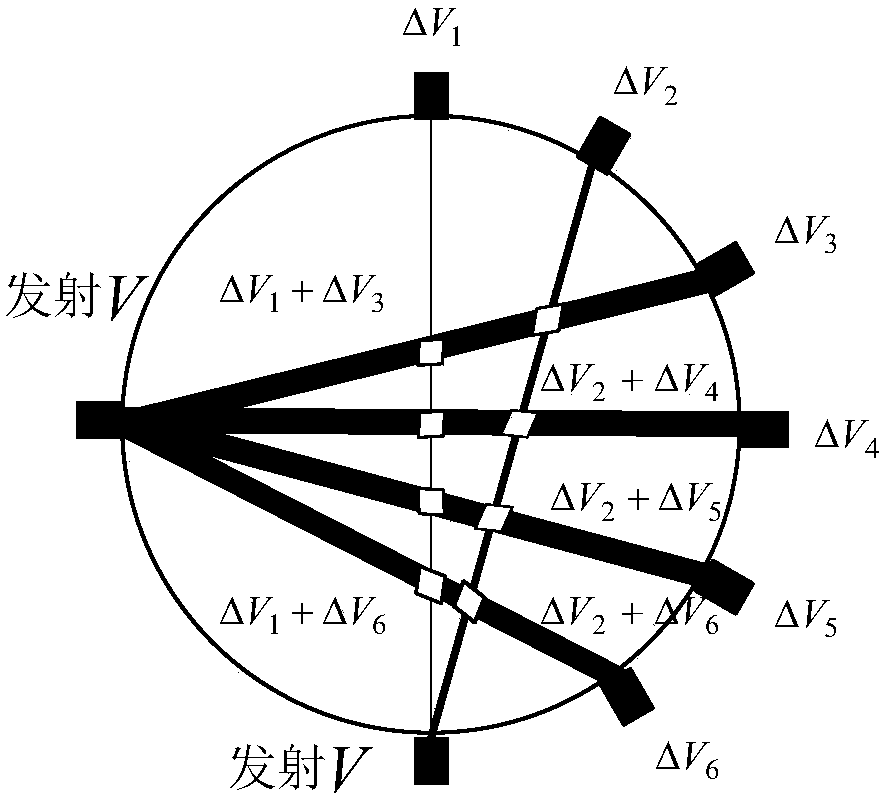

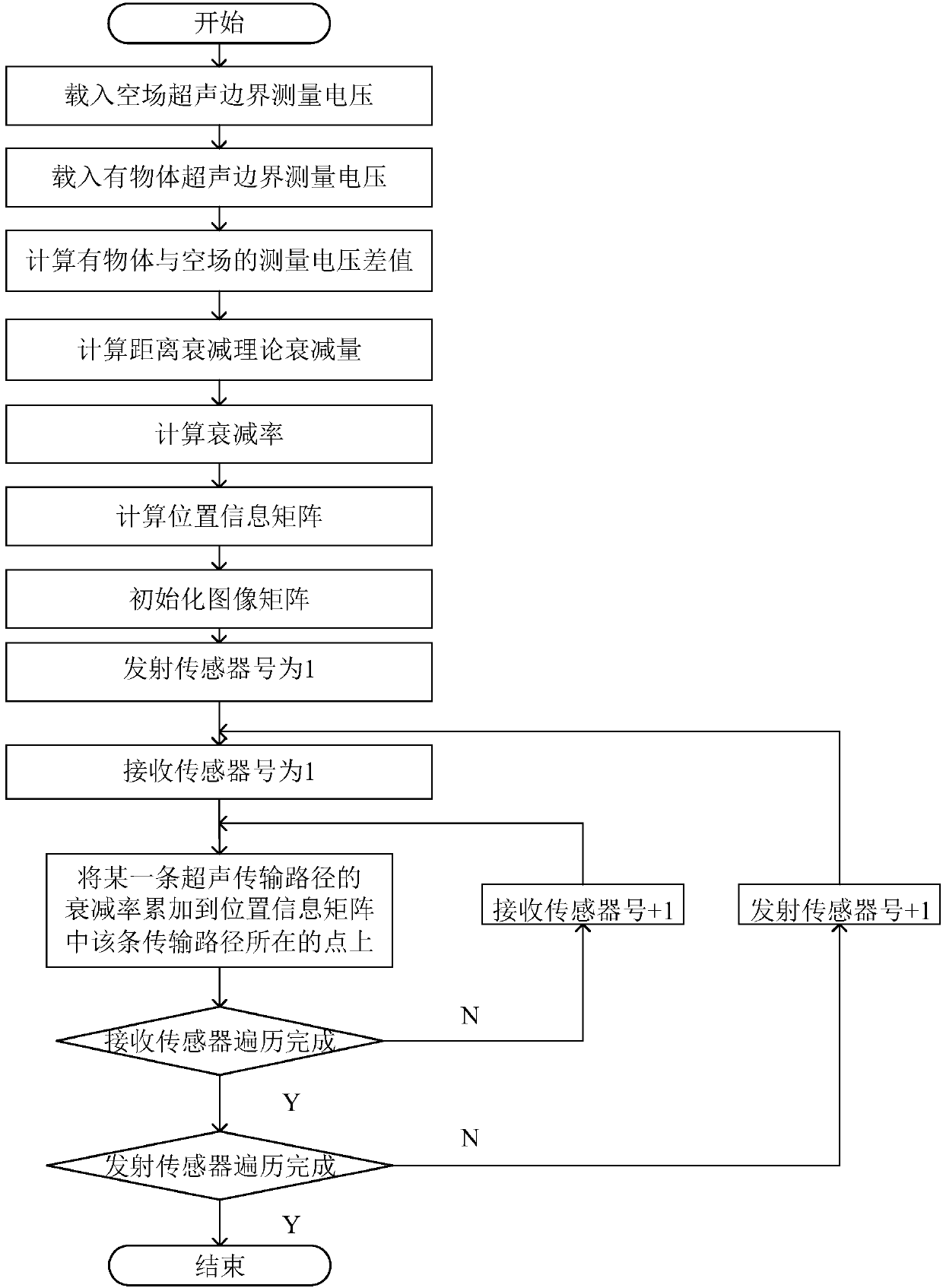

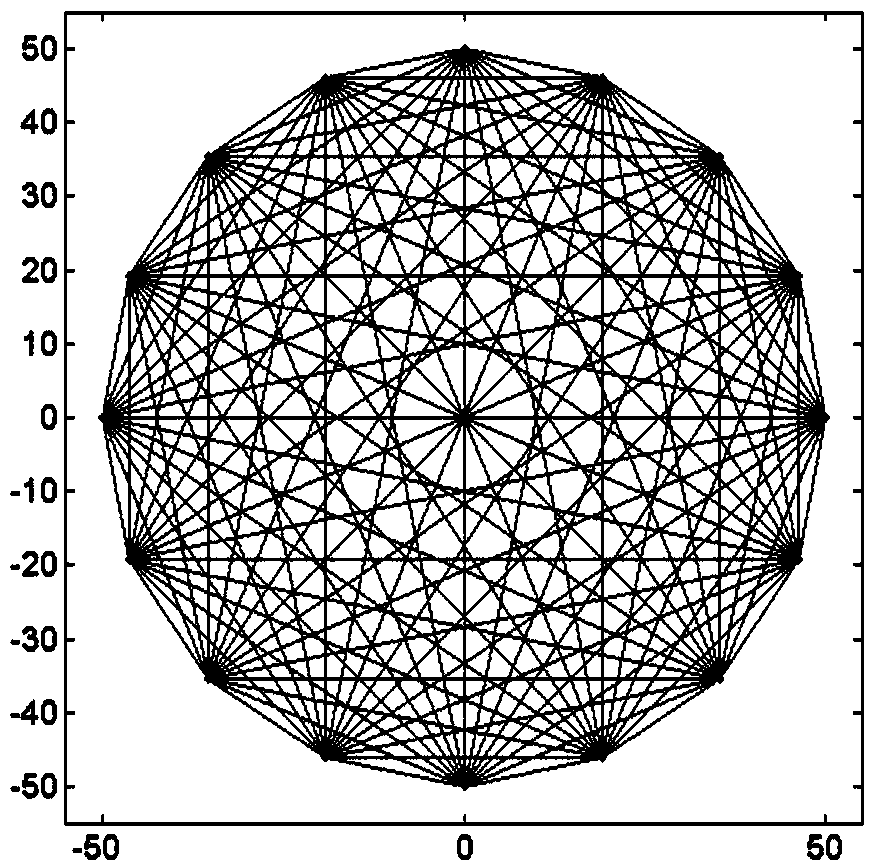

Propagation path mesh generation based ultrasonic transmission mode tomographic method

ActiveCN108287199AImprove recognitionHigh image precisionProcessing detected response signalPath generationUltrasound

The invention relates to a propagation path mesh generation based ultrasonic transmission mode tomographic method, the central point of a tested area is taken as the origin of coordinates to constructa rectangular plane coordinate system, an image matrix I is constructed in the rectangular plane coordinate system, N ultrasonic sensors are distributed on the boundary of the tested area, a connecting line of any two ultrasonic sensors is an ultrasonic propagation path, the points of intersection of the ultrasonic propagation paths form an N*N grid matrix P. The traditional square or triangularmesh generation method is changed to irregular shape mesh generation based on the propagation characteristic of the ultrasonic wave to serve as the computing base. On the basis of the ultrasonic propagation path mesh generation method, the mesh generation based ultrasonic tomographic method is given.

