Device and method for detecting surface defects of perforated plate workpiece

A technology for detecting workpieces with holes and defects, applied in the field of visual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in combination with specific embodiments.

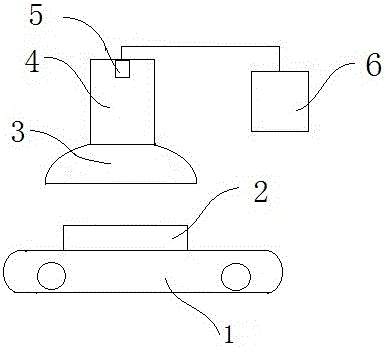

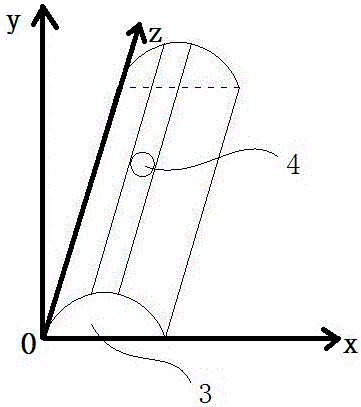

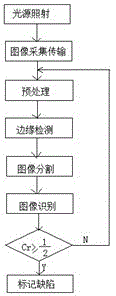

[0047] like figure 1 As shown, a surface defect detection device of a plate-shaped workpiece with holes in the present invention includes a transmission system 1 , a special-shaped lighting source 3 , an industrial CCD image sensor 4 , an image acquisition card 5 and a processor 6 . The conveying system 1 is used to horizontally convey the plate-shaped workpiece 2 with holes to be inspected and conveyed in a straight line at a constant speed; the special-shaped lighting source 3 is used to provide a uniform lighting source, and the special-shaped lighting source 3 can cover the area where the entire plate-like workpiece with holes to be detected is located; the industrial CCD image sensor 4 is used to convert optical signals into electrical signals to complete the image acquisition part; the image acquisition card 5 is used to receive from The electrical signal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com