Production method for calibration block of radioactive fluid density logging instrument

A technology of fluid density and production method, which is applied in the direction of measurement, instruments, measuring devices, etc., can solve the problem of large scale block error, achieve the effect of solving the error exceeding the standard and improving the scale accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment one: the present invention is realized according to the following steps:

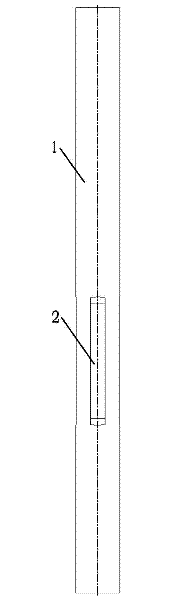

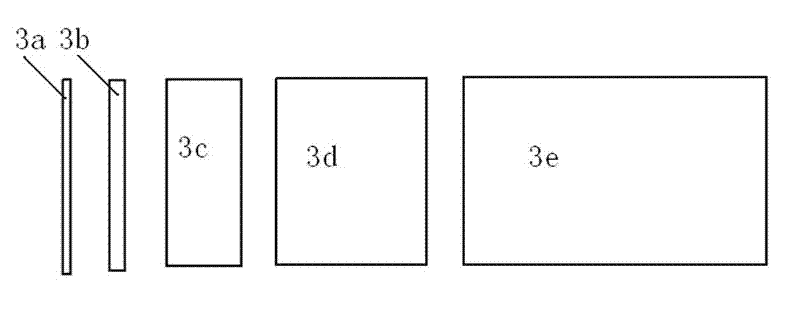

[0017] 1. Determine the length and width of the scale according to the size of the sampling channel of the radioactive fluid density logging tool 1, and make the density scale 3 with a length of 42.60mm, a width of 12.40mm, and a height of 0.5mm, 1.0mm, 5.0mm, and 10.0mm, 20.0mm material is aluminum density scale 3a, 3b, 3c, 3d, 3e, see figure 2 and image 3 ;

[0018] 2. The fluid density logging tool is powered by the logging ground system. After it works normally, the radioactive fluid density logging tool is placed in the air and subjected to 0.00g / cm 3 Scale; put the sampling chamber of the radioactive fluid density logging instrument in pure water, and test it at 1.00 g / cm 3 Scale; use the fluid density scale software to calculate the scale coefficients A and B, and save them;

[0019] 3. Put the radioactive fluid density logging tool 1 in the air, put density scales 3 of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com