Weld joint internal defect intelligent detection device and method and medium

A technology of intelligent detection and internal defects, applied in the field of intelligent detection, can solve the problems of low detection efficiency and detection consistency, achieve the effects of improving image accuracy and sensitivity, improving work efficiency, and avoiding human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0046]The present invention is mainly applied to the weld detection of complex structural parts, which can effectively improve the detection quality and consistency, improve the accuracy and efficiency of detection image evaluation, and finally improve the quality of welds. At the same time, the detection data can be stored and pushed on the cloud platform, providing The digitization and intelligent application of the production process provide the foundation.

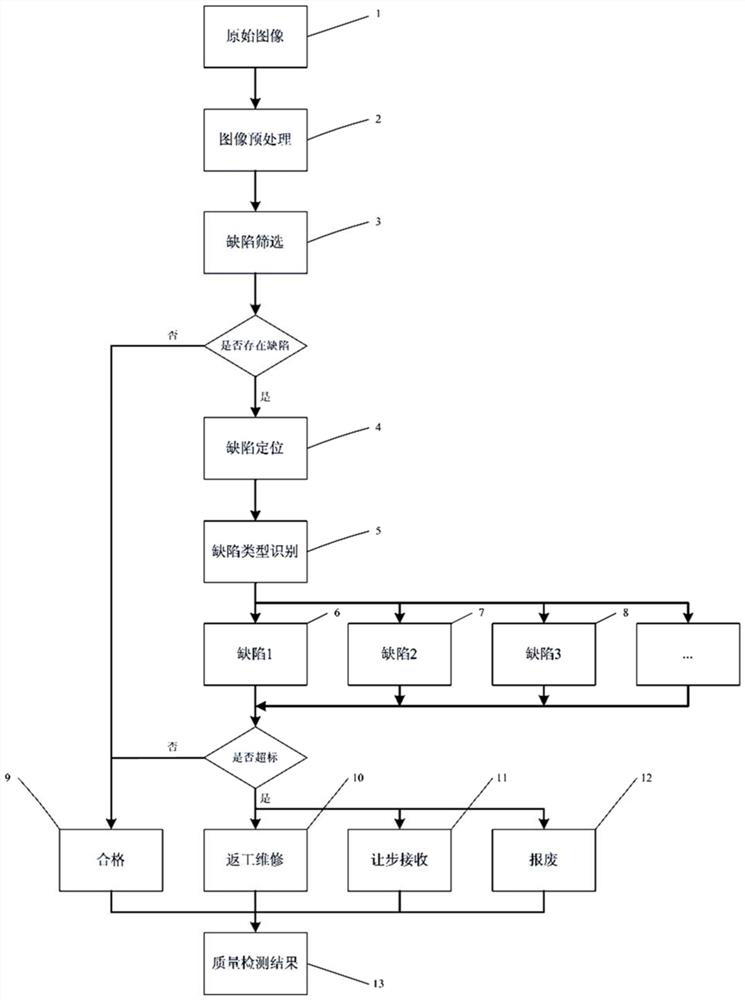

[0047] figure 1 It is a schematic block diagram of the intelligent defect detection method of digital radiographic image of welding seam according to the present invention, figure 1 Middle, 1-original image, 2-image preprocessing, 3-defect screening, 4-defect location, 5-defect type identification, 6-defect 1, 7-defect 2, 8-defect 3, 9-qualified, 10- Rework maintenance, 11-c...