Owner:TIANJIN UNIV

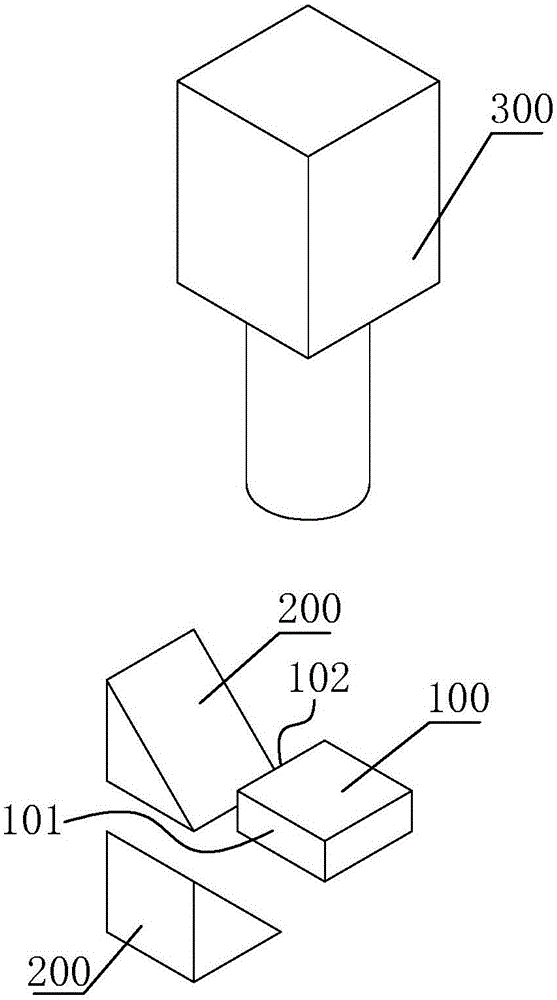

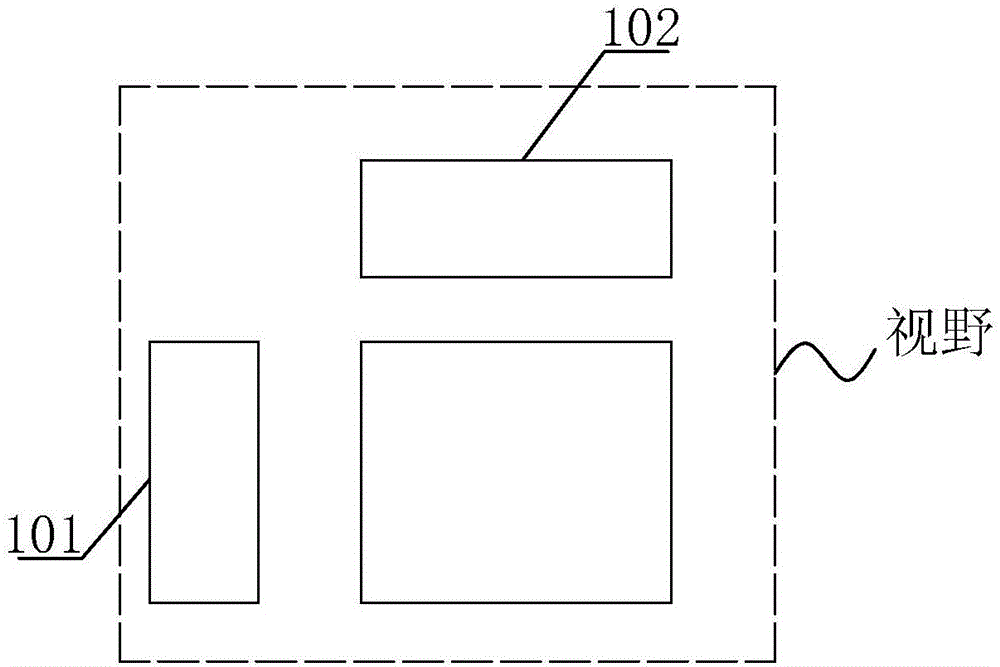

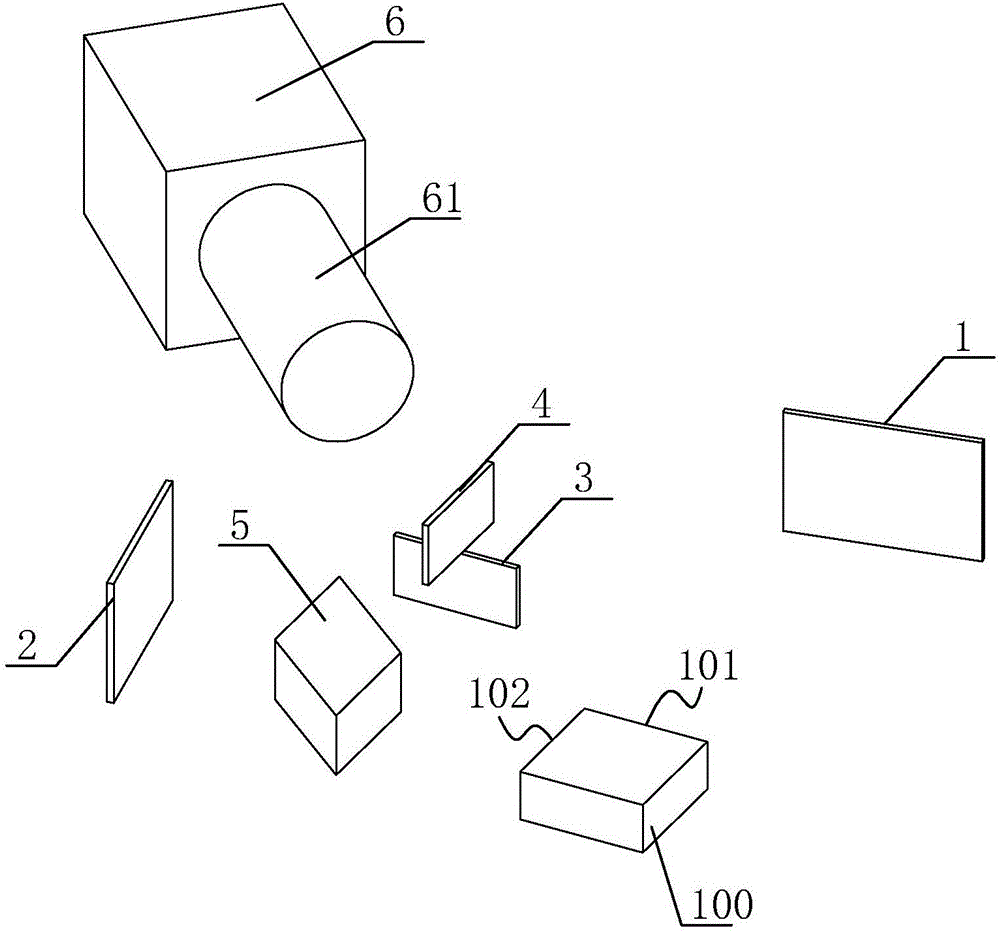

Non-coplanar image acquisition device

ActiveCN106647147AReduce in quantityHigh image precisionPanoramic photographyOptical elementsOptoelectronicsPrism

The invention relates to a non-coplanar image acquisition device. The non-coplanar image acquisition device comprises the components of a first reflector, a second reflector, a third reflector, a fourth reflector, a rhombic prism, a camera and a light source. The rhombic prism is arranged in a transmission optical path of light reflected from a second side surface. The rhombic prism can perform translational transmission of the light reflected from the second side surface for forming emergent light which is parallel with the light reflected from the second side surface. The second reflector is arranged in a transmission optical path of light reflected from the rhombic prism. The lens of the camera is arranged in an optical path of light reflected from the third reflector and the fourth reflector. The lens of the camera can realize displaying of images of a first side surface and a second side surface in the field-of-view of the lens in a staggered manner. The non-coplanar image acquisition device can simultaneously acquire side surface image information of two non-coplanar surfaces, thereby reducing the number of required cameras. Furthermore the two images of the two side surfaces fill the field-of-view of the camera, thereby sufficiently using the pixel area of the camera and greatly improving precision of an acquired image.

