Non-coplanar image acquisition device

An image acquisition device, non-coplanar technology, applied in optics, instruments, wide-screen photography, etc., can solve the problems of low specific gravity, pixel waste, and reduced accuracy, and achieve good compatibility, simple structure, and reduce the number of cameras. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

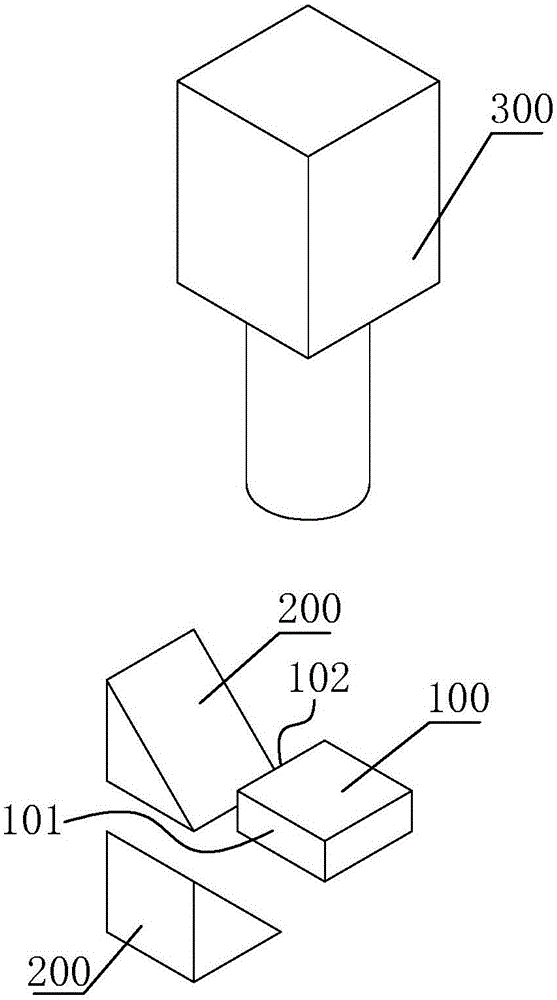

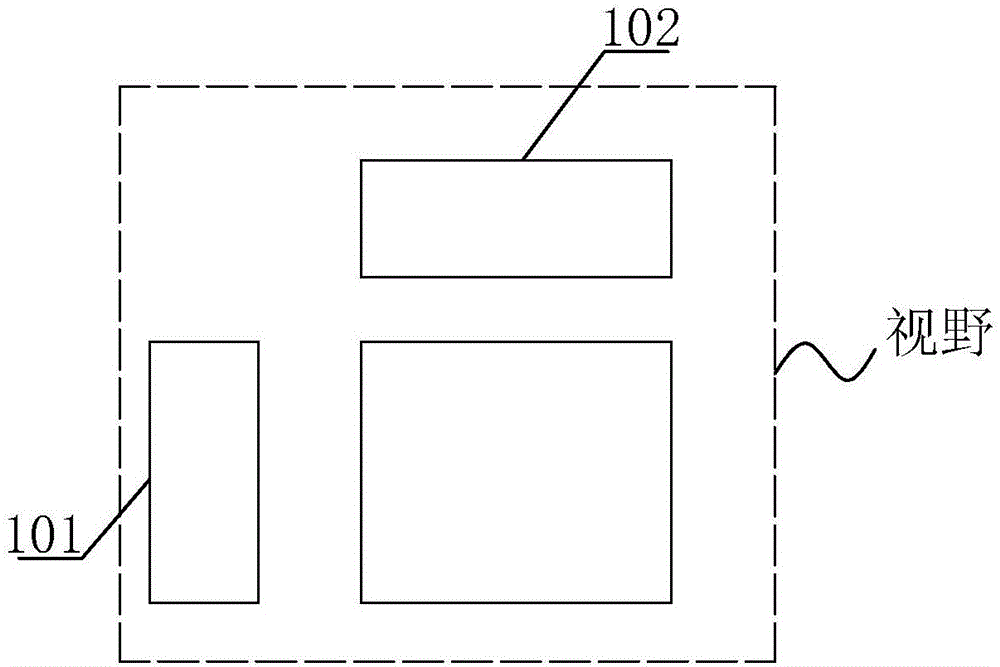

[0023] Such as figure 1 As shown, an existing non-coplanar image acquisition device includes total reflection mirrors 200 disposed on two intersecting sides of a workpiece 100 . The two sides are respectively the first side 101 and the second side 102 . The reflected light rays from the first side 101 and the