Embodiment 2

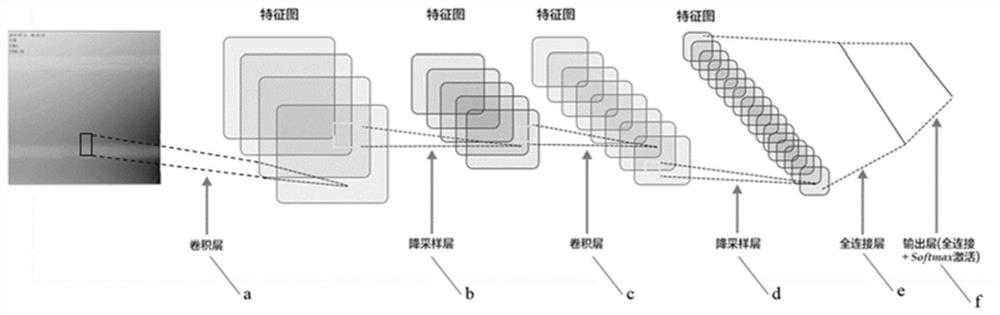

[0087] The technical problem solved by the present invention is: to overcome the deficiencies in the prior art, to provide an intelligent detection device and method for weld internal defects, which is applied to the quality inspection task of the weld, and according to the characteristics of the internal defects of the weld, the computer deep learning method is used to analyze the digital Radiographic image analysis and intelligent interpretation of results can effectively reduce the time of manual inspection, avoid errors caused by human operation and improve the efficiency of weld quality inspection under the premise of ensuring the accuracy of defect identification.

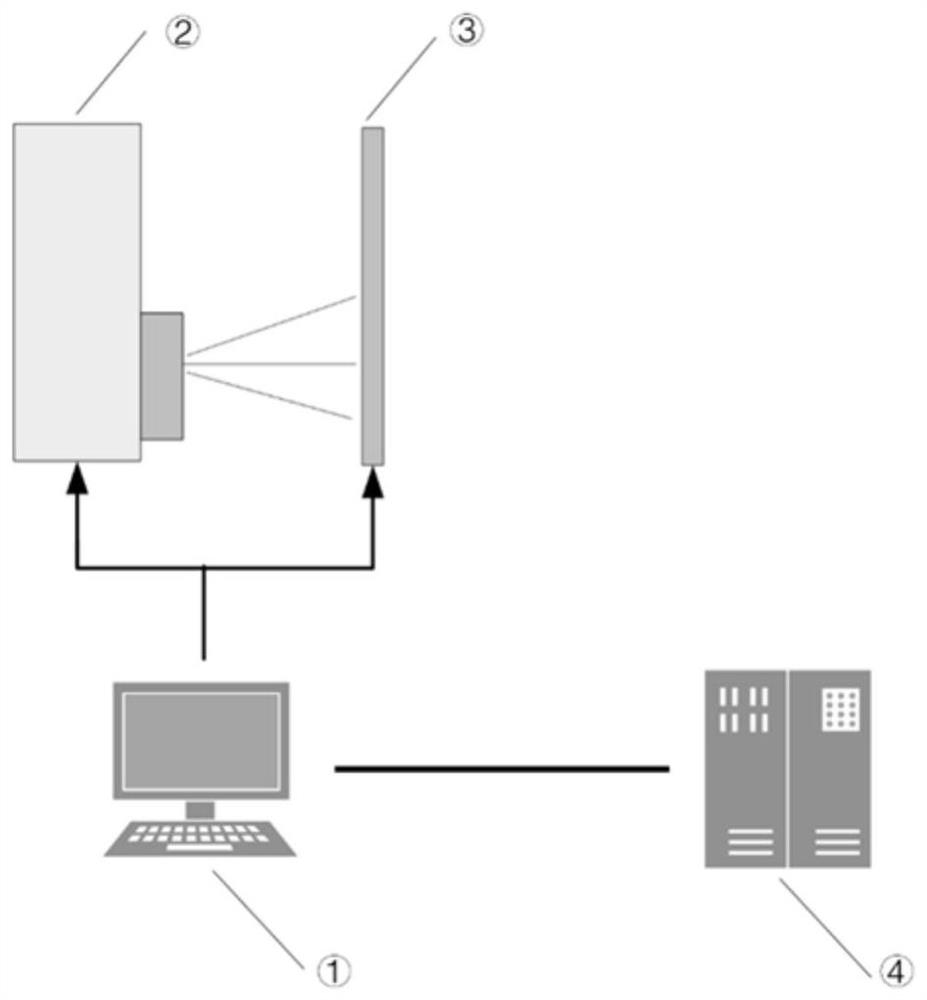

[0088] The technical solution solved by the present invention is: an intelligent detection device and method for internal defects of welds, including: an X-ray tube, an imaging board, an optical path simulation and control unit, and a cloud platform server;

[0089] The light path simulation and control unit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com