Owner:苏州德创测控科技有限公司

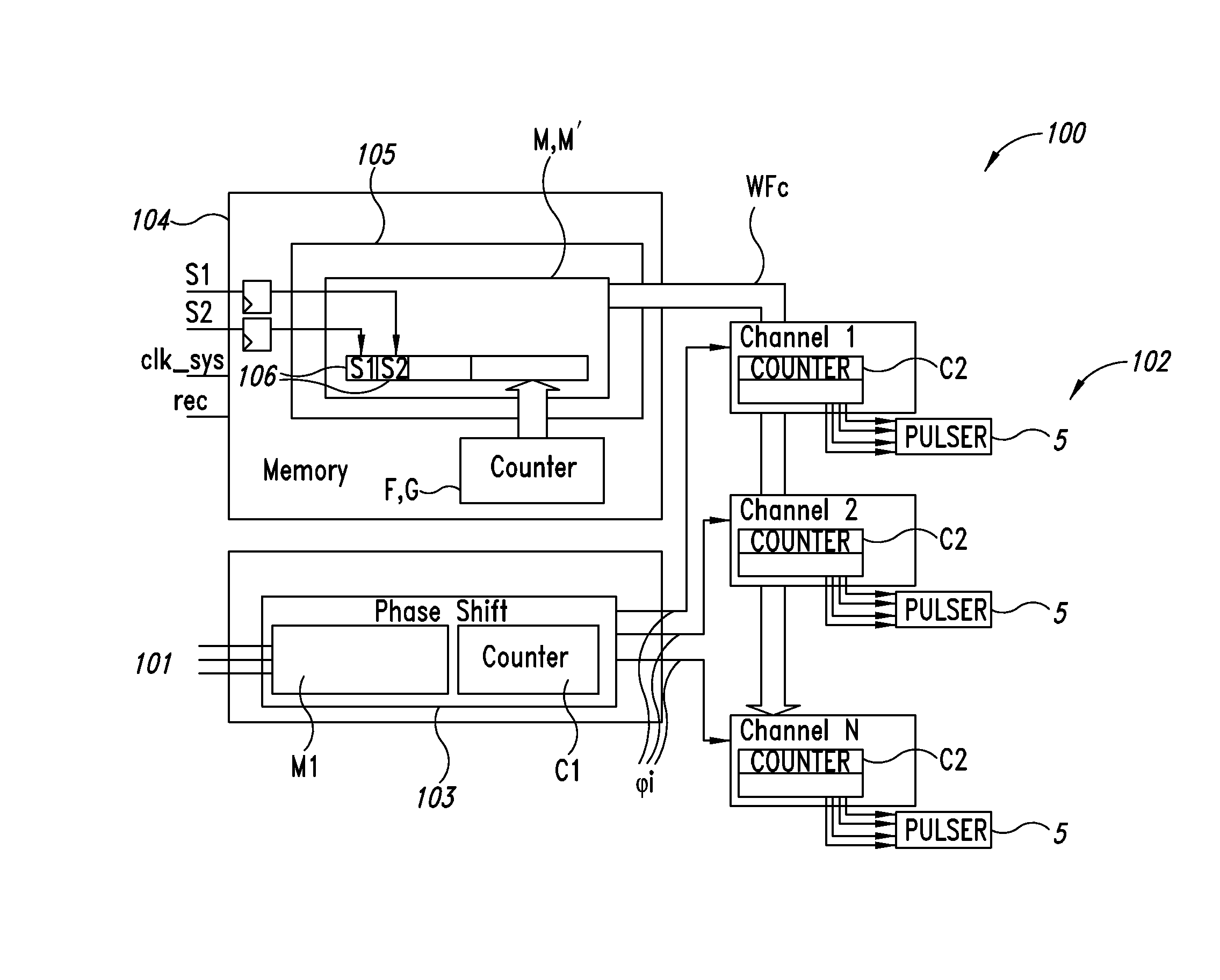

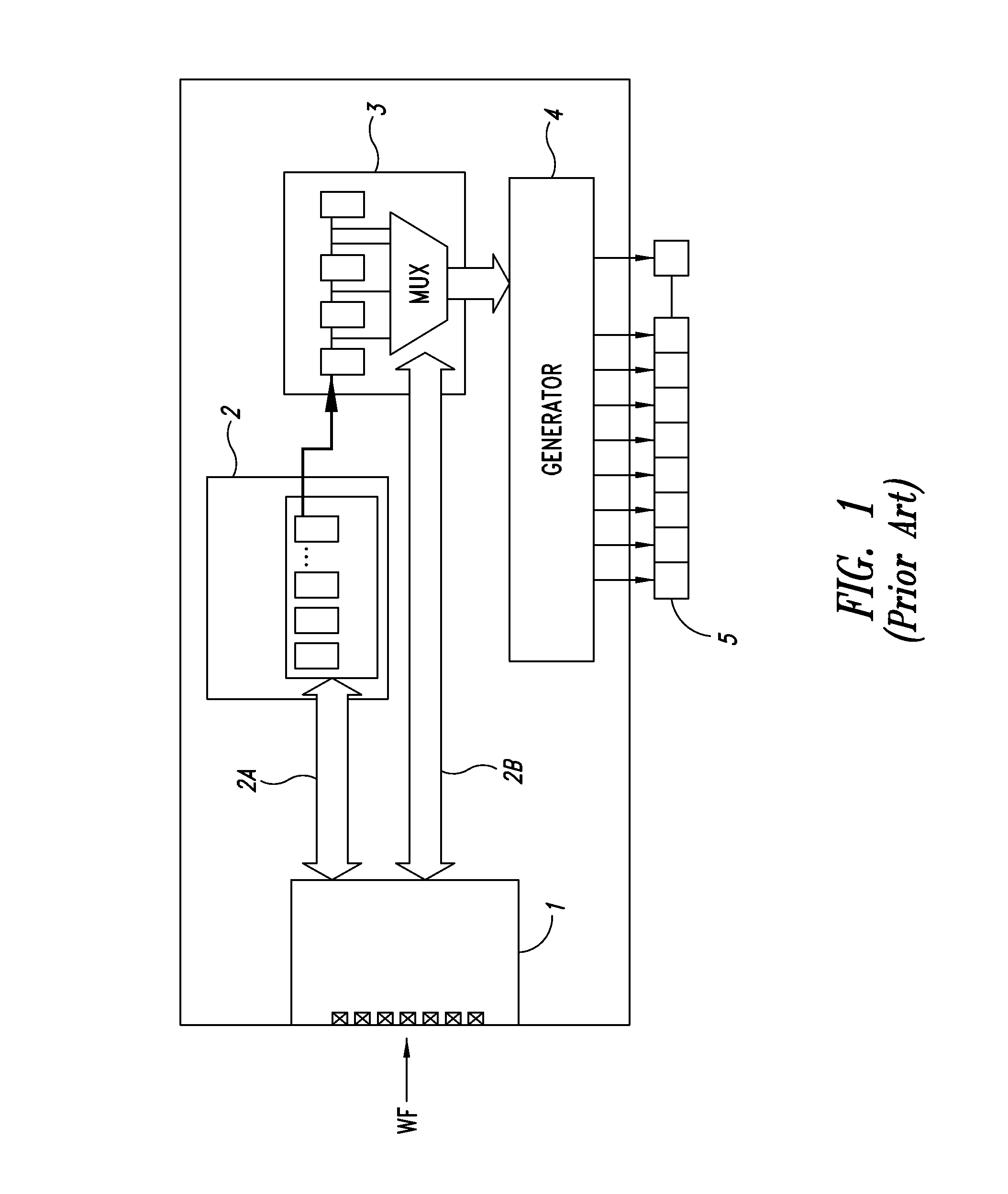

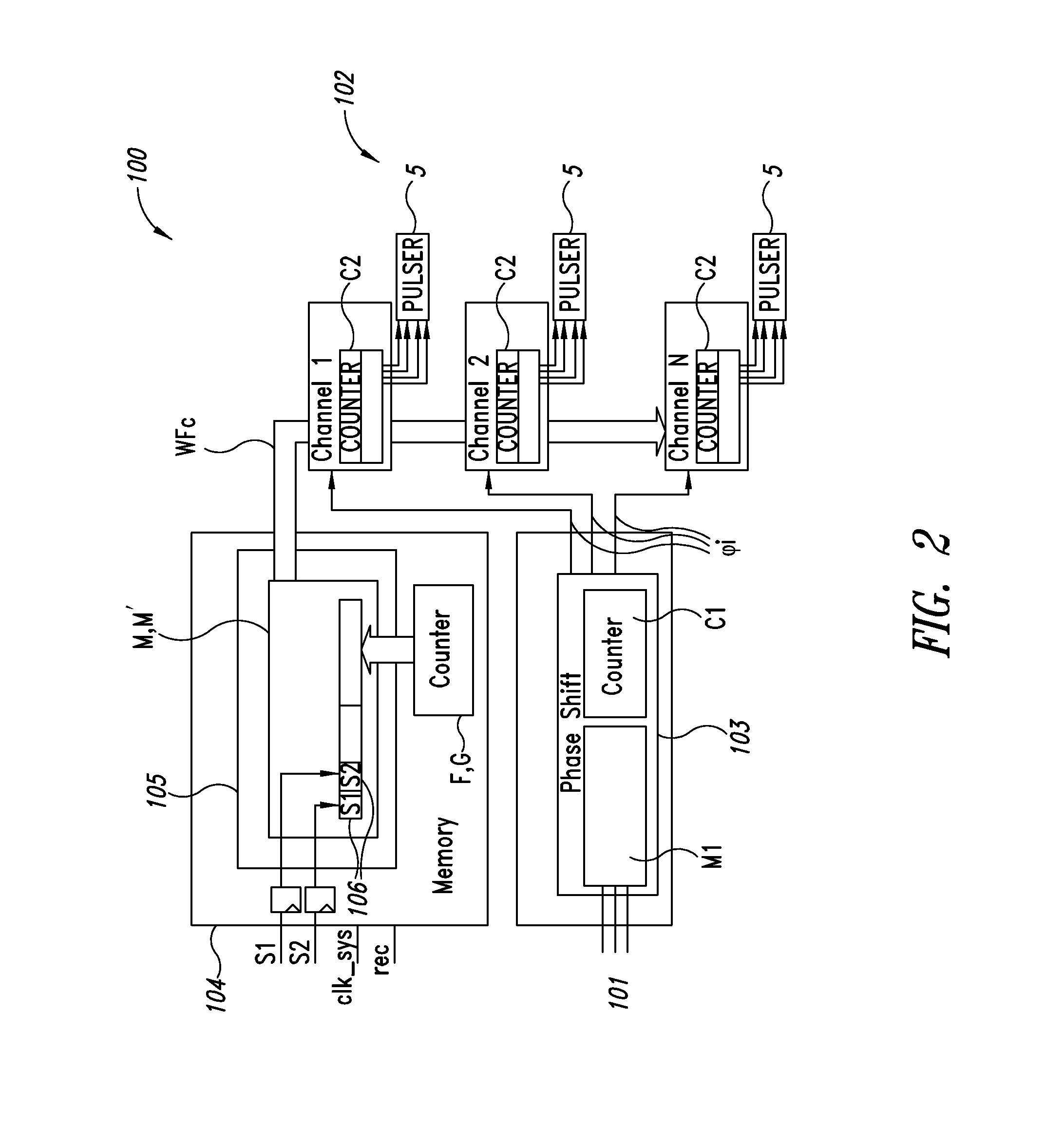

Method of setting a waveform signal in an ultrasound imaging apparatus and apparatus for setting an ultrasonic waveform signal using such method

ActiveUS20140323871A1High image precisionReduce bitrateWave based measurement systemsOrgan movement/changes detectionUltrasound imagingSonification

A digital representation of a waveform is generated based on signals received during a recording period. The received signals include a digital clock signal providing a determined number of clock pulses during the recording period, a plurality of binary digital signals defining, for each clock pulse of the determined number of clock pulses, a waveform state associated with the clock pulse. A digital representation of the waveform is generated and storing. The waveform has a duration based on the recording period and a profile based on the defined waveform states associated with the clock pulses of the determined number of clock pulses.

Owner:STMICROELECTRONICS INT NV

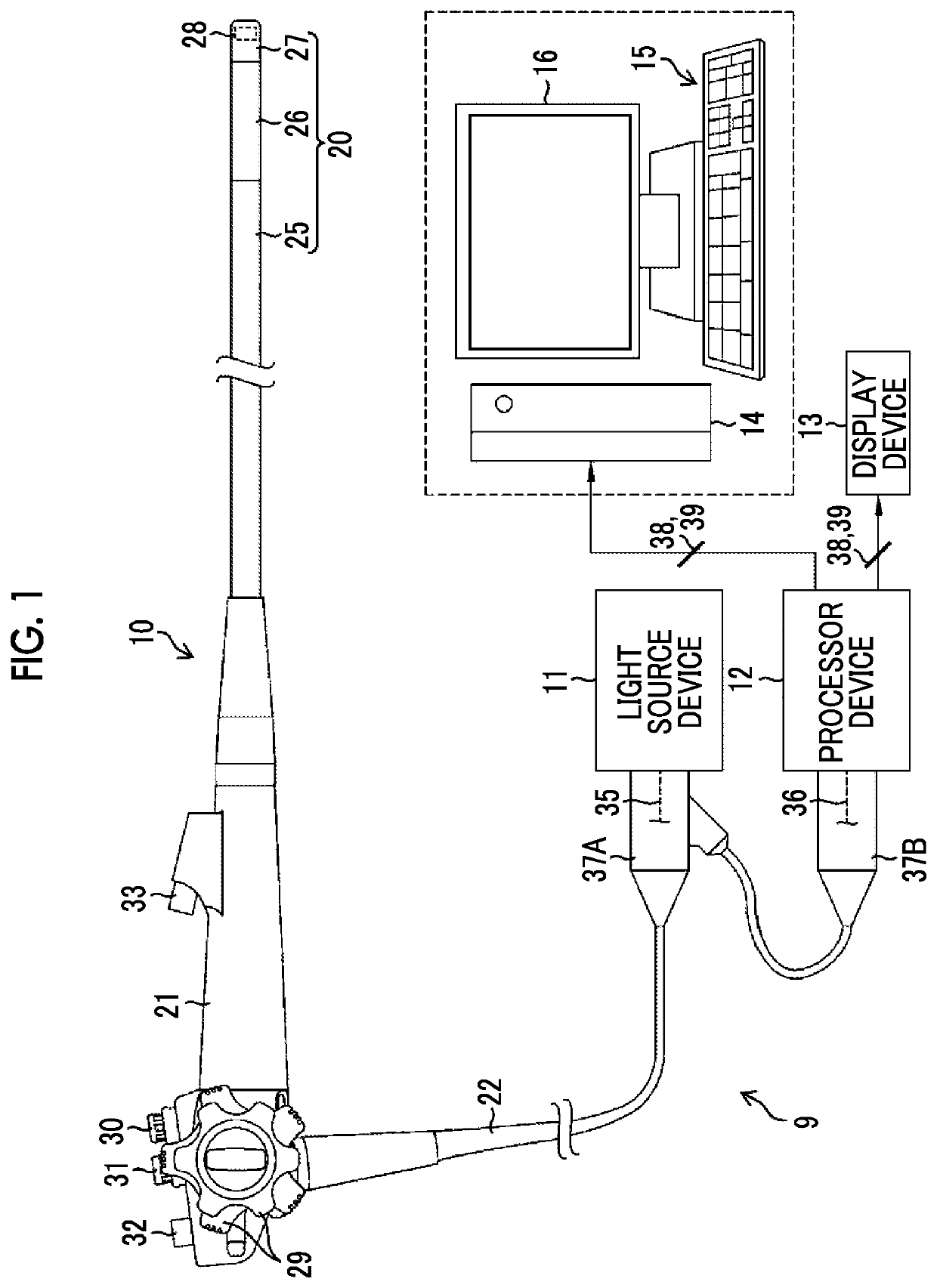

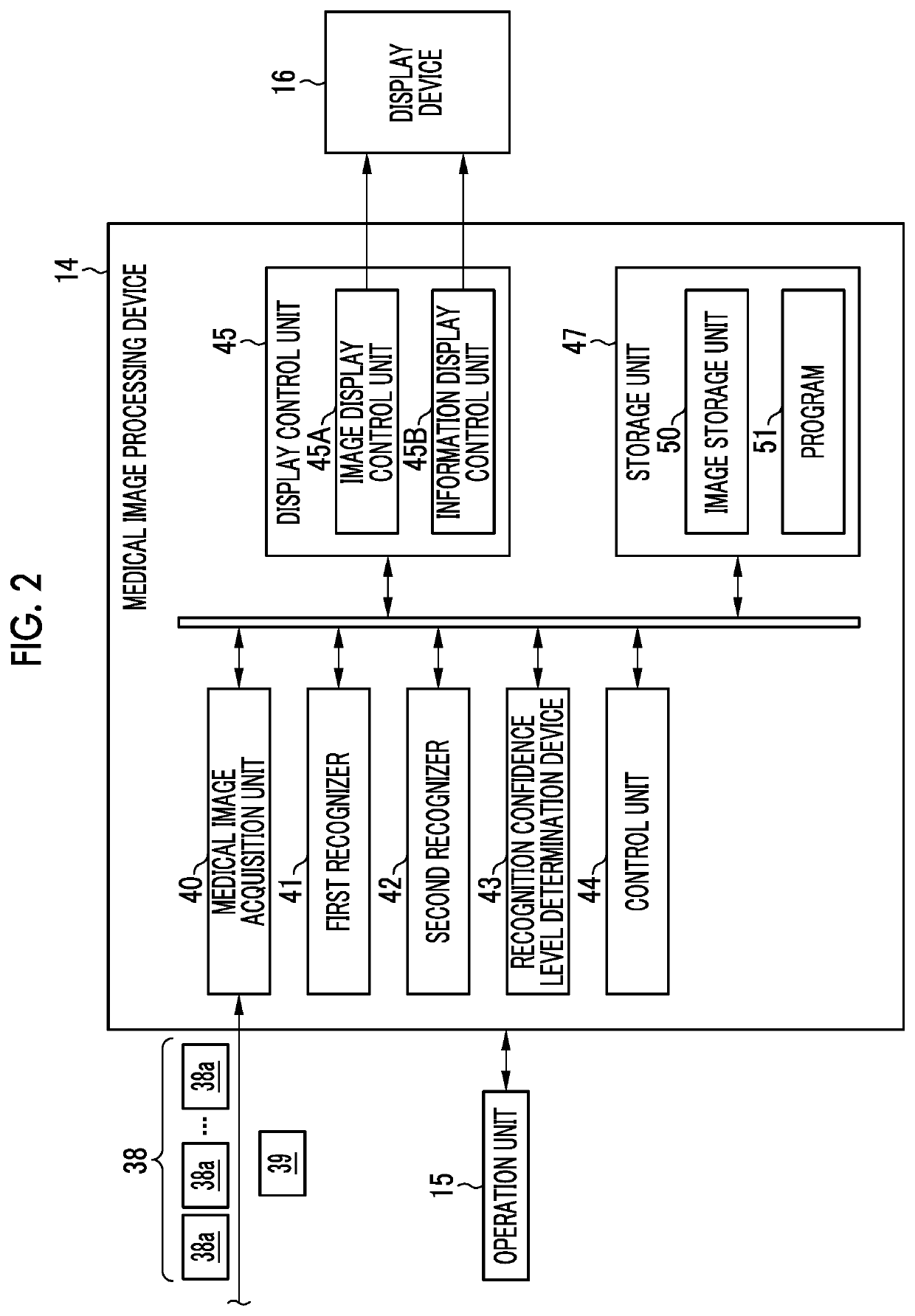

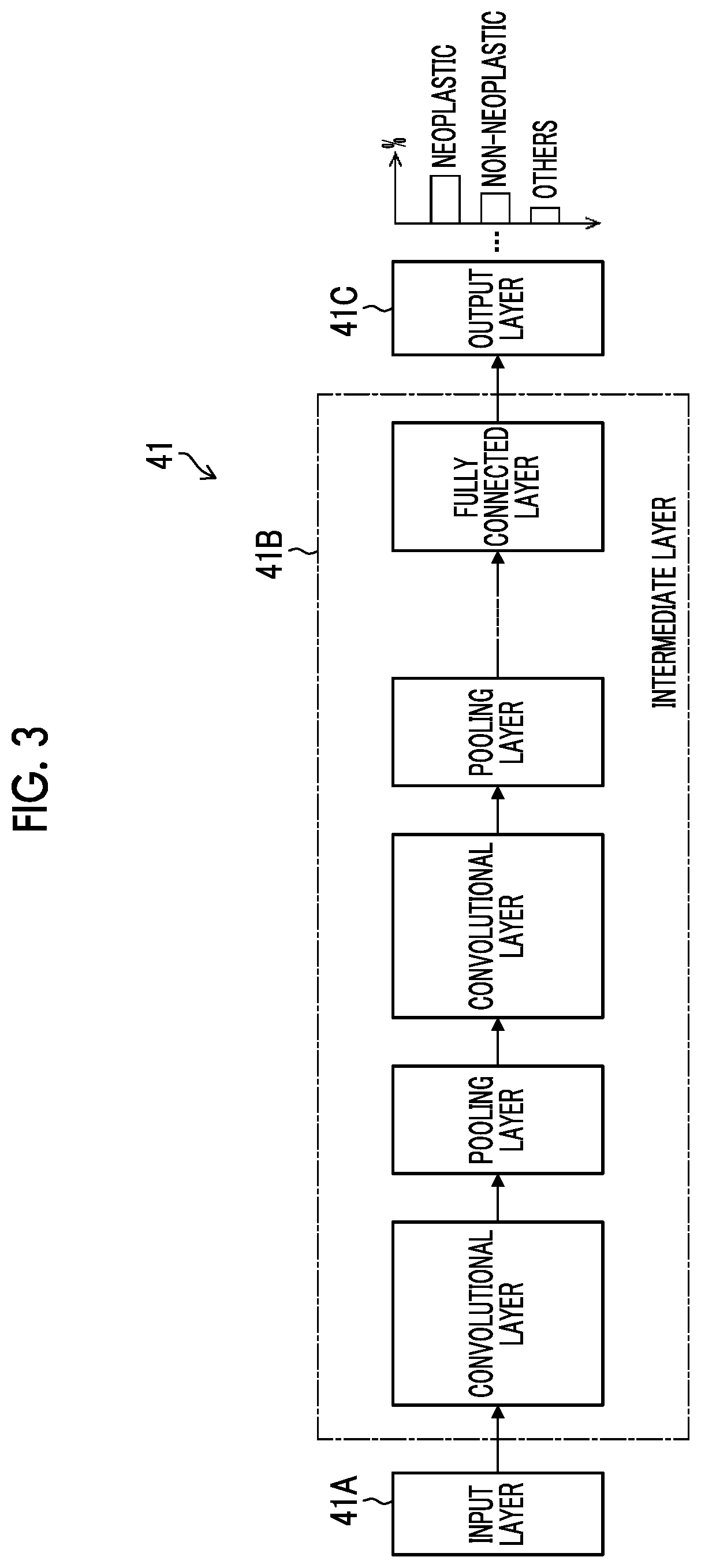

Medical image processing device, medical image processing method, and medical image processing program

ActiveUS20200193236A1SpeedImprove recognition accuracyImage enhancementImage analysisImaging processingComputer vision

A medical image processing device having a processor configured to: acquire a medical image including an image of a subject; perform a first recognition of the medical image using a first recognizer; determine a confidence level for a recognition result of a first recognition by the first recognition; and perform a second recognition of the medical image using a second recognizer according to the confidence level for the recognition result of the first recognition, the second recognition having higher recognition accuracy than the first recognition.

Owner:FUJIFILM CORP

Line-width inspection device

InactiveUS20120113246A1High image precisionHigh precisionMaterial analysis by optical meansColor television detailsLine widthOptoelectronics

The present invention discloses a line-width inspection device. The line-width inspection device has a platform, an image capturing device, a main light source device and at least one compensation light source device. The image capturing device is mounted above the platform, aligned with an inspection area of the platform and captures images of a pattern under inspection in the inspection area. The main light source device is disposed above the platform and correspondingly provides forward illumination to the inspection area, and an incident direction thereof is perpendicular to the platform. The at least one compensation light source device is mounted above the platform and provides compensation illumination to the inspection area. The additional compensation light source device can prevent edges of the pattern under inspection from occurring shadows and affecting image capturing, so as to enhance precision of image capturing.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

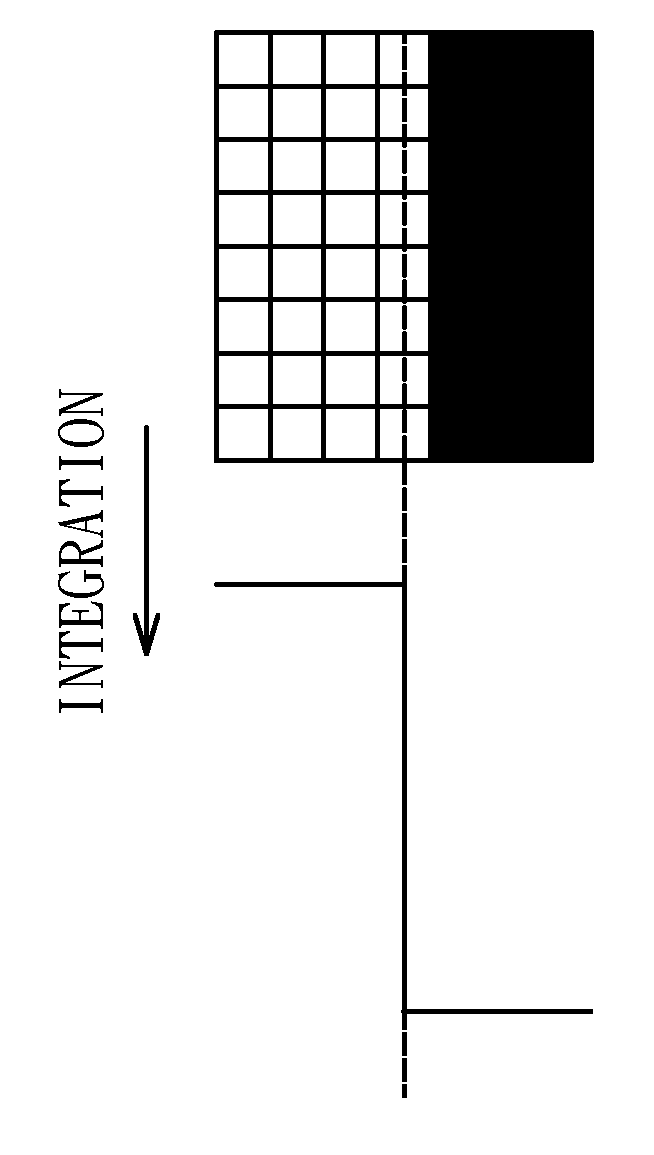

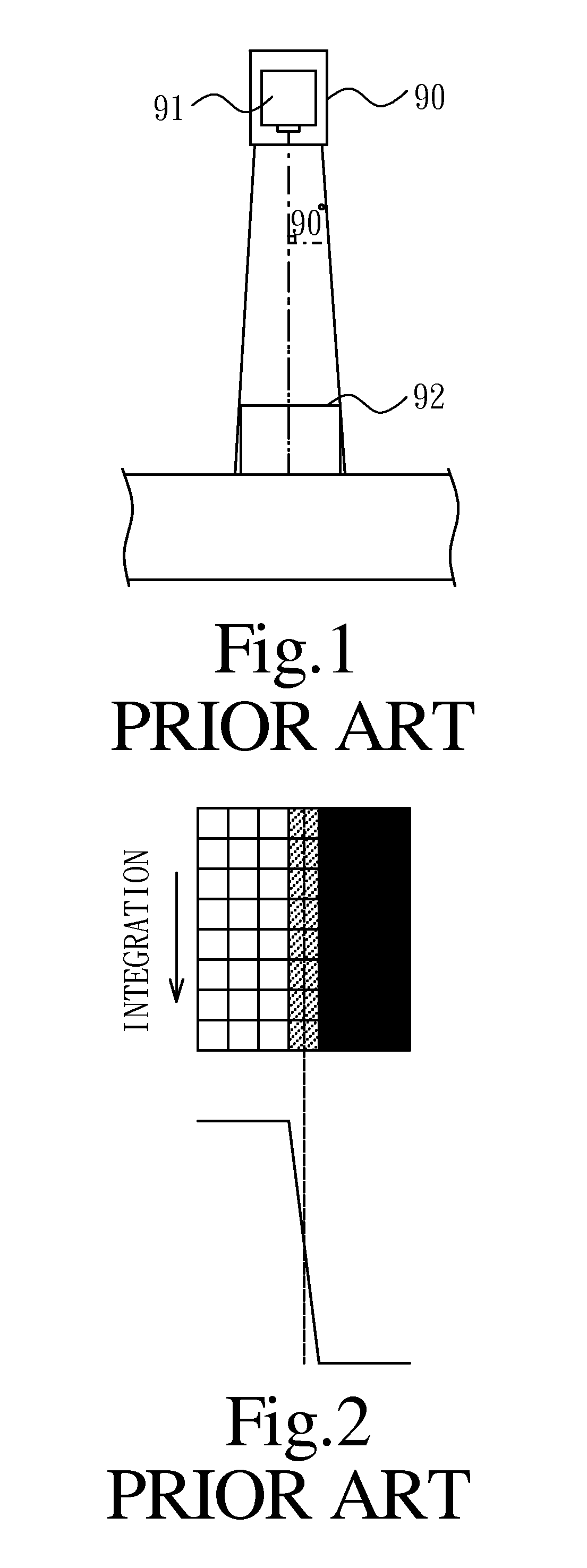

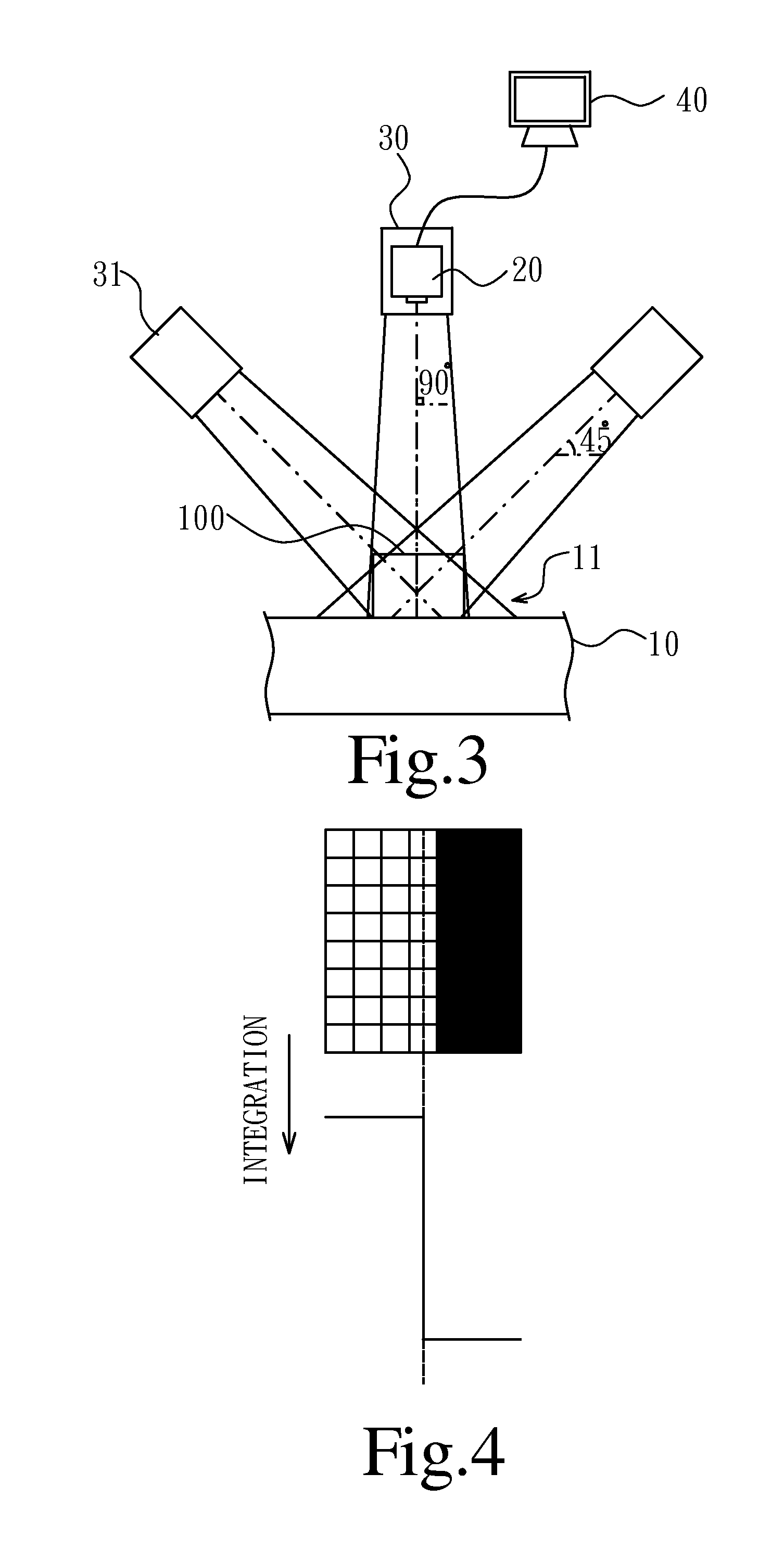

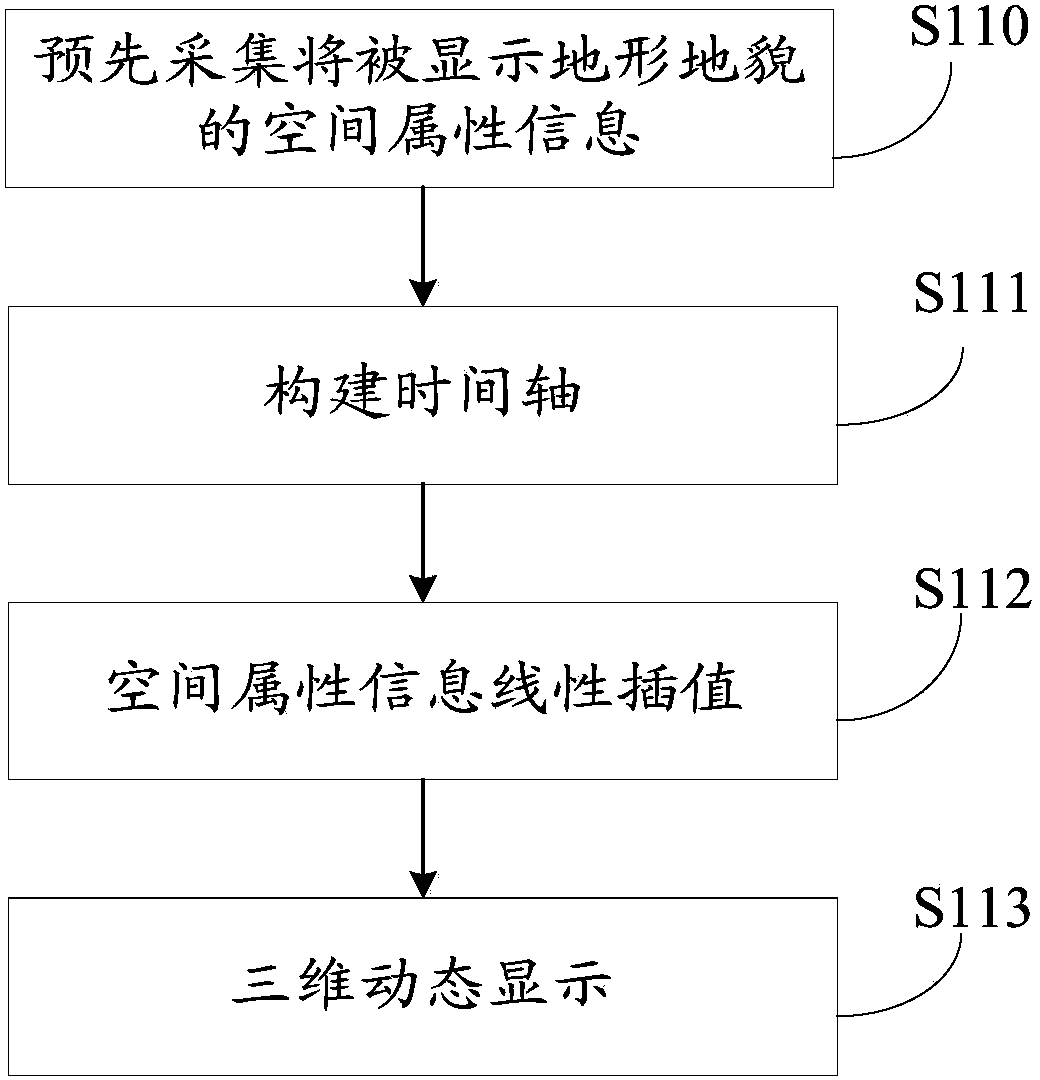

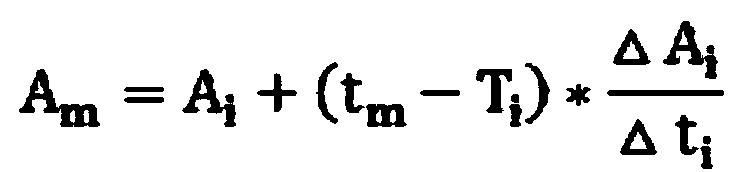

Landform three-dimensional dynamic analog display method and system

The invention relates to the technical field of geographic information, in particular to a landform three-dimensional dynamic analog display method and system. The landform three-dimensional dynamic analog display method comprises the steps that spatial attribute information of a landform to be displayed is collected in advance; actual time in the spatial attribute information is divided through first time nodes, simulated time in the spatial attribute information is divided through second time nodes, and the actual time and the simulated time are mapped to the same time axis according to the time duration proportional relation; the spatial attribute information of the second time nodes is calculated in a linear mode, and linear interpolation is carried out on the spatial attribute information of the second time nodes; each second time node on the time axis is traversed, and the spatial attribute information corresponding to each second time node is displayed and updated. The landform three-dimensional dynamic analog display system comprises a collection module and a display control module. The landform three-dimensional dynamic analog display method and system have the advantages that analog display of images with higher precision can be achieved, and limitation of the size of a collection area is avoided.

Owner:SATELLITE SURVEYING & MAPPING APPL CENTSASMAC NAT ADMINISTATION OF SURVEYING MAPPING & GEOINFORMATION OF CHINANASG

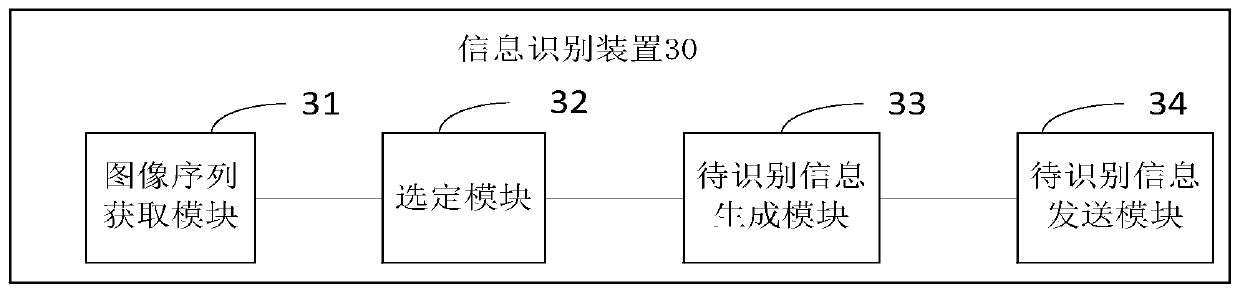

Information identification method, device and system, electronic equipment and storage medium