second side 102 are turned back by the two total reflection mirrors 200 and enter the lens of the camera 300 at the same time, so that the two side images are imaged in the field of view of the camera 200 at the same time. Such as figure 2 As shown, the detection features of the images of the two sides captured by the existing non-coplanar image capture device have a low proportion in the field of view of the camera 200 , resulting in waste of pixels, thereby reducing the accuracy of image capture.

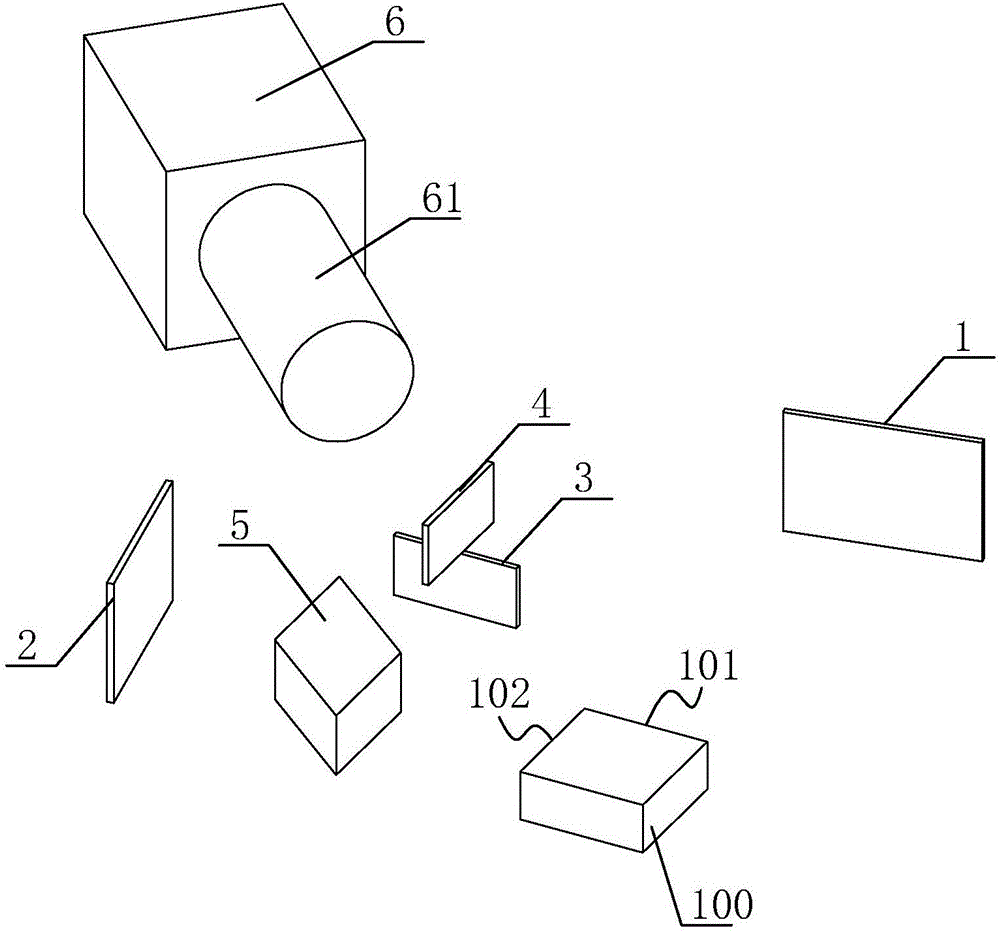

[0024] Such as Figure 3 to Figure 6 As shown, a non-coplanar image acquisition device according to the present invention is used to acquire image information of two non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com