Hot stamping process for promoting meterage realia graduation precision

A precision and scale technology, applied in the direction of printing, printing machines, rotary printing machines, etc., can solve the problems of not conforming to hot stamping products, not having practical performance, etc., and achieve the effect of low cost, small error and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

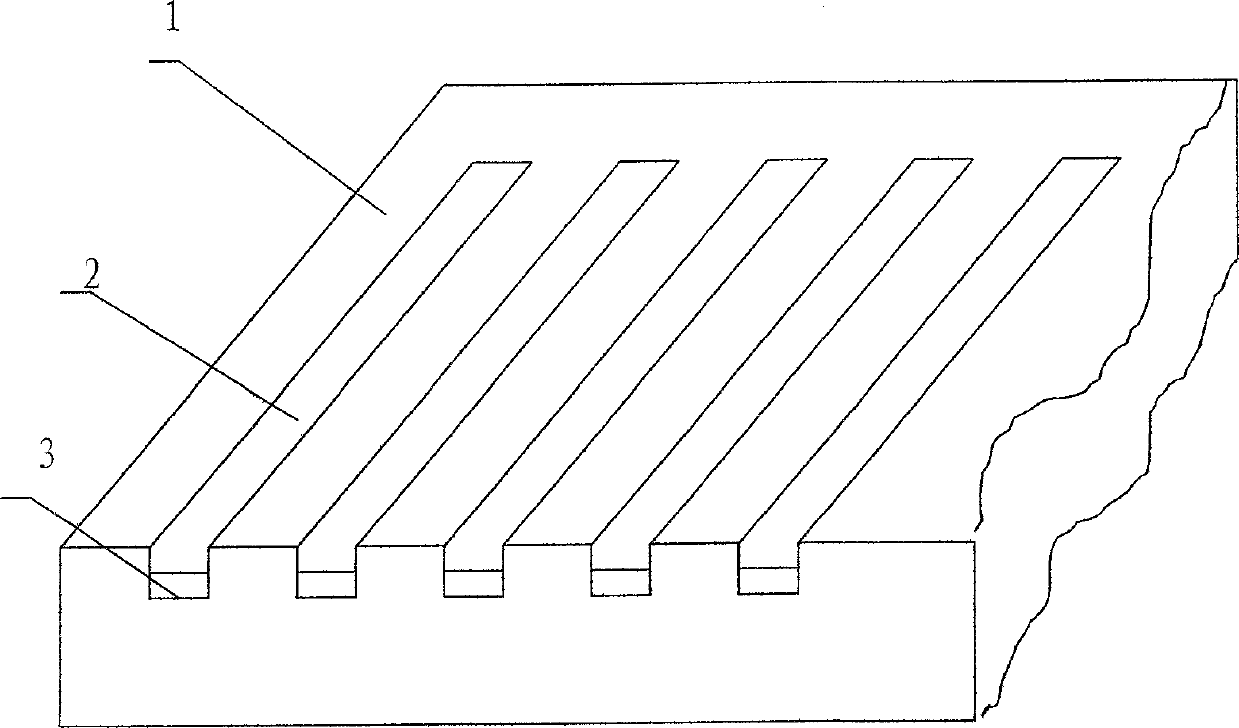

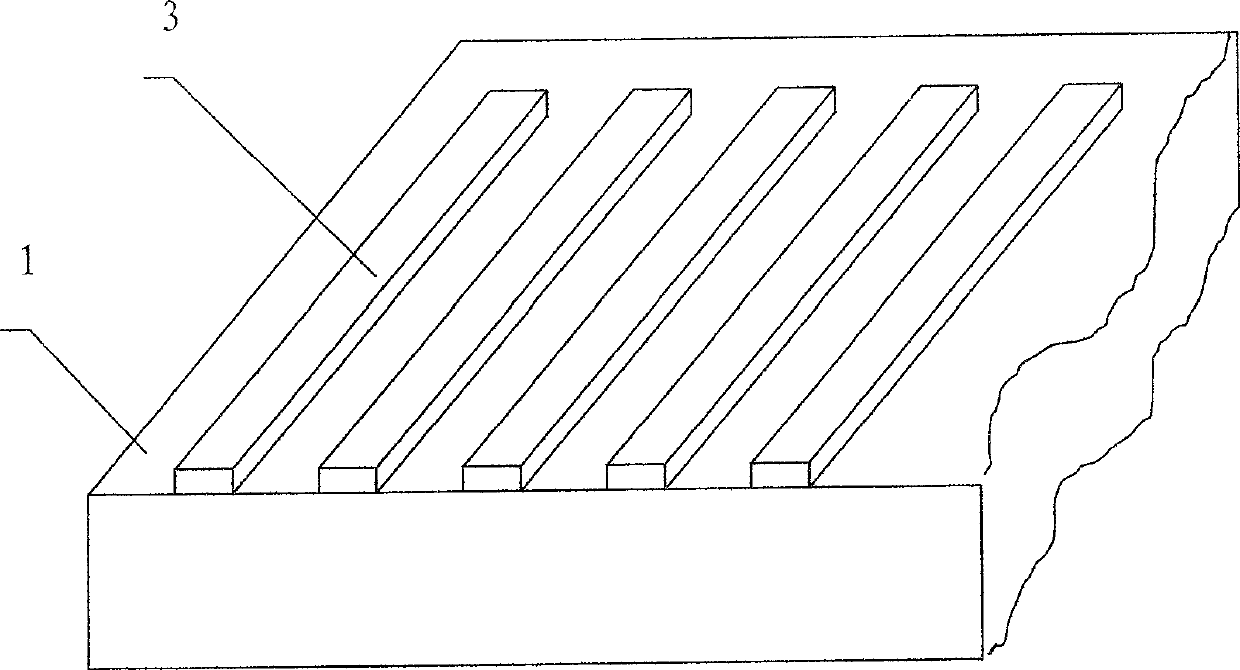

[0035] The measuring teaching aid includes a substrate 1 and a scale mark 3 , wherein a groove 2 is provided on the surface of the substrate 1 , and the scale mark 3 is located at the bottom of the groove 2 .

Embodiment 2

[0037] The hot stamping process to improve the scale accuracy of measuring teaching aids, the surface of the substrate 1 is provided with a groove 2, and the scale mark 3 is located at the bottom of the groove 2, wherein: the steps of the hot stamping method are as follows: prepare the hot stamping with scale Letterpress; place the hot stamping paper between the hot stamping letterpress and the substrate 1; turn on the hot stamping machine so that the hot stamping heating element contacts the hot stamping letterpress with heat, and the substrate 1 is heated and deformed during the hot stamping process to form a depression Groove 2; hot stamping time 3-60 seconds; hot stamping temperature 85-185°C; the scale on the hot stamping letterpress is transferred to the bottom of the groove 2 of the substrate 1 along with the hot stamping paper to form a scale mark 3; the finished product is obtained. All the other are with embodiment 1.

Embodiment 3

[0039] Hot stamping process to improve the scale accuracy of measuring teaching aids, wherein: the ratio of hot stamping temperature to hot stamping time is 18°C / 1 second - 36°C / 1 second. All the other are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com