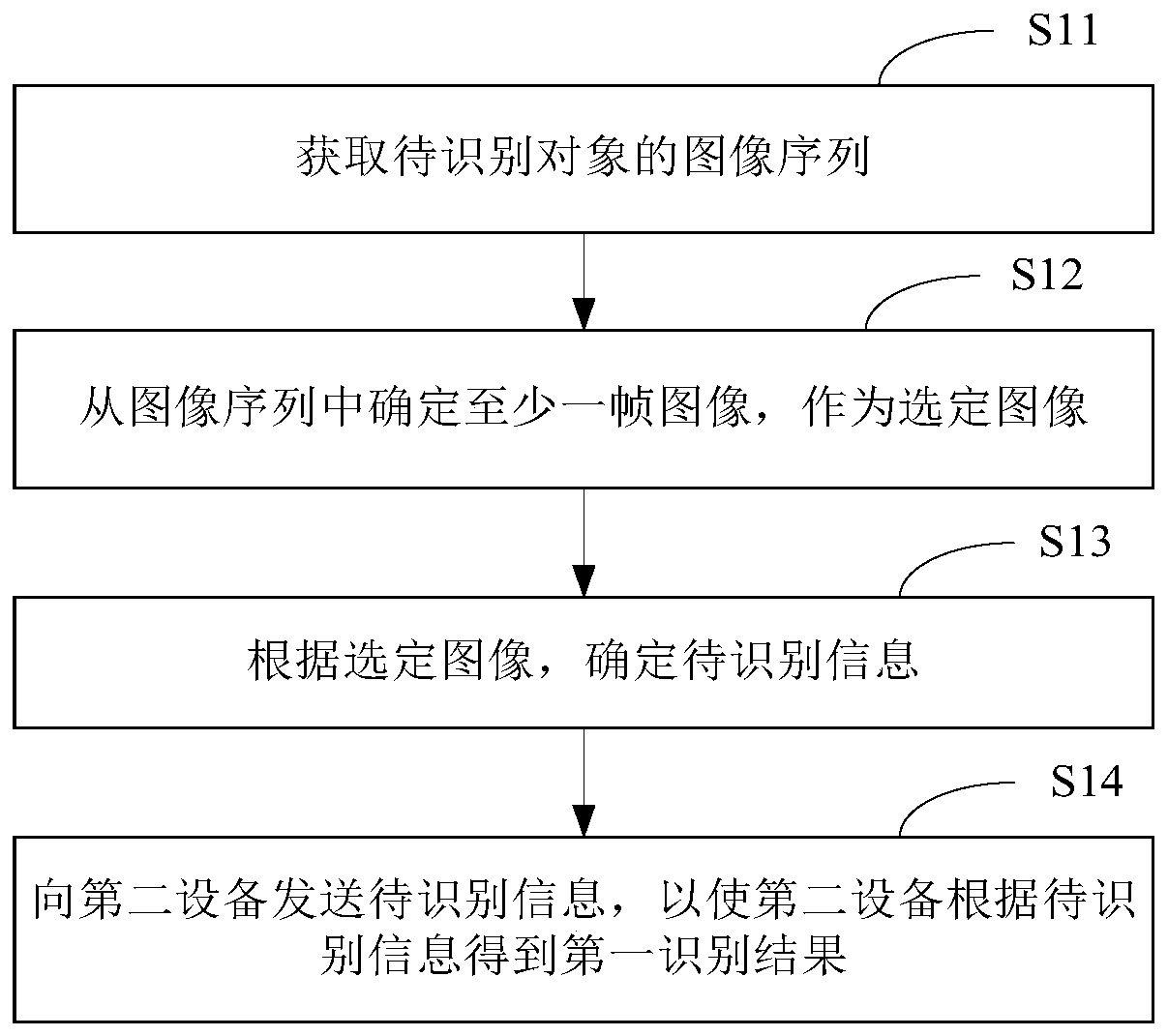

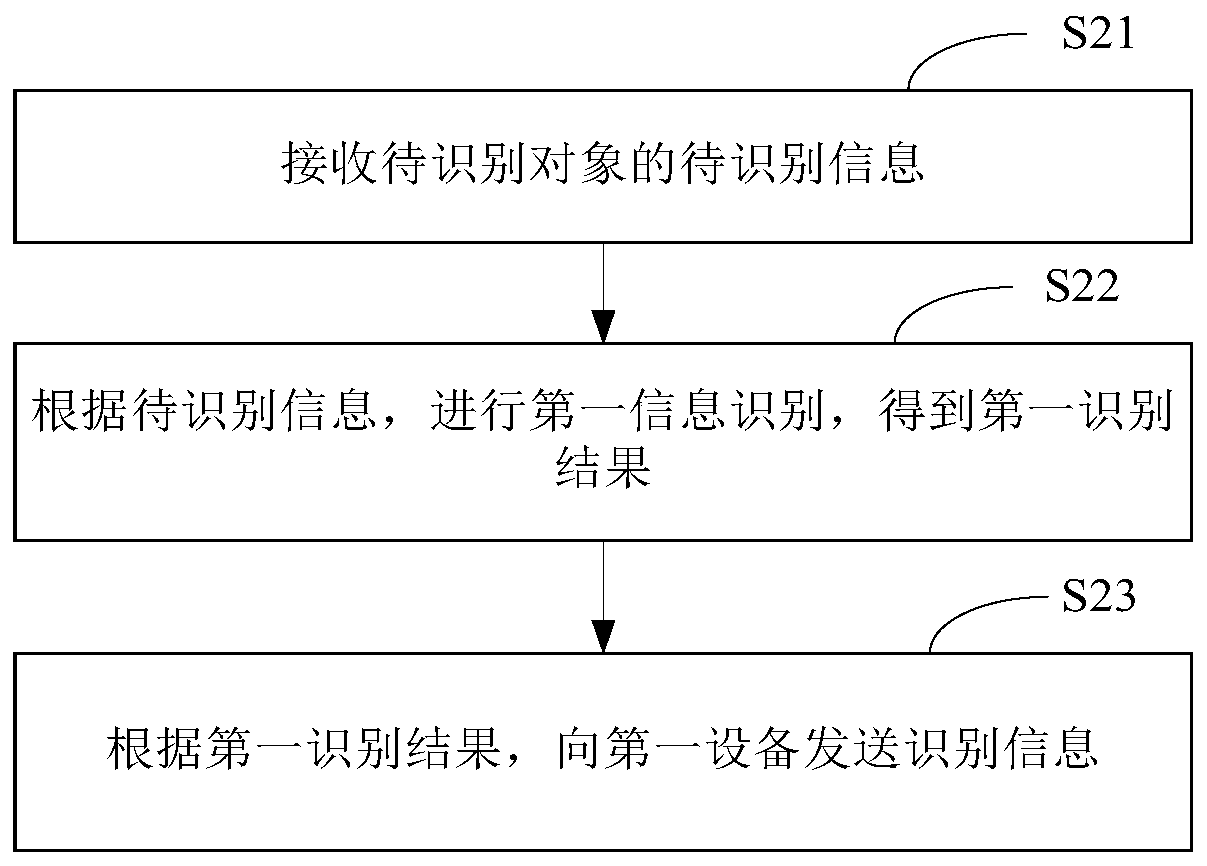

PendingCN111353434AHigh image precisionEasy to identifyCharacter and pattern recognitionEngineeringImage sequence

The invention relates to an information identification method, device and system, electronic equipment and a storage medium. The information identification method comprises the steps: obtaining an image sequence of a to-be-identified object, wherein the image sequence comprises at least two frames of images; determining at least one frame of image from the image sequence as a selected image; determining to-be-identified information according to the selected image; and sending the to-be-identified information to a second device, so that the second device obtains a first identification result according to the to-be-identified information. The information identification method further comprises the steps: receiving to-be-identified information of a to-be-identified object; performing first information identification according to the to-be-identified information to obtain a first identification result; and sending identification information to the first device according to the first identification result.

Owner:BEIJING SENSETIME TECH DEV CO LTD

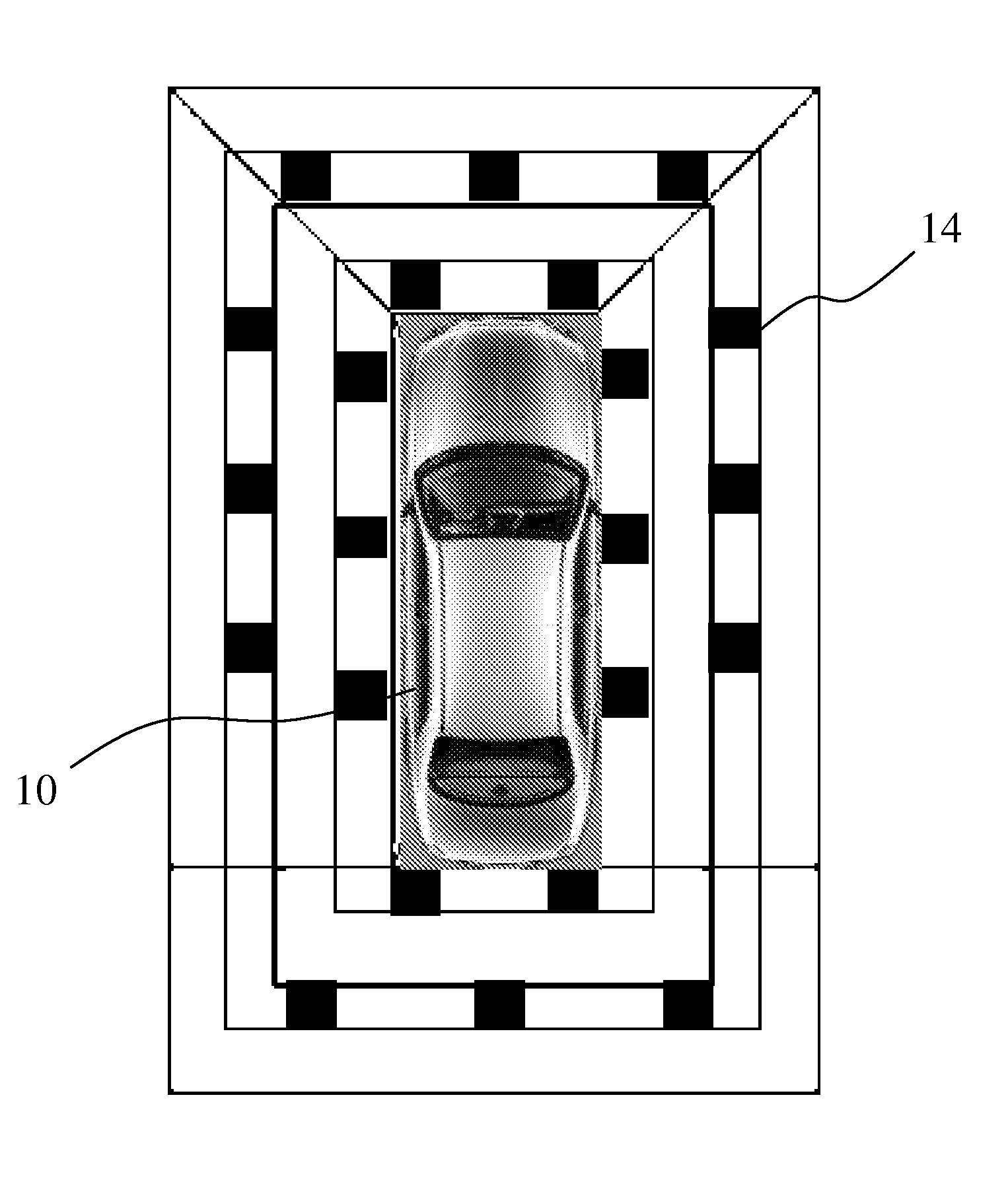

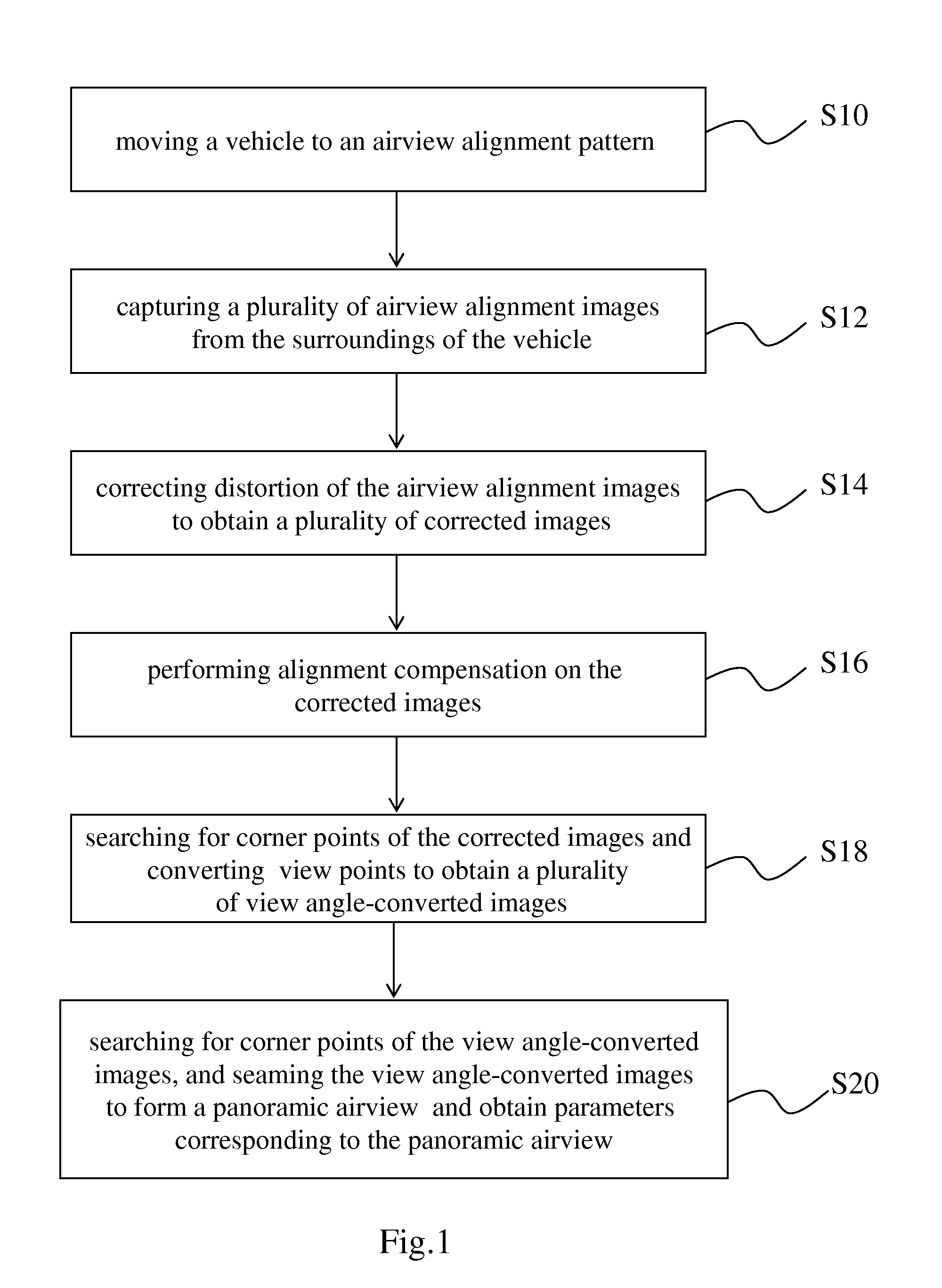

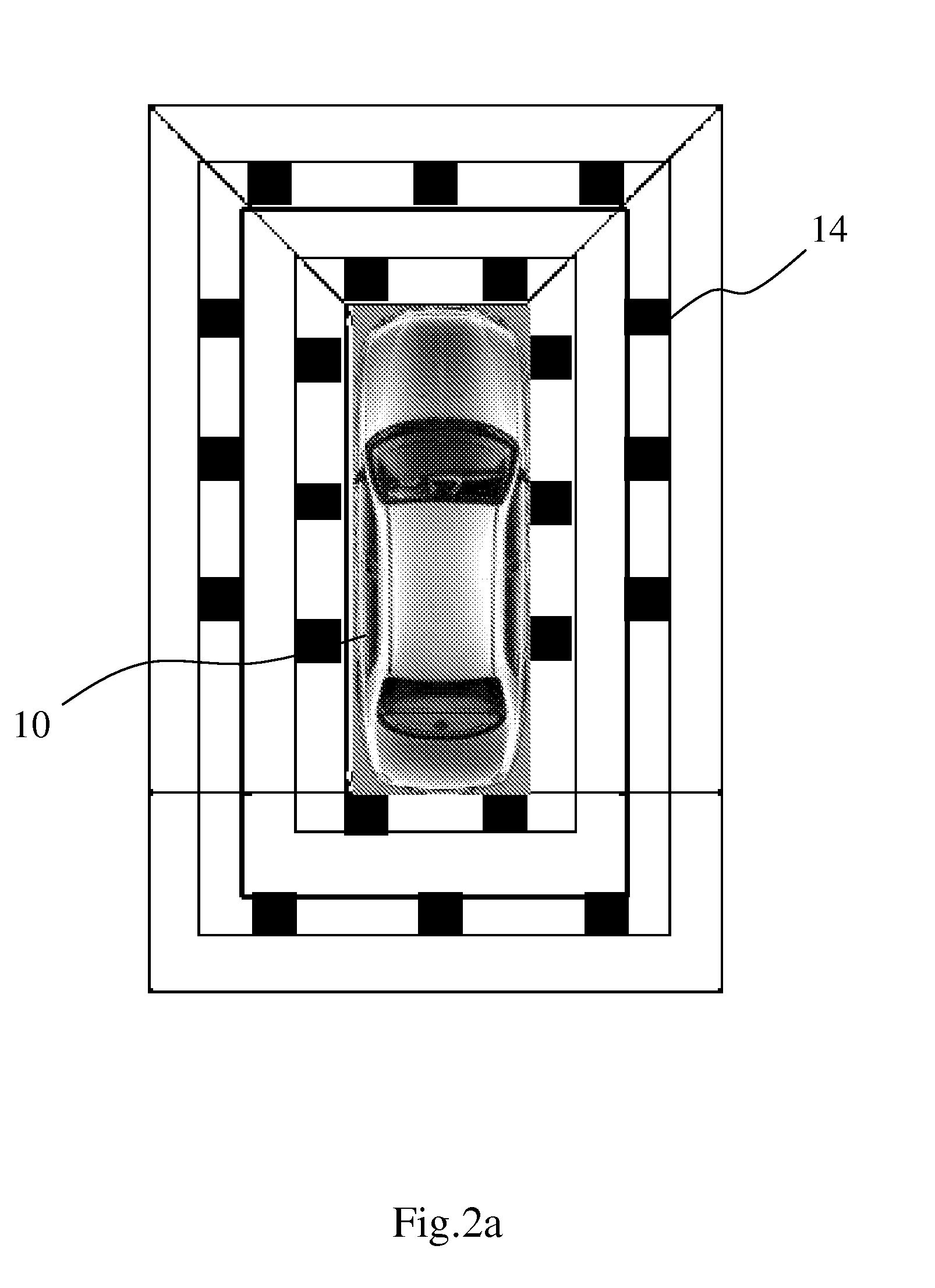

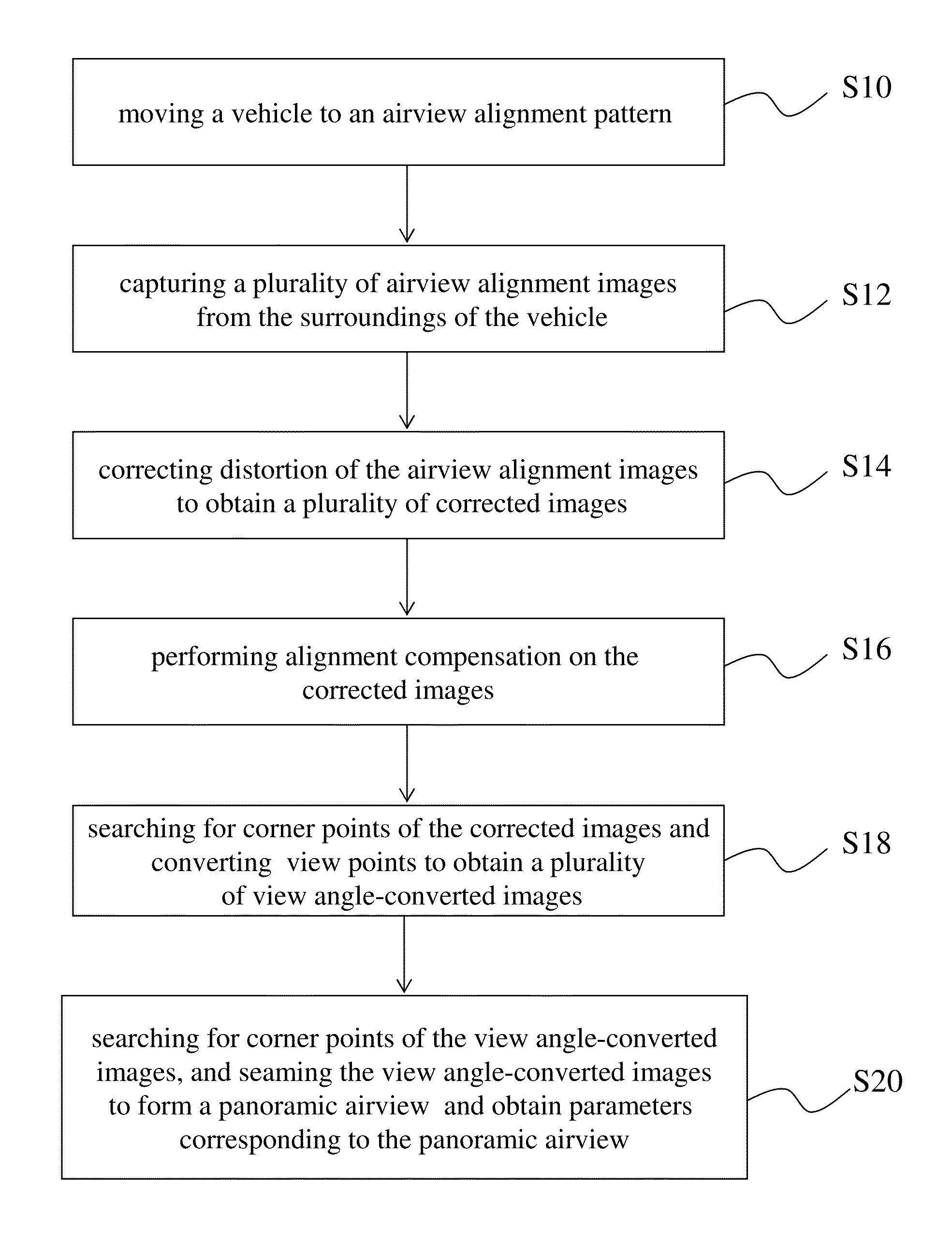

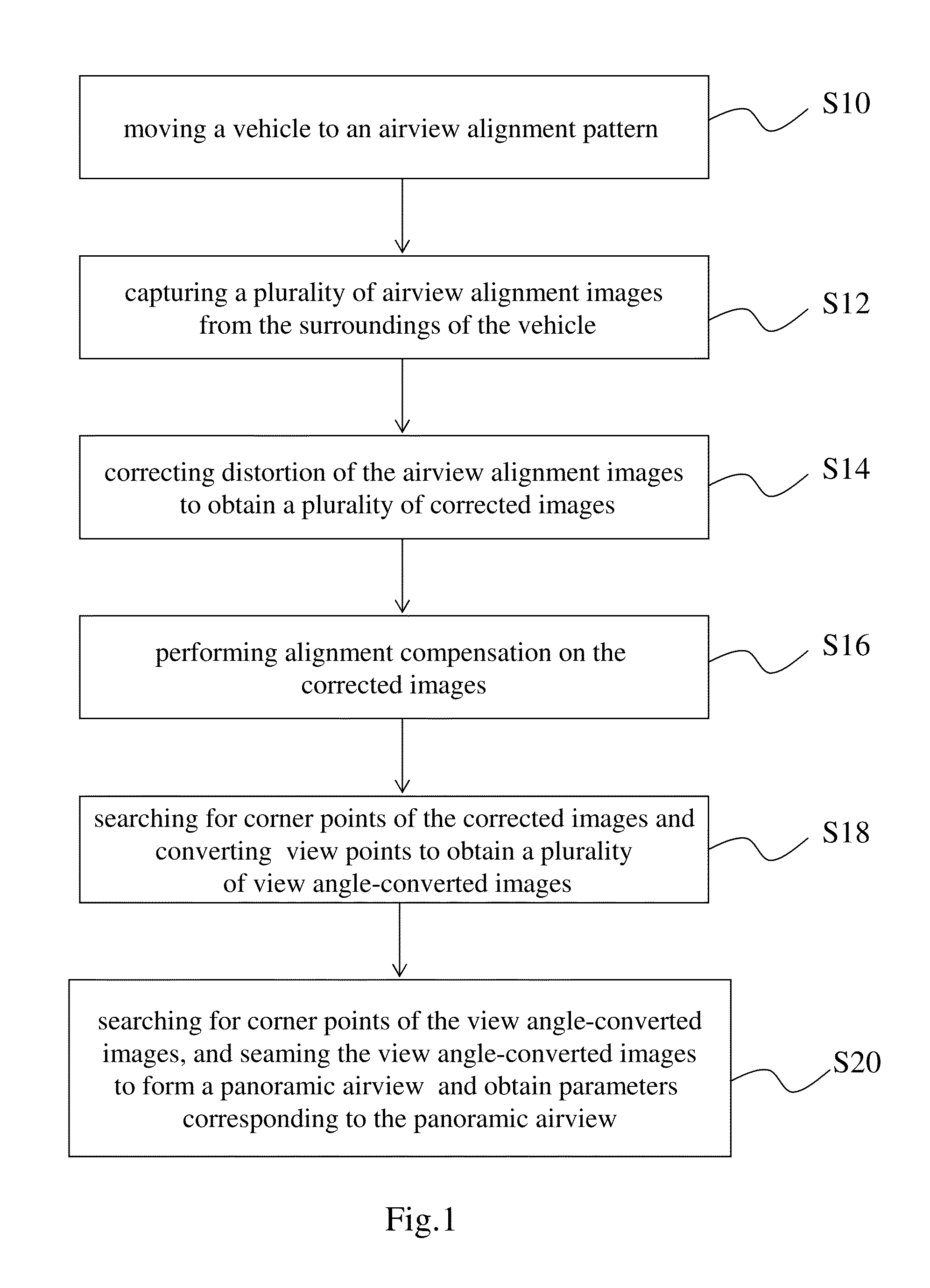

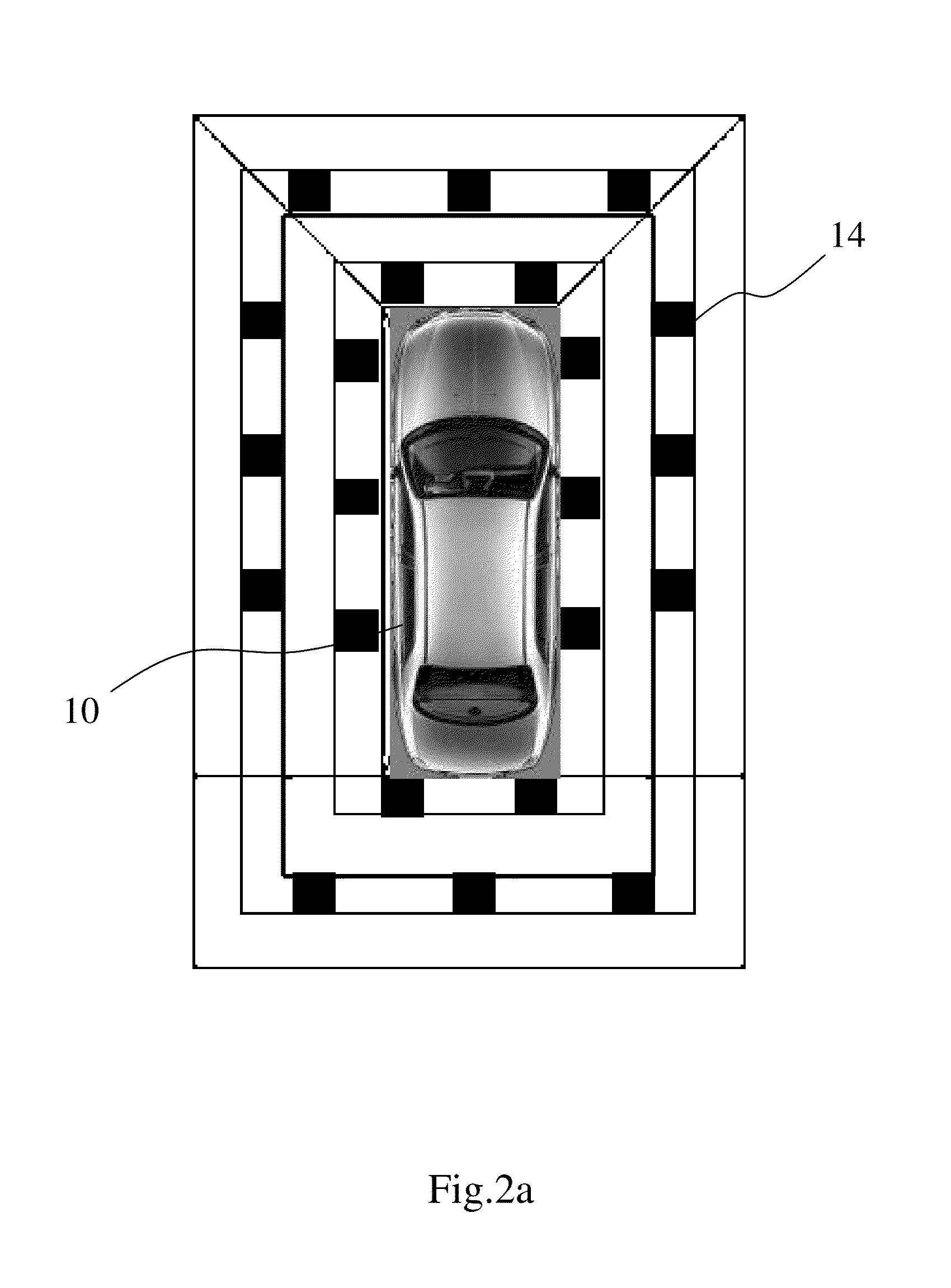

Automatic airview correction method

ActiveUS20140010411A1High image precisionComplete and clear airviewImage enhancementImage analysisAngular pointCorrection method

An automatic airview correction method comprises steps: moving a vehicle to an airview alignment pattern; capturing a plurality of airview alignment images of the surroundings of the vehicle; correcting distortion of the airview alignment images to obtain a plurality of corrected images; performing alignment compensation on the corrected images; searching for corner points of the corrected images and converting view point s to obtain a plurality of view angle-converted images; and searching for corner points of the view angle-converted images, and seaming the view angle-converted images to form a panoramic airview and obtain parameters corresponding to the panoramic airview. The present invention can automatically align images and can also automatically detect corner points to seam the images of the surroundings of a vehicle, whereby to form a panoramic airview.

Owner:AUTOMOTIVE RES & TESTING CENT

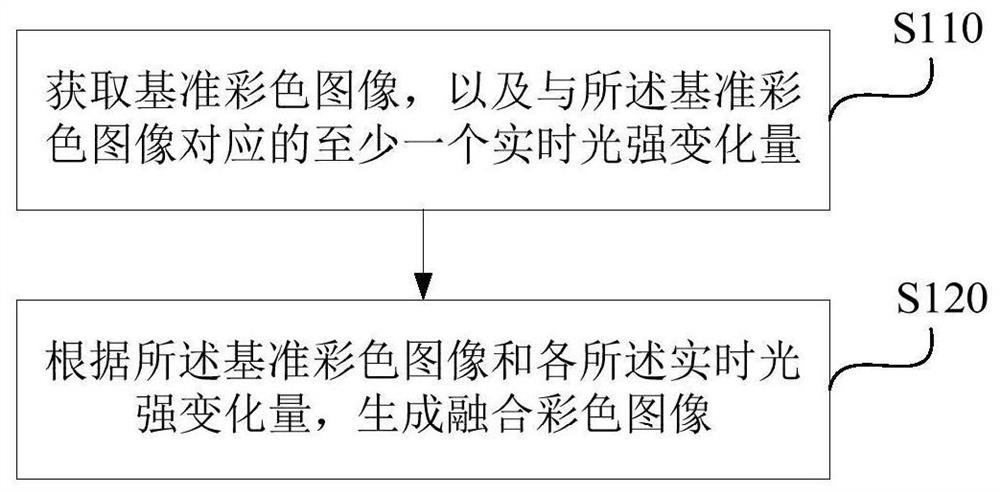

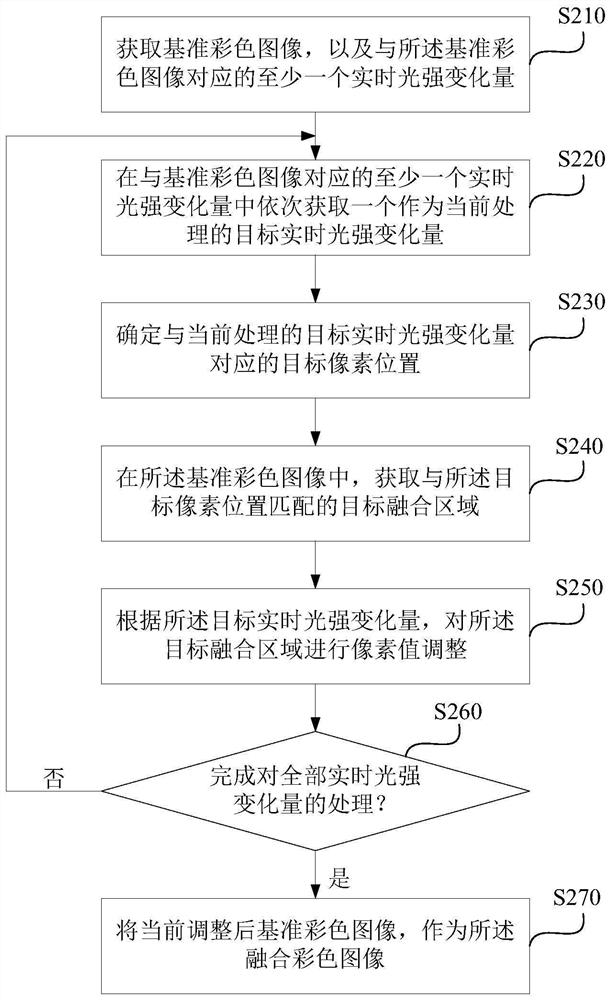

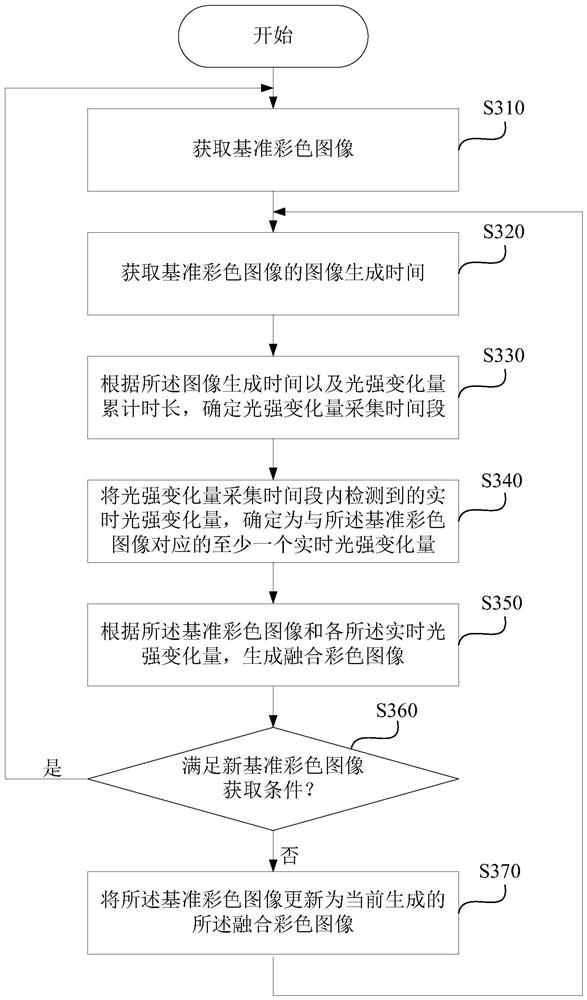

Image processing method and device, computer equipment and storage medium

PendingCN112200757AHigh image precisionQuality improvementImage enhancementImage analysisColor imageImaging processing

The invention discloses an image processing method and device, computer equipment and a storage medium. The image processing method comprises the following steps: acquiring a reference color image andat least one real-time light intensity variation corresponding to the reference color image; and generating a fused color image according to the reference color image and each real-time light intensity variation. According to the technical scheme of the embodiment of the invention, a bimodal image fusion technology for fusing the low-speed color image and the high-speed light intensity variable quantity is provided, and the characteristics of the high-speed real-time light intensity variable quantity are added into the color image obtained by fusion, so that the image precision and the imagequality of the fused color image are improved.

Owner:LYNXI TECH CO LTD

Automatic airview correction method

ActiveUS9087374B2High image precisionComplete and clear airviewImage enhancementImage analysisComputer scienceCorrection method

Owner:AUTOMOTIVE RES & TESTING